Documente Academic

Documente Profesional

Documente Cultură

Risk Assessment For Flushing of Chilled Water Piping

Încărcat de

Anandu AshokanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Risk Assessment For Flushing of Chilled Water Piping

Încărcat de

Anandu AshokanDrepturi de autor:

Formate disponibile

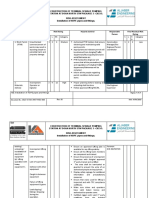

Document Reference

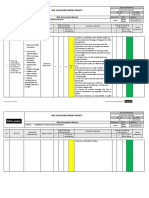

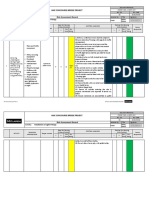

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0022

Rev. No. Rev. Date

00 29/04/02019

Risk Assessment Record Assessed by Title Signature

Activity: Flushing of Chilled Water Pipeline Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. STARRT card briefing must before start the

activity

2. Ensure the PTW in place and comply the

procedure.

3. Ensure proper working platform with

Work at height complete fall protection

4. Ensure Full body harness and 100% Tie off

5. Ensure the scaffold platform is properly

Fall form height erected with "Safe to use" tag.

Working on Operatives/Staff/ 6. Ensure castor wheels are locked Supervisors

Falling objects Visitors Med 7. Hand tools must be secured/tethered

1 mobile

Others

3 4 12 1 4 4 Low Foreman, Site

scaffolding

ium 8. Work materials strictly not allowed to be Eng.

Over loading stored on platform except for working tools

9. Ensure avoid over reaching and climb on handrail.

Protruding objects 10. Ensure unauthorised person not allowed to

modify the scaffolding and if needed to any

Access & egress changes then must be modified by trained

and certified scaffolder.

11. Ensure safe access to the working platform

12. Scaffold access must be free from obstruction

13. Ensure sufficient illumination in work area

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

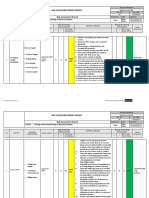

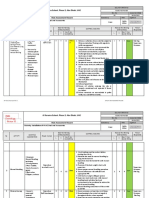

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0022

Rev. No. Rev. Date

00 29/04/02019

Risk Assessment Record Assessed by Title Signature

Activity: Flushing of Chilled Water Pipeline Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Ladder is not to use daily basis but in certain

cases where there is very narrow place and

even podium ladder not possible to place in

that cases Ladder can be use if permission

granted from McLaren Safety

2. Never try to overreach with any ladders

3. Check the ladder is adequately maintained

and free from damages/good condition

4. Maintain a minimum of 3 points of contact

with stepladders at all times

(feet/thighs/hands)

Falling from

5. If possible avoid the use of stepladders at a

height

working height of 2 meters and more.

Operatives/ Supervisor Site

Use of Ladder Med 6. Check the ladder legs (and stays) are fully

2 Working on Staff/ 3 4 12 1 4 4 Low Eng.

ium deployed or locked (depending on type) to

Uneven ground Foreman,

maintain maximum base dimensions and the

step ladder is orientated to provide maximum

Falling objects

stability.

7. Stepladders/ladders has to be used on leveled

ground/firm base

8. Ensure that during using ladder from the top

2 step is blocked to avoid climb on that.

9. The ladder securely fixed to prevent slipping

outwards or sideways or securely footed at all

times.

10. Person must hold the ladder while another

operative working on it

11. Materials should not be placed above the

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

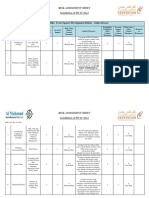

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0022

Rev. No. Rev. Date

00 29/04/02019

Risk Assessment Record Assessed by Title Signature

Activity: Flushing of Chilled Water Pipeline Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

thread of ladders/step ladders

12. Do not carry any materials in one hand while

climbing or getting down from ladder

13. Ensure the area under the ladder is

barricaded especially if it is being used in a

public area.

14. Ensure the ladder is electrical insulated

podium type if working in live services

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0022

Rev. No. Rev. Date

00 29/04/02019

Risk Assessment Record Assessed by Title Signature

Activity: Flushing of Chilled Water Pipeline Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

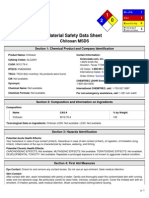

1. Ensure the work permit obtained before

the activity.

2. STARRT card to be filled and briefed to

the operatives.

3. All the Flushing kits must be calibrated

Injury due to

4. Ensure all the chemicals used for flushing

slips trips and

falls. activity must have MSDS and COSHH

Test kit may assessment.

failure if not 5. Ensure all the risk factor of Chemicals and

maintained. control measure must brief to the

Flushing activity Injury due to operatives. Site engineer

Operatives

3 for Chilled water manual handling involved

3 4 12 Med 6. Work area must be barricaded with 1 4 4 Low Supervisor

piping Side effect of caution signage. Foreman

chemical such as 7. Spill kit must be in place.

burn or skin 8. Work area will be kept tidy and dry to

contact or eye minimize trip hazards and slippery floor.

injury.

9. Ensure that after flushing activity should

Environment

Hazard

not drain the water in direct soil to

pollute the environment.

10. Ensure all operatives are trained and

competent for the flushing activity.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

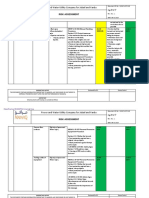

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0022

Rev. No. Rev. Date

00 29/04/02019

Risk Assessment Record Assessed by Title Signature

Activity: Flushing of Chilled Water Pipeline Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

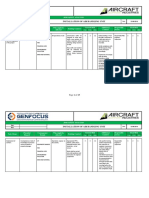

1. Ensure that all chemical substances have a

COSHH assessment

2. Refer SDS prior to any handling of hazardous

substances and ensure SDS is easily accessible

at site while working with chemicals.

3. Ensure chemicals are properly stacked.

4. Ensure all chemical containers are properly

labeled.

Spillage/ soil

5. Spill kits to be available at site.

contamination

6. Ensure operatives use the correct PPE

7. Competent person to oversee the storage,

Burns

use and disposal of hazardous materials.

Contact with skin Supervisors

Use of 8. Ensure that correct welfare/first aid facilities

Operatives Med

4 Chemicals- 3 4 12 are available in the area i.e. washing 1 4 4 Low Foreman,

Acute/Chronic using solvent ium

Hazardous facility/eye wash. Site Eng.

adverse heath

Substance 9. Proper and adequate PPE to be used always

effect.

10. Ensure all chemical containers are properly

Fire labeled.

11. Adjust work schedules so that workers are not

overexposed to a hazardous chemical.

12. Wear respiratory protection

13. Ensure proper and adequate PPE to be used

always.

14. Ensure smoking only in designated area

15. Ensure appropriate Firefighting equipment’s

are in place and easily accessible

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0022

Rev. No. Rev. Date

00 29/04/02019

Risk Assessment Record Assessed by Title Signature

Activity: Flushing of Chilled Water Pipeline Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. All portable electrical equipment must be PAT

tested and color coded. Make sure the test

dates are visible on the equipment.

2. Ensure all disk shall be appropriate and expiry

date is over.

3. Ensure all power tools are in good condition

and periodically maintained

Damaged

4. PTW to be obtained for above 110 volt

Sockets & cable

electrical permit prior to commencing the

insulation.

task.

Electrocution

5. Damaged industrial sockets and power cables

Electric shock

must be removed from service.

Short circuit &

Burns 6. Ensure the electrical cable is not damaged Supervisor

Use of power Operatives Med

5 Trip/Fall 3 4 12 and has not been repaired with insulating 1 4 4 Low Foreman

tools and pump and staff ium

Noise tape or unsuitable connectors. Site Eng.

Hearing loss 7. Ensure cables from power tools shall be

Vibration organized so as not to present a tripping

Dust hazard

8. Only trained competent operatives to operate

the power tools.

9. Ensure proper and regular maintenance of

equipment that takes account of noise

10. Ensure proper hearing protection always.

11. Make sure people use the right tool for the

job and are trained to use it correctly

12. Ensure defective tools that require

maintenance is reported for repair or

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0022

Rev. No. Rev. Date

00 29/04/02019

Risk Assessment Record Assessed by Title Signature

Activity: Flushing of Chilled Water Pipeline Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

replacement.

13. Instruct workers to keep their hands warm

and dry, and to not grip a vibrating tool too

tightly.

14. Ensuring proper job rotation and limiting time

operatives working with power tools and

hand tools.

15. Use dust mask

16. Ensure proper earth leakage protection is

provided.

17. All power tools must be 110V to be ensured.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

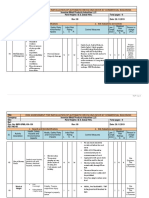

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0022

Rev. No. Rev. Date

00 29/04/02019

Risk Assessment Record Assessed by Title Signature

Activity: Flushing of Chilled Water Pipeline Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Hand tools should be visually inspected for

Improper defects, prior to use.

selection of hand 2. Never use damaged, blunt or broken tools to

tools. avoid injury.

Damaged and Operatives/Staff 3. Select right tools for right Job Site engg

Defective Hand 4. Ensure no Homemade or makeshift tools to Supervisor

Use of Hand tools tools. be used at site Foreman

Med

6 Hand injuries 3 3 9 5. Remove from service any tool that shows 1 3 3 Low

ium

Pinch point signs of damage or defect

Ergonomics 6. Ensure Hand tools are Stored in accordance

Repetitive strain with the manufacturer’s instructions.

injury 7. Ensure hands are not in direct line of fire

while working with hand tools

8. Ensure appropriate PPE at all times.

Approved By: Name Position __________ Signature _________ ___________

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

RISK ASSESSMENT & CONTROL GUIDELINES

1. Executing Steps:

1.1. Planning

a) Construction and HSE team must ensure that hazard identification is complete.

b) Construction and HSE team must prioritize the hazard issues, which are of significant in nature. (It means that risks have well

established legal requirements, potentially high risks).

c) Construction and HSE team to prepare the risk assessment plan for the priorities identified hazards for these potential high

risks.

1.2. Risk Assessment

Risk is the probability of an event occurring in a given set of circumstances. The ‘event’ is an exposure to hazard. The hazard is the

potential to cause harm. The risk assessment is the technique of evaluating not just the likelihood of an event occurring, but also the

outcome will be in terms of injury, loss, damage or harm.

1.3. Risk Assessment Process

The process of carrying out a risk assessment should be as follows.

1. Identify the hazards.

2. Identify who might be harmed and how.

3. Evaluate the risk and implement the control measures.

4. Record the significant findings.

5. Review the assessment and update if necessary.

1.4. Examination of the Hazards and Risk Associated

Competent staff must be used in examining the risk associated with the identified hazard.

Competent staff should examine following aspect to determine the risk involved:

o Examine the existing control measures in place.

o Identify employees at risk.

o Likelihood of risk.

o Severity

o Risk level and their tolerability.

1.5. Evaluating the risk:

Once the necessary information has been obtained on the hazards encountered by work activities, next stage is to access the risks.

1.5.1. Risk Rating Score

Risk rating score is a combination of two factors.

The severity of the risk that could injure persons or cause damage to plant.

The likelihood of the risk that it could happen (Probability).

RISK RATING = LIKELIHOOD X SEVERITY

NOTE: Each activity has to be assessed for the risk value for determining the level of Severity and likelihood are mentioned in the table

below.

No Injury Minor Moderate Major

Catastrophic (5)

(1) Injury (2) Injury (3) Injury (4)

1 2 3 4 5

Rarely (1)

Unlikely (2) 2 4 6 8 10

LIKELIHOOD Possible (3) 3 6 9 12 15

Likely (4) 4 8 12 16 20

Almost

5 10 15 20 25

RISK LEVEL: Certain (5)

Low Medium High

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

S-ar putea să vă placă și

- Risk Assessment For Installation of Drainage PipesDocument17 paginiRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- Risk Assessment For Installation of Fire Fighting SystemDocument20 paginiRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan93% (30)

- Risk Assessment For Installation of Fire Fighting SystemDocument20 paginiRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan93% (30)

- Risk Assessment For Installation of Water Supply PipeDocument18 paginiRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Installation of Water Supply PipeDocument18 paginiRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 paginiRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan83% (12)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 paginiRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan83% (12)

- Risk Assessment For CABLE TRAYDocument11 paginiRisk Assessment For CABLE TRAYAnandu Ashokan86% (14)

- Risk Assessment For Installation of Light FittingsDocument11 paginiRisk Assessment For Installation of Light FittingsAnandu Ashokan88% (8)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument7 paginiRisk Assessment For Testing and Commissioning of Electrical Systemvo100% (2)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument8 paginiRisk Assessment For Testing and Commissioning of Electrical SystemAnandu Ashokan100% (8)

- Risk Assessment For MEP Isolation WorksDocument8 paginiRisk Assessment For MEP Isolation WorksAnandu Ashokan100% (5)

- Risk Assessment of Fire Hose Reel InstallationDocument9 paginiRisk Assessment of Fire Hose Reel Installationfidgety100% (2)

- Method Statement For Structured Cabling System InstallationDocument9 paginiMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- Pump Installation Risk AssessmentDocument17 paginiPump Installation Risk AssessmentAnandu Ashokan75% (8)

- Risk Assessment For Installation of Grill, Diffuser and LouversDocument13 paginiRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- Risk Assessment For Installation of Grill, Diffuser and LouversDocument13 paginiRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- Risk Assessment For Installation of Fan Coil UnitsDocument18 paginiRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Risk Assessment For Installation & Testing of BMS UnitDocument15 paginiRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Risk Assessment For Installation of Air Handling UnitsDocument19 paginiRisk Assessment For Installation of Air Handling UnitsAnandu Ashokan100% (8)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 paginiRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan75% (4)

- Risk Assessment HVAC DuctingDocument5 paginiRisk Assessment HVAC DuctingAsad Zakria100% (6)

- Risk Assessment Concrete Cutting - 02Document6 paginiRisk Assessment Concrete Cutting - 02kapsarc75% (4)

- CALACA POWER RISK ASSESSMENTDocument17 paginiCALACA POWER RISK ASSESSMENTJayson Escamillan80% (5)

- RISK ASSESSMENT For Installation of HDPE Pipes and Fittings...Document21 paginiRISK ASSESSMENT For Installation of HDPE Pipes and Fittings...721917114 4757% (7)

- Risk Assessment For Air BlowingDocument8 paginiRisk Assessment For Air BlowingAriel Dela Cruz100% (5)

- Risk Assessment For Installation of Sanitary WaresDocument14 paginiRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of SMDB&DBDocument15 paginiRisk Assessment For Installation of SMDB&DBAnandu Ashokan78% (9)

- Risk Assessment - FM 200Document5 paginiRisk Assessment - FM 200Nangyal KhanÎncă nu există evaluări

- Risk Assessment of Testing and Commissioning of Fire Alarm SystemDocument4 paginiRisk Assessment of Testing and Commissioning of Fire Alarm Systemfidgety67% (3)

- RA For Hvac Duct InstallationDocument10 paginiRA For Hvac Duct InstallationAnandu Ashokan88% (8)

- Risk Assessment For Installation of Sanitary WaresDocument14 paginiRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of Toilet Exhaust FanDocument11 paginiRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- Risk Assessment of Installation of Chilled Water PipesDocument19 paginiRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan80% (10)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 paginiRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Chilled Water Pipe Installation - ACMVDocument4 paginiChilled Water Pipe Installation - ACMVbinhjuki100% (2)

- Risk Assessment - CHW PumpDocument4 paginiRisk Assessment - CHW PumpAdnan Attish100% (1)

- Installation of Air Handling UnitDocument15 paginiInstallation of Air Handling UnitAnandu Ashokan100% (2)

- Method Statement For Water Heaters InstallationDocument9 paginiMethod Statement For Water Heaters InstallationAnandu Ashokan100% (1)

- Method Statement For Cable Tray and Truncking InstallationDocument9 paginiMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanÎncă nu există evaluări

- Stoller - Write Like A ChemistDocument27 paginiStoller - Write Like A ChemistKenny CohenÎncă nu există evaluări

- Risk Assessment For MEP Services in P6 Existing ParkingDocument16 paginiRisk Assessment For MEP Services in P6 Existing ParkingAnandu Ashokan100% (2)

- Sanitary Fixtures Risk AssessmentDocument12 paginiSanitary Fixtures Risk AssessmentAnandu Ashokan100% (1)

- RISK ASSESSMENTDocument8 paginiRISK ASSESSMENTEm Niax100% (1)

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 paginiRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- Risk Assessment For Installation of Grill, Diffuser & Louvers RA 36Document12 paginiRisk Assessment For Installation of Grill, Diffuser & Louvers RA 36Anandu Ashokan100% (1)

- Installation of Fire Fighting Pipes Risk AssessmentDocument15 paginiInstallation of Fire Fighting Pipes Risk AssessmentAnandu Ashokan80% (5)

- Risk Assessment for Handrail ProjectDocument5 paginiRisk Assessment for Handrail ProjectKalid Jmal100% (1)

- Risk assessment for automatic revolving doorsDocument8 paginiRisk assessment for automatic revolving doorssabirbdk100% (1)

- Flushingchemical Cleaning of Chilled Water PipesDocument9 paginiFlushingchemical Cleaning of Chilled Water PipesAnandu AshokanÎncă nu există evaluări

- Risk Assessment - Installation of Ventilation FanDocument6 paginiRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Method Statement For Earthing and Lightning ProtectionDocument12 paginiMethod Statement For Earthing and Lightning ProtectionAnandu Ashokan100% (1)

- Method Statement For Drainage Pipes InstallationDocument11 paginiMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Method Statement LV Distribution Boards InstallationDocument9 paginiMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocument11 paginiMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- Method Statement For Wiring Accessories InstallationDocument9 paginiMethod Statement For Wiring Accessories InstallationAnandu AshokanÎncă nu există evaluări

- RAMS EvaluationDocument3 paginiRAMS EvaluationAnandu AshokanÎncă nu există evaluări

- MS For Installation of Grills, Diffuser & LouversDocument21 paginiMS For Installation of Grills, Diffuser & LouversAnandu AshokanÎncă nu există evaluări

- Msds Pig IronDocument6 paginiMsds Pig Ironcampag12350% (2)

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 paginiRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanÎncă nu există evaluări

- Risk Assessment For Installation of SMDB DBDocument12 paginiRisk Assessment For Installation of SMDB DBRAMA100% (1)

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDocument12 paginiRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- Risk Assessment For Installation of Fire Fighting SystemDocument14 paginiRisk Assessment For Installation of Fire Fighting SystemMohamed Elhadad100% (5)

- MS For Installation of Light FittingsDocument11 paginiMS For Installation of Light FittingsAnandu Ashokan100% (2)

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 paginiRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- Risk Assessment For Installation of MDBSMDB DB (Modified)Document15 paginiRisk Assessment For Installation of MDBSMDB DB (Modified)Anandu Ashokan100% (1)

- RA For Installation of Air Colled ChillersDocument8 paginiRA For Installation of Air Colled ChillersAnandu Ashokan100% (2)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 paginiRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Risk Assessment For Water Heaters InstallationDocument6 paginiRisk Assessment For Water Heaters Installationfidgety100% (1)

- RA For Flushing of Chilled Water PipesDocument8 paginiRA For Flushing of Chilled Water PipesAnandu AshokanÎncă nu există evaluări

- Installation of Under Ground Chilled Water PipingDocument18 paginiInstallation of Under Ground Chilled Water PipingAnandu Ashokan100% (1)

- Risk assessment for conduit pipe installationDocument17 paginiRisk assessment for conduit pipe installationJayson Escamillan75% (4)

- Risk Assessment For Installation of Drainage Pipes and FittingsDocument8 paginiRisk Assessment For Installation of Drainage Pipes and Fittingsfaizan khan100% (1)

- False CeilingDocument1 paginăFalse CeilingChandru67% (3)

- Risk Assessment - Installation of Air-Cooled ChillersDocument4 paginiRisk Assessment - Installation of Air-Cooled ChillersBabar ShehzadÎncă nu există evaluări

- Installation of Chilled Water PipesDocument6 paginiInstallation of Chilled Water PipesAnandu AshokanÎncă nu există evaluări

- Risk Assessment For Cable TrayDocument11 paginiRisk Assessment For Cable Traynellaika puspa dewiÎncă nu există evaluări

- MS For Installation of FF Pipes FittingsDocument23 paginiMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- Risk Assessment For FlushingDocument9 paginiRisk Assessment For FlushingABDUL BASITHÎncă nu există evaluări

- Method Statement For Fire Alarm and Emergency System InstallationDocument9 paginiMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- Method Statement For PPR Pipes and Fittings InstallationDocument9 paginiMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanÎncă nu există evaluări

- Method Statement For PVC Conduits InstallationDocument9 paginiMethod Statement For PVC Conduits InstallationAnandu AshokanÎncă nu există evaluări

- Method Statement For GI Conduits InstallationDocument9 paginiMethod Statement For GI Conduits InstallationAnandu AshokanÎncă nu există evaluări

- Method Statement For PEX Pipes and Fittings InstallationDocument9 paginiMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanÎncă nu există evaluări

- MS Cover SheetDocument1 paginăMS Cover SheetAnandu AshokanÎncă nu există evaluări

- MS For Installation of Sanitary WaresDocument22 paginiMS For Installation of Sanitary WaresAnandu AshokanÎncă nu există evaluări

- MS Comments SheetDocument1 paginăMS Comments SheetAnandu AshokanÎncă nu există evaluări

- MS For Installation of Duct & AccessariesDocument21 paginiMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- MS For Installation of Drainage PipesDocument20 paginiMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS For Installation of FF Pipes FittingsDocument23 paginiMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- MS For Installation of Toilet Exhaust FanDocument20 paginiMS For Installation of Toilet Exhaust FanAnandu AshokanÎncă nu există evaluări

- MS - Installation of Water Supply PipeDocument20 paginiMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- Hydrogen Sulfide (0.0001% - 0.05%), Oxygen (19.5 - 23.5%) in Balance NitrogenDocument10 paginiHydrogen Sulfide (0.0001% - 0.05%), Oxygen (19.5 - 23.5%) in Balance NitrogenpcatruongÎncă nu există evaluări

- Portland Cement: Safety Data SheetDocument11 paginiPortland Cement: Safety Data Sheetanon_381289007Încă nu există evaluări

- SDS MSDS 000012 Bio-Enzymatic Urine Digester 2009 01-14 EconomyDocument5 paginiSDS MSDS 000012 Bio-Enzymatic Urine Digester 2009 01-14 EconomyeadriesÎncă nu există evaluări

- Fire & Emergency EvacuationDocument11 paginiFire & Emergency EvacuationCharisse KharyleÎncă nu există evaluări

- CMPAK 2020 BIDDING Project EHS Checklist: Category No. EHS Checking Items Remark (If Not Comply) Compliance Yes/ No/ NADocument1 paginăCMPAK 2020 BIDDING Project EHS Checklist: Category No. EHS Checking Items Remark (If Not Comply) Compliance Yes/ No/ NAGayas ShaikÎncă nu există evaluări

- Afety Data Sheet - EOS Fixer Part BDocument5 paginiAfety Data Sheet - EOS Fixer Part BMinamii NadiaÎncă nu există evaluări

- Safety Data Sheet: Section 1 - IdentificationDocument7 paginiSafety Data Sheet: Section 1 - IdentificationeadriesÎncă nu există evaluări

- (English) SDS PERTAMINA GRISKLINDocument13 pagini(English) SDS PERTAMINA GRISKLINaudreyÎncă nu există evaluări

- Chemical Storage Compatibility GuidelinesDocument6 paginiChemical Storage Compatibility GuidelinesbaluchakpÎncă nu există evaluări

- Jotun Resist 86Document5 paginiJotun Resist 86Ansar AliÎncă nu există evaluări

- FSP SDS FX100Document5 paginiFSP SDS FX100Prajjwal PatidarÎncă nu există evaluări

- Astm B154-2016Document4 paginiAstm B154-2016Mukesh kumarÎncă nu există evaluări

- SDSDocument9 paginiSDSlordgin lausaÎncă nu există evaluări

- Msds KitosanDocument5 paginiMsds KitosanNuky Dwifirly Pratiwi ArhathaÎncă nu există evaluări

- Safety Data Sheet 1907/2006/EC - REACH (GB) Cartridges - For Tools, Blank or Powder LoadDocument11 paginiSafety Data Sheet 1907/2006/EC - REACH (GB) Cartridges - For Tools, Blank or Powder LoadJadinson GuerreroÎncă nu există evaluări

- Operator Manual UE6 MkIIDocument54 paginiOperator Manual UE6 MkIIANDRES CASTRO100% (2)

- GLUCONIC ACID MsdsDocument6 paginiGLUCONIC ACID MsdsNino ValenciaÎncă nu există evaluări

- SDS - PG Satin Part ADocument9 paginiSDS - PG Satin Part AIsabelo AbaoÎncă nu există evaluări

- Msds Hydroxyethyl Methyl Cellulose MhecDocument5 paginiMsds Hydroxyethyl Methyl Cellulose MhecWANGYUSHENG Kima Chemical Co LtdÎncă nu există evaluări

- Clariant Micronized WaxesDocument28 paginiClariant Micronized WaxesShyam YadavÎncă nu există evaluări

- Hebel AdhesiveDocument7 paginiHebel AdhesiveNathan CoomberÎncă nu există evaluări

- 210 CatalystDocument5 pagini210 CatalystViVek VermaÎncă nu există evaluări

- MSDS NaOH 45 EN NewDocument5 paginiMSDS NaOH 45 EN NewlvhaquyenÎncă nu există evaluări

- Resincoat Epoxy Crack Repair Filler Technical Data Sheet: Appearance & Typical Uses: PackagingDocument3 paginiResincoat Epoxy Crack Repair Filler Technical Data Sheet: Appearance & Typical Uses: PackagingVaittianathan MahavapillaiÎncă nu există evaluări

- Technical Data Sheet: Si-COAT® 570™Document9 paginiTechnical Data Sheet: Si-COAT® 570™Juan SÎncă nu există evaluări

- Safety Data Sheet: Brite Shield™ Enzymatic CleanerDocument7 paginiSafety Data Sheet: Brite Shield™ Enzymatic CleanerSoumya Saswat PandaÎncă nu există evaluări

- CASTOL - Hysol SL 50 XBB - SDSDocument21 paginiCASTOL - Hysol SL 50 XBB - SDSXto PeregrinÎncă nu există evaluări

- Jsa PDFDocument5 paginiJsa PDFVAMSIÎncă nu există evaluări