Documente Academic

Documente Profesional

Documente Cultură

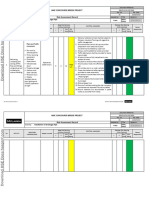

Risk Assessment For Installation of Grill, Diffuser and Louvers

Încărcat de

Anandu AshokanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Risk Assessment For Installation of Grill, Diffuser and Louvers

Încărcat de

Anandu AshokanDrepturi de autor:

Formate disponibile

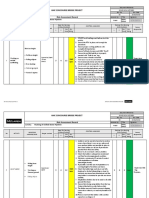

Document Reference

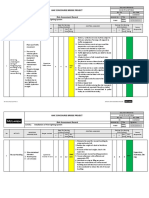

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0016

Rev. No. Rev. Date

00 18/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Grill, Diffuser & Louvers Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Delivery/ collection drivers shall be subject to

McLaren induction/Training with regards to

traffic management.

Plant and Traffic 2. Ensure exclusion zone is set up around the

movement preparation work area and all plant

movement and checked by supervisor

Run over by 3. Always use the pedestrian access provided

vehicles/plants 4. Traffic light batons shall be provided for banks

man at night

Hit by reversing

5. All plant to have a fully trained banks man

equipment

present all times.

Delivering, Overhead

unloading and 6. No plant to reverse without banks man.

obstructions

storing of Grill, Operatives 7. Ensure access route are sufficient and safe to Site Eng.

Vehicle break Staff/visitors

1 diffuser and Medi use. Supervisor,

down 3 4 12 1 4 4 Low

Louvers using um 8. Do not take rest in or under vehicles Foreman,

pickup and Property damage

9. Proper barricade and safety signboard

unloading by Collision with

provided on open excavation

manual handling other vehicles

10. All vehicles must be fitted with reverse alarm

Personal injury / Flashing light.

Fatality 11. The work place and all access to be well

Accident due to illuminated.

poor lighting and 12. Enforce Speed limit

visibility (operation 13. Ensure all vehicles entering the site is properly

at night maintained and reported if found any defect

14. Ensure materials are secured/tied in pallet

trolley to avoid fall from trolley.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

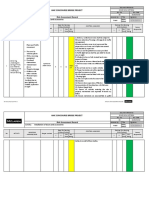

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0016

Rev. No. Rev. Date

00 18/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Grill, Diffuser & Louvers Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

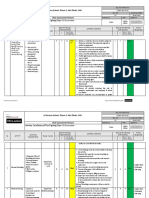

1. Eliminate the need for manual handling by

using mechanical aid.

2. Reduce the weight of a load to limit force

exertion or just increase the manpower to

reduce the load

3. If unsure of the load weight, check with

Musculoskeletal supervisor.

disorders

Supervisor,

4. Ensure proper manual handling procedure

Manual Handling Operatives Med Foreman,

2 Cut & bruises 5. Ensure adherence with sufficient and Low

involved in work 3 4 12 ium 1 4 4 Site Eng.

Hand injuries, appropriate PPE.

Sharp edges 6. Limit load carrying to 20kg per person

7. Supervisor must make sure while manual

handling loads individual task and environment

to be considered to reduce the risk of manual

handling.

8. ) Identify and eliminate sharp edges before any

manual lift and use appropriate PPE.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0016

Rev. No. Rev. Date

00 18/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Grill, Diffuser & Louvers Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Ensure accesses are kept clear at all times.

2. Housekeeping to be carried out regularly

throughout the day when required

3. Supervisor to ensure operatives are stacking

material neatly and stacks are stable and in a

safe condition

4. Provide adequate lighting especially during

Slips, Trips and fall Operatives Supervisor,

night hours

Poor house Staff/storekeeper Med

5. Appropriate space is allowed around storage

Foreman,

3 Material storing 3 4 12 1 4 4 Low

keeping ium areas for employees to move around safely Site Eng.

without the risk being trapped between

stacked materials.

6. Maintain good housekeeping.

7. Ensure all Louvers grill and diffuser item

covered with plastic sheet.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

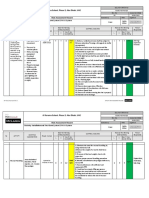

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0016

Rev. No. Rev. Date

00 18/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Grill, Diffuser & Louvers Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

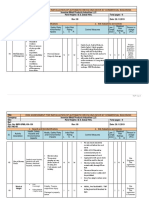

1. STARRT card briefing must before start the

activity.

2. Ensure the PTW in place.

3. Ensure proper working platform with

complete fall protection.

4. Ensure Full body harness and 100% Tie off

5. Ensure the scaffold platform is properly

erected with "Safe to use" tag..

Work at height 6. Ensure castor wheels are locked.

7. Hand tools must be secured/tethered.

8. Work materials strictly not allowed to be

Installation of Fall form height stored on platform except for working tools

Grill. Diffuser & Operatives/Staff/ 9. Ensure avoid over reaching and climb on handrail.

10. Ensure unauthorised person not allowed to Supervisors

Louver with Falling objects Visitors Med

4

Others

3 4 12 modify the scaffolding and if needed to any 1 4 4 Low Foreman,

accessories ium

changes then must be modified by trained Site Eng.

fittings using Over loading

mobile Tower and certified scaffolder.

Protruding objects 11. Ensure safe access to the working platform

12. Ensure while installation of grill, diffuser and

Access & egress louvers use proper procedure considering

sharp edge of materials.

13. Ensure sufficient illumination in work area

14. Ensure while fittings the GI clamp and brackets

operatives must safely use drill machine to avoid

finger injury.

15. Ensure that working near fragile surface special

care of body and eye protection with necessary

PPE.

16. Must clean the debris after completion the

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0016

Rev. No. Rev. Date

00 18/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Grill, Diffuser & Louvers Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

job and maintain good housekeeping.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0016

Rev. No. Rev. Date

00 18/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Grill, Diffuser & Louvers Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Only light work, off short duration and work in

which the operative can maintain secure hand

and foot hold can be undertaken form a

ladder

2. Never try to overreach with any ladders

3. Check the ladder is periodical maintained and

in good condition

4. Maintain a minimum of 3 points of contact

with stepladders at all times

(feet/thighs/hands)

5. If possible avoid the use of stepladders at a

Falling from

working height of 2 meters and more.

height

6. Check the ladder legs (and stays) are fully

Operatives/ Supervisor

Use of Ladder Med deployed or locked (depending on type) to

5 Working on Staff/ 3 4 12 1 4 4 Low Site Eng.

ium maintain maximum base dimensions and the

Uneven ground Foreman,

step ladder is orientated to provide maximum

stability.

Falling objects

7. Stepladders/ladders has to be used on leveled

ground/firm base

8. Ensure that during using ladder from the top

2 step is blocked to avoid climb on that.

9. The ladder securely fixed to prevent slipping

outwards or sideways or securely footed at all

times.

10. Person must hold the ladder while another

operative working on it

11. Materials should not be placed above the

thread of ladders/step ladders

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0016

Rev. No. Rev. Date

00 18/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Grill, Diffuser & Louvers Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

12. Do not carry any materials in one hand while

climbing or getting down from ladder

13. Ensure the area under the ladder is

barricaded especially if it is being used in a

public area.

14. Ensure the ladder is electrical insulated

podium type if working in live services

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0016

Rev. No. Rev. Date

00 18/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Grill, Diffuser & Louvers Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Ensure that all chemical substances have a

COSHH assessment

2. Refer SDS prior to any handling of hazardous

substances and ensure SDS is easily accessible

at site while working with chemicals.

3. Ensure chemicals are properly stacked.

4. Ensure all chemical containers are properly

labeled.

5. Spill kits to be available at site.

Spillage/ soil

6. Ensure operatives use the correct PPE

contamination

7. Competent person to oversee the storage,

Burns

use and disposal of hazardous materials. Supervisors

Contact with skin

Use of Touch-up 8. Ensure that correct welfare/first aid facilities

Acute/Chronic Operatives Med Foreman,

6 paint (Cold 3 4 12 are available in the area i.e. washing 1 4 4 Low

galvanising paint

adverse heath using solvent ium facility/eye wash.

Site Eng.

effect. g

and mastic 9. Proper and adequate PPE to be used always

sealant Fire 10. Ensure all chemical containers are properly

application labeled.

(Hazardous 11. Adjust work schedules so that workers are not

Substance) overexposed to a hazardous chemical.

12. Wear respiratory protection

13. Ensure proper and adequate PPE to be used

always.

14. Ensure smoking only in designated area

15. Ensure appropriate Firefighting equipment’s

are in place and easily accessible

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0016

Rev. No. Rev. Date

00 18/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Grill, Diffuser & Louvers Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. All portable electrical equipment must be PAT

tested and color coded. Make sure the test

dates are visible on the equipment.

2. Ensure all disk shall be appropriate and no

expiry date is over.

3. Ensure all power tools are in good condition

and periodicaly maintained

Damaged

4. PTW to be obtained, prior to commencing the

Sockets & cable

task

insulation.

5. Damaged industrial sockets and power cables

Electrocution

Electric shock must be removed.

Short circuit & 6. Ensure the electrical cable is not damaged

Use of power and has not been repaired with insulating

Burns Supervisor

tools such as Operatives Med

7 Trip/Fall 3 4 12 tape or unsuitable connectors. 1 4 4 Low Foreman

Grinder/Cutter & and staff ium

Noise 7. Ensure cables from power tools shall be Site Eng.

Drill machine,

Hearing loss organized so as not to present a tripping

Vibration hazard

Dust 8. Only trained competent operatives to operate

the power tools.

9. Ensure proper and regular maintenance of

equipment that takes account of noise

10. Ensure proper hearing protection always.

11. Make sure people use the right tool for the

job and are trained to use it correctly

12. Ensure defective tools that require

maintenance is reported for repair or

replacement.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0016

Rev. No. Rev. Date

00 18/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Grill, Diffuser & Louvers Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

13. Instruct workers to keep their hands warm

and dry, and to not grip a vibrating tool too

tightly.

14. Ensuring proper job rotation and limiting time

operatives working with power tools and

hand tools.

15. Use dust mask

16. Ensure proper earth leakage protection is

provided.

17. All power tools must be 110V to be ensured.

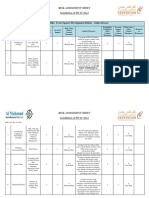

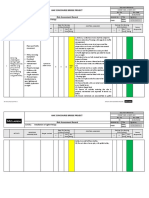

1. Arrange adequate drinking water and rest shelter

2. Drink plenty of water with electrolyte

3. If feel something unusual immediately inform

Heat exhaustion.

supervisor and report to site clinic.

Working under Heat stroke

4. Make shift to operate the routine work

High temperature Dehydration Site Eng.

Workers 5. Do not allowed alone work

8 Direct sun light Personal injuries due 4 4 16 High 1 4 4 Low Supervisors,

6. Frequent breaks

Dusty to high temperature, Foreman

7. Proper supervision available

High wind Sunstroke &

8. Correct PPE must use

Tiredness

9. Provide heat stress training

10. Conduct tool box talk

11. Proper signage for drinking water

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0016

Rev. No. Rev. Date

00 18/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Grill, Diffuser & Louvers Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Ensure proper night work permit is obtained

2. Proper lighting system should be in place

3. Ensure proper Communication / Coordination

and close supervision

Poor visibility Operatives/staff 4. Industrial safe torches to be available for Site Engr

Working at night due to darkness / Med emergency situations

9 time 3 4 12 1 4 4 Low Supervisor

poor illumination 5. High visibility Traffic Vest for personnel’s in

ium Foreman

Lone worker night shift

6. Avoid lone working and always ensure buddy

system while working at night

7. Employees to be trained and understand

McLaren Crises plan.

1. Ensure all fragile surfaces can easy impact of

body injury and supervisor must have briefed

to the operatives about the hazard of fragile

ceiling and precaution.

Fragile surface 2. Ensure your body parts and dress should not

Sharp metal engagement with sharp metal sheets and Site Eng

sheet ceiling.

Working near Operatives Med Supervisor

10

Fragile ceiling Fiber involved

3 4 12 3. Ensure while making hole and using drill 1 4 4 Low

ium cement dust and metal dust should not direct

Foreman

cement/silica

dust contact with your skin and body.

4. Use dust mask

5. Use necessary PPE

6. Housekeeping must be carried after

completion of work

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST-0016

Rev. No. Rev. Date

00 18/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Grill, Diffuser & Louvers Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. Hand tools should be visually inspected for

Improper defects, prior to use.

selection of hand 2. Never use damaged, blunt or broken tools to

tools. avoid injury.

Damaged and Operatives/Staff 3. Select right tools for right Job Site engg

Defective Hand 4. Ensure no Homemade or makeshift tools to Supervisor

Use of Hand tools tools. be used at site Foreman

Med

11 Hand injuries 3 3 9 5. Remove from service any tool that shows 1 3 3 Low

ium

Pinch point signs of damage or defect

Ergonomics 6. Ensure Hand tools are Stored in accordance

Repetitive strain with the manufacturer’s instructions.

injury 7. Ensure hands are not in direct line of fire

while working with hand tools

8. Ensure appropriate PPE at all times.

Approved By: Name Position __________ Signature _________ ___________

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

RISK ASSESSMENT & CONTROL GUIDELINES

1. Executing Steps:

1.1. Planning

a) Construction and HSE team must ensure that hazard identification is complete.

b) Construction and HSE team must prioritize the hazard issues, which are of significant in nature. (It means that risks have well

established legal requirements, potentially high risks).

c) Construction and HSE team to prepare the risk assessment plan for the priorities identified hazards for these potential high

risks.

1.2. Risk Assessment

Risk is the probability of an event occurring in a given set of circumstances. The ‘event’ is an exposure to hazard. The hazard is the

potential to cause harm. The risk assessment is the technique of evaluating not just the likelihood of an event occurring, but also the

outcome will be in terms of injury, loss, damage or harm.

1.3. Risk Assessment Process

The process of carrying out a risk assessment should be as follows.

1. Identify the hazards.

2. Identify who might be harmed and how.

3. Evaluate the risk and implement the control measures.

4. Record the significant findings.

5. Review the assessment and update if necessary.

1.4. Examination of the Hazards and Risk Associated

Competent staff must be used in examining the risk associated with the identified hazard.

Competent staff should examine following aspect to determine the risk involved:

o Examine the existing control measures in place.

o Identify employees at risk.

o Likelihood of risk.

o Severity

o Risk level and their tolerability.

1.5. Evaluating the risk:

Once the necessary information has been obtained on the hazards encountered by work activities, next stage is to access the risks.

1.5.1. Risk Rating Score

Risk rating score is a combination of two factors.

The severity of the risk that could injure persons or cause damage to plant.

The likelihood of the risk that it could happen (Probability).

RISK RATING = LIKELIHOOD X SEVERITY

NOTE: Each activity has to be assessed for the risk value for determining the level of Severity and likelihood are mentioned in the table

below.

No Injury Minor Moderate Major

Catastrophic (5)

(1) Injury (2) Injury (3) Injury (4)

1 2 3 4 5

Rarely (1)

Unlikely (2) 2 4 6 8 10

LIKELIHOOD Possible (3) 3 6 9 12 15

Likely (4) 4 8 12 16 20

Almost

5 10 15 20 25

RISK LEVEL: Certain (5)

Low Medium High

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

S-ar putea să vă placă și

- Risk Assessment For Installation of Drainage PipesDocument17 paginiRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- Risk Assessment For Installation of Drainage PipesDocument17 paginiRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- Excavation Risk Assessment SheetDocument3 paginiExcavation Risk Assessment SheetMuhammad Ibrahim93% (46)

- Risk Assessment For Installation of Fire Fighting SystemDocument20 paginiRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan90% (31)

- Risk Assessment For Installation of Fire Fighting SystemDocument20 paginiRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan90% (31)

- Risk Assessment For Installation of Water Supply PipeDocument18 paginiRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Installation of Water Supply PipeDocument18 paginiRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Structured CablingDocument7 paginiRisk Assessment For Structured CablingAnandu Ashokan67% (6)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 paginiRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan85% (13)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 paginiRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan85% (13)

- Risk Assessment For CABLE TRAYDocument11 paginiRisk Assessment For CABLE TRAYAnandu Ashokan86% (14)

- Risk Assessment For Installation of Light FittingsDocument11 paginiRisk Assessment For Installation of Light FittingsAnandu Ashokan88% (8)

- Risk Assessment For Installation of Electrical Wiring & Cable PullingDocument13 paginiRisk Assessment For Installation of Electrical Wiring & Cable PullingAnandu Ashokan94% (17)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument8 paginiRisk Assessment For Testing and Commissioning of Electrical SystemAnandu Ashokan100% (8)

- Risk Assessment For MEP Isolation WorksDocument8 paginiRisk Assessment For MEP Isolation WorksAnandu Ashokan100% (5)

- Risk Assessment of Fire Hose Reel InstallationDocument9 paginiRisk Assessment of Fire Hose Reel Installationfidgety100% (2)

- Method Statement For Structured Cabling System InstallationDocument9 paginiMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- Risk Assessment For Installation & Testing Commissioning of PumpsDocument17 paginiRisk Assessment For Installation & Testing Commissioning of PumpsAnandu Ashokan75% (8)

- Risk Assessment For Installation of Fan Coil UnitsDocument18 paginiRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Risk Assessment For Installation & Testing of BMS UnitDocument15 paginiRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Risk Assessment For Installation of Air Handling UnitsDocument19 paginiRisk Assessment For Installation of Air Handling UnitsAnandu Ashokan100% (8)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 paginiRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan75% (4)

- Risk Assessment For Installation of Fire Alarm System & PAVA SystemDocument11 paginiRisk Assessment For Installation of Fire Alarm System & PAVA SystemAnandu Ashokan88% (8)

- Risk Assessment HVAC DuctingDocument5 paginiRisk Assessment HVAC DuctingAsad Zakria100% (6)

- Risk Assessment For Installation of Sanitary WaresDocument14 paginiRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of Toilet Exhaust FanDocument11 paginiRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- Risk Assessment For Installation of SMDB&DBDocument15 paginiRisk Assessment For Installation of SMDB&DBAnandu Ashokan78% (9)

- Risk Assessment For Flushing of Chilled Water PipingDocument9 paginiRisk Assessment For Flushing of Chilled Water PipingAnandu AshokanÎncă nu există evaluări

- Risk Assessment For Cable InstallationDocument15 paginiRisk Assessment For Cable InstallationKaruppu Samy86% (7)

- Block Work - Risk AssessmentDocument5 paginiBlock Work - Risk AssessmentJamal Khawaldeh0% (1)

- RA For Hvac Duct InstallationDocument10 paginiRA For Hvac Duct InstallationAnandu Ashokan88% (8)

- Risk Assessment of Installation of Chilled Water PipesDocument19 paginiRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan80% (10)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 paginiRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Chilled Water Pipe Installation - ACMVDocument4 paginiChilled Water Pipe Installation - ACMVbinhjuki100% (2)

- Risk Assessment For .TESTING AND COMMISSIONING OF 11 KV CABLEDocument18 paginiRisk Assessment For .TESTING AND COMMISSIONING OF 11 KV CABLEarun kurlan89% (9)

- Method Statement For Water Heaters InstallationDocument9 paginiMethod Statement For Water Heaters InstallationAnandu Ashokan100% (1)

- Method Statement For Cable Tray and Truncking InstallationDocument9 paginiMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanÎncă nu există evaluări

- Risk Assessment For MEP Services in P6 Existing ParkingDocument16 paginiRisk Assessment For MEP Services in P6 Existing ParkingAnandu Ashokan100% (2)

- Risk Assessment For Installation of Sanitary Fixtures and Mixers (New)Document12 paginiRisk Assessment For Installation of Sanitary Fixtures and Mixers (New)Anandu Ashokan100% (1)

- Risk Assessment For Installation of Fire Fighting Pipe & AccessoriesDocument15 paginiRisk Assessment For Installation of Fire Fighting Pipe & AccessoriesAnandu Ashokan83% (6)

- Risk Assessment For Installation and Testing of ACS (RA33)Document11 paginiRisk Assessment For Installation and Testing of ACS (RA33)Anandu Ashokan100% (3)

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 paginiRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- Risk Assessment For Installation of Grill, Diffuser & Louvers RA 36Document12 paginiRisk Assessment For Installation of Grill, Diffuser & Louvers RA 36Anandu Ashokan100% (1)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument8 paginiRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- Risk Assessment of Scaffolding Works - Rev. 1Document20 paginiRisk Assessment of Scaffolding Works - Rev. 1Jayson Escamillan67% (3)

- Environmental, Health and Safety Risk AssessmentDocument2 paginiEnvironmental, Health and Safety Risk AssessmentAdnan100% (2)

- Risk Assessment - Installation of Ventilation FanDocument6 paginiRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment For Installation of Toilet Exhaust FanDocument10 paginiRisk Assessment For Installation of Toilet Exhaust FanMaria Carmela Rachel GazilÎncă nu există evaluări

- Method Statement For Drainage Pipes InstallationDocument11 paginiMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Method Statement For Earthing and Lightning ProtectionDocument12 paginiMethod Statement For Earthing and Lightning ProtectionAnandu Ashokan100% (1)

- Method Statement For Wiring Accessories InstallationDocument9 paginiMethod Statement For Wiring Accessories InstallationAnandu AshokanÎncă nu există evaluări

- Method Statement LV Distribution Boards InstallationDocument9 paginiMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocument11 paginiMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- RAMS EvaluationDocument3 paginiRAMS EvaluationAnandu AshokanÎncă nu există evaluări

- MS For Installation of Grills, Diffuser & LouversDocument21 paginiMS For Installation of Grills, Diffuser & LouversAnandu AshokanÎncă nu există evaluări

- Involved in The Leadership and Management of Project TeamDocument13 paginiInvolved in The Leadership and Management of Project TeamMahendra paudel PaudelÎncă nu există evaluări

- Case StudyDocument7 paginiCase StudyMotilaldass100% (1)

- Crisis Management Manual Manual 1996Document62 paginiCrisis Management Manual Manual 1996jomar ico100% (1)

- Lesson 2 The Secret To Consistent Forex Trading Profits: by Adam KhooDocument15 paginiLesson 2 The Secret To Consistent Forex Trading Profits: by Adam Khoodaysan100% (3)

- Risk Assessment For Installation of SMDB DBDocument12 paginiRisk Assessment For Installation of SMDB DBRAMA100% (1)

- MS For Installation of Light FittingsDocument11 paginiMS For Installation of Light FittingsAnandu Ashokan100% (2)

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 paginiRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanÎncă nu există evaluări

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 paginiRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- Risk Assessment For Temporary ServicesDocument15 paginiRisk Assessment For Temporary Servicesfaizan khan100% (2)

- Risk Assessment For Installation of Fire Fighting SystemDocument14 paginiRisk Assessment For Installation of Fire Fighting SystemMohamed Elhadad100% (5)

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDocument12 paginiRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- Risk Assessment For Installation of MDBSMDB DB (Modified)Document15 paginiRisk Assessment For Installation of MDBSMDB DB (Modified)Anandu Ashokan100% (1)

- NPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemDocument15 paginiNPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemabbasÎncă nu există evaluări

- RA For Installation of Air Colled ChillersDocument8 paginiRA For Installation of Air Colled ChillersAnandu Ashokan100% (2)

- Risk Assessment For Dismantling of Temporary ServicesDocument17 paginiRisk Assessment For Dismantling of Temporary ServicesAnandu AshokanÎncă nu există evaluări

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 paginiRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel Factor50% (4)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 paginiRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- RA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & TrenchesDocument11 paginiRA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & Trenchesthomson100% (1)

- Risk Assessment - Installation of Air CurtainDocument25 paginiRisk Assessment - Installation of Air CurtainMohsin Mohd100% (1)

- Ra For Installation of Grills, Diffusers & LouversDocument8 paginiRa For Installation of Grills, Diffusers & LouversAnandu Ashokan100% (1)

- Installation of Copper Pipes and Fittings.: Barq Group Risk AssessmentDocument8 paginiInstallation of Copper Pipes and Fittings.: Barq Group Risk AssessmentYousaf Richu67% (3)

- Risk Assessment For Installation of Drainage PipesDocument17 paginiRisk Assessment For Installation of Drainage PipesMahdi MkaouarÎncă nu există evaluări

- Risk Assessment For Installation of Cooling TowersDocument19 paginiRisk Assessment For Installation of Cooling TowersVlad Karo100% (1)

- Method Statement For PEX Pipes and Fittings InstallationDocument9 paginiMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanÎncă nu există evaluări

- Method Statement For PPR Pipes and Fittings InstallationDocument9 paginiMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanÎncă nu există evaluări

- Method Statement For GI Conduits InstallationDocument9 paginiMethod Statement For GI Conduits InstallationAnandu AshokanÎncă nu există evaluări

- Method Statement For Fire Alarm and Emergency System InstallationDocument9 paginiMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- MS Cover SheetDocument1 paginăMS Cover SheetAnandu AshokanÎncă nu există evaluări

- Method Statement For PVC Conduits InstallationDocument9 paginiMethod Statement For PVC Conduits InstallationAnandu AshokanÎncă nu există evaluări

- MS For Installation of Duct & AccessariesDocument21 paginiMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- MS For Installation of Sanitary WaresDocument22 paginiMS For Installation of Sanitary WaresAnandu AshokanÎncă nu există evaluări

- MS Comments SheetDocument1 paginăMS Comments SheetAnandu AshokanÎncă nu există evaluări

- MS For Installation of Toilet Exhaust FanDocument20 paginiMS For Installation of Toilet Exhaust FanAnandu AshokanÎncă nu există evaluări

- MS For Installation of Drainage PipesDocument20 paginiMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS - Installation of Water Supply PipeDocument20 paginiMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- MS For Installation of FF Pipes FittingsDocument23 paginiMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- Solution Overview Presentation - SAP Treasury and Risk ManagementDocument59 paginiSolution Overview Presentation - SAP Treasury and Risk ManagementAna Maria Martins Doval91% (11)

- Iins5211 MoDocument23 paginiIins5211 MoarronyeagarÎncă nu există evaluări

- DRRR 11 Group ReportDocument24 paginiDRRR 11 Group ReportKarl Michael RubinÎncă nu există evaluări

- Effect of Increasing Age On Cataract Surgery OutcoDocument4 paginiEffect of Increasing Age On Cataract Surgery OutcoKanneaufii KaramelÎncă nu există evaluări

- WinCatt 7 Tech Manual REV OCT2017Document92 paginiWinCatt 7 Tech Manual REV OCT2017Richard AldazÎncă nu există evaluări

- SPM-M.techDocument19 paginiSPM-M.techNaga Phaniraj YechuriÎncă nu există evaluări

- Working in Close Proximity To Overheadpowerlines: Huawei ConfidentialDocument5 paginiWorking in Close Proximity To Overheadpowerlines: Huawei ConfidentialmosesÎncă nu există evaluări

- Credit Risk Management in Karnataka State Credit Risk Management in Karnataka StateDocument98 paginiCredit Risk Management in Karnataka State Credit Risk Management in Karnataka StatePrashanth PBÎncă nu există evaluări

- C 21Document18 paginiC 21Priyanka RoyÎncă nu există evaluări

- Risk and Return: All Rights ReservedDocument28 paginiRisk and Return: All Rights ReservedWasif KhanÎncă nu există evaluări

- Accenture Grows Pharma SolutionsDocument8 paginiAccenture Grows Pharma SolutionsmiriyamsatyanarayanaÎncă nu există evaluări

- Section 45 & 64 VBDocument11 paginiSection 45 & 64 VBRiya_Biswas_8955100% (1)

- Group 1: Strategic ManagementDocument3 paginiGroup 1: Strategic ManagementVenjo SanchezÎncă nu există evaluări

- Assessment Task 2 Oral PresentationDocument17 paginiAssessment Task 2 Oral PresentationadhbawaÎncă nu există evaluări

- 01.vaseem Akbar - Qhse OfficerDocument2 pagini01.vaseem Akbar - Qhse OfficerqhsedkÎncă nu există evaluări

- A Guide To Risk Assessment in Ship OperationsDocument6 paginiA Guide To Risk Assessment in Ship OperationsDmytro OparivskyÎncă nu există evaluări

- ICT Feasibility StudyDocument22 paginiICT Feasibility StudyShakir AbdullahÎncă nu există evaluări

- Audit of Vehicle Lien Sales Report HighlightsDocument65 paginiAudit of Vehicle Lien Sales Report HighlightsLong Beach PostÎncă nu există evaluări

- Mitigation ProjectDocument12 paginiMitigation ProjectMegha DalmiaÎncă nu există evaluări

- Children's Wear ManufacturingDocument9 paginiChildren's Wear ManufacturingMamello Meme BolofoÎncă nu există evaluări

- Business Case: DefinitionsDocument13 paginiBusiness Case: DefinitionsJohanna BlanquicethÎncă nu există evaluări

- Chapter Four: The Meanings and Dimensions of CultureDocument48 paginiChapter Four: The Meanings and Dimensions of CultureChristianWiradendiÎncă nu există evaluări

- TitagarhDocument94 paginiTitagarhdhruvfeedbackÎncă nu există evaluări

- IG1 - IGC1 0010 ENG OBE Answer Sheet V1Document11 paginiIG1 - IGC1 0010 ENG OBE Answer Sheet V1Saad MalikÎncă nu există evaluări

- Your Safety AttitudeDocument16 paginiYour Safety Attitudesindarth raveendrakrishnanÎncă nu există evaluări

- DNV Os H101Document55 paginiDNV Os H101Noralia Amanina Osman100% (2)