Documente Academic

Documente Profesional

Documente Cultură

Design Aspects of Modern Cement Concrete

Încărcat de

Shahid PerwezTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Design Aspects of Modern Cement Concrete

Încărcat de

Shahid PerwezDrepturi de autor:

Formate disponibile

ISSN 0974-5904, Volume 10, No.

02

DOI:10.21276/ijee.2017.10.0249

www.cafetinnova.org April 2017, P.P. 455-461

Design Aspects of Modern Cement Concrete Pavements in India

AVISHRESHTH AND TANUJ CHOPRA

Civil Engineering Department, Quantum Global Campus, Roorkee-247667, INDIA

Email: avi.theriac@gmail.com, tchopra@thapar.edu

Abstract: There is an increasing trend for using concrete pavement all over the world because of its ability to

handle complex loading and environmental conditions that occur in highways. Finite element method is the best

tool for analysis of the pavement slab. The pavement slab deteriorates under combined action of axle loads and

temperature differential across the depth of slab. The present study illustrates a case study for thickness design

and describes the different parameters associated with the design of rigid pavement for a National Highway in

Punjab State using tied concrete shoulders. The possibility of bottom-up and top-down cracking was considered.

The effect of moisture variations on the development of warping stresses is ignored. The thickness of a pavement

slab reduces by about 30 percent if there is a tied concrete shoulder or when the slab has a widened outer lane.

Keywords: Concrete pavement, Axle loads, Temperature differential

1. Introduction load and pavement temperature. In this paper,

different parameters associated with the design of

India has the second largest road network across the

pavement with tied concrete shoulders are discussed

world at 4.87 million km. Indian road network carries

for a National Highway in Punjab State.

almost 85 per cent of the country’s passenger traffic

and around 60 per cent of its freight. The economic 2.0 Factors Governing Pavement Design

growth of a developing nation like India depends on a

2.1 Axle Loads and Tyre Pressures

well-connected, efficient and safe road network. This

includes not only National Highways but other roads Though the legal axle load limits in India are 10.2, 19

also which facilitate fast movement of goods and and 24 ton for single, tandem and tridem axles

people. The construction of highways has reached an respectively, the actual axle loads operating on

all-time high and the increased pace of construction is highways in India are much higher due to lack of

expected to continue for the coming years. Indian enforcement. It, therefore, becomes essential to

roads are primarily bitumen-based macadam roads collect the data on axle load spectrum of commercial

and the share of concrete roads is very small. vehicles both during the day and night hours to

However, India’s Ministry of Road Transport and analyze and compute the flexural fatigue damage with

Highways has decided to shift towards making rigid a higher precision and determine the possibility of

pavement the default mode of construction on top-down cracking. The tyre inflation pressures of

national highways after considering factors related to commercial highway vehicles may range from 0.7

service life, fuel consumption, weather conditions and MPa to 1.0 MPa. It is observed that the variation in

maintenance costs. tyre pressure for concrete pavement slab of thickness

200 mm or more has little effect on the stresses in

A concrete pavement is a rigid pavement structure

pavement slabs [1].

which in general consists of three layers; subgrade,

base course and the concrete slab. A concrete 2.2 Wheel Base Characteristics and Design Period

pavement distributes heavy axle loads over a large

During night hours, the slab has a tendency to curl up

area by beam action which means that concrete

and maximum fatigue develops when the axle loads

pavements are less sensitive to the subgrade support

acts close to transverse joints. The distance between

and do not require the thick sub-base layers like

steering axle and center point of driving axle group

asphalt concrete pavements. The design of concrete

for different truck models generally range from 3.6m

pavements has become more scientific with time.

to more than 5.0m whereas the commonly used

Efforts to avoid premature performance failing of

transverse joint spacing is 4.5m, so the axles with

concrete roads are, at a larger degree, considered than

spacing between the front and rear axles greater than

for other pavement alternatives since rehabilitation

the proposed transverse joint widths do not contribute

techniques are expensive. The development of Finite

to top-down fatigue cracking. Therefore, it becomes

Element Method (FEM) and the use of softwares have

essential to establish the typical spacing between

made the evaluation of stresses under complex

successive axles of commercial vehicles and thus the

loading condition easy. A modern design

proportion of axles contributing to top-down fatigue

methodology of IRC: 58-2015 aims at rationalizing

cracking during night period from axle load survey.

the design procedure by considering cumulative

fatigue damage due to the combined effect of wheel

Received: December 02, 2016; Accepted: February 13, 2017; Published: April 26, 2017

International Journal of Earth Sciences and Engineering, 10(02), 455-461, 2017, DOI:10.21276/ijee.2017.10.0249

Copyright ©2017 CAFET-INNOVA TECHNICAL SOCIETY. All rights reserved.

456 AVISHRESHTH AND T ANUJ C HOPRA

Cement concrete pavements are generally designed slightly and reverts back to its original shape when a

for a life period of 30 years or more. However, factors vehicle passes over it. It is commonly assumed that

such as traffic volume, uncertainty of traffic growth the foundation or the sub-base is composed of springs

rate, road capacity and possibility to boost the bonded to the concrete slab, and the reactive pressure

capacity by widening in future must be considered for per unit deflection is termed as modulus of subgrade

taking the design period. reaction (k). The k-value is determined by Plate Load

Test from the pressure sustained at a deflection of

2.3 Design Traffic

1.25mm. The standard test uses a 750mm diameter

Assessment of average daily traffic shall normally be plate [10].

based on seven day 24 hour count made in accordance

The plate load test is time-consuming, expensive,

with IRC: 9 “Traffic Census on Non-Urban Roads”

sometimes leads to overestimation of strength and

[2]. As per IRC: SP: 84 annual growth rates of

does not give reliable results for different moisture

commercial vehicles shall be taken to be a minimum

conditions, therefore the design k-value is often

of 5% [3]. When the outer wheel of vehicles move

estimated from soaked CBR value. A minimum CBR

tangentially to the longitudinal edge, the edge flexural

of 8% is recommended for the 500 mm of the select

stress for bottom-up cracking is highest and is

soil used as subgrade [1].

considered critical for design thickness [4]. A very

small percentage of wheel load repetitions (less than Falling Weight Deflectometer (FWD) tests can also

2%) meet this condition for both 2-way 2-lane and 4- be done to compute the value of modulus of subgrade

lane divided highways in India [5]. Design traffic of reaction for an existing pavement or a prepared

25% of the total 2-lane 2-way commercial vehicles foundation. If the Falling Weight Deflectometer

should be considered for thickness design. In case of (FWD) tests are done at the corners, interiors and

4-lane and multi-lane divided highways, 25% of the edge region, different k-values would be obtained on

total traffic in the direction of predominant traffic may back calculation since the spring model is only a

be considered for design of pavement. The design mathematical idealization though the behaviour of

traffic for top-down cracking is usually fifty percent subgrade/sub-base under confined condition would be

of the design traffic for bottom-up cracking analysis almost elastic under repeated loading. Hence, to

[1]. evaluate the realistic stress and deflection values,

different k-values must be used for corner, interior

2.4 Temperature Differential

and edge loading [11].

The temperature gradient in a slab of concrete

A sub-base is responsible to provide support to the

pavement is generally non-linear during the day-time

concrete slab. It must, therefore be uniform, stable

and nearly linear during the night hours. Several

and strong to resist erosion and disintegration due to

studies have shown that non-linear temperature

adverse climatic variations and movement of heavy

variation prevails across the depth of slab and some

wheel loads. DLC sub-base being stronger than the

parts of the concrete slab have a tendency to lift up

conventional granular sub-base is recommended for

when a moisture or temperature difference exists

all major highways in India [1]. A de-bonding inter

across the depth of slab [6][7][8][9]. Also, the peak

layer of 125-micron thick polythene sheet is placed

temperature difference occurs only for a short

over the DLC layer before placing of concrete slab to

duration. The peak temperature differential during the

reduce the inter layer friction and reflection cracking

night is almost half of the day time maximum

in pavement slab. In such pavement structures,

temperature differential.

composite action of the slab and the DLC is lost and

Temperature differentials are considered positive both act independently in resisting the applied axle

when the top surface of a pavement slab curls to have loads. If the pavement slab and the DLC layer are

a convex shape during the day hours and negative bonded, it will result in a monolithic action of the two

when the slab curls with a concave shape during the layers, which will greatly reduce the pavement

night. The axle load stresses should be computed for thickness because of low bending stresses [4]. Since

fatigue analysis when the slab is in a curled state due the 7-day strength of DLC is usually 10 MPa or

to the temperature differential during the day as well higher it is necessary to provide contraction joints in

as night hours. The maximum temperature the DLC also below the contraction joints or slab.

differentials for concrete slabs for different

2.6 Concrete Strength

states/regions are recommended in Table 1 of IRC:

58-2015 [1]. The flexural strength of cement concrete slab is the

most important requirement as it distributes heavy

2.5 Characteristics of Sub-Grade and Sub-Base

axle loads over a large area by beam action. The 90

When a vehicle moves over a cement concrete days and one year flexural strengths are about 110 and

pavement, the concrete slab deflects under the load 117 percent respectively of the 28-day flexural

similar to the beam action. This load is resisted by a strength [4]. The cumulative fatigue damage is very

reactive pressure from subgrade at the bottom of slab. small in the first few months as the number of load

The foundation of the pavement slab deforms only repetitions is very few during the initial period. It is,

International Journal of Earth Sciences and Engineering

ISSN 0974-5904, Vol. 10, No. 02, April, 2017, pp. 455-461

Design Aspects of Modern Cement Concrete Pavements in India 457

therefore, logical that 90 day flexural strength of

concrete should be used as design strength of

concrete. For the initial 4 to 5 years, the joints of

concrete pavements are impervious but the joint seals

are lost with passage of time and rain water starts to

enter freely through them. Hence, a permeable

granular or cement treated sub-base can ensure better

performance of heavy duty pavements helping in

quick removal of rainwater by infiltration through the

joints. The minimum value of 28-day flexural strength

for pavement quality concrete (PQC) is 4.5 MPa [1].

2.7 Fatigue behaviour of Cement Concrete Single Tandem Tridem

Axle Axle Axle

A cement concrete pavement is subjected to dynamic

loads due to repeated applications of vehicle loads.

These cyclic loadings cause distress in cement

concrete slab by gradual development of micro-cracks

especially when the stress ratio, i.e., the ratio between

applied flexural stress and flexural strength of

concrete, exceeds 0.45. The number of load

Figure 2: Symbol gives the location of

repetitions required to cause cracking decrease with

maximum edge flexural stress due to single, tandem

an increase in stress ratio [1].

and tridem axles

2.8 Flexural Stress & Fatigue Damage

The flexural stress at the top layer of the concrete slab

The PQC slab is subjected to flexural stresses due to is the maximum during night hours when axle loads

single, tandem and tridem axle loads; temperature act close to transverse joints on the pavement slab

differential between the top and bottom of slab and; when there is a negative temperature gradient. Since,

warping caused by moisture variations across the the top surface of a pavement slab is cooler than the

depth of slab. However, the effect of moisture bottom surface during the night hours; the ends of

variation is generally ignored and is not considered slab have a tendency to curl up in a concave shape

critical to thickness design [1]. which results in a loss of support for the slab. Due to

the combination of high negative temperature

A slab is subjected to temperature differential

gradient, moisture gradient and different axle loads, a

between the top and bottom due to quick changes in

high tensile stress develops at the top of slab near the

daily temperature causing the slab to warp. It warps

middle of the critical longitudinal edge and thus

with convex upwards during the daytime when the top

initiating Top-Down Cracking (TDC) as shown in

of the slab is much hotter than the bottom. Reverse is

Figure 3 [1].

the case during the night hours, the self-weight of the

slab causes warping stresses in the slab during the Location of

warping process. maximum

The flexural stress at the bottom layer of the concrete tensile stress

slab is the maximum during the day hours when the

axle loads act midway on the pavement slab while

there is a positive temperature gradient as illustrated

in Figures 1 and 2. The location of maximum flexural

stress at the bottom of pavement slab with or without

tied concrete shoulders for single, tandem and tridem

axles is the same [1]. Concrete Slab

Location of FOUNDATION

maximum

tensile stress

Figure 3: Placement of two axles of a commercial

Concrete Slab vehicle on a warped pavement slab during the night

hours

A pavement slab is gradually damaged due to

FOUNDATION repeated flexural stresses, low or high in magnitude,

causing crack propagation in a pavement and

Figure 1: Axle load placed in the middle of slab ultimately to the development of micro-cracks under

during day-time repeated loading and thus failure. Analysis indicates

International Journal of Earth Sciences and Engineering

ISSN 0974-5904, Vol. 10, No. 02, April, 2017, pp. 455-461

458 AVISHRESHTH AND T ANUJ C HOPRA

that contribution to Cumulative Fatigue Damage in the form of cement slurry may be applied over it

(CFD) for bottom-up cracking is significant only before laying the pavement slab. In order to promote

during 10 A.M. to 4 P.M. because of higher flexural monolithic action between the two layers, transverse

stresses caused by axle load and warping. For the top- joints shall be provided in the DLC layers also to one-

down cracking analysis, only the CFD caused during third of its depth exactly below the regions where

the night between 0 A.M. and 6 A.M. is significant transverse joints will be provided in the pavement

[1]. slab. The minimum 7-day compressive strength of a

DLC layer should be 10MPa.

Finite Element Analysis is done for stress

computation by using IITSLAB-II, software 3.0 Stress Charts and Regression Equations

developed at IIT Kharagpur, to compute flexural

Appendix-1 gives the stress charts for Bottom-up

stress due to combined action of load and different

Cracking Analysis for different categories of axles

temperature differentials. The flexural stresses can

and modulus of subgrade reaction used in the design

also be computed using Appendix I and Appendix II

of pavement thickness in this paper. The empirical

given in IRC: 58 [1].

formula given in Appendix-5 of IRC: 58 – 2015 may

2.9 Design Criterion of Rigid Pavements be referred for the calculation of Top-down Cracking

Analysis [1].

If the sum of Cumulative Fatigue Damage (CFD) due

to (i) wheel load and curling stresses at the bottom 4.0 Limitations and Future Scope of Work

and (ii) wheel load and curling stresses at the top is

The subgrade is considered as a Winkler’s foundation

less than 1, the pavement is safe. Thus if CFD (BUC)

However, this may not be a very practical approach as

+ CFD (TDC) = 1, the pavement is safe from large

it may not give an exact estimation of the strength of

scale cracking. The design thickness may be increased

foundation and also the DLC layer has high shear

by 10mm to (i) to permit two texturing and (ii)

strength. Modeling of the foundation as a solid elastic

grinding to rectify faulting during the service life [1].

mass may be more realistic. The study of annual

2.10 Tied Concrete Shoulder and Widened Outer temperature differentials across the country shall be

Lane done to cover different climatic zones and thus for

correct evaluation of stresses. Currently, there are no

Tied concrete shoulders and widened outer lanes can

specifications for retexturing and its methodology.

significantly improve the cracking by reducing

The issues highlighted above shall be examined and

flexural stresses at the edges of high volume highway

incorporated in the revised guidelines for the design

pavements where critical loadings occur. Widening of

and construction of concrete roads in India.

outer lanes by 0.5m to 0.6m reduce the edge flexural

stress by 20 percent to 30 percent. In tied concrete 5.0 Conclusions

shoulders, the stress at edges is reduced by about 30

Based on the research work done in this paper,

percent. Figure 4 shows the widened part of the outer

following conclusions are drawn which should help in

lane, which can be given a rough texture to discourage

rationalizing the design procedure to suggest a

vehicles from coming over the shoulder from safety

mechanistic design for concrete pavements in India.

consideration.

Care must be taken to select the value of modulus

0.5m to 0.6m of subgrade reaction (k) by considering factors

such as loss of support due to erosion, slab

deformation and moisture variations.

If the pavement slab thickness is greater than or

equal to 200mm, then tyre pressure has little

effect on flexural stresses.

The vehicles travelling tangential to the outer

edge cause highest flexural stresses in a

Widened Part of Pavement Outer Lane pavement. However, the percentage of wheels

falling tangentially to the longitudinal edge is

Figure 4: Concrete pavement with widened outer lane generally very small.

2.11 Bonded Rigid Pavement The flexural stress shall be computed for the

combined effect of axle loads and temperature

If the PQC slab is laid directly over the DLC layer

differential. Since majority of heavy vehicles

and a proper bond is ensured between them, then it

travel during night hours, therefore, roads shall be

leads to considerable reduction in the pavement

examined for top-down cracking.

thickness. It is because the monolithic action of the

The cumulative fatigue damage due to the

two layers reduces the overall flexural stress in both

combined action of axle loads and warping stress

the pavement slab and DLC layer. The surface of

shall be computed during 10A.M. to 4P.M. for

DLC layer shall be roughened within 3 to 6 hours of

its placement by using wire brush and a bonding agent

International Journal of Earth Sciences and Engineering

ISSN 0974-5904, Vol. 10, No. 02, April, 2017, pp. 455-461

Design Aspects of Modern Cement Concrete Pavements in India 459

Bottom-up Cracking and between 0A.M. to Distribution of truck traffic

6A.M. for Top-down Cracking.

Day time: 40%

If the concrete slab is bonded to cemented sub-

Night time: 60%

base, monolithic action prevails leading to a

reduced thickness design and increased economy. Design Steps

Widening of outer lanes and use of tied concrete Present traffic (cvpd) = 4000 in each direction

shoulders reduce the overall stress at edges by Design period (years) = 30

about 30 percent. Traffic growth rate (decimal) = 0.075

A lot of work needs to be done to evaluate the % traffic in predominant direction = 50%

parameters associated with subgrade and Total 2-way commercial vehicles during 30 years:

temperature of a region due to varying soil and C = 365 × 8000 × ((1+0.075)30 – 1) / 0.075

climatic condition in India. Therefore, C = 301,926,255 CV’s

A Case Study of Thickness Design for a National Provide a debonding layer of polythene sheet of 125

Highway in Punjab State micron thickness between DLC and concrete slab.

A cement concrete pavement with tied concrete Average number of axles

shoulders with doweled transverse joints is designed (steering/single/tandem/tridem) per commercial

for a 4-lane divided National Highway with 2-lanes in vehicle = 2.35

each direction in the state of Punjab. The road is Total two-way axle load repetitions during the design

expected to carry, about 4000 commercial vehicles period = 301,926,255 × 2.35 = 709,526,700 axles.

per day in each direction, in the year of completion of Number of axles in predominant direction =

construction. The design parameters are: 709,526,700 × 0.5 = 354,763,350

28-days flexural strength of concrete: 4.5MPa Design traffic after adjusting for lateral placement of

90-days flexural strength of concrete: 4.5 × 1.1 = axles (25% of predominant direction traffic for multi-

4.95MPa lane highway) = 354,763,350 × 0.25 = 88,690,838

Effective CBR of compacted subgrade: 10% Night time (12-hour) design axle repetitions =

Effective k-value of subgrade: 55MPa/m 88,690,838 × 0.6 = 53,214,503 (since 60% traffic

Thickness of DLC layer: 150mm during night time).

Elastic modulus of concrete: 30000MPa Day time (12-hour) design axle load repetitions =

Effective modulus of subgrade reaction (keff): 88,690,838 × (1-0.6) = 35,476,335

300MPa/m Day time 6-hour axle load repetitions = 35476335/2 =

Poisson’s ratio of concrete: 0.15 17,738,168

Temperature differential: 13ºC Hence, design number of axle load repetitions for

Lane width: 3.5m bottom-up cracking analysis = 17,738,168

Transverse joint spacing: 4.5m Night time 6-hour axle load repetitions = 53214503 /

2 = 26,607,251

Table 1: Axle Load Spectrum Percentage of commercial vehicles having spacing

Single Axle T andem Axle T ridem Axle

between the steering axle and the first axle of the rear

axle unit less than, 4.50m = 55%. Hence, the 6-hour

Load % of Axle Load % of Axle Load % of Axle

night time design axle load repetitions for top-down

Class Loads Class Loads Class Loads cracking analysis (wheel base < 4.5 m) = 26607251 ×

185-195 18 380-400 14.6 530-560 5 0.55 = 14,633,988.

175-185 17 360-380 10.4 500-530 5 The axle load category-wise design axle load

165-175 18 340-360 4 470-500 3 repetitions for bottom-up and top-down fatigue

155-165 13 320-340 2.4 440-470 7 cracking analysis are given in the following table:

145-155 3 300-320 2.6 410-440 10 Table2: Design Axle Load Repetitions for Bottom-up

& Top-down Cracking Analysis

135-145 2 280-300 2 380-410 12

125-135 3 260-280 4 350-380 16 Category-Wise Category-Wise

Proportion of

Axle Repetitions Axle Repetitions

Axle Category the Axle

115-125 3 240-260 5 320-350 13 for Bottom-up for T op-Down

Category

Cracking Analysis Cracking Analysis

105-115 3 220-240 6 290-320 5

Front (steering )

0.45 7982176 6585295

95-105 3 200-220 6 260-290 3 single

85-95 3 180-200 9 230-260 3 Rear Single 0.15 2660725 2195098

<95 14 <180 34 <230 18 T andem 0.25 4434542 3658497

100 100 100 T ridem 0.15 2660725 2195098

International Journal of Earth Sciences and Engineering

ISSN 0974-5904, Vol. 10, No. 02, April, 2017, pp. 455-461

460 AVISHRESHTH AND T ANUJ C HOPRA

Maximum day-time Temperature Differential in slab Table 4: Fatigue Life Analysis for Rear Tandem Axles

(for bottom-up cracking) = 13ºC. for a period of 6-hour during day time when

Night-time Temperature Differential in slab (for top- Temperature Gradient is Positive

down cracking) = 13 º - 5º = 8º

Expected Flex Stress Stress Ratio Allowable Fatigue

Concrete Pavement with Tied Concrete Shoulders Rep (ni) (MPa) (SR) Rep. (Ni) Damage (ni/Ni)

with Dowel Bar across Transverse Joints

647443 1.775 0.358585859 Infinite 0

Trial thickness of slab, h = 0.27 m 461192 1.725 0.348484848 Infinite 0

Radius of relative stiffness, l = { } 0.25 177382 1.675 0.338383838 Infinite 0

Therefore, l = 0.64002 106429 1.625 0.328282828 Infinite 0

Beta factor in the stress equations given in Appendix 115298 1.575 0.318181818 Infinite 0

V.2 of IRC: 58 will be 0.66 for doweled transverse

88691 1.525 0.308080808 Infinite 0

joints for carrying out Top-down Cracking analysis

[1]. 177382 1.475 0.297979798 Infinite 0

221727 1.425 0.287878788 Infinite 0

Computation of bottom-up and top-down cumulative

fatigue damage is illustrated in Tables below. 266072 1.388 0.28040404 Infinite 0

In order to compute the flexural stresses, mid-point of 266072 1.362 0.275151515 Infinite 0

axle load class from axle load spectrum given in 399209 1.338 0.27030303 Infinite 0

Table-1 is considered. The flexural stress in day time 1507744 1.312 0.265050505 Infinite 0

is computed using the stress charts given in IRC: 58-

4434641 Fat Dam From Single Axles = 0

2015.

The design is safe since the fatigue life consumed is

If the sum of Cumulative fatigue damage due to

less than 1.

Bottom-up Cracking and Top-down Cracking is less

than 1, the pavement slab is considered to be safe Table 5: Fatigue Life Analysis for Rear Single Axles

from large scale cracking. for a period of 6-hour during night when Temperature

Gradient is Negative

Table 3: Fatigue Life Analysis for Rear Single Axles

for a period of 6-hour during day time when Expected Flex Stress Stress Ratio Allowable Fatigue

Temperature Gradient is Positive Rep (ni) (MPa) (SR) Rep. (Ni) Damage (ni/Ni)

395118 1.8864 0.381090909 Infinite 0

Expected Flex Stress Stress Ratio Allowable Fatigue

Rep (ni) (MPa) (SR) Rep. (Ni) Damage (ni/Ni) 373167 1.8267 0.369030303 Infinite 0

478930 2.425 0.48989899 1301652 0.367940125 395118 1.767 0.356969697 Infinite 0

452323 2.35 0.474747475 3536902 0.127886778 285363 1.7073 0.344909091 Infinite 0

65853 1.6476 0.332848485 Infinite 0

478930 2.275 0.45959596 15221144 0.0314

43902 1.5879 0.320787879 Infinite 0

345894 2.2 0.444444444 Infinite 0

65853 1.5282 0.308727273 Infinite 0

79822 2.125 0.429292929 Infinite 0

65853 1.4685 0.296666667 Infinite 0

53214 2.05 0.414141414 Infinite 0

65853 1.4088 0.284606061 Infinite 0

79822 1.975 0.398989899 Infinite 0

65853 1.3491 0.272545455 Infinite 0

79822 1.9 0.383838384 Infinite 0

65853 1.2894 0.260484848 Infinite 0

79822 1.825 0.368686869 Infinite 0

307314 1.25955 0.254454545 Infinite 0

79822 1.75 0.353535354 Infinite 0

2195100 Fat Dam from Single Axle = 0

79822 1.675 0.338383838 Infinite 0

372501 1.638 0.330909091 Infinite 0

The design is safe since the fatigue life consumed is

less than 1.

2660724 Fat Dam From Single Axles = 0.5271

The design is safe since the fatigue life consumed is

less than 1.

International Journal of Earth Sciences and Engineering

ISSN 0974-5904, Vol. 10, No. 02, April, 2017, pp. 455-461

Design Aspects of Modern Cement Concrete Pavements in India 461

Table 6: Fatigue Life Analysis for Rear Tandem Axles References

for a period of 6-hour during day time when

[1] IRC: 58-2015, “Guidelines for the Design of Plain

Temperature Gradient is Negative

Jointed Rigid Pavements for Highways”, Indian

Expected Flex Stress Stress Ratio Allowable Fatigue Road Congress, New Delhi.

Rep (ni) (MPa) (SR) Rep. (Ni) Damage (ni/Ni) [2]IRC: 9-1972, “Traffic Census on Non-Urban

Roads”, Indian Road Congress, New Delhi, India

534140 1.91625 0.387121212 Infinite 0

[3]IRC: SP: 84-2014, “Manual of Specifications and

380484 1.85655 0.375060606 Infinite 0 Standards for Four Laning of Highways Through

146340 1.79685 0.363 Infinite 0 Public Private Partnership”, Indian Road

Congress, New Delhi, India

87804 1.73715 0.350939394 Infinite 0

[4]PCA, “Thickness Design of Concrete Highways

95121 1.67745 0.338878788 Infinite 0 and Street Pavements”, Portland Cement

73170 1.61775 0.326818182 Infinite 0 Association, New York, 1984.

146340 1.55805 0.314757576 Infinite 0 [5] Reddy, K.S., Pandey, B.B., “Lateral Placement of

Commercial Vehicle on National Highways”,

182925 1.49835 0.30269697 Infinite 0

Highway Research Board, Indian Road Congress,

219510 1.43865 0.290636364 Infinite 0 Bulletin No. 47, 1992.

219510 1.37895 0.278575758 Infinite 0 [6]Choubane, B., Tia, M., “Non-linear Temperature

Gradient Effect on Maximum Warping Stresses

329265 1.31925 0.266515152 Infinite 0

in Rigid Pavements”, Transportation Research

1243889 1.2894 0.260484848 Infinite 0 Board, Transportation Research Record 1370, pp.

3658498 Fat Dam from Tandem Axle = 0 11-19, 1995

[7]Choubane, B., Tia, M., “Analysis and Verification

The design is safe since the fatigue life consumed is

of Thermal Gradient effects on Concrete

less than 1.

Pavements”, Journal of Transportation

Table 7: Fatigue Life Analysis for Rear Tridem Axles Engineering, ASCE, pp. 75-81, 1995

for a period of 6-hour during day time when [8]Croney, D., Croney, P., “The Design and

Temperature Gradient is Negative Performance of Road Pavements”, McGraw-Hill

Book Co. 2nd Ed., pp. 97-98, 1992

Expected Flex Stress Stress Ratio Allowable Fatigue

[9]Thomlinson, J., “Temperature Variations and

Rep (ni) (MPa) (SR) Rep. (Ni) Damage (ni/Ni)

Consequent Stresses produced by Daily and

109755 1.8267 0.369030303 Infinite 0 Seasonal Temperature Cycles in Concrete Slabs”,

109755 1.767 0.356969697 Infinite 0 Concrete Constructional Engineering, 36(6), pp.

298-307 and 36(7), pp. 352-360, 1940.

65853 1.7073 0.344909091 Infinite 0

[10IS: 9214-1979, “Method of Determination of

153657 1.6476 0.332848485 Infinite 0 Modulus of Subgrade Reaction of Soil in the

219510 1.5879 0.320787879 Infinite 0 Field”, Bureau of Indian Standards, New Delhi,

263412 1.5282 0.308727273 Infinite 0 India

[11]Huang, Y.H., Wang, S.T., “Finite Element

351216 1.4685 0.296666667 Infinite 0

Analysis of Rigid Pavements with Partial

285363 1.41477 0.285812121 Infinite 0 Subgrade Contact”, Transportation Research

109755 1.35507 0.273751515 Infinite 0 Board, Transportation Research Record 485, pp.

65853 1.29537 0.261690909 Infinite 0

39-54, 1974.

[12]Kumar, S., Srinivas, T., Suresh, K.., Pandey,

65853 1.26552 0.255660606 Infinite 0 B.B., “Mechanistic Design of Concrete

395118 1.20582 0.2436 Infinite 0 Pavement”, Journal of the Indian Road Congress,

2195100 Fat Dam from Tridem Axle = 0 pp. 209-224, 2006

[13]AASHTO, “AASHTO Guide for Design of

The design is safe since the fatigue life consumed is Pavement Structures”, American Association of

less than 1. State Highway and Transport Officials,

The cumulative fatigue damage consumed for Washington D.C., 1993

Bottom-up cracking = 0.5271 + 0 = 0.5271 [14]IRC: 15-2011, “Standard Specifications and Code

of Practice for Construction of Concrete Roads”,

Similarly, the cumulative fatigue damage consumed Indian Road Congress, New Delhi, India

for Top-down cracking = 0 + 0 + 0 = 0 [15]IRC: SP: 62-2014, “Guidelines for the Design and

Hence, the cumulative fatigue life consumed = 0.5271 Construction of Cement Concrete Pavements for

+ 0 + 0 + 0 + 0 = 0.5271 which is less than 1, the Rural Roads”, Indian Road Congress, New Delhi.

pavement is safe. Therefore, adopt the thickness of [16]MORTH, “Specifications for Road and Bridge

pavement slab as 270 mm. Works”, Indian Road Congress, 2013, New

Delhi, India

International Journal of Earth Sciences and Engineering

ISSN 0974-5904, Vol. 10, No. 02, April, 2017, pp. 455-461

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Naming Compounds WorksheetDocument5 paginiNaming Compounds Worksheet吴蔓华Încă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Moment Connection: Supporting Column UC254X254X89 Supported Beam UC203X203X71Document3 paginiMoment Connection: Supporting Column UC254X254X89 Supported Beam UC203X203X71massive85Încă nu există evaluări

- Pipe Flow-Friction Factor Calculations With ExcelDocument31 paginiPipe Flow-Friction Factor Calculations With Excelmichael_mic99100% (1)

- Basics of Radiography Testing and Image ProcessingDocument30 paginiBasics of Radiography Testing and Image ProcessingbmrasheedÎncă nu există evaluări

- Acceptance of ConcreteDocument8 paginiAcceptance of ConcretesperwezÎncă nu există evaluări

- Radiography Test Inspection Free NDT Sample ProcedureDocument4 paginiRadiography Test Inspection Free NDT Sample ProcedureAjay KumarÎncă nu există evaluări

- Radiography Test Inspection Free NDT Sample ProcedureDocument4 paginiRadiography Test Inspection Free NDT Sample ProcedureAjay KumarÎncă nu există evaluări

- Supplement To Austroads Guide To Bridge Technology Part 8, Chapter 5: Bridge Scour (2018)Document69 paginiSupplement To Austroads Guide To Bridge Technology Part 8, Chapter 5: Bridge Scour (2018)Vishnu S DasÎncă nu există evaluări

- NHAI Safety Manual PDFDocument239 paginiNHAI Safety Manual PDFgk_kishoree8167% (3)

- Geoploymer Mix DesignDocument13 paginiGeoploymer Mix DesignShahid PerwezÎncă nu există evaluări

- Geoploymer Mix DesignDocument13 paginiGeoploymer Mix DesignShahid PerwezÎncă nu există evaluări

- Geoploymer Mix DesignDocument13 paginiGeoploymer Mix DesignShahid PerwezÎncă nu există evaluări

- ALLWEILER-Pump GK 796451 CWH 250-500 GB PDFDocument8 paginiALLWEILER-Pump GK 796451 CWH 250-500 GB PDFGeorge_Wabag_2014100% (1)

- Amorphous MaterialsDocument12 paginiAmorphous MaterialsdevendrakphyÎncă nu există evaluări

- 18M Truss DesignDocument24 pagini18M Truss DesignShahid PerwezÎncă nu există evaluări

- Clay BrickDocument83 paginiClay BrickShahid PerwezÎncă nu există evaluări

- Caly Brick Strength PDFDocument12 paginiCaly Brick Strength PDFShahid PerwezÎncă nu există evaluări

- Caly Brick Strength PDFDocument12 paginiCaly Brick Strength PDFShahid PerwezÎncă nu există evaluări

- Lec24 Alkali Agregate ReactionDocument30 paginiLec24 Alkali Agregate ReactionShahid PerwezÎncă nu există evaluări

- Lec24 Alkali Agregate ReactionDocument30 paginiLec24 Alkali Agregate ReactionShahid PerwezÎncă nu există evaluări

- Lec37 RepairDocument29 paginiLec37 RepairShahid PerwezÎncă nu există evaluări

- Lateral Cap PDFDocument1 paginăLateral Cap PDFShahid PerwezÎncă nu există evaluări

- Lec13 Concrete AcceptanceDocument27 paginiLec13 Concrete AcceptancesperwezÎncă nu există evaluări

- Road Marking PDFDocument74 paginiRoad Marking PDFShahid PerwezÎncă nu există evaluări

- Concrete Design Mix TutorialDocument5 paginiConcrete Design Mix TutorialRavi KumarÎncă nu există evaluări

- 12 - MoM 05 05 16Document42 pagini12 - MoM 05 05 16Shahid PerwezÎncă nu există evaluări

- NOTES8Document16 paginiNOTES8milan_popovic_2Încă nu există evaluări

- Steps For RCC Design 10.01.08Document12 paginiSteps For RCC Design 10.01.08Prisco AtabongÎncă nu există evaluări

- Technical Paper - SanjibDocument5 paginiTechnical Paper - SanjibalenriderÎncă nu există evaluări

- Steel PlatformDocument1 paginăSteel PlatformShahid PerwezÎncă nu există evaluări

- Correlation Between Soil Bearing Capacity and Modulus of Subgrade ReactionDocument5 paginiCorrelation Between Soil Bearing Capacity and Modulus of Subgrade ReactionCristian Camilo Londoño PiedrahítaÎncă nu există evaluări

- Spectator IndexDocument1 paginăSpectator IndexShahid PerwezÎncă nu există evaluări

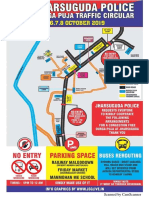

- Jharsuguda Police TrafficDocument1 paginăJharsuguda Police TrafficShahid PerwezÎncă nu există evaluări

- Amp 1Document2 paginiAmp 1Revitha Kishiore KumarÎncă nu există evaluări

- Edexcel A-Level CHEM3B June 2007 QP PDFDocument16 paginiEdexcel A-Level CHEM3B June 2007 QP PDFapi-3726022Încă nu există evaluări

- API 650 Design Calculations: #REF! #REF! Shell Design: From (Bottom Course) Plate To (Top Course) PlateDocument6 paginiAPI 650 Design Calculations: #REF! #REF! Shell Design: From (Bottom Course) Plate To (Top Course) PlateHgagselim SelimÎncă nu există evaluări

- Lab Report - Heat of CombustionDocument3 paginiLab Report - Heat of CombustionDexter ClamohoyÎncă nu există evaluări

- Mitosek1993 Article OscillatoryLiquidFlowInElasticDocument15 paginiMitosek1993 Article OscillatoryLiquidFlowInElasticbaja2014Încă nu există evaluări

- Cation ExcluderDocument3 paginiCation ExcluderAnand RajÎncă nu există evaluări

- Lldpe Ga564189Document3 paginiLldpe Ga564189xy2zjgÎncă nu există evaluări

- PQR Amp WPQ Standard Testing Parameter WorksheetDocument4 paginiPQR Amp WPQ Standard Testing Parameter WorksheetvinodÎncă nu există evaluări

- ANSI Cast and Ductile Iron Flange Chart Dimensions Pressure Temperature RatingsDocument3 paginiANSI Cast and Ductile Iron Flange Chart Dimensions Pressure Temperature RatingsMohamedGhanemÎncă nu există evaluări

- Cartech Trimrite® Stainless: IdentificationDocument7 paginiCartech Trimrite® Stainless: IdentificationYassinSalahÎncă nu există evaluări

- 2016 - Thermal Performance Calculation and Analysis of Heat Transfer Tube in Super Open Rack VaporizerDocument10 pagini2016 - Thermal Performance Calculation and Analysis of Heat Transfer Tube in Super Open Rack VaporizerLong Nguyễn HoàngÎncă nu există evaluări

- Ni触媒MSDS 英文Document4 paginiNi触媒MSDS 英文dil1717Încă nu există evaluări

- GoldyDocument1 paginăGoldyAniket DubeÎncă nu există evaluări

- Taglio Sez Circ 2Document3 paginiTaglio Sez Circ 2mariorossi_4Încă nu există evaluări

- BOQ SSB Part 1 PDFDocument358 paginiBOQ SSB Part 1 PDFakshanshrail100% (1)

- Surface ChemistryDocument13 paginiSurface ChemistrysunilkumarpatrosisintyÎncă nu există evaluări

- CarbonCure Technical Note - Types of Concrete CarbonationDocument4 paginiCarbonCure Technical Note - Types of Concrete CarbonationSakineÎncă nu există evaluări

- Experiments 3,4,5Document13 paginiExperiments 3,4,5Athirah JamalludinÎncă nu există evaluări

- Aluminum-Promoted Tungstated Zirconia CatalystDocument12 paginiAluminum-Promoted Tungstated Zirconia CatalystzahiraÎncă nu există evaluări

- WO2008033224A1 Polycaprolactone PolyurethaneDocument31 paginiWO2008033224A1 Polycaprolactone PolyurethaneGİZEM DEMİRÎncă nu există evaluări

- Carpentry and MasonryDocument81 paginiCarpentry and MasonryCassandra Noreen Pacayra SantosÎncă nu există evaluări

- Device Technology For Nanoscale III-V Compound Semiconductor Field Effect TransistorsDocument161 paginiDevice Technology For Nanoscale III-V Compound Semiconductor Field Effect TransistorsRaghu Vamsi ChavaliÎncă nu există evaluări

- Bridge Construction Specifications 2013 - Summary of ChangesDocument139 paginiBridge Construction Specifications 2013 - Summary of ChangesCaoimhín JonesÎncă nu există evaluări

- Spreading Dynamics of Polymer Nanodroplets: Sandia National Laboratories, Albuquerque, New Mexico 87185, USADocument10 paginiSpreading Dynamics of Polymer Nanodroplets: Sandia National Laboratories, Albuquerque, New Mexico 87185, USAmh123456789Încă nu există evaluări

- TDS RS580iDocument1 paginăTDS RS580iforismei5644Încă nu există evaluări