Documente Academic

Documente Profesional

Documente Cultură

Steel Tempering

Încărcat de

Salem GarrabTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Steel Tempering

Încărcat de

Salem GarrabDrepturi de autor:

Formate disponibile

DATASHEET FOR NON-HEAT-TREATERS

THE CONTRACT HEAT TREATMENT ASSOCIATION

HARDENING AND TEMPERING OF

TOOL AND DIE STEELS

(A separate CHTA datasheet relates to “Hardening and Tempering of Engineering Steels”)

WHAT ARE THE STEELS? WHAT ARE THE PROCESSING OPTIONS?

Tool and die steels are covered in BS 4659:1989, Most tools and dies must be protected from oxidation and

although both American nomenclature and a variety of decarburisation during treatment. The heat treater uses

trade names are also in use. Available in high-quality four basic types of furnace with various processing media

grades, these specifically-designed steels can be grouped to meet this requirement:

broadly according to their intended application: • Salt baths - the traditional route capable of treating the

• High-speed steels (BM and BT series in BS 4659) for complete range of tool steels with tight control.

drilling/cutting, with an ability to retain hot hardness. • Fluidised beds - a more recent development capable of

treating a wide range of tool steels other than those

• Cold-work steels (BA, BD and BO series) for stamping,

requiring high hardening temperatures.

blanking, pressing and forming.

• Sealed-quench furnaces - applications restricted by

• Hot-work steels (BH series) for hot forming and preci- lower hardening temperatures and the choice of oil

sion die casting. quenching or “still” gas cooling.

• Plastic-moulding steels (BP series) for plastic-moulding • Vacuum furnaces - the cleanest route, mainly employ-

and highly-polished dies, where toughness is required. ing gas quenching; the recent introduction of high-pres-

• Shock-resistant steels (BS series) for chisels, punches sure gas quenching has widened the range of steels

and tools subject to impact loading. which can be successfully treated.

The table lists the capabilities of these furnaces in relation

• Hammer die steels for cold forging, hammering and

to some commonly-used BS 4659 steels.

stamping.

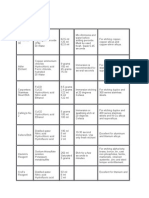

Furnace capabilities for tools and dies.

WHAT ARE THE TREATMENTS?

Steel Salt Vacuum Fluidised Sealed-quench

All tool and die steels must be heat treated to develop type baths furnaces beds furnaces

optimum properties in terms of hardness, strength, tough- BA2 ✔ ✔ ✔ -

ness and wear resistance. Almost all are hardened and BD2 ✔ ✔ ✔ L

tempered. BD3 ✔ L ✔ L

BO1 ✔ L ✔ ✔

Hardening involves controlled heating to a critical tem- BO2 ✔ L ✔ ✔

perature dictated by the type of steel (in the range 760- BS1 ✔ L ✔ ✔

1300°C) followed by controlled cooling. Dependent on the BW2 ✔ - ✔* -

type of material, appropriate cooling rates vary from very

BP20 ✔ L ✔ ✔

fast (water quench) to very slow (air cool).

BH11 ✔ ✔ ✔ -

Tempering involves reheating the hardened tool/die to a BH12 ✔ ✔ ✔ -

temperature between 150-675°C, depending on the steel BH13 ✔ ✔ ✔ -

type. A process which controls final properties whilst BM1 ✔ ✔* - -

relieving stresses after hardening, tempering can be com- BM2 ✔ ✔* - -

plex; some steels must be subjected to multiple tempering BM15 ✔ ✔* - -

operations. BT1 ✔ L* - -

In some cases, a sub-zero treatment can be incorporated BT15 ✔ L* - -

into the hardening and tempering cycle in order to devel-

Key:

op maximum hardness and optimise dimensional and ✔= capable; - = not capable;

metallurgical stability. L= limited capability; * = speak to heat treater

Published by The Contract Heat Treatment Association

Secretariat: c/o WHTC, Aston University, Aston Triangle, Birmingham B4 7ET, UK

WHAT ARE THE LIMITATIONS? grinding or EDM.

• Incorrect heat treatment.

Hardenability

The measure of a steel’s ability to harden in depth, hard- The latter should not occur if a specialist CHTA heat

enability can vary widely depending on the type of tool treater is employed. He will also advise on avoiding the

steel used. For example, low-hardenability BW grades will other factors if consulted at an early stage.

only harden to a depth of a few millimetres, even with a

severe water quench, whilst high-hardenability steels, HOW CAN I ENSURE SUCCESSFUL TREATMENT?

such as BH grades, can harden through a section in

excess of 1 metre with gas quenching. • Do use good-quality steel from a reputable supplier.

Considered in conjunction with section size, steel harden- • Do design for heat treatment by eliminating features

ability can limit the choice of processing route. It is recom- such as sharp corners and abrupt changes in section.

mended that requirements be discussed with the heat • Do talk to your heat treater before design and specifi-

treater at an early stage. cation are decided.

• Do specify a steel capable of giving the required hard-

Hardening temperature ness in the section size involved.

Some high-speed steels require extremely high hardening • Do remove all “black” and decarburised layers and sur-

temperatures which can restrict the processing route face defects - ensure the initial section size is large

options. enough to allow this.

• Do consider intermediate stress relieving to minimise

Physical size distortion.

Contract heat treatment furnaces come in a variety of • Do allow for any post-heat-treatment grinding, etc.

sizes, as do customer’s jobs. Always check the availability when the tool/die is produced.

of appropriate capacity at an early stage. • Do use a specialist tool steel heat treater.

• Do ensure all your requirements are specified correctly.

WHAT PROBLEMS CAN ARISE?

HOW DO I SPECIFY?

Distortion

Distortion of hardened and tempered tools and dies can If uncertain, consult your heat treater before producing a

arise from a variety of factors. Many of these are outside specification. Always include:

the control of the heat treater who cannot therefore accept • The material used, quoting the BS grade, other

responsibility for its prediction or its consequences. standard designation or trade name.

Complex shapes and sharp changes in section will gener- • The hardness required (HRC, HB or HV), quoting a

ate stress, and hence distortion, during rapid cooling for realistic range.

hardening. If it is impossible to avoid such stress-raisers, • The processing route required, if this is relevant (e.g.

select a high-hardenability steel so that slower cooling “vacuum treat” or “salt-bath treat”).

rates can be utilised. The possibility of distortion can also

• Any special requirements (e.g. “area to be kept soft”,

be reduced by specifying stress relieving prior to final

“press temper to keep flat”).

machining.

• Any area where testing must or must not be applied.

Cracking • Any special certification or testing requirements.

Cracking usually results from factors such as:

• Poor-quality or incorrect steel. WHERE DO I GO?

• Defects in the steel.

• Decarburisation - usually because of insufficient or In order to locate contract heat treaters offering specialist

unequal metal removal during initial machining of hardening and tempering services for tools and dies, con-

“black” billet. sult the current edition of CHTA’s Buyers Guide. It is

• Poor design and material selection. important to involve your heat treater at an early

• Poor post-heat-treatment practice, such as incorrect stage before commencing manufacture.

This datasheet is compiled in good faith solely to assist others to evaluate the heat treatment techniques described.

Users do so entirely at their own risk. Neither CHTA nor the presenter is responsible for any consequences from any such

use. Datasheets shall not be used for contractual purposes neither directly nor by implication.

c Contract Heat Treatment Association 1996

S-ar putea să vă placă și

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopDe la EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopEvaluare: 4.5 din 5 stele4.5/5 (2)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantDe la EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantEvaluare: 3.5 din 5 stele3.5/5 (3)

- Data 2 PDFDocument2 paginiData 2 PDFSalem GarrabÎncă nu există evaluări

- BD 2Document3 paginiBD 2MUHAMMAD SIDDIQUEÎncă nu există evaluări

- Post Weld Heat TreatmentDocument51 paginiPost Weld Heat Treatmenttbmari97% (32)

- Stress Relieving, Normalising and Annealing: Datasheet For Non-Heat-TreatersDocument2 paginiStress Relieving, Normalising and Annealing: Datasheet For Non-Heat-TreatersGani PateelÎncă nu există evaluări

- ASME 193 and 193MDocument4 paginiASME 193 and 193MGauravÎncă nu există evaluări

- Steel Bars, Alloy, Hot-Wrought or Cold-Finished, Quenched and TemperedDocument4 paginiSteel Bars, Alloy, Hot-Wrought or Cold-Finished, Quenched and TemperedCK CkkouÎncă nu există evaluări

- Martempering and Austempering Final SlideDocument25 paginiMartempering and Austempering Final SlidekeirthÎncă nu există evaluări

- Flame HardeningDocument2 paginiFlame Hardenings_manikandanÎncă nu există evaluări

- Heat TreatmentDocument2 paginiHeat TreatmentUsman MuhammadÎncă nu există evaluări

- Extrusion A Manufacturing ProcessDocument36 paginiExtrusion A Manufacturing Processrsurao24Încă nu există evaluări

- Pre-Treatments of Iron or Steel For Reducing Risk of Hydrogen EmbrittlementDocument3 paginiPre-Treatments of Iron or Steel For Reducing Risk of Hydrogen EmbrittlementDanZel DanÎncă nu există evaluări

- Seminar Report On Heat Treatment Process For Shear Machining Blade, Hexoblade, Nozzle of Ajm, Plier ToolsDocument20 paginiSeminar Report On Heat Treatment Process For Shear Machining Blade, Hexoblade, Nozzle of Ajm, Plier ToolsChetan PrajapatiÎncă nu există evaluări

- IslahDocument2 paginiIslahnecdet_karagülleÎncă nu există evaluări

- As Rolled, Hot Rolled, Hot Finished: Applied ToDocument8 paginiAs Rolled, Hot Rolled, Hot Finished: Applied ToAlaaÎncă nu există evaluări

- Cold Work Steels: Available Product VariantsDocument5 paginiCold Work Steels: Available Product VariantsAnonymous oyUAtpKÎncă nu există evaluări

- Postweld Heat Treatment: Key Concepts in Welding EngineeringDocument2 paginiPostweld Heat Treatment: Key Concepts in Welding EngineeringChouial BilelÎncă nu există evaluări

- GN06 Post Weld Heat Treatment of Welded PDFDocument11 paginiGN06 Post Weld Heat Treatment of Welded PDFGregory FenwickÎncă nu există evaluări

- D2 Tool Steel: Shipping PolicyDocument2 paginiD2 Tool Steel: Shipping Policyالسيد ابراهيم عبدالعزيز عبداللهÎncă nu există evaluări

- Cswip - Section 20-Heat TreatmentDocument9 paginiCswip - Section 20-Heat TreatmentNsidibe Michael Etim100% (1)

- PWHT, HT, Igc, MawpDocument40 paginiPWHT, HT, Igc, Mawpsachinshirnath100% (1)

- BS4659 B01Document2 paginiBS4659 B01yogy81100% (1)

- Sa 193Document18 paginiSa 193Haridev MoorthyÎncă nu există evaluări

- Heat Treatment of SteelsDocument9 paginiHeat Treatment of SteelsAnkit MauryaÎncă nu există evaluări

- Rolling Technology Training Programme - AnnealingDocument52 paginiRolling Technology Training Programme - Annealingrabikm100% (1)

- Post Weld Heat TreatmentDocument10 paginiPost Weld Heat Treatmentcristian291011Încă nu există evaluări

- Flame HardeningDocument2 paginiFlame HardeningDimaz Iyas ArmezyÎncă nu există evaluări

- Impact AR500 PlateDocument2 paginiImpact AR500 PlateMario Diez100% (1)

- Round Bar Tensile StrengthDocument2 paginiRound Bar Tensile StrengthChong Wee LinÎncă nu există evaluări

- Unit-4 Steels As Cutting Tool MaterialsDocument13 paginiUnit-4 Steels As Cutting Tool MaterialsItachi UchihaÎncă nu există evaluări

- Becu Alloy 172: High Strength Beryllium Copper Mold AlloyDocument6 paginiBecu Alloy 172: High Strength Beryllium Copper Mold AlloydivyarasinÎncă nu există evaluări

- UNIT-II - Heat TreatmentDocument21 paginiUNIT-II - Heat Treatmentadityakarkera786Încă nu există evaluări

- Heat treatment of welded joints - Part 2: Tempering, PWHT application and monitoringDocument3 paginiHeat treatment of welded joints - Part 2: Tempering, PWHT application and monitoringJlkKumarÎncă nu există evaluări

- PWHTDocument2 paginiPWHTvsajuÎncă nu există evaluări

- HB Industrial Immersion Heater PDFDocument2 paginiHB Industrial Immersion Heater PDFrgarros1990Încă nu există evaluări

- Heat Treatment ProcessesDocument61 paginiHeat Treatment ProcessesMadhubalan100% (1)

- moldmax_hh-eng_p_1609_e6Document8 paginimoldmax_hh-eng_p_1609_e6gurtekinkubra8Încă nu există evaluări

- Product information on RWL 34 stainless knife steelDocument4 paginiProduct information on RWL 34 stainless knife steeljose cuervoÎncă nu există evaluări

- Moule RondelleDocument7 paginiMoule RondelleFaiz BrahimiÎncă nu există evaluări

- Guidance Note Plate Bending No. 5.04: ScopeDocument3 paginiGuidance Note Plate Bending No. 5.04: ScoperoldoguidoÎncă nu există evaluări

- Heat Treatment ProcessesDocument44 paginiHeat Treatment Processesmesa142Încă nu există evaluări

- Steel Bars, Alloy, Hot-Wrought or Cold-Finished, Quenched and TemperedDocument3 paginiSteel Bars, Alloy, Hot-Wrought or Cold-Finished, Quenched and TemperedDarwin Darmawan100% (1)

- ME137L - Heat TreatmentDocument34 paginiME137L - Heat TreatmentDiego LoyzagaÎncă nu există evaluări

- Post Weld Heat TreatmentDocument2 paginiPost Weld Heat TreatmentgullenariÎncă nu există evaluări

- NEW TOOL STEEL EXCELS AT WARM FORGINGDocument11 paginiNEW TOOL STEEL EXCELS AT WARM FORGINGSinan YıldızÎncă nu există evaluări

- Ruukki Hot Rolled Steels Processing of Material Thermal Cutting and Flame StraighteningDocument6 paginiRuukki Hot Rolled Steels Processing of Material Thermal Cutting and Flame StraighteningtechspawÎncă nu există evaluări

- Lecture 12 - Hardening MethodsDocument53 paginiLecture 12 - Hardening MethodssimÎncă nu există evaluări

- Tooling Materials&Heat TreatmentDocument13 paginiTooling Materials&Heat TreatmentVinod MadireddyÎncă nu există evaluări

- Flame HardeningDocument29 paginiFlame Hardeningzaid sulaimanÎncă nu există evaluări

- Asm Alloy Digest SampleDocument2 paginiAsm Alloy Digest SampleSteve OoiÎncă nu există evaluări

- Flowserve Argus FK76M Technical Bulletin Arenbr0015 EnaqDocument92 paginiFlowserve Argus FK76M Technical Bulletin Arenbr0015 Enaqsonalpanchal7Încă nu există evaluări

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDe la EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonÎncă nu există evaluări

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithDe la EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithÎncă nu există evaluări

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelDe la EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelÎncă nu există evaluări

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDe la EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonEvaluare: 4 din 5 stele4/5 (1)

- Effectiveness of Organic Corrosion Inhibitor Under Chloride Attack inDocument2 paginiEffectiveness of Organic Corrosion Inhibitor Under Chloride Attack inSalem GarrabÎncă nu există evaluări

- Manufacture and Repair of Shafts For PDFDocument3 paginiManufacture and Repair of Shafts For PDFSalem GarrabÎncă nu există evaluări

- العلاقة بين الحماية الكاثودية والاثر البيولوجي للتآكلDocument11 paginiالعلاقة بين الحماية الكاثودية والاثر البيولوجي للتآكلSalem GarrabÎncă nu există evaluări

- 2 Corrosion Its ControlDocument71 pagini2 Corrosion Its ControlOjas BendaleÎncă nu există evaluări

- Centrifugal CastingDocument8 paginiCentrifugal Castingassignment2012Încă nu există evaluări

- Secondary SedimentationDocument7 paginiSecondary SedimentationSalem GarrabÎncă nu există evaluări

- Speaker BiographyDocument1 paginăSpeaker BiographySalem GarrabÎncă nu există evaluări

- What Controls The Rate of ElectrolysisDocument11 paginiWhat Controls The Rate of ElectrolysisSalem GarrabÎncă nu există evaluări

- Scientific Search Engines 2017Document1 paginăScientific Search Engines 2017Salem GarrabÎncă nu există evaluări

- Lecture7 PDFDocument5 paginiLecture7 PDFrashidÎncă nu există evaluări

- Weld Assistant SoftwareDocument1 paginăWeld Assistant SoftwareSalem GarrabÎncă nu există evaluări

- Double Reverse Flotation Process of Collophanite and Regulating Froth ActionDocument5 paginiDouble Reverse Flotation Process of Collophanite and Regulating Froth ActionSalem GarrabÎncă nu există evaluări

- Condensate ChemistryDocument2 paginiCondensate ChemistrySalem GarrabÎncă nu există evaluări

- Solid-Liquid Extraction (Leaching)Document4 paginiSolid-Liquid Extraction (Leaching)Dozdi83% (6)

- Introduction To Electrometallurgy SyllabusDocument3 paginiIntroduction To Electrometallurgy SyllabusSalem GarrabÎncă nu există evaluări

- Basic Electrolysis Calculations: Chemguide - AnswersDocument2 paginiBasic Electrolysis Calculations: Chemguide - AnswersSalem GarrabÎncă nu există evaluări

- Effect of CaO On Oxidation Resistance and Microstructure of Pure MGDocument3 paginiEffect of CaO On Oxidation Resistance and Microstructure of Pure MGSalem GarrabÎncă nu există evaluări

- Literature Review On The Effect of Processing On T He Mechanical and Metallurgical Properties of Low CarbonDocument5 paginiLiterature Review On The Effect of Processing On T He Mechanical and Metallurgical Properties of Low CarbonSalem GarrabÎncă nu există evaluări

- مقاومة الموادDocument60 paginiمقاومة الموادhasnen83100% (5)

- F04943847 PDFDocument10 paginiF04943847 PDFNur Aini MaghfirohÎncă nu există evaluări

- Effect of CaO On Oxidation Resistance and Microstructure of Pure MGDocument3 paginiEffect of CaO On Oxidation Resistance and Microstructure of Pure MGSalem GarrabÎncă nu există evaluări

- (Al-Mg) دراسة انتقال الحرارة لمسبوكةDocument14 pagini(Al-Mg) دراسة انتقال الحرارة لمسبوكةSalem GarrabÎncă nu există evaluări

- Industry in LibyaDocument4 paginiIndustry in LibyaSalem GarrabÎncă nu există evaluări

- Progress on Microstructure and Plastic BehaviorDocument39 paginiProgress on Microstructure and Plastic BehaviorSalem GarrabÎncă nu există evaluări

- Introduction to Refractory PropertiesDocument10 paginiIntroduction to Refractory Propertiessandi1111Încă nu există evaluări

- Effect of CaO On Oxidation Resistance and Microstructure of Pure MGDocument3 paginiEffect of CaO On Oxidation Resistance and Microstructure of Pure MGSalem GarrabÎncă nu există evaluări

- The Decay Effects of Sea SaltDocument6 paginiThe Decay Effects of Sea SaltSalem GarrabÎncă nu există evaluări

- Lecture7 PDFDocument5 paginiLecture7 PDFrashidÎncă nu există evaluări

- Foundry Technology: Reference BooksDocument34 paginiFoundry Technology: Reference BooksGowtham VishvakarmaÎncă nu există evaluări

- Refinery InspectionDocument44 paginiRefinery InspectiongamadiyaÎncă nu există evaluări

- A325m 14 PDFDocument8 paginiA325m 14 PDFAquino0% (1)

- CH 29-Fundamentals of WeldingDocument39 paginiCH 29-Fundamentals of WeldingNasir MaqsoodÎncă nu există evaluări

- J-DMS: Project HarmonyDocument1 paginăJ-DMS: Project HarmonyMary DenizeÎncă nu există evaluări

- MSM Lab ManualDocument31 paginiMSM Lab Manualprashant patilÎncă nu există evaluări

- Alloy Steel Chain SlingsDocument3 paginiAlloy Steel Chain Slingsmoha19841100% (1)

- Selection For Welding Consumables: A 479 Gr.316LDocument2 paginiSelection For Welding Consumables: A 479 Gr.316LanandmlÎncă nu există evaluări

- Project Profile MsmeDocument97 paginiProject Profile MsmeDinesh RajputÎncă nu există evaluări

- BIWDocument8 paginiBIWvasant100% (2)

- Fiber Laser Cutting MachineDocument19 paginiFiber Laser Cutting MachineKerry SaintzÎncă nu există evaluări

- A320A320M 17bDocument8 paginiA320A320M 17bNUR SALSABILLA MOHD. SYAHRIL AMRIÎncă nu există evaluări

- Ain Shams Engineering Journal: Yousef R. Alharbi, Aref A. Abadel, Nourhan Elsayed, Ola Mayhoub, Mohamed KohailDocument7 paginiAin Shams Engineering Journal: Yousef R. Alharbi, Aref A. Abadel, Nourhan Elsayed, Ola Mayhoub, Mohamed KohailMAHESH A VÎncă nu există evaluări

- Steel Grades Equivalence TableDocument16 paginiSteel Grades Equivalence Tabletwintwinkai100% (3)

- Penawaran / Quotation: Part No. Description UOM Price SOHDocument1 paginăPenawaran / Quotation: Part No. Description UOM Price SOHAwal NursantoÎncă nu există evaluări

- ASME BPVC Sec IX 2023 - Demonstration FormDocument1 paginăASME BPVC Sec IX 2023 - Demonstration Formmr.bakhtiari.mahmoudÎncă nu există evaluări

- Ms 966 Part 1 2001 Playground Equipment Part 1 Specifications For Materials First Revision PDFDocument17 paginiMs 966 Part 1 2001 Playground Equipment Part 1 Specifications For Materials First Revision PDFAhmad HafizÎncă nu există evaluări

- Vol-1, Issue-4Document13 paginiVol-1, Issue-4Ijrei JournalÎncă nu există evaluări

- Basic Welding GMAW Lab SheetDocument2 paginiBasic Welding GMAW Lab SheetMUHAMMAD AFIQ IQWAN KAMARUL BADRINÎncă nu există evaluări

- WPSDocument1 paginăWPSRodica TimofteÎncă nu există evaluări

- List of Etchant For MetallographyDocument3 paginiList of Etchant For Metallographyniraj_hwbÎncă nu există evaluări

- AssignmentDocument3 paginiAssignmentAviral Sansi0% (1)

- Progress in Cold Roll Bonding of MetalsDocument12 paginiProgress in Cold Roll Bonding of MetalsADRIANOÎncă nu există evaluări

- Ugiweb 913082Document128 paginiUgiweb 913082psychedelic_lullabyÎncă nu există evaluări

- Weld-Ing On in Inservice Pipelines - tcm153574190Document7 paginiWeld-Ing On in Inservice Pipelines - tcm153574190Freddy Rondonil SÎncă nu există evaluări

- 2015 Widin CatalogueDocument413 pagini2015 Widin Catalogue*mile*Încă nu există evaluări

- Comparison of Steel Grades by ChemistryDocument5 paginiComparison of Steel Grades by ChemistryMehman NasibovÎncă nu există evaluări

- Catalogo Welding&Metal Fab NortonDocument184 paginiCatalogo Welding&Metal Fab NortonAmando FuentesÎncă nu există evaluări

- UYU Cat Apr 2023 - 230323 - 222505Document40 paginiUYU Cat Apr 2023 - 230323 - 222505gabzhaddadÎncă nu există evaluări

- Cold Formed Carbon Structural Steel Tubing Made From Metallic Precoated Sheet SteelDocument3 paginiCold Formed Carbon Structural Steel Tubing Made From Metallic Precoated Sheet SteelDanZel DanÎncă nu există evaluări

- Full-Range Stress-Strain Curves For Stainless SteelDocument15 paginiFull-Range Stress-Strain Curves For Stainless SteelNurul HudaÎncă nu există evaluări