Documente Academic

Documente Profesional

Documente Cultură

Lalpir Process Flow

Încărcat de

Inaam Ur RehmanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lalpir Process Flow

Încărcat de

Inaam Ur RehmanDrepturi de autor:

Formate disponibile

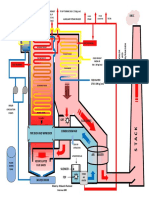

Line 1 Line 1

To Kot To

ADDU Isolator Muzafargarh LEGENDS

11 Steam re-enters the Turbine to accomplish a work Isolator

through a Double-Flow 12 LPT Reaction Stages. 220KV

6 Steam Drum: It is where the steam is separated Pressure-Drop occurs on moving blade. On Fixed SWITCHYARD 1. FDF

from the steam-water mixture. Also,it is where

STEAM GENERATING UNIT Blade the steam velocity increase with a decrease 1.a VVVF Drives

the Boiler Water mixes with the supply FW 6 STEAM

DRUM (BOILER) in pressure. CIRCUIT 2. AIR PRE HEATER

through the Economizer. 13 The STEP-UP BREAKER 3. FUEL SYSTEM

Hot Reheat from Boiler Re-enters the Turbine Transformer steps- 4. Boiler Furnace

10 Reheated steam re-enters the Turbine up the Electrical CT

Energy to 220 KV.

5. RISERS

to accomplish a work through 10 IPT

Reaction Stages. . Isolator 6. Steam drum

13 GSU 7. SUPER HEATER

Main Steam from Boiler enters the Turbine STEAM TURBINE 220KV

PT 8. HP TURBINE

Atmosphere 26 9 24KV 9. REHEATERS

7 SUPER

ECONOMIZER REHEATERS HEATERS 8 The Heat Energy in steam is converted into 10. Intermediate Pressure

Steam from The Steam at Mechanical Energy in Turbine Shaft. The Turbine

Economizer: LOW-

Turbine (HPT) is saturation Internal Energy in steam turns the Turbine-

Recovers the PRESSURE 11. Low Pressure Turbine

27 reheated back in temp. is Generator’s rotor to accomplish a work

27 heat energy from TURBINE 12. GENERATOR (AC

Boiler Boiler Primary heated up through 12 HPT Impulse & Reaction Stages

Boiler exit Flue 15 To 11 KV SOURCE)

BCP: Circulates the Circulation Gas and it raises

ans secondary through the at constant pressure on moving blades. UAT Switch Gear

Boiler Water from Pump up the FW temp.

Reheaters. The Primary, 11 11

for Aux. Load

13. GSU Transformer

8 10

Steam Drum to Mud steam absorbs Secondary LPT LPT 14. Excitation

to a near HPT Exciter

Drum. the heat energy and Tertiary HIGH- IPT

saturation temp. 24KV Transformer

BCP in Flue Gas. superheaters PRESSURE 489V

TURBINE 14 EXCITATION 15. UAT

Pre-heats the Air 16. Condenser

2 for combustion. INTERMEDIATE

12 GENERATOR TRANSFORMER

Cold Reheat Steam Returns to Boiler PRESSURE The Mechanical 17. Circ Water

Provides Excitation

STACK CHIMNEY FLUE GAS 4 TURBINE Energy is converted 18. Howell

to the Alternator

STEAM AIR AIR PRE- BOILERFURNACE

to Electrical Energy. 19. Condensate pump

Power Genetated=365MW 16 CONDENSER

HEATER HEATER Combustion 22 LP Heater raises the The Main Steam 20. Jet Air ejector

Feedwater

1 FORCED 2 Process takes

temperature up to

LP HEATER 2 22 Condenser 21. Gland Steam

DRAFT FAN Comb. Air

place. It Forms condenses Condenser

(Supplies Fire ball. Flame 23 steam saturation

Drain the steam from LP 22. Lp Heaters

Combustion temperature. In Cooling

Deaerator addition to an 17 Turbine exhaust, it 23. Deaerator

Air) HEAVY FUEL OIL (HFO) 22 Towers

3 scavenges increase in cycle LP HEATER 1 22

Circ Water CW Circwater is the reduces the back-

24. Boiler Feed Pump

Dissolved efficiency. Inlet 17 Pump Cooling medium for pressure through

1a VVVF DRIVES HEAVY FUEL OIL PUMP gases in 16 vacuum and 25. Hp heaters

condensing the

Feedwater 26. Economizer

Variable Voltage & (Delivers HSFO Fuel for

DIESEL OIL 5 Radiant Heat 16 steam exhaust from improve the Turbine

Combustion) absorbed in the Turbine. The CW efficiency. 27 BCP

Variable Frequency DEAERATOR Extraction 5 Drain CONDENSER

FUEL the Boiler Circ water carries away the Latent 28. MUD DRUM

drives. is a system for DIESEL OIL PUMP 23 HEATER

(For initial Plant start-up) Water Auxlliary Outlet Heat of Condensation. 29. Water treatment(

controlling the

Walls,i.e Header There are 8 cooling Tower cells. BOP)

rotational speed of an RISERS

AC electric motor by IGNITOR OIL PUMP

(For initial Plant start- IGNITOR OIL

18 Hotwell

controlling the

up)

frequency of the 18 Main Condenser Hotwell; is a

electrical power DEAERATOR collection chamber for condensates.

MUD 19

supplied to the motor 28 STORAGE TANK

DRUM 19 The Condensate Pump

Extraction 8 CONDENSATE Delivers the FW from a

BOILER FEEDWATER 20 PUMP

Steam In From negative suction pressure to

Steam Convetor Extraction 4

STEAM JET

AIR EJECTOR

a full delivery pressure. Canal

Discharge Strainer

Maintains vacuum 29 Water

25 Heater raises the HP HEATER 8 25

Discharge Heaters Feedwater 22

in condenser, Treatment

Heats up the Feed

temperature close to

LP HEATER 4 water

System(BOP) Canal Pump

Boiler Flue Gas exit Drain Extraction 7

3

Steam Out

temperature to

increase the Plant Extraction 3 625m Well

300m3

Drain

Thermal Efficiency HP HEATER 7 25 Demineralized

and Fuel savings. 22 Water Condensate

***The Extractions Storage Tank Well

Steam In from Steam Convertor LP HEATER 3 StorageTank

from HP turbine Drain Extraction 6 Settling

heats up the Anion Well Pumps Basin

Feedwater. Exchanger There are 9 Wells

HP HEATER 6 25 It’s a Polisher, Removes positive ions.

HFO TANK removes +ve Mix for a unit

30000m3 It Provides settling

Drain to LP HTR2 and -ve ions Bed of sludge from

21 water

Suction Heater

HFO Supply Drain to DA 21

Pump Suction Strainer

GLAND STEAM Filtered Clarifier

CONDENSER Water

Steam Out Gland(Sealing)

Steam from the

Basin Distribution

Cation RO Bag Multi Box

Turbine ends Dual Clear Clarifier

Decarbonator Permeate Filter &

Exchanger Media

Heats up the Media Well

LALPIR THERMAL POWER PLANT 24 BOILER

FEEDWATER PUMP

Feedwater Removes CO2 Removes positive

Tank RO

System

Filter

It is for filtration. Filter

This process

removes TSS from

from the water. ions.

Delivers a high A membrane Anthracite, Sand, It is for filtration. raw water.

By M ZULFIQAR

pressure contained RO Banks Gravel and Granite Anthracite, Sand,

Feedwater to Boiler remove dissolved layers are Gravel are

salts from the water. present. present.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- LPG Properties and Safe HandlingDocument54 paginiLPG Properties and Safe Handlinglestermusca100% (2)

- Ongc BopDocument385 paginiOngc BopFSTÎncă nu există evaluări

- Riello Burner Handbook PDFDocument169 paginiRiello Burner Handbook PDFfsijest50% (2)

- A Presentation On Lithium Bromide Absorption Refrigeration SystemDocument15 paginiA Presentation On Lithium Bromide Absorption Refrigeration SystemAyub GNÎncă nu există evaluări

- pb3-06 510series Broc QX PDFDocument8 paginipb3-06 510series Broc QX PDFJaime LondoñoÎncă nu există evaluări

- Everything You Need to Know About Centrifugal CompressorsDocument19 paginiEverything You Need to Know About Centrifugal CompressorsInaam Ur RehmanÎncă nu există evaluări

- Air CompressorDocument51 paginiAir CompressorInaam Ur RehmanÎncă nu există evaluări

- BearingsDocument48 paginiBearingsInaam Ur RehmanÎncă nu există evaluări

- BOP Training ReportDocument68 paginiBOP Training ReportInaam Ur RehmanÎncă nu există evaluări

- Centrifugal Pumps-ConstructionDocument28 paginiCentrifugal Pumps-ConstructionInaam Ur RehmanÎncă nu există evaluări

- Mcquay Chiller FundamentalsDocument20 paginiMcquay Chiller FundamentalsSajith MenonÎncă nu există evaluări

- Faisal - Internship Report'12Document88 paginiFaisal - Internship Report'12Inaam Ur RehmanÎncă nu există evaluări

- Understanding Mechanical SealsDocument42 paginiUnderstanding Mechanical SealsMUHAMMAD SOHAIB UR REHMANÎncă nu există evaluări

- AlignmentDocument44 paginiAlignmentMadan Yadav92% (13)

- Boiler SchematicDocument1 paginăBoiler SchematicInaam Ur RehmanÎncă nu există evaluări

- Shaft Alignment & CouplingsDocument30 paginiShaft Alignment & CouplingsInaam Ur RehmanÎncă nu există evaluări

- Air CompressorDocument51 paginiAir CompressorInaam Ur RehmanÎncă nu există evaluări

- Centrifugal Pumps Explained: Types, Parts, Working & MoreDocument16 paginiCentrifugal Pumps Explained: Types, Parts, Working & MoreInaam Ur RehmanÎncă nu există evaluări

- Balance of Plant Lalpir/Pakgen Made by Mubashir Rasheed Internee GikiDocument1 paginăBalance of Plant Lalpir/Pakgen Made by Mubashir Rasheed Internee GikiInaam Ur RehmanÎncă nu există evaluări

- The Israeli-Palestinian Conflict in Transition From Oc-Cupation To de LegitimizationDocument6 paginiThe Israeli-Palestinian Conflict in Transition From Oc-Cupation To de LegitimizationInaam Ur RehmanÎncă nu există evaluări

- The Reconstruction of Religious Thought in Islam PDFDocument163 paginiThe Reconstruction of Religious Thought in Islam PDFRana Muhammad TalhaÎncă nu există evaluări

- The Role of Saiyid Ahmad Khan in The Shift To Modern Education of Muslims of South Asia PDFDocument16 paginiThe Role of Saiyid Ahmad Khan in The Shift To Modern Education of Muslims of South Asia PDFInaam Ur RehmanÎncă nu există evaluări

- Capex 21-07-2014Document7 paginiCapex 21-07-2014Inaam Ur RehmanÎncă nu există evaluări

- The Water Accord - 1991Document5 paginiThe Water Accord - 1991Inaam Ur RehmanÎncă nu există evaluări

- The Interim Constitution 1947Document13 paginiThe Interim Constitution 1947Inaam Ur RehmanÎncă nu există evaluări

- Water Security-Challenges of Transboundary Water IssuesDocument18 paginiWater Security-Challenges of Transboundary Water IssuesInaam Ur RehmanÎncă nu există evaluări

- International Journal of Social Science and Humanity Publishes Article on Muhammad Iqbal's Concept of Muslim CultureDocument5 paginiInternational Journal of Social Science and Humanity Publishes Article on Muhammad Iqbal's Concept of Muslim CultureInaam Ur RehmanÎncă nu există evaluări

- Centrifugal Pump: Generation of Centrifugal Force Conversion of Kinetic Energy To Pressure EnergyDocument5 paginiCentrifugal Pump: Generation of Centrifugal Force Conversion of Kinetic Energy To Pressure EnergyInaam Ur RehmanÎncă nu există evaluări

- The Two Nation Theory and Demand of PakistanDocument10 paginiThe Two Nation Theory and Demand of PakistanInaam Ur RehmanÎncă nu există evaluări

- SSRN Id1912944Document186 paginiSSRN Id1912944KAmran PRinceÎncă nu există evaluări

- Operation and Application of Variable Frequency Drive (VFD) TechnologyDocument10 paginiOperation and Application of Variable Frequency Drive (VFD) TechnologyPravin LandgeÎncă nu există evaluări

- Voice From Balochistan PDFDocument367 paginiVoice From Balochistan PDFInaam Ur RehmanÎncă nu există evaluări

- Cent. Comp. For Trainee EngrsDocument141 paginiCent. Comp. For Trainee EngrsInaam Ur Rehman100% (1)

- Mcquay Chiller FundamentalsDocument20 paginiMcquay Chiller FundamentalsSajith MenonÎncă nu există evaluări

- CH4 2 Welding Joint PreparationDocument46 paginiCH4 2 Welding Joint PreparationMatija BušićÎncă nu există evaluări

- Tower A chilled water pipe sizing and loss calculationDocument3 paginiTower A chilled water pipe sizing and loss calculationceshesolÎncă nu există evaluări

- Catalog Ach OldDocument25 paginiCatalog Ach Oldprakash1010Încă nu există evaluări

- Heat Recovery Steam Generator (HRSG) - Chemical EngineeringDocument3 paginiHeat Recovery Steam Generator (HRSG) - Chemical EngineeringMahmoud RagabÎncă nu există evaluări

- Tanks Thickness & Pipe Size CalculationDocument4 paginiTanks Thickness & Pipe Size CalculationANKITA BISWASÎncă nu există evaluări

- Shell Middle Distillate Synthesis: The Process, The Plant, The ProductsDocument5 paginiShell Middle Distillate Synthesis: The Process, The Plant, The ProductsEan7731451Încă nu există evaluări

- General Chemistry: Pressure and Its Common UnitsDocument15 paginiGeneral Chemistry: Pressure and Its Common UnitsDenver John Caloza LamarcaÎncă nu există evaluări

- Basics of Turbo Machines in 40 CharactersDocument14 paginiBasics of Turbo Machines in 40 CharactersBF3nobelÎncă nu există evaluări

- Turbocharging in Switzerland - A HistoryDocument14 paginiTurbocharging in Switzerland - A HistoryDiego KuschauskyÎncă nu există evaluări

- Hidráulica IndustrialDocument220 paginiHidráulica IndustrialFernandoAbreuÎncă nu există evaluări

- GRU Volume Hold UpDocument14 paginiGRU Volume Hold Upengr.shahid041Încă nu există evaluări

- Ensuring Reliability of Compressor Gas Seals During Long Periods of Pressurized HoldDocument10 paginiEnsuring Reliability of Compressor Gas Seals During Long Periods of Pressurized HoldKader BenÎncă nu există evaluări

- V5X VRF Service Manual 380V-3Ph-60HzgfjDocument105 paginiV5X VRF Service Manual 380V-3Ph-60HzgfjSam RVÎncă nu există evaluări

- JFM - Tryggvason - Burner - Effect of Bubble Deformation On The Properties of Bubbly FlowsDocument42 paginiJFM - Tryggvason - Burner - Effect of Bubble Deformation On The Properties of Bubbly FlowsSubhajit BiswasÎncă nu există evaluări

- HM 150.01 Pipe Friction For Laminar Turbulent Flow Gunt 548 PDF - 1 - en GBDocument3 paginiHM 150.01 Pipe Friction For Laminar Turbulent Flow Gunt 548 PDF - 1 - en GBPimployÎncă nu există evaluări

- Reciprocating CompressorDocument37 paginiReciprocating CompressorJithin DasÎncă nu există evaluări

- Hydraulics Lecture Part I (Introduction)Document46 paginiHydraulics Lecture Part I (Introduction)Kristal AbalosÎncă nu există evaluări

- 7.16 P HowTo NeptuneDocument2 pagini7.16 P HowTo NeptuneMo OsÎncă nu există evaluări

- PSV SizingDocument8 paginiPSV SizingMinh DoÎncă nu există evaluări

- High Pressure Mud PumpDocument4 paginiHigh Pressure Mud PumpMihai OpreaÎncă nu există evaluări

- 1 Colmac DX Ammonia Piping Handbook 4th EdDocument64 pagini1 Colmac DX Ammonia Piping Handbook 4th EdAlbertoÎncă nu există evaluări

- Optimization of Drilling Fluid Rheology and HydraulicsDocument10 paginiOptimization of Drilling Fluid Rheology and HydraulicsadeebÎncă nu există evaluări

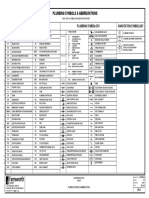

- Plumbing Symbols & AbbreviationsDocument8 paginiPlumbing Symbols & AbbreviationsThel Cruz100% (1)

- Types of Agitators and Their FunctionsDocument5 paginiTypes of Agitators and Their FunctionsELISHAMORE MACHINGURAÎncă nu există evaluări

- Competitor Comparison - AWC 25-350 A - EnglishDocument1 paginăCompetitor Comparison - AWC 25-350 A - EnglishLeonardo Augusto Ramirez SaenzÎncă nu există evaluări

- Cat - Dcs.sis - Controllerattachment - Stick Lowering Control ValveDocument2 paginiCat - Dcs.sis - Controllerattachment - Stick Lowering Control ValveFrancoÎncă nu există evaluări