Documente Academic

Documente Profesional

Documente Cultură

PARTTT

Încărcat de

Omar BermúdezDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PARTTT

Încărcat de

Omar BermúdezDrepturi de autor:

Formate disponibile

MAINTENANCE MANUAL 73-10-07 - COMPRESSOR DELIVERY AIR LINES - MAINT.

PRACTICES

Manual Part No.3034342 Rev. 52.0 - 08/APR/19

73-10-07

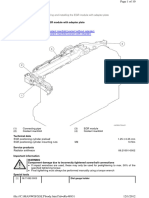

Figure 201 Removal/Installation of P3 Air Filter Element

c13113a

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 1

Printed on 09/MAY/19 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 73-10-07 - COMPRESSOR DELIVERY AIR LINES - MAINT. PRACTICES

Manual Part No.3034342 Rev. 52.0 - 08/APR/19

1. Air Filter Cover (Pre-SB13175)

2. Preformed Packing (Pre-SB13175)

3. Filter Element (Pre-SB13175)

4. Locating Spigot (Ref.)

5. Air Filter Housing (Ref.)

6. Preformed Packing (Pre-SB13175)

7. Drain Valve Adapter (Post-SB13175)

8. Preformed Packing (Post-SB13175)

9. Spring (Post-SB13175)

10. Drain Valve (Post-SB13175)

11. Retaining Ring (Post-SB13175)

12. Filter Cover (Post-SB13175)

13. Preformed Packing (Post-SB13175)

14. Preformed Packing (Post-SB13175)

15. Filter Element (Post-SB13175)

16. Preformed Packing (Post-SB13175)

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 2

Printed on 09/MAY/19 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 73-10-07 - COMPRESSOR DELIVERY AIR LINES - MAINT. PRACTICES

Manual Part No.3034342 Rev. 52.0 - 08/APR/19

6. Removal/Installation

CAUTION: WHEN REMOVAL OR INSTALLATION OF AN INDIVIDUAL ITEM IS REQUIRED,

IT IS ESSENTIAL THAT TUBES ARE NOT SUBJECTED TO BENDING STRESSES.

UNDER NO CIRCUMSTANCES BEND OR FORCE TUBES IN OR OUT OF

POSITION. WHEN REMOVING ANY ONE TUBE, THE ADJACENT TUBE,

COUPLING OR ELBOW, TOGETHER WITH SEAL RETAINING PLATES (IF

APPLICABLE), MUST FIRST BE REMOVED, AND THE PROCEDURE REVERSED

AT REINSTALLATION.

A. Removal of Compressor Delivery Air Lines (Ref. Fig. 202)

(1) Remove bolt (2) and self-locking nut (5) fastening loop clamp (4) to support bracket (3).

Keep loop clamp on rear tube assembly (1).

(2) Disconnect coupling nuts and remove rear tube assembly (1) from between FCU and filter

housing (6).

(3) Pre-SB13323:

(a) Remove nut (7) and bolt (13) fastening loop clamp (8) of front tube assembly (9). Keep

clamp on tube assembly (9).

(b) Disconnect rear coupling nut and remove front tube assembly (9) from filter housing

(6) forward of rear mount ring.

(c) Remove bolts (10) fastening front tube assembly (9), adapter (12) and gasket (11).

Discard gasket (11).

(4) Post-SB13323:

(a) Remove nut (7) and bolt (13) fastening loop clamp (8) of front tube assembly (14).

Keep clamp on tube assembly (14).

(b) Disconnect rear coupling nut and remove front tube assembly (14) from filter housing

(6) forward of rear mount ring.

(c) Remove bolts (10) fastening front tube assembly (14) and gasket (11). Discard gasket

(11).

(5) Install suitable protective caps or covers on tubes and

openings.

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 3

Printed on 09/MAY/19 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 73-10-07 - COMPRESSOR DELIVERY AIR LINES - MAINT. PRACTICES

Manual Part No.3034342 Rev. 52.0 - 08/APR/19

Figure 202 Removal/Installation of Compressor Delivery Air Lines

c176722

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 4

Printed on 09/MAY/19 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 73-10-07 - COMPRESSOR DELIVERY AIR LINES - MAINT. PRACTICES

Manual Part No.3034342 Rev. 52.0 - 08/APR/19

1. Rear Tube Assembly

2. Bolt

3. Bracket

4. Loop Clamp

5. Nut, self-locking

6. Filter Housing

7. Nut, self-locking

8. Loop Clamp

9. Front Tube Assembly (Pre-SB13323)

10. Bolt

11. Gasket

12. Adapter (Pre-SB13323)

13. Bolt

14. Front Tube Assembly (Post-SB13323)

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 5

Printed on 09/MAY/19 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 73-10-07 - COMPRESSOR DELIVERY AIR LINES - MAINT. PRACTICES

Manual Part No.3034342 Rev. 52.0 - 08/APR/19

B. Removal of Air Filter Housing Post-SB13175 Drain Valve (Ref. Fig. 201)

(1) Remove filter cover (12) and discard preformed packing

(13).

(2) Remove drain valve adapter (7) and discard preformed packing

(8).

(3) Remove retaining ring (11), drain valve (10) and spring

(9).

C. Installation of Compressor Delivery Air Lines (Ref. Fig. 202)

CAUTION: HOLD THE FITTING CORRECTLY IN POSITION WHEN YOU TORQUE THE

COUPLING NUT.

NOTE: It is important to make sure that all solid P3 lines are properly and correctly fitted

before the coupling nuts are tightened. The coupling nuts should be seated without the

use of tools (finger tight) before torquing. The installation of any brackets or clamps

should not distort the line in any way.

(1) Pre-SB13323: Install front tube assembly (9), adapter (12) and gasket (11) on P3 boss on

gas generator case with two bolts (10). Connect coupling nut to P3 filter housing (6). Do not

tighten coupling nut at rear of tube.

(2) Post-SB13323: Install front tube assembly (14) between P3 port on gas generator case and

nipple on P3 air filter housing (6). Install gasket (11) under flange and loosely attach flange

to gas generator case with bolts (10). Do not tighten coupling nut at rear of tube.

NOTE: Do not lockwire components until completion of pressure test (Ref.

Adjustment/Test).

(3) Install rear tube assembly (1) between fitting at P3 input port on FCU and filter housing (6),

passing tube assembly between fuel interconnect hose and fuel pump. Tighten coupling nuts

90 to 100 lbf.in.

(4) Fasten loop clamp (2), spacer (13) and rear tube to bracket (3) with bolt (2) and self-

locking nut (5). Tighten nut 36 to 40 lbf.in.

(5) Leak test fuel control pneumatic system (Ref.

Adjustment/Test).

D. Installation of Air Filter Housing Post-SB13175 Drain Valve (Ref. Fig. 201)

(1) Install spring (9), drain valve (10) into adapter (7) and install retaining ring (11). Make sure

valve moves smoothly and freely, and that retaining ring is installed properly.

CAUTION: COVER (12) MUST NOT BE INSTALLED IN FILTER HOUSING WHEN YOU

TIGHTEN THE ADAPTER.

CAUTION: THE P3 FILTER COVER IS MADE FROM ALUMINUM ALLOY. TAKE CARE

NOT TO DAMAGE THE COVER ASSEMBLY WHEN LOCKWIRING THE

DRAIN VALVE ASSEMBLY TO THE COVER ASSEMBLY. BEFORE

LOCKWIRING, EXAMINE THE LOCKWIRE ATTACHMENT HOLES ON THE

COVER ASSEMBLY FOR EVIDENCE OF TEARING. IF TEARING IS

EVIDENT, SECURE LOCKWIRE TO AN ALTERNATE SERVICEABLE

LOCATION (REF. 70-00-00, STANDARD PRACTICES - MAINTENANCE

PRACTICES).

(2) Install preformed packing (8) on adapter (7), and install valve assembly in cover. Torque

adapter (7) 225 to 250 lb. in. and lockwire to cover.

(3) Install preformed packing (13) on filter cover (12). Lubricate threads of cover with oil

(PWC03-001) and install in filter housing. Torque cover 60 to 70 lb. in.

(4) Leak test fuel control pneumatic system (Ref.

Adjustment/Test).

(5) Lockwire air filter cover (12) when no leaks have been detected or

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 6

Printed on 09/MAY/19 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 73-10-07 - COMPRESSOR DELIVERY AIR LINES - MAINT. PRACTICES

Manual Part No.3034342 Rev. 52.0 - 08/APR/19

found.

7. Cleaning/Painting

A. Cleaning of P3 Air Filter (Ref. Fig. 203)

(1) Place P3 filter element vertically, with open end of element at bottom, in cleaning tank or

suitable electrosonic cleaner, generating less than 10 kHz.

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 7

Printed on 09/MAY/19 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 73-10-07 - COMPRESSOR DELIVERY AIR LINES - MAINT. PRACTICES

Manual Part No.3034342 Rev. 52.0 - 08/APR/19

Figure 203 Cleaning of P3 Air Filter Element

c7140e

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 8

Printed on 09/MAY/19 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 73-10-07 - COMPRESSOR DELIVERY AIR LINES - MAINT. PRACTICES

Manual Part No.3034342 Rev. 52.0 - 08/APR/19

(2) Pour sufficient quantity of solvent (PWC11-002) or (PWC11-014) into tank to a level

approximately 1/4 inch below top.

(3) Operate cleaner for 10

minutes.

(4) Turn element 180 degrees (open end of element at

top).

(5) Operate cleaner for five

minutes.

(6) Turn element to original position in tank (Ref. Step (1)

).

(7) Operate cleaner for five minutes.

NOTE: Cleaning duration should be adjusted to suit condition of filter element. However, for

optimum results, cleaning solvent should be replaced every 20 minutes.

(8) Wear clean, lint-free gloves and remove element from

tank.

(9) Dry element with clean, dry compressed air (30

psi).

(10)Inspect filter element (Ref. Inspection/Check).

(11)Vibropeen cleaning date on end cap.

(12)Store cleaned filter elements in clean polyethylene bags until required for installation.

B. Cleaning of Air Tubes

CAUTION: DURING CLEANING, MAKE SURE SOLVENT DOES NOT CONTACT

RUBBER INSULATED SECTIONS OF AIR TUBE ASSEMBLIES.

(1) Pressure flush tubes with solvent (PWC11-027) or (PWC11-

031).

(2) Dry interior and exterior of tubes using clean, dry compressed

air.

(3) Cap open ends to prevent ingress of dirt, oil or other contaminants until tubes are required

for installation.

C. Cleaning of Air Filter Housing Post-SB13175 Drain Valve Adapter (Ref. Fig. 201)

(1) Clean adapter (7), spring (9), and valve (10) with solvent (PWC11-027) or (PWC011-31)

and non-metallic bristle brush.

8. Inspection/Check

A. Inspection of Air Tubes

(1) Examine air tubes (Ref. 70-00-00, INSPECTION, Inspection of Fuel, Oil and Air

Tubes).

(2) Examine insulation for cuts in outer rubber sheath. Surface cuts up to three inches long may

be repaired (Ref. Approved Repairs).

B. Inspection of Air Filter Element

(1) Inspect air filter element at intervals recommended in Chapter 72-00-00, INSPECTION,

Periodic Inspection. Filter must be free of visible heavy contamination, and should not

provide undue restriction when blown through. If repeated electrosonic cleaning (Ref.

Cleaning/Painting) fails to restore filter to an acceptable condition, filter element should be

shipped to an approved overhaul facility for ultrasonic cleaning and flow checking.

(2) Use a 10x magnifying glass to inspect the filter element for detachment of end cap or

broken wires. Reject element if any of these conditions are evident.

C. Inspection of Air Filter Housing Post-SB13175 Drain Valve Adapter (Ref. Fig. 201)

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 9

Printed on 09/MAY/19 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 73-10-07 - COMPRESSOR DELIVERY AIR LINES - MAINT. PRACTICES

Manual Part No.3034342 Rev. 52.0 - 08/APR/19

(1) Filter Cover (12):

(a) Check lockwire holes for damage (tearing, cracks).

(b) Check threads for damage.

(c) Check that contact area is free of nicks and/or

scratches.

(2) Drain Valve Adapter (7):

(a) Check threads for damage.

(b) Check contact area is free of nicks and/or scratches.

(c) Check flats and lockwire holes are free of damage.

(d) Check retaining ring groove. Reject if damaged or

worn.

(3) Drain Valve (10):

(a) Check contact area is free of nicks and/or

scratches.

(b) Make sure drain holes are clear and unobstructed.

(4) Valve Spring (9):

(a) Check for corrosion and/or damage. Reject if

unsatisfactory.

(5) Retaining Ring (11):

(a) Check for distortion. Replace if

distorted.

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 10

Printed on 09/MAY/19 P&WC Proprietary – subject to restrictions in Technical Data Agreement

S-ar putea să vă placă și

- 70.00.00 Standard Practices - Removal - InstallationDocument23 pagini70.00.00 Standard Practices - Removal - InstallationTimoteo Molina RomeroÎncă nu există evaluări

- Cat c15 Cylinder Head InstallationDocument7 paginiCat c15 Cylinder Head InstallationMUHSIN MTÎncă nu există evaluări

- Filter Assy - Avionics Ventilation - Removal & InstallationDocument13 paginiFilter Assy - Avionics Ventilation - Removal & Installationjoby619100% (1)

- Inlet and Exhaust Valve Seals - Remove and Install: ShutdownDocument3 paginiInlet and Exhaust Valve Seals - Remove and Install: ShutdownLuis TepezanoÎncă nu există evaluări

- Orden de Ingenieria - Efectividad - 0363Document24 paginiOrden de Ingenieria - Efectividad - 0363Eduardo SalinasÎncă nu există evaluări

- Remove and Install Air CompressorDocument2 paginiRemove and Install Air CompressorBuku DigitalÎncă nu există evaluări

- 24 Serrage D'une Culasse.Document6 pagini24 Serrage D'une Culasse.AliHabesÎncă nu există evaluări

- Oil System - Servicing: Draining Filling, Flushing Replenishing Engine OilDocument7 paginiOil System - Servicing: Draining Filling, Flushing Replenishing Engine OilAre Soo YantoÎncă nu există evaluări

- Cylinder Head - Install: Disassembly and AssemblyDocument8 paginiCylinder Head - Install: Disassembly and AssemblyMahmoud AliÎncă nu există evaluări

- Cat c15 Cylinder Head RemovalDocument6 paginiCat c15 Cylinder Head RemovalMUHSIN MTÎncă nu există evaluări

- Compressor ClutchDocument6 paginiCompressor Clutchbobbynicky007100% (1)

- 72 01 40 Rem-InstDocument13 pagini72 01 40 Rem-Instfernando heÎncă nu există evaluări

- Disassemble TurbochargerDocument11 paginiDisassemble TurbochargerAnonymous cS9UMvhBqÎncă nu există evaluări

- EGR Flap AdjustingDocument10 paginiEGR Flap Adjustingesam PhilipeÎncă nu există evaluări

- Toyota Hiace MantenimientoDocument20 paginiToyota Hiace Mantenimientofranktrevi75% (4)

- 207 8FS ExhaustDocument6 pagini207 8FS ExhaustAli KhedirecheÎncă nu există evaluări

- Vdocuments - MX - Caterpillar Cat 320l Track Excavator Prefix 8lk Service Repair Manual 8lk00001 and Up 1586311769Document30 paginiVdocuments - MX - Caterpillar Cat 320l Track Excavator Prefix 8lk Service Repair Manual 8lk00001 and Up 1586311769Ikeo100% (1)

- Service Repair Manual - (Cat) Caterpillar 3126 Machine Engine SN 1bw, 55kDocument1.094 paginiService Repair Manual - (Cat) Caterpillar 3126 Machine Engine SN 1bw, 55kLen Wal100% (2)

- SB3 1 102Document6 paginiSB3 1 102jussmeeeÎncă nu există evaluări

- Bulkline 650 & 1000 Installation, Operating & Maintenance InstructionsDocument22 paginiBulkline 650 & 1000 Installation, Operating & Maintenance InstructionsNelson KardozoÎncă nu există evaluări

- DCEM 2100 TUV Installalation & Commisioning ManualDocument37 paginiDCEM 2100 TUV Installalation & Commisioning ManualQuan Nguyen VanÎncă nu există evaluări

- Cylinder Head - Install: Disassembly and AssemblyDocument8 paginiCylinder Head - Install: Disassembly and AssemblySaeed KazemiÎncă nu există evaluări

- Caterpillar Cat M313C WHEELED Excavator (Prefix H2A) Service Repair Manual (H2A00001 and Up) PDFDocument27 paginiCaterpillar Cat M313C WHEELED Excavator (Prefix H2A) Service Repair Manual (H2A00001 and Up) PDFfkdmmaÎncă nu există evaluări

- Valve - Pressure Regulating - Removal & InstallationDocument8 paginiValve - Pressure Regulating - Removal & Installationjoby619Încă nu există evaluări

- Remove & Install Water Pump Fluid Spillage ContainmentDocument7 paginiRemove & Install Water Pump Fluid Spillage ContainmentMohammed MostafaÎncă nu există evaluări

- Landinggear Strut and Oleo - ServicingDocument6 paginiLandinggear Strut and Oleo - ServicingOSCAR RODRIGUEZÎncă nu există evaluări

- Cylinder Head installSMCS - 1100 - 012Document7 paginiCylinder Head installSMCS - 1100 - 012ToispuoliÎncă nu există evaluări

- 61 20Document12 pagini61 20Miguel Condor100% (1)

- Caterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)Document26 paginiCaterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)kfm8seuuduÎncă nu există evaluări

- Caterpillar Cat 322c L 322cl Excavator Prefix Fed Service Repair Manual Fed00001 and Up 1594396296Document27 paginiCaterpillar Cat 322c L 322cl Excavator Prefix Fed Service Repair Manual Fed00001 and Up 1594396296Jhon VillamizarÎncă nu există evaluări

- 300-5617 Cooler AssemblyDocument13 pagini300-5617 Cooler Assemblyharikrishnanpd3327Încă nu există evaluări

- Cam ShaftDocument7 paginiCam ShaftMahmoud AliÎncă nu există evaluări

- Cylinder Head - Install: Disassembly and AssemblyDocument4 paginiCylinder Head - Install: Disassembly and AssemblyВиталийÎncă nu există evaluări

- Install Water PumpDocument8 paginiInstall Water PumpSteven Y.MÎncă nu există evaluări

- John Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)Document17 paginiJohn Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)laopaodunÎncă nu există evaluări

- 24 21 51 400 041 BDocument4 pagini24 21 51 400 041 BDorival VenâncioÎncă nu există evaluări

- Cilindro de Direccion 416DDocument9 paginiCilindro de Direccion 416DjulianmatabajoyÎncă nu există evaluări

- 2009-07!28!045630 Remove Install Electrohydraulic Control Module Transmission InstalledDocument3 pagini2009-07!28!045630 Remove Install Electrohydraulic Control Module Transmission InstalledfulltransmissionÎncă nu există evaluări

- Dustribiteur 330c 3 Sisweb Sisweb Techdoc Techdoc Print Page - JSPDocument51 paginiDustribiteur 330c 3 Sisweb Sisweb Techdoc Techdoc Print Page - JSPMehdi ChakrouneÎncă nu există evaluări

- Caterpillar Cat 330B L Excavator (Prefix 5LR) Service Repair Manual (5LR00001 and Up)Document27 paginiCaterpillar Cat 330B L Excavator (Prefix 5LR) Service Repair Manual (5LR00001 and Up)kfm8seuudu100% (1)

- Cylinder Head Instalation ProceduresDocument9 paginiCylinder Head Instalation ProceduresNasser AyoubÎncă nu există evaluări

- EXT Eva Air: Job CardDocument19 paginiEXT Eva Air: Job CardLê Viết DũngÎncă nu există evaluări

- 320dl Joystick AssemblingDocument6 pagini320dl Joystick AssemblingDaniel Rhasty-ghee AhmanorÎncă nu există evaluări

- ML C 650 c65mm213Document6 paginiML C 650 c65mm213operacionesÎncă nu există evaluări

- Sis 2.0 3Document1 paginăSis 2.0 3kqgy9s6sgvÎncă nu există evaluări

- SEars Riello f10 Oil Burner ManualDocument20 paginiSEars Riello f10 Oil Burner ManualLeslie FlemingÎncă nu există evaluări

- Caterpillar Cat 320D Excavator (Prefix DHK) Service Repair Manual (DHK00001 and Up)Document22 paginiCaterpillar Cat 320D Excavator (Prefix DHK) Service Repair Manual (DHK00001 and Up)kfmuseddk100% (1)

- Aircraft Maintenance Manual: Task 21 51 13 140 801 Restoration (Cleaning) of The Water Separator CoalescersDocument8 paginiAircraft Maintenance Manual: Task 21 51 13 140 801 Restoration (Cleaning) of The Water Separator CoalescersCHIMOÎncă nu există evaluări

- Clean Emissions Module - Remove and Install: Shutdown SISDocument5 paginiClean Emissions Module - Remove and Install: Shutdown SISMbahdiro KolenxÎncă nu există evaluări

- C18 Industrial Engine WRH0Document6 paginiC18 Industrial Engine WRH0Miguel Angel Garrido CardenasÎncă nu există evaluări

- Bell 429 ItbDocument17 paginiBell 429 ItbSarp TEMURÎncă nu există evaluări

- Cylinder Head Instalation Procedures (Converted)Document9 paginiCylinder Head Instalation Procedures (Converted)Nasser AyoubÎncă nu există evaluări

- Caterpillar Cat 330C FM EXCAVATOR (Prefix B2L) Service Repair Manual (B2L00001 and Up)Document24 paginiCaterpillar Cat 330C FM EXCAVATOR (Prefix B2L) Service Repair Manual (B2L00001 and Up)kfm8seuudu100% (2)

- Cameron U Ram BopDocument29 paginiCameron U Ram BopAnaruzzaman SheikhÎncă nu există evaluări

- Piston & Rod RemovalDocument5 paginiPiston & Rod RemovalsxturboÎncă nu există evaluări

- 320D2 Excavator XBA00001-UP (MACHINE) POWERED BY C7.1 Engine (M0065912 - 13) - Systems & ComponentsDocument8 pagini320D2 Excavator XBA00001-UP (MACHINE) POWERED BY C7.1 Engine (M0065912 - 13) - Systems & ComponentsYudi setiawanÎncă nu există evaluări

- Load Control Valve (Boom Cylinder) - AssembleDocument6 paginiLoad Control Valve (Boom Cylinder) - AssemblechanlinÎncă nu există evaluări

- Installation and Service Instructions Solar Divicon, Solar Circuit Pump LineDocument16 paginiInstallation and Service Instructions Solar Divicon, Solar Circuit Pump LineIonut SomneaÎncă nu există evaluări

- Component Code AJ: Printed in Japan (02) 1Document5 paginiComponent Code AJ: Printed in Japan (02) 1PepeTRBKÎncă nu există evaluări

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachDe la EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachÎncă nu există evaluări

- Cargo: C3E 100R C3E 130R C3E 150RDocument198 paginiCargo: C3E 100R C3E 130R C3E 150RAntonio NovoÎncă nu există evaluări

- Accord International, Inc.: No. KC - King Combination NipplesDocument1 paginăAccord International, Inc.: No. KC - King Combination Nipplesadvantage025Încă nu există evaluări

- Boiler Operator Training PP PresentationDocument44 paginiBoiler Operator Training PP PresentationANIL YADAVÎncă nu există evaluări

- 165D6 - Thermo King 2000 Hose System: 3/8/14Document75 pagini165D6 - Thermo King 2000 Hose System: 3/8/14Elliot WuÎncă nu există evaluări

- Course Contents For 5 Days GT, HRSG, ST & GenDocument2 paginiCourse Contents For 5 Days GT, HRSG, ST & GenFazalur Rehman BabarÎncă nu există evaluări

- 18ME54 Turbo Machines Module 03 Question No 5a & 5bDocument14 pagini18ME54 Turbo Machines Module 03 Question No 5a & 5bThanmay JSÎncă nu există evaluări

- Asme b31 3 2022Document23 paginiAsme b31 3 2022Surendra Tholchuri50% (22)

- Inducer Design That Avoids Rotating CavitationDocument10 paginiInducer Design That Avoids Rotating CavitationJavad AckbariÎncă nu există evaluări

- Air-Conditioning Module Slides-FinalDocument37 paginiAir-Conditioning Module Slides-FinalMorgan HengÎncă nu există evaluări

- Tank SizeDocument6 paginiTank SizeNghiaÎncă nu există evaluări

- Udor Maintenance Trouble ShootingDocument4 paginiUdor Maintenance Trouble ShootingMONA100% (1)

- Api Iso Equivalent Standards PDFDocument8 paginiApi Iso Equivalent Standards PDFSantiago IsazaÎncă nu există evaluări

- Thermostatic Expansion Valve: Series RFGBDocument10 paginiThermostatic Expansion Valve: Series RFGBRajat JunejaÎncă nu există evaluări

- Aeroquip AdaptersDocument98 paginiAeroquip AdaptersSetyohdWÎncă nu există evaluări

- Möller Turbuflow Transport SystemDocument4 paginiMöller Turbuflow Transport SystemAhmad NilÎncă nu există evaluări

- Stanley Tp08 User Manual 03 2018 v21Document20 paginiStanley Tp08 User Manual 03 2018 v21Shahaji ChavanÎncă nu există evaluări

- Line ProportionerDocument2 paginiLine ProportionerpsycopaulÎncă nu există evaluări

- Air Over Oil Packing Lube System OM - 6288330 - 01Document14 paginiAir Over Oil Packing Lube System OM - 6288330 - 01harshal patilÎncă nu există evaluări

- Working Principle: Oil/Gas-ActuationDocument14 paginiWorking Principle: Oil/Gas-ActuationCristian LuqueÎncă nu există evaluări

- US0606Document29 paginiUS0606Maria DazaÎncă nu există evaluări

- ABB Valve Series 14Document8 paginiABB Valve Series 14HafziÎncă nu există evaluări

- AccumlatorDocument59 paginiAccumlatorahmedsaid85Încă nu există evaluări

- Piping Info Blogspot Com Piping 20questionsDocument53 paginiPiping Info Blogspot Com Piping 20questionsravirawat15Încă nu există evaluări

- What Are Double Pipe Heat Exchangers and Their Working PrinciplesDocument8 paginiWhat Are Double Pipe Heat Exchangers and Their Working PrinciplesAngel RatuÎncă nu există evaluări

- EN-MISTRAL-DDM-SS-rev0.18-user ManualDocument72 paginiEN-MISTRAL-DDM-SS-rev0.18-user ManualHenry PCÎncă nu există evaluări

- 2007-Current MaxxForce Engine Breakout Harness Reference (EGES545)Document14 pagini2007-Current MaxxForce Engine Breakout Harness Reference (EGES545)Enrrique Lara100% (1)

- Eil VMSDocument37 paginiEil VMSJennifer FrenchÎncă nu există evaluări

- EX3600-6 PartsRecommendDocument112 paginiEX3600-6 PartsRecommendmirbek mairykovÎncă nu există evaluări

- 122002Document39 pagini122002wdavid81Încă nu există evaluări

- Visual Flow Test ProcedureDocument11 paginiVisual Flow Test ProceduresandeshÎncă nu există evaluări