Documente Academic

Documente Profesional

Documente Cultură

JVS M22X2.5P B7M Blackodising 47H6712FX-D6

Încărcat de

GauravTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

JVS M22X2.5P B7M Blackodising 47H6712FX-D6

Încărcat de

GauravDrepturi de autor:

Formate disponibile

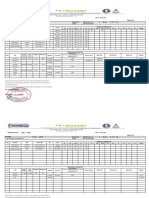

2.

5X45° MARKING

BOTH SIDES Ø22 LOCATION

30±0.2 95±0.2 M22X2.5P

470±1

NOTE :

TOLERANCE FOR STUDS TO SUIT 6g RING

THREAD GAUGE.

TOLERACE FOR NUTS TO SUIT 6H PLUG

THREAD GAUGE.

REFER ASME B 1.13M NOTE : GRINDING DIAMETER 20.53 TO 20.55

COATING : BLACKODISING CRITICAL COMPONENT MACHINING DRAWING

DRAWN G. KELKAR THE DRAWING IS PROPRIETARY ARTICLE AND IS LOANED IN CONFIDENCE SUBJECT TO RETURN

UPON DEMAND. REPRODUCTION THEREOF OR MANUFACTURING OF PARTS THEREFROM IS NOT RAW MATERIAL 4140 Ø24

CHECKED B. SONAWANE PERMISSIBLE WITHOUT THE WRITTEN PERMISSION OF MASK FASTENERS PVT. LTD.

GENERAL MACHINING TOLERANCES for linear dimensions

APPROVED G. THORVE PRODUCT GRADE A193 B7M

400 TO 1000 TO 2000 TO

0.5 UPTO 6 6 TO 30 30 TO 120 120 TO 400

NOTES : 1000 2000 4000

± 0.1 ± 0.2 ± 0.3 ± 0.5 ± 0.8 ± 1.2 ± 2.0

1) All dimensions are in mm. WEIGHT

2) Remove all sharp corners and edges by 0.5 radii / 0.5*45° GENERAL MACHINING TOLERANCES for angular dimensions

3) Critical dimension with its surface finish & GD&T marked LENGTH UPTO10 10 TO 50 50 TO 120 120 TO 400 400 TO 1000

as DRG. NO. JVS/47HF6712FX-D6

4) Dimensions showed in (_) only for reference. ANGLE ± 1° ± 0° 30' ± 0° 20' ±0° 10' ± 0 5'

5)For any clarification or suggestions please contact R&D. TITLE:

SCALE : N.T.S

Machining from 6.3 um to 3.2 um HALF THREADED STUD M22X2.5PX470L

Grinding from 0.8 um to 0.4 um

MASK FASTENERS PVT. LTD.

00 -- New Release 6) Refer table MFPL/MFG/TRSIZES FOR THREAD

DIMENSIONS.

REV. DCN. NO. BRIEF RECORD SIGN.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Full 3-4 10unc 115 B7 BlackodisingDocument1 paginăFull 3-4 10unc 115 B7 BlackodisingGauravÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - GrindingDocument1 paginăSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - GrindingGauravÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Full 3-4 10unc 130 B7 BlackodisingDocument1 paginăFull 3-4 10unc 130 B7 BlackodisingGauravÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Full 3-4 10unc 90 B7 BlackodisingDocument1 paginăFull 3-4 10unc 90 B7 BlackodisingGauravÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingDocument1 paginăSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingGauravÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - Blanking PDFDocument1 paginăSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - Blanking PDFGauravÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - RollingDocument1 paginăSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - RollingGauravÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingDocument1 paginăSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingGauravÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - MarkingDocument1 paginăSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - MarkingGauravÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingDocument1 paginăSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingGauravÎncă nu există evaluări

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - MarkingDocument1 paginăSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - MarkingGauravÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - RollingDocument1 paginăSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - RollingGauravÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - BlankingDocument1 paginăSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - BlankingGauravÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - GrindingDocument1 paginăSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - GrindingGauravÎncă nu există evaluări

- M16X2PX52L 4140 B7 BlackodisingDocument1 paginăM16X2PX52L 4140 B7 BlackodisingGauravÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- M20X2.5PX60L 4140 B7 BlackodisingDocument1 paginăM20X2.5PX60L 4140 B7 BlackodisingGauravÎncă nu există evaluări

- M16X2PX52L B8Document1 paginăM16X2PX52L B8GauravÎncă nu există evaluări

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - RollingDocument1 paginăSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - RollingGauravÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- KGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingDocument1 paginăKGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingGauravÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Eee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0Document1 paginăEee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0GauravÎncă nu există evaluări

- Full M12X1.75PX60 B7 ZN Al - BlankingDocument1 paginăFull M12X1.75PX60 B7 ZN Al - BlankingGauravÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Full M20X2.5PX210L A193 B8M CL-1Document1 paginăFull M20X2.5PX210L A193 B8M CL-1GauravÎncă nu există evaluări

- Gargi EnterprisesDocument10 paginiGargi EnterprisesGauravÎncă nu există evaluări

- Mic Full m12x1.75px45l b7 Blackodising Mi0000000011Document1 paginăMic Full m12x1.75px45l b7 Blackodising Mi0000000011GauravÎncă nu există evaluări

- MPCPL BSR M12X1.75PX45 4140 B7 Blackodising M12-45-SB7Document1 paginăMPCPL BSR M12X1.75PX45 4140 B7 Blackodising M12-45-SB7GauravÎncă nu există evaluări

- BEC 013 Automotie ElectronicsDocument70 paginiBEC 013 Automotie Electronicsjimshith jimmuÎncă nu există evaluări

- Eee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0Document1 paginăEee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0GauravÎncă nu există evaluări

- Mic Full m12x1.75px45l b7 Blackodising Mi0000000011Document1 paginăMic Full m12x1.75px45l b7 Blackodising Mi0000000011GauravÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- MPCPL BSR M10X1.5PX50 4140 B7 Blackodising M10-50-SB7 PDFDocument1 paginăMPCPL BSR M10X1.5PX50 4140 B7 Blackodising M10-50-SB7 PDFGauravÎncă nu există evaluări

- MPCPL BSR M10X1.5PX45 4140 B7 Blackodising M10-45-SB7Document1 paginăMPCPL BSR M10X1.5PX45 4140 B7 Blackodising M10-45-SB7GauravÎncă nu există evaluări

- Threaded Mechanical FastenersDocument32 paginiThreaded Mechanical FastenersfahkingmoronÎncă nu există evaluări

- Difference Between SEAMless and ERW PipesDocument3 paginiDifference Between SEAMless and ERW PipesnewspaÎncă nu există evaluări

- Precision Measuring ToolsDocument4 paginiPrecision Measuring Toolsabyzen100% (1)

- Catalogo Ricambi Liste de Pieces Parts Manual ErsatzteillisteDocument156 paginiCatalogo Ricambi Liste de Pieces Parts Manual ErsatzteillistealexÎncă nu există evaluări

- BMP - DrawingDocument22 paginiBMP - Drawingmantra2010Încă nu există evaluări

- 8l Pkgcomparison 1220a 003Document1 pagină8l Pkgcomparison 1220a 003Ben LernerÎncă nu există evaluări

- Data Pemakaian ConsumableDocument115 paginiData Pemakaian ConsumableRogersÎncă nu există evaluări

- DrillingDocument10 paginiDrillingAce Michael AldamarÎncă nu există evaluări

- Organograma ASME IX Art. I PDFDocument4 paginiOrganograma ASME IX Art. I PDFfabiocorreasilvaÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Bosch 20182019 Catalog - Drillingfastening PDFDocument52 paginiBosch 20182019 Catalog - Drillingfastening PDFPray OcampoÎncă nu există evaluări

- Cutting Force Measurement Using DynamometerDocument3 paginiCutting Force Measurement Using Dynamometershashankmay18100% (3)

- SHOT Peening EquipmentsDocument9 paginiSHOT Peening EquipmentssomujazÎncă nu există evaluări

- ML10, Speed 10 and Diamond 10 Spare PartsDocument6 paginiML10, Speed 10 and Diamond 10 Spare PartsDanielle KarlssonÎncă nu există evaluări

- Operation Manual: Bench LatheDocument55 paginiOperation Manual: Bench LatheJhon SantosÎncă nu există evaluări

- Split Pattern of Green Sand Molding and Hollow Casting ProductionDocument11 paginiSplit Pattern of Green Sand Molding and Hollow Casting ProductionJorge Sánchez100% (2)

- TI KAL: A Chart To Choose The Right FastenerDocument2 paginiTI KAL: A Chart To Choose The Right Fastenervelu.gÎncă nu există evaluări

- MM5640: Sheet Metal FormingDocument1 paginăMM5640: Sheet Metal FormingKrunal MoreyÎncă nu există evaluări

- Revisi API - 1000 PDFDocument3 paginiRevisi API - 1000 PDF213eknoÎncă nu există evaluări

- Electrical Brochure 2015Document19 paginiElectrical Brochure 2015Quest-Air TechnologyÎncă nu există evaluări

- Lapping Process - Definition, Working Principle, Types, Material, Advantages, Application (Notes With PDF) - Learn MechanicalDocument13 paginiLapping Process - Definition, Working Principle, Types, Material, Advantages, Application (Notes With PDF) - Learn MechanicalMirko DujmićÎncă nu există evaluări

- Er308 PDFDocument1 paginăEr308 PDFKhedira Al JibrillÎncă nu există evaluări

- J S Auto Cast Foundry India PVT LTD.,: Tool LayoutDocument24 paginiJ S Auto Cast Foundry India PVT LTD.,: Tool Layoutkishore RavindranÎncă nu există evaluări

- Lecture Objectives: To Develop An Understanding ofDocument24 paginiLecture Objectives: To Develop An Understanding ofMuhammad IrfanÎncă nu există evaluări

- Friction WeldingDocument8 paginiFriction WeldingGopi KrishnaÎncă nu există evaluări

- Expoentes - Aço AISI 4340Document5 paginiExpoentes - Aço AISI 4340Nathanael Wagner MetalÎncă nu există evaluări

- Petrofast MTC 3.1 PO-400234 Anchor Bolts - Option FDocument2 paginiPetrofast MTC 3.1 PO-400234 Anchor Bolts - Option Fحسن صالح حسن المياحيÎncă nu există evaluări

- Engraving Tools Catalog: Quality Cutting Tools and Resharpening Service For The Engraving and Sign Making IndustriesDocument8 paginiEngraving Tools Catalog: Quality Cutting Tools and Resharpening Service For The Engraving and Sign Making IndustriesCristian FuentesÎncă nu există evaluări

- Siddh UpdatedDocument33 paginiSiddh UpdatedVikrantÎncă nu există evaluări

- GaugesDocument1 paginăGaugesNang DapiÎncă nu există evaluări

- Laboratory Exercises - Machine Elements: Assembling and De-Assembling A Gear UnitDocument5 paginiLaboratory Exercises - Machine Elements: Assembling and De-Assembling A Gear UnitAndreea PricopneacÎncă nu există evaluări