Documente Academic

Documente Profesional

Documente Cultură

Tanque STA RITE

Încărcat de

Charlie MartinezDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tanque STA RITE

Încărcat de

Charlie MartinezDrepturi de autor:

Formate disponibile

steel pressurized water system tanks

APPLICATIONS

■ Use wherever pressurized

tanks are needed in water

systems applications.

SPECIFICATIONS

Shell – Heavy gauge steel

Base – High-impact composite; ABS

Finish – Electrostatically applied,

baked-on polyester paint

Water Cell – One piece seamless

PVC, made from FDA listed material

Flange – Reinforced polypropylene

Service Connection – Reinforced

polypropylene integral to flange

UL Classified to ANSI/NSF Standard 61, Air Valve – Rubber stem/brass body

Drinking Water System Components – Health Effects Schrader valve assembly

UV Valve Cover – High density

PRO-Source™ is a trademark of WICOR Industries. polyethylene

In order to provide the best products possible, specifications are subject to change.

ORDERING INFORMATION

Maximum Connection

Drawdown in Gallons/Liter

Catalog Capacity Diameter* Height* Length Precharge Size Weight

Number gal/liter inch/cm inch/cm inch/cm PSI/kPa Female 20-40 30-50 40-60 lbs/kg

VERTICAL MODELS

PS15-S02 6.0 / 22.7 12 / 30.5 16.1 / 40.9 – 40 / 276 3/4" NPT 2.2 / 8.3 1.8 / 6.8 1.6 / 6.0 18 / 8.2

PS30-T01 14 / 53 16 / 40.6 23 / 54.4 – 40 / 276 1" NPT 4.8 / 18.2 4.1 / 15.5 3.6 / 13.6 37 / 16.8

PS42S-T02 19 / 72 20 / 51 21 / 53.3 – 40 / 276 1" NPT 6.9 / 26.1 5.8 / 21.9 5.0 / 18.9 45 / 20.4

PS42T-T02 19 / 72 16 / 40.6 27.5 / 70 – 40 / 276 1" NPT 6.9 / 26.1 5.8 / 21.9 5.0 / 18.9 40 / 18.1

PS75T-T03 32 / 121 16 / 40.6 43 / 109 – 40 / 276 1" NPT 11.6 / 43.9 9.8 / 37.1 8.5 / 32.2 56 / 25.4

PS82T-T05 35 / 133 20 / 51 33 / 84 – 40 / 276 1" NPT 12.7 / 48.1 10.7 / 40.5 9.3 / 35.2 66 / 29.9

PS120-T50 50 / 189 24 / 61 32.5 / 83 – 40 / 276 1-1/4" NPT 18.3 / 69.3 15.5 / 58.7 13.4 / 50.7 84 / 38.1

PS200-T51 62 / 235 24 / 61 39.5 / 100 – 40 / 276 1-1/4" NPT 21.4 / 81.0 18.3 / 69.3 16.0 / 60.6 112 / 50.8

PS220-T52 85 / 322 24 / 61 51 / 130 – 40 / 276 1-1/4" NPT 30 / 113.6 26 / 98.4 22 / 83.3 124 / 56.2

PS320-TR50 119 / 450 24 / 61 68 / 173 – 40 / 276 1-1/4" NPT 41.3 / 156.3 35.4 / 134.0 31.0 / 117.3 140/ 63.5

HORIZONTAL MODELS

PS15H-S05 6.0 / 22.7 12 / 30.5 13.8 / 35.0 16 / 40.6 40 / 276 3/4" NPT 2.2 / 8.3 1.8 / 6.8 1.6 / 6.0 22 / 10

PS42H-S00 19 / 72 16 / 40.6 17.5 / 44.5 28 / 71.1 40 / 276 1" NPT 6.9 / 26.1 5.8 / 21.9 5.0 / 18.9 40 / 18

*Subject to change without notice.

Maximum Operating Pressure = 100 PSI

Maximum Liquid Temperature: 120°F (49°C) Maximum External (Ambient) Temperature: 125°F (52°C)

S5530WS • Customer Service: (262) 728-9181 98 Delavan, WI 53115 USA • www.pumps.com

steel pressurized water system tanks

FEATURES – Reinforcing ribs strengthen and

Heavy Gauge Metal Construction – maintain a flat smooth sealing

surface. PRO-Source™

Sturdy “welded wrapper and head

design.” Built to last. Integral Stand Pipe – Keeps the Tank Sizing Rule:

Polyester Paint Finish – Electro- water cell standing erect, promoting Size tank for one gallon of

complete flushing of the water

statically powder painted, then oven drawdown for each gallon per

baked for a smooth high-gloss, appli- entering/exiting the tank.

minute of pump capacity.

ance-quality finish. Resists corrosion. Nitrogen-Rich Precharge –

Elongated, Seamless Water Cell – Decreases air permeation three to

– Controlled 2-dimensional cell four times over straight air precharge.

40 PSI Precharge – Ready for use Example:

expansion.

– Rugged, seamless “water cell” with 40/60 pressure range systems. For a 1 HP 20 GPM unit

prevents the most common cause Enables installer to reduce pressure pumping 20 gallons per

of pump failure – “waterlogging” depending on pressure switch setting. minute on a 30-50 pressure

– Water never touches the steel tank Sturdy Base – Tested-tough switch setting, the properly

material. composite construction.

sized PRO-Source™ tank is

– Translucent bag material facilitates Five Year Warranty – Managed

and provided by WICOR Industries, a PS220-T52 which has a

manufacturing quality control

inspection. the only US pump manufacturer 26 gallon drawdown.

Composite Sealing Flange – to design and manufacture fibre-

– Corrosion-resistant. wound and steel tanks!

– Integral o-ring groove better traps

the water cell’s sealing ring.

CHART A – CHART B –

TANK SELECTION CHART DRAWDOWN VOLUME MULTIPLIER* (APPROX.)

System Pressure Switch Setting – PSI Pump Off Pump Start Pressure – PSI

Pump 20-40 30-50 40-60 Pressure

GPM Run Times PSI 10 20 30 40 50 60 70 80

1 Minute 2 Minute 1 Minute 2 Minute 1 Minute 2 Minute 20 0.26

5 PS42T PS75T PS42T PS82T PS42T PS82T 30 0.41 0.22

7-1/2 PS75T PS82T PS75T PS120 PS75T PS200 40 0.37 0.18

10 PS75T PS200 PS82T PS200 PS82T PS220

12-1/2 PS82T PS200 PS120 PS220 PS120 PS220 50 0.46 0.31 0.15

15 PS120 PS220 PS120 PS120 (2) PS200 PS200 (2) 60 0.40 0.27 0.13

20 PS200 PS200 (2) PS200 PS200 (2) PS220 PS220 (2) 70 0.47 0.35 0.24 0.12

30 PS220 PS220 (2) PS120 (2) PS220 (2) PS200 (2) PS220 (3) 80 0.42 0.32 0.21 0.11

PS320 + 90 0.48 0.38 0.29 0.19 0.10

30 – – PS320 PS320 PS320 (2)

PS220

PS200 + 100 0.44 0.35 0.26 0.17

50 PS220 (3) PS220 (2) PS220 (4) PS220 (2) PS220 (5)

PS220

*Utilize this chart if proper selection cannot be made using

PS320 (2) +

50 – – PS320 (3) PS320 (2) PS320 (4) Chart A. Drawdown based on Boyle’s Law.

PS200

Procedure: 1. Identify drawdown multiplier relating to specific application.

NOTE: Drawdown will be affected by operating temperature 2. Insert multiplier (X) into the following formula:

of the system, accuracy of the pressure switch and Pump GPM x Min Run Time

gauge, the actual precharge pressure, and rate of fill. = Minimum Tank

Multiplier (X) Capacity Required

Pumps installed with a PRO-Source™ tank require a Example: An example of a 20 GPM pump with a minimum run time of

100 PSI relief valve. Relief valve must be capable of 1 minute, installed on a 50 - 70 PSIG system pressure range:

relieving entire flow of pump at relief pressure. 20 GPM x 1 minute = 83.3 minimum U.S.

.24 (factor) from Chart B gallon tank capacity

Referring to “Ordering Information” chart, the model PS220-T52 has the

closest U.S. gallon capacity that is greater or equal to the minimum volume

requirement of 83.3 U.S. gallons.

S5530WS • Customer Service: (262) 728-9181 99 Delavan, WI 53115 USA • www.pumps.com

steel pressurized water system tanks

SEQUENCE OF OPERATION

WATER CELL IS WATER BEGINS TO PUMP-UP CYCLE WATER IS BEING

COMPLETELY EMPTY: ENTER THE TANK: COMPLETED: DRAWN FROM THE

A new cycle is ready to Air is compressed around Air is now compressed TANK: Compressed air

begin. Simple, positive the water cell as it fills to the cut-off setting of in the tank forces water

action produces maximum with water. pressure switch. out of the water cell.

drawdown on every cycle.

S5530WS • Customer Service: (262) 728-9181 101 Delavan, WI 53115 USA • www.pumps.com

S-ar putea să vă placă și

- Toma Chemetron Serie 500Document4 paginiToma Chemetron Serie 500ricardo velascoÎncă nu există evaluări

- SB MultiVIV HighStaticDucted ARNU363B8A4!12!15Document2 paginiSB MultiVIV HighStaticDucted ARNU363B8A4!12!15ags387Încă nu există evaluări

- VRF Outdoor Unit X-Power Full DC Inverter Super X SeriesDocument3 paginiVRF Outdoor Unit X-Power Full DC Inverter Super X SeriesAlfrh67% (3)

- DKC Manual Uso Aires AcondicionadosDocument44 paginiDKC Manual Uso Aires AcondicionadosROOGER FABIAN M. NUÑEZ RONCANCIOÎncă nu există evaluări

- Condensador Ciac Ca43ax 18 Seer InverterDocument2 paginiCondensador Ciac Ca43ax 18 Seer InverterMantenimiento TechniaireÎncă nu există evaluări

- CG41C - CH41C - S13 CiacDocument1 paginăCG41C - CH41C - S13 CiacYadhira Dominguez ZuritaÎncă nu există evaluări

- Multisplit InverterDocument8 paginiMultisplit Invertermaria jimenez100% (1)

- Ansi Asme b16.5 Class 150 Forged Flanges VJVMCHDocument1 paginăAnsi Asme b16.5 Class 150 Forged Flanges VJVMCHZachary HuffmanÎncă nu există evaluări

- Lennox - Split Pared R-22Document2 paginiLennox - Split Pared R-22Saidy Jimena Plazas MarlesÎncă nu există evaluări

- Manual Dwyer MS-111 Pressure TransmitterDocument4 paginiManual Dwyer MS-111 Pressure TransmitterSunko MachineryÎncă nu există evaluări

- Ficha y Eca-Aval-60 000 Btu McquayDocument16 paginiFicha y Eca-Aval-60 000 Btu McquayJAQAÎncă nu există evaluări

- Elevador Dunlop - DTM810Document1 paginăElevador Dunlop - DTM810Jim GarciaÎncă nu există evaluări

- Carlin 40200Document2 paginiCarlin 40200luzvid alejo ochoaÎncă nu există evaluări

- Commissioning Checklist for Mechanical, Electrical, Plumbing and Renewable Energy SystemsDocument5 paginiCommissioning Checklist for Mechanical, Electrical, Plumbing and Renewable Energy Systemskunta_kÎncă nu există evaluări

- Catalogo Actualizado ChintDocument39 paginiCatalogo Actualizado Chint12dante1767% (3)

- York DC Fan Coil Units Deliver Quiet, Efficient ComfortDocument14 paginiYork DC Fan Coil Units Deliver Quiet, Efficient Comforthector martinezÎncă nu există evaluări

- Ficha Tecnica y Certificado Ul Puerta CortafuegoDocument8 paginiFicha Tecnica y Certificado Ul Puerta CortafuegoAndres Ruiz HuamanÎncă nu există evaluări

- Trane Concealed DuctingDocument9 paginiTrane Concealed DuctingDiar RachmaningtyasÎncă nu există evaluări

- Six Zone Fire Alarm SystemDocument2 paginiSix Zone Fire Alarm SystemPablo Jesús Huapaya ChumpitazÎncă nu există evaluări

- Teodolito Con Distanciometro South NT-023Document2 paginiTeodolito Con Distanciometro South NT-023JoséLuis100% (1)

- Temspec Hi-Rise BookDocument35 paginiTemspec Hi-Rise Bookvn8480Încă nu există evaluări

- Tabla de Torque - HdpeDocument3 paginiTabla de Torque - HdpeDevi SalcedoÎncă nu există evaluări

- Manual Servicios LG Aruv PDFDocument42 paginiManual Servicios LG Aruv PDFHERIBERTOÎncă nu există evaluări

- Especificacion de TanquesDocument3 paginiEspecificacion de TanquesRoberto EnriquezÎncă nu există evaluări

- خزانات ضغط ستارايتDocument4 paginiخزانات ضغط ستارايتwpt_meÎncă nu există evaluări

- 50 - Model FP 420 BFDocument2 pagini50 - Model FP 420 BFAdriano Moyses OutlookÎncă nu există evaluări

- 52 - Model FP 43q BFDocument2 pagini52 - Model FP 43q BFAdriano Moyses OutlookÎncă nu există evaluări

- 49 - Model FP 430 UfDocument2 pagini49 - Model FP 430 UfAdriano Moyses OutlookÎncă nu există evaluări

- MyersDocument3 paginiMyersJuan Camilo Tejada OrjuelaÎncă nu există evaluări

- Catalog Series 212 Composite Asco Global en 3674082Document5 paginiCatalog Series 212 Composite Asco Global en 3674082LuisÎncă nu există evaluări

- Bermad: FP/FS 400Y Torrent Valve Engineering DataDocument12 paginiBermad: FP/FS 400Y Torrent Valve Engineering Dataeitan-daliaÎncă nu există evaluări

- Asco Series 316 Air Water CatalogDocument4 paginiAsco Series 316 Air Water CatalogekoÎncă nu există evaluări

- Burmad 400 Series-Globe Type Deluge ValveDocument8 paginiBurmad 400 Series-Globe Type Deluge Valvenastyn-1Încă nu există evaluări

- Series 825YD Specification SheetDocument2 paginiSeries 825YD Specification SheetFEBCOÎncă nu există evaluări

- Nibco Wafer Style Twin Disc Ductile Iron Check ValveDocument1 paginăNibco Wafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaÎncă nu există evaluări

- Back Pressure Valve Tech SheetDocument2 paginiBack Pressure Valve Tech SheetchenguemoralesÎncă nu există evaluări

- LcaDocument26 paginiLcaProingmeca CAÎncă nu există evaluări

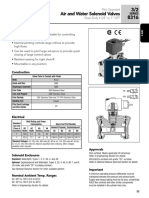

- Pilot Operated Air and Water Solenoid ValvesDocument4 paginiPilot Operated Air and Water Solenoid ValvesDevinÎncă nu există evaluări

- DP Series Wafer Check Valve CiDocument2 paginiDP Series Wafer Check Valve CiAerox neoÎncă nu există evaluări

- MAR - GI Pipes & Fittings - 02.08.22Document107 paginiMAR - GI Pipes & Fittings - 02.08.22Ansaf AskyÎncă nu există evaluări

- 400Y Torrent Engineering - v27 PDFDocument16 pagini400Y Torrent Engineering - v27 PDFKrishna N HÎncă nu există evaluări

- Catalog Series 223 Asco en 3674094Document2 paginiCatalog Series 223 Asco en 3674094LouisÎncă nu există evaluări

- DEN-JET CE20 SERIES HIGH PRESSURE WATER BLASTERSDocument2 paginiDEN-JET CE20 SERIES HIGH PRESSURE WATER BLASTERSSoloniainaÎncă nu există evaluări

- Wellforce PDFDocument2 paginiWellforce PDFMark Joey David0% (1)

- Asco8210 PDFDocument6 paginiAsco8210 PDFoscar_rent_torresÎncă nu există evaluări

- Drawing 80H30Document3 paginiDrawing 80H30kpranjal15Încă nu există evaluări

- 701-40-010 Avkcms en 430527Document2 pagini701-40-010 Avkcms en 430527Aleksandar PetrovićÎncă nu există evaluări

- Asco Series 344 Piston Poppet CatalogDocument4 paginiAsco Series 344 Piston Poppet CatalogSANKAR SIVANÎncă nu există evaluări

- Air and Water Solenoid Valves: FeaturesDocument4 paginiAir and Water Solenoid Valves: FeaturesZuñiga AntonioÎncă nu există evaluări

- FT - 8210 - V. SolenoideDocument6 paginiFT - 8210 - V. SolenoideClaudia Patricia Carazas SarmientoÎncă nu există evaluări

- Affordable Convertibility: Pressures To 10,000 PSI Flows To 200 GPM Power To 600 HPDocument2 paginiAffordable Convertibility: Pressures To 10,000 PSI Flows To 200 GPM Power To 600 HPDyddier RojasÎncă nu există evaluări

- QF-450HC 2016Document2 paginiQF-450HC 2016David BahenaÎncă nu există evaluări

- Asco Series 290 Angle Body CatalogDocument10 paginiAsco Series 290 Angle Body CatalogcillongÎncă nu există evaluări

- 5417 Installation Kennet CentrifugalDocument20 pagini5417 Installation Kennet Centrifugalbayu kusumaÎncă nu există evaluări

- Drawing 80AQ15-60 Non CodedDocument2 paginiDrawing 80AQ15-60 Non Codeddaus nasÎncă nu există evaluări

- 01 Rubber HoseDocument26 pagini01 Rubber Hosewenny_tpdÎncă nu există evaluări

- High Flow Direct Acting Valves: FeaturesDocument2 paginiHigh Flow Direct Acting Valves: FeaturesBurhan AyubÎncă nu există evaluări

- USF Series: ASME Code Multi-Cartridge Filter Housings-Four Through Fifty-Two RoundDocument2 paginiUSF Series: ASME Code Multi-Cartridge Filter Housings-Four Through Fifty-Two Roundprabal rayÎncă nu există evaluări

- Fast & Affordable Convertibility: Pressures To 20,000 PSI Flows To 54 GPM Power To 330 HPDocument2 paginiFast & Affordable Convertibility: Pressures To 20,000 PSI Flows To 54 GPM Power To 330 HPFrederik CañabiÎncă nu există evaluări

- BV502Document3 paginiBV502plvillarrealÎncă nu există evaluări

- THERMAL COMFORT OPTIMIZATIONDocument10 paginiTHERMAL COMFORT OPTIMIZATIONCharlie MartinezÎncă nu există evaluări

- Introduction To FAN SELECTION: Model DesignationDocument5 paginiIntroduction To FAN SELECTION: Model Designationradreamer14Încă nu există evaluări

- Kent Benson: SOLICITATION NUMBER: 72051921R10015 Issuance Date: Closing Date/TimeDocument10 paginiKent Benson: SOLICITATION NUMBER: 72051921R10015 Issuance Date: Closing Date/TimeCharlie MartinezÎncă nu există evaluări

- Amisol Trio™: Skin Barrier and Hair ConditionerDocument18 paginiAmisol Trio™: Skin Barrier and Hair ConditionerCharlie MartinezÎncă nu există evaluări

- DUCT - Duct System Sizing Program: PurposeDocument7 paginiDUCT - Duct System Sizing Program: PurposeCharlie MartinezÎncă nu există evaluări

- DOE 2.2 - Libraries & ReportsDocument286 paginiDOE 2.2 - Libraries & ReportsCharlie MartinezÎncă nu există evaluări

- Art. 44o NECDocument4 paginiArt. 44o NECCharlie MartinezÎncă nu există evaluări

- AAA Dimensiones de Perfil HDocument3 paginiAAA Dimensiones de Perfil HCharlie MartinezÎncă nu există evaluări

- Hvac Myths Realities 2017Document110 paginiHvac Myths Realities 2017Daniel Michel AndradeÎncă nu există evaluări

- Pressurization CodesDocument23 paginiPressurization CodesCharlie MartinezÎncă nu există evaluări

- Catologo Lennox Xc20 - Elite SeriesDocument20 paginiCatologo Lennox Xc20 - Elite SeriesCharlie MartinezÎncă nu există evaluări

- Manometro Presion Diferencial PDFDocument1 paginăManometro Presion Diferencial PDFCharlie MartinezÎncă nu există evaluări

- Motor Protection Selection TablesDocument1 paginăMotor Protection Selection TablesCharlie MartinezÎncă nu există evaluări

- Catologo Lennox Cbx32mv - Elite SeriesDocument28 paginiCatologo Lennox Cbx32mv - Elite SeriesCharlie MartinezÎncă nu există evaluări

- Implementing Hot and Cold Air CONTAIMENT in Existing Data CenterDocument16 paginiImplementing Hot and Cold Air CONTAIMENT in Existing Data CenterSlobodanÎncă nu există evaluări

- Introduction To FAN SELECTION: Model DesignationDocument5 paginiIntroduction To FAN SELECTION: Model Designationradreamer14Încă nu există evaluări

- American Wire GaugeDocument3 paginiAmerican Wire GaugepalmalacÎncă nu există evaluări

- Hoja Tecnica de Motores WegDocument3 paginiHoja Tecnica de Motores WegCharlie MartinezÎncă nu există evaluări

- Equest Tutorial v364 PDFDocument151 paginiEquest Tutorial v364 PDFRaniPaviÎncă nu există evaluări

- HvacLoadExplorer ManualDocument52 paginiHvacLoadExplorer ManualCharlie MartinezÎncă nu există evaluări

- Pressurization CodesDocument23 paginiPressurization CodesCharlie MartinezÎncă nu există evaluări

- Brochure - Minisplit - Lennox (English)Document4 paginiBrochure - Minisplit - Lennox (English)Charlie MartinezÎncă nu există evaluări

- Chapter 1Document21 paginiChapter 1Charlie MartinezÎncă nu există evaluări

- ASME JHT Enthalpy 001605jhrDocument6 paginiASME JHT Enthalpy 001605jhrCharlie MartinezÎncă nu există evaluări

- Section 3 Basic OperationsDocument17 paginiSection 3 Basic OperationsCharlie MartinezÎncă nu există evaluări

- Manual Omron E5csDocument108 paginiManual Omron E5csFernando Barragán LúaÎncă nu există evaluări

- Clase 1Document38 paginiClase 1Charlie MartinezÎncă nu există evaluări

- T ESISDocument1 paginăT ESISCharlie MartinezÎncă nu există evaluări

- Clase 1Document9 paginiClase 1Charlie MartinezÎncă nu există evaluări

- Teodorico M. Collano, JR.: ENRM 223 StudentDocument5 paginiTeodorico M. Collano, JR.: ENRM 223 StudentJepoyCollanoÎncă nu există evaluări

- Ethanol: Safety Data SheetDocument19 paginiEthanol: Safety Data SheetNitika SinhaÎncă nu există evaluări

- Amber ToolsDocument309 paginiAmber ToolshkmydreamsÎncă nu există evaluări

- The Truth of Extinction: 7.1 Nietzsche's FableDocument2 paginiThe Truth of Extinction: 7.1 Nietzsche's FableGraciela Barón GuiñazúÎncă nu există evaluări

- How To Approach To Case Study Type Questions and MCQsDocument4 paginiHow To Approach To Case Study Type Questions and MCQsKushang ShahÎncă nu există evaluări

- Non-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesDocument2 paginiNon-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesveeramalaiÎncă nu există evaluări

- Final Term Quiz 2 On Cost of Production Report - Average CostingDocument4 paginiFinal Term Quiz 2 On Cost of Production Report - Average CostingYhenuel Josh LucasÎncă nu există evaluări

- What Is A Lecher AntennaDocument4 paginiWhat Is A Lecher AntennaPt AkaashÎncă nu există evaluări

- Quiz 1Document3 paginiQuiz 1JULIANNE BAYHONÎncă nu există evaluări

- Whirlpool FL 5064 (ET)Document8 paginiWhirlpool FL 5064 (ET)long_kongo100% (1)

- Mohammad Abu-Radi ResumeDocument4 paginiMohammad Abu-Radi ResumeMohammad Abu-RadiÎncă nu există evaluări

- Managerial Performance Evaluation ProceduresDocument3 paginiManagerial Performance Evaluation Procedures1robcortesÎncă nu există evaluări

- Giljang - Bsn2-A10 - Sas 1-3Document7 paginiGiljang - Bsn2-A10 - Sas 1-3Cherylen Casul GiljangÎncă nu există evaluări

- SEM 3037E Tower Piping.Document52 paginiSEM 3037E Tower Piping.Kodali Naveen KumarÎncă nu există evaluări

- Designers' Guide To Eurocode 7 Geothechnical DesignDocument213 paginiDesigners' Guide To Eurocode 7 Geothechnical DesignJoão Gamboias100% (9)

- Proejcr ManduaDocument552 paginiProejcr ManduaDanny NguyenÎncă nu există evaluări

- Sinavy Pem Fuel CellDocument12 paginiSinavy Pem Fuel CellArielDanieli100% (1)

- ResumeDocument5 paginiResumeSaeed SiriÎncă nu există evaluări

- (Math 6 WK 5 L9) - Problems Involving Addition and or Subtraction of DecimalsDocument43 pagini(Math 6 WK 5 L9) - Problems Involving Addition and or Subtraction of DecimalsRhea OciteÎncă nu există evaluări

- Rúbrica de composición escritaDocument2 paginiRúbrica de composición escritafrancisco alonsoÎncă nu există evaluări

- Language Culture and ThoughtDocument24 paginiLanguage Culture and ThoughtLý Hiển NhiênÎncă nu există evaluări

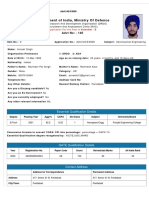

- DrdoDocument2 paginiDrdoAvneet SinghÎncă nu există evaluări

- 6 Main Rotor Config DesignDocument44 pagini6 Main Rotor Config DesignDeepak Paul TirkeyÎncă nu există evaluări

- Mock DataDocument56 paginiMock DataAnonymous O2bvbOuÎncă nu există evaluări

- DLP Din8Document2 paginiDLP Din8KOUDJIL MohamedÎncă nu există evaluări

- GCSE H3 02g4 02 3D TrigonometryDocument2 paginiGCSE H3 02g4 02 3D TrigonometryAndrei StanescuÎncă nu există evaluări

- Pop-Up SystemDocument4 paginiPop-Up Systemkothat82Încă nu există evaluări

- PMMAEE Application FormDocument2 paginiPMMAEE Application Formshiero501100% (15)

- Rules For Assigning Activity Points: Apj Abdul Kalam Technological UniversityDocument6 paginiRules For Assigning Activity Points: Apj Abdul Kalam Technological UniversityAnonymous KyLhn6Încă nu există evaluări

- Wiley Wesleyan UniversityDocument36 paginiWiley Wesleyan UniversityBirunda SilvaÎncă nu există evaluări