Documente Academic

Documente Profesional

Documente Cultură

FCU Specification For CUC PDF

Încărcat de

Li LiuTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

FCU Specification For CUC PDF

Încărcat de

Li LiuDrepturi de autor:

Formate disponibile

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

SECTION 238219 - FAN COIL UNITS

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary

Conditions and Division 01 Specification Sections, apply to this Section.

1.2 SUMMARY

A. This Section includes fan-coil units and accessories.

1.3 DEFINITIONS

A. BAS: Building automation system.

1.4 SUBMITTALS

A. Product Data: Include rated capacities, operating characteristics, furnished specialties, and

accessories.

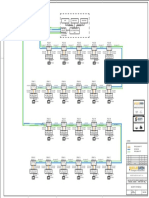

B. Shop Drawings: Detail equipment assemblies and indicate dimensions, weights, loads,

required clearances, method of field assembly, components, and location and size of each

field connection.

1. Wiring Diagrams: Power, signal, and control wiring.

C. Coordination Drawings: Floor plans, reflected ceiling plans, and other details, drawn to

scale, on which the following items are shown and coordinated with each other, based on

input from installers of the items involved:

1. Ceiling suspension components.

2. Structural members to which fan-coil units will be attached.

3. Method of attaching hangers to building structure.

4. Size and location of initial access modules for acoustical tile.

5. Items penetrating finished ceiling, including the following:

a. Lighting fixtures.

b. Air outlets and inlets.

c. Speakers.

d. Sprinklers.

e. Access panels.

6. Perimeter moldings for exposed or partially exposed cabinets.

D. Samples for Initial Selection: For units with factory-applied color finishes.

E. Samples for Verification: For each type of fan-coil unit indicated.

FAN COIL UNIT 238219 - Page 1 of 6

E18066-0105D-DD-17-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

F. Manufacturer Seismic Qualification Certification: Submit certification that fan-coil units,

accessories, and components will withstand seismic forces defined in Division 23 Section

"Vibration and Seismic Controls for HVAC Piping and Equipment." Include the following:

1. Basis for Certification: Indicate whether withstand certification is based on actual

test of assembled components or on calculation.

a. The term "withstand" means "the unit will remain in place without separation

of any parts from the device when subjected to the seismic forces specified."

b. The term "withstand" means "the unit will remain in place without separation

of any parts from the device when subjected to the seismic forces specified and

the unit will be fully operational after the seismic event."

2. Dimensioned Outline Drawings of Equipment Unit: Identify center of gravity and

locate and describe mounting and anchorage provisions.

3. Detailed description of equipment anchorage devices on which the certification is

based and their installation requirements.

G. Field quality-control test reports.

H. Operation and Maintenance Data: For fan-coil units to include in emergency, operation, and

maintenance manuals. In addition to items specified in Division 01 Section "Operation and

Maintenance Data," include the following:

1. Maintenance schedules and repair part lists for motors, coils, integral controls, and

filters.

I. Warranty: Special warranty specified in this Section.

1.5 QUALITY ASSURANCE

A. Electrical Components, Devices, and Accessories: Listed and labeled as defined in

NFPA 70, Article 100, by a testing agency acceptable to authorities having jurisdiction, and

marked for intended use.

B. ASHRAE Compliance: Applicable requirements in ASHRAE 62.1, Section 5 - "Systems

and Equipment" and Section 7 - "Construction and Startup."

C. ASHRAE/IESNA 90.1 Compliance: Applicable requirements in ASHRAE/IESNA 90.1,

Section 6 - "Heating, Ventilating, and Air-Conditioning."

D. If the Contractor believes there are conflicts or missing information in the project

documents, the Contractor shall promptly request clarification and instruction from the

design team before the bids opening, otherwise the Contactor shall furnish and handover the

works at no additional cost to the Contract and according to Engineer instructions.

1.6 COORDINATION

A. Coordinate layout and installation of fan-coil units and suspension system components with

other construction that penetrates or is supported by ceilings, including light fixtures, HVAC

equipment, fire-suppression-system components, and partition assemblies.

FAN COIL UNIT 238219 - Page 2 of 6

E18066-0105D-DD-17-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

1.7 WARRANTY

A. Special Warranty: Manufacturer's standard form in which manufacturer agrees to repair or

replace components of condensing units that fail in materials or workmanship within

specified warranty period.

1. Warranty Period: Four years from date of Substantial Completion.

2. Provide system warranty in which Manufacturer, Installer, and Contractor are jointly

and severally liable and agree to repair or replace defective components of the

warranted item.

Warranty shall include:

a. Defective materials and installation.

b. Failure to comply with requirements stated in technical specifications.

c. Structural failures including, but not limited to, excessive deflection.

d. Faulty operation of movable parts such as hardware.

e. Deterioration of metals, metal finishes, and other materials beyond normal

weathering and use.

f. Delamination of exterior or interior facing materials.

g. Making good and installation and finishing all items that are disturbed and that

may be required due to repair or replacement of defective items. Coordinate

with Employer, manufacturer, and installer of adjacent disturbed items to

ensure that their warranty is not cancelled due to the repair work.

1.8 EXTRA MATERIALS

A. Furnish extra materials described below that match products installed and that are packaged

with protective covering for storage and identified with labels describing contents.

1. Fan-Coil-Unit Filters: Furnish spare filters for each filter installed.

2. Fan Belts: Furnish spare fan belts for each unit installed.

PART 2 - PRODUCTS

2.1 HORIZONTAL AND VERTICAL TYPE-CONCEALED

A. Units of blow through design complete with fans, motors, insulated drain pan, insulated

auxiliary drain pan and water coil, as follows:

1. 1.2mm galvanized steel housing fully lined with 15mm, elastomeric acoustic and

thermal insulation.

FAN COIL UNIT 238219 - Page 3 of 6

E18066-0105D-DD-17-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

2. Fabricate main drain pan, extended type, and auxiliary drain pan of 1.2mm

galvanized steel and line them with a closed cell, fire retardant, sound foam

insulation.

3. Fans are to be centrifugal, forward curved, DWDI direct connected type, dynamically

and statically balanced. Construct the blower assembly of galvanized steel or

thermoplastic material.

4. Motors are to be 3-speed tap wound; permanent split capacitor type with UL listed

thermal overload protection. Arrange the motor blower assembly for easy removal,

including a quick disconnect on the motor cord. Include sleeve type or ball bearing

type motor bearings with oil tubes and oversized oil reservoirs.

5. Coil no less than 4-rows deep, fabricated of 3/8” or larger nominal size copper tubes

and aluminum fins mechanically bonded to the tubes with minimum spacing between

fins 2.5mm. Include a manual air vent discharging to the drain pan and a drain cock.

Factory leak test at 2,410 KPa and rate coils at a working pressure of 2,067 KPa.

6. Provide mounting brackets for ceiling suspension, including approved vibration

elimination devices and discharge duct collar.

7. All electric wiring between the fan motor, unit mounted controls and junction box

mounted on the unit will be run in BX cable and factory installed by the

manufacturer. Provide suitable terminals for field connections of power and

thermostat and valve control wiring.

8. Units are to be provided complete with integral unit controller which shall be capable

of two-way communication with the site wide BEMS and shall enable the fan coil

unit to operate to the temperature set-point and time schedule provided by the BEMS.

The unit controller shall be capable of continuous operation based on the last set of

time schedule and temperature set-points received from the central BEMS should

site-side communications fail. Refer to control and building management system

documents for detailed requirements.

9. Sound-power-level, decibels reference, 10 to the minus 12 power watt, at the fan

operating speed selected to meet the specified capacity, shall not exceed the following

values at the midfrequency of each octave band:

Frequency

(hertz) 250 500 1,000 2,000 4,000

Power Level 60 55 53 50 48

10. Sound-power-level data or values for these units shall be obtained in accordance with

the test procedures specified in ANSI/ASA S12.23. Sound-power values apply to

units provided with factory-fabricated cabinet enclosures and standard grilles. Values

obtained for the standard cabinet models will be acceptable for concealed models

without separate tests provided there is no variation between models as to the coil

configuration, blowers, motor speeds, or relative arrangement of parts. Each unit shall

be fastened securely to the building structure.

FAN COIL UNIT 238219 - Page 4 of 6

E18066-0105D-DD-17-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

PART 3 - EXECUTION

3.1 EXAMINATION

A. Examine areas to receive fan-coil units for compliance with requirements for installation

tolerances and other conditions affecting performance.

B. Examine roughing-in for piping and electrical connections to verify actual locations before

fan-coil-unit installation.

C. Proceed with installation only after unsatisfactory conditions have been corrected.

3.2 INSTALLATION

A. Install fan-coil units level and plumb.

B. Install fan-coil units to comply with NFPA 90A.

C. Suspend fan-coil units from structure with elastomeric hangers. Vibration isolators are

specified in Division 23 Section "Vibration and Seismic Controls for HVAC Piping and

Equipment."

D. Verify locations of thermostats, humidistats, and other exposed control sensors with

Drawings and room details before installation. Install devices 1525 mm above finished

floor.

E. Install new filters in each fan-coil unit within two weeks after Substantial Completion.

3.3 CONNECTIONS

A. Piping installation requirements are specified in other Division 23 Sections. Drawings

indicate general arrangement of piping, fittings, and specialties. Specific connection

requirements are as follows:

1. Install piping adjacent to machine to allow service and maintenance.

2. Connect piping to fan-coil-unit factory hydronic piping package. Install piping

package if shipped loose.

3. Connect condensate drain to indirect waste.

a. Install condensate trap of adequate depth to seal against the pressure of fan.

Install cleanouts in piping at changes of direction.

B. Connect supply and return ducts to fan-coil units with flexible duct connectors specified in

Division 23 Section "Air Duct Accessories." Comply with safety requirements in UL 1995

for duct connections.

C. Ground equipment according to Division 26 Section "Grounding and Bonding for Electrical

Systems."

FAN COIL UNIT 238219 - Page 5 of 6

E18066-0105D-DD-17-G00-SPC-ME-01 REV 0

S-ar putea să vă placă și

- HAP 4.2 ManualDocument148 paginiHAP 4.2 ManualMohamed Abdel Monem .Chicco80% (5)

- 9 - E09 LuandryDocument53 pagini9 - E09 LuandryLi LiuÎncă nu există evaluări

- Central Business District CBD EAST - Phase 1 of The New Administrative CapitalDocument20 paginiCentral Business District CBD EAST - Phase 1 of The New Administrative CapitalLi LiuÎncă nu există evaluări

- Annex 1 GA DrawingsDocument1 paginăAnnex 1 GA DrawingsLi LiuÎncă nu există evaluări

- Ultrasonic Examination Procedure (Issue 2)Document14 paginiUltrasonic Examination Procedure (Issue 2)Li Liu100% (1)

- AHU Selection Details and ClarificationDocument1 paginăAHU Selection Details and ClarificationLi LiuÎncă nu există evaluări

- Compliance Statement for Cooling TowersDocument39 paginiCompliance Statement for Cooling TowersLi LiuÎncă nu există evaluări

- 1.2 Sample ITPDocument1 pagină1.2 Sample ITPLi LiuÎncă nu există evaluări

- Technical specifications and compliance review for cooling tower installationDocument5 paginiTechnical specifications and compliance review for cooling tower installationLi LiuÎncă nu există evaluări

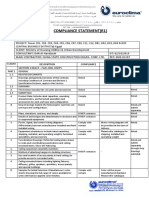

- Fan-Coil Units Compliance Statement for Egypt Tower ProjectsDocument9 paginiFan-Coil Units Compliance Statement for Egypt Tower ProjectsLi Liu100% (1)

- Psychrometric Analyzer Version 6.8 by Mcquay InternationalDocument1 paginăPsychrometric Analyzer Version 6.8 by Mcquay InternationalLi LiuÎncă nu există evaluări

- Annex 5 API 650 Storage Tanks Certificate of Compliance SampleDocument3 paginiAnnex 5 API 650 Storage Tanks Certificate of Compliance SampleLi LiuÎncă nu există evaluări

- Magnetic Particle Examination Report: Project: .........................................Document1 paginăMagnetic Particle Examination Report: Project: .........................................Li LiuÎncă nu există evaluări

- Painting Procedure: Total Solutions Integrated ServicesDocument9 paginiPainting Procedure: Total Solutions Integrated ServicesLi LiuÎncă nu există evaluări

- Annex 4.5 API 650 Storage Tanks Certificate of Compliance SampleDocument1 paginăAnnex 4.5 API 650 Storage Tanks Certificate of Compliance SampleLi LiuÎncă nu există evaluări

- Tank Data Sheet Rev CCDocument2 paginiTank Data Sheet Rev CCLi LiuÎncă nu există evaluări

- Hydrostatic Testing ProceduresDocument3 paginiHydrostatic Testing ProceduresLi LiuÎncă nu există evaluări

- Magnetic Particle Examination Report: Project: .........................................Document1 paginăMagnetic Particle Examination Report: Project: .........................................Li LiuÎncă nu există evaluări

- Roof Design CalculationsDocument4 paginiRoof Design CalculationsLi LiuÎncă nu există evaluări

- TS Vacumm FormDocument1 paginăTS Vacumm FormLi LiuÎncă nu există evaluări

- Quality Control Plan: Elevated Temperatures Storage TankDocument6 paginiQuality Control Plan: Elevated Temperatures Storage TankLi LiuÎncă nu există evaluări

- TS RT FormDocument1 paginăTS RT FormLi LiuÎncă nu există evaluări

- Hydrostatic Test ReportDocument1 paginăHydrostatic Test ReportLi LiuÎncă nu există evaluări

- Bottom Design CalculationsDocument5 paginiBottom Design CalculationsLi LiuÎncă nu există evaluări

- Total Solutions LTD., Egypt: Design Appraisal DocumentDocument2 paginiTotal Solutions LTD., Egypt: Design Appraisal DocumentLi LiuÎncă nu există evaluări

- Response To SCG Comment-29June2020Document1 paginăResponse To SCG Comment-29June2020Li LiuÎncă nu există evaluări

- Shell Design CalculationsDocument35 paginiShell Design CalculationsLi LiuÎncă nu există evaluări

- Ifc Check & Revise Record - Cbd-Cuc-E04-El-001Document3 paginiIfc Check & Revise Record - Cbd-Cuc-E04-El-001Li LiuÎncă nu există evaluări

- Mat Cscec 00 Me PL 0110 01Document2 paginiMat Cscec 00 Me PL 0110 01Li LiuÎncă nu există evaluări

- Ifc Check & Revise Record - Cbd-Cuc-E01-El-001Document17 paginiIfc Check & Revise Record - Cbd-Cuc-E01-El-001Li LiuÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Lenovo Storage d1212 PDFDocument2 paginiLenovo Storage d1212 PDFOussama BennaniÎncă nu există evaluări

- NMS 2-MS-Rectification of Excess Gap Between The Door Frame and WallDocument8 paginiNMS 2-MS-Rectification of Excess Gap Between The Door Frame and WallsathiyaprasathÎncă nu există evaluări

- Door Schedule Door TypesDocument1 paginăDoor Schedule Door TypesPau LlenaÎncă nu există evaluări

- LogRhythm File Integrity Monitoring Data SheetDocument1 paginăLogRhythm File Integrity Monitoring Data SheetjordagroÎncă nu există evaluări

- Frequently Asked Questions GigEVDocument4 paginiFrequently Asked Questions GigEVRehan AhmadÎncă nu există evaluări

- Excel 2003 Online Keyboard ShortcutsDocument13 paginiExcel 2003 Online Keyboard ShortcutsShishir ModakÎncă nu există evaluări

- Micrologix 1400 ComunicationDocument15 paginiMicrologix 1400 ComunicationSaddam HusainÎncă nu există evaluări

- About Trail and Training FilesDocument15 paginiAbout Trail and Training FilesAziz Abbas0% (1)

- Designing an efficient hospital outpatient departmentDocument17 paginiDesigning an efficient hospital outpatient departmentVenkat100% (3)

- Flash CS3 Practical 5Document9 paginiFlash CS3 Practical 5EngSoonCheahÎncă nu există evaluări

- Boris Groys - Self Design and Public SpaceDocument6 paginiBoris Groys - Self Design and Public SpaceMartaÎncă nu există evaluări

- Archicad 21 BrochureDocument8 paginiArchicad 21 BrochureVa LiÎncă nu există evaluări

- Praveen TK PDFDocument10 paginiPraveen TK PDFPraveen KuralÎncă nu există evaluări

- Inno Monitor Q&ADocument3 paginiInno Monitor Q&Ajose navarroÎncă nu există evaluări

- Keylogger in CDocument3 paginiKeylogger in CPrashant UniyalÎncă nu există evaluări

- Karnataka Housing Board Suvarna Karnataka Housing Programme: Detaails of Completed ProjectsDocument3 paginiKarnataka Housing Board Suvarna Karnataka Housing Programme: Detaails of Completed ProjectsRavi KumarÎncă nu există evaluări

- Boq-Ac For Esd PremisesDocument11 paginiBoq-Ac For Esd Premisesfarshan296015Încă nu există evaluări

- Unit 1: Q2e Listening & Speaking 2: Audio ScriptDocument2 paginiUnit 1: Q2e Listening & Speaking 2: Audio ScriptAnh DangÎncă nu există evaluări

- Voip Codecs - FAQSDocument3 paginiVoip Codecs - FAQSNaim100% (5)

- Bsl1-Ele-032 Security System SLD .Rev 0Document1 paginăBsl1-Ele-032 Security System SLD .Rev 0jdzarzalejoÎncă nu există evaluări

- Asus A8n Sli PremiumDocument88 paginiAsus A8n Sli Premiumjohn.aboodÎncă nu există evaluări

- Shura IslandDocument7 paginiShura IslandMohamed ElbanaÎncă nu există evaluări

- Top 40 Character Fit-testing Consultants ListDocument15 paginiTop 40 Character Fit-testing Consultants ListGabriel AlvesÎncă nu există evaluări

- QnUCPU UserManual CommunicationViaBuiltInEthernetPort SH 080811 IDocument156 paginiQnUCPU UserManual CommunicationViaBuiltInEthernetPort SH 080811 IEvandro OrtegaÎncă nu există evaluări

- Cable Suspended Roof StructureDocument12 paginiCable Suspended Roof StructureAkshay Chaudhari75% (4)

- Specs for Underground Fire TanksDocument5 paginiSpecs for Underground Fire TanksTeguh SetionoÎncă nu există evaluări

- DSP Architecture PDFDocument353 paginiDSP Architecture PDFNhật TrungÎncă nu există evaluări

- WebCenter Sites Avanzado - v2Document130 paginiWebCenter Sites Avanzado - v2Demon_TigerÎncă nu există evaluări

- Iglu'® Ventilated Roof - Disposable Formwork For Sloped or Flat Ventilated RoofsDocument7 paginiIglu'® Ventilated Roof - Disposable Formwork For Sloped or Flat Ventilated RoofsDaliform GroupÎncă nu există evaluări