Documente Academic

Documente Profesional

Documente Cultură

Eng GB20044112A

Încărcat de

Burik8Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Eng GB20044112A

Încărcat de

Burik8Drepturi de autor:

Formate disponibile

VOLVO CONSTRUCTION EQUIPMENT

Service Programme

L60G Z, L90G Z

Machine Model Serial No. Operating hours

SERVICE PROGRAMMEDelivery Date page

1(3)

Owner Date Dealer Sign

Foreword

A Service Programme is a summary of all maintenance intervals

for a specific range of models and it is to be used as a check list

during maintenance inspections. Service Programme shows only

intervals under standard operating conditions.

For any factory warranty to be valid, the machine has to be

maintained according to this Service Programme.

All service steps listed in the columns "First" should be performed

by an authorized Volvo dealer.

Service steps listed in the columns "First" and "Additional

intervals" have to be performed in addition to the "Standard

intervals".

Service steps with varying intervals are marked with *. Further

information can be found in the Service Manual.

NOTE!

Please pay attention to the safety instructions in the Operator's

and Service Manuals concerned.

Additional

interval,

OPERATING HOURS / INTERVAL First Standard intervals every

1000 50 250 500 1000 2000 4000 6000

Basic service

Engine oil level, checking

Lubrication

Tyres, wear and air pressure, checking

Oil-bath air cleaner reservoir oil, checking

(Optional equipment)

Oil-bath air cleaner reservoir oil, changing

(Optional equipment)

Battery, checking

Engine oil and filter, changing

*

Fuel filters, replacing

Extra fuel prefilter, replacing(optional

equipment)

Ref no: PUB 20044112-A English

2015.05

Volvo Construction Equipment

Please send comments about the Service Programme to sp@volvo.com

VOLVO CONSTRUCTION EQUIPMENT

SERVICE PROGRAMME

Machine Model Serial No. Operating hours Delivery Date page

2(3)

Additional

interval,

OPERATING HOURS / INTERVAL First Standard intervals every

1000 50 250 500 1000 2000 4000 6000

Transmission oil level, checking

Hydraulic oil level, checking

Automatic central lubrication filter,

replacing

Coolers, cleaning

Service brakes function, checking

Parking brake function, checking

Hydraulic tank sediment, draining

Cab prefilter, replacing

Service brake disc wear, checking

Hinge, lubricating

Engine air cleaner primary filter, replacing

Engine belt condition, checking

Engine air cleaner secondary filter,

replacing

Oil-bath air cleaner reservoir filter insert,

cleaning

(Optional equipment)

Fuel tank breather filter, replacing

Coolant freezing point, checking

Hydraulic tank return oil filter and magnetic

rod, cleaning and replacing

Hydraulic oil tank breather filter, replacing

Cab main filter, replacing

Valves, adjusting

Drive axle oil, changing

Axle, breather filters, replacing

Hydraulic transmission, oil and filter

replacing. Strainer cleaning.

*

Hydraulic oil, changing

*

Coolant, changing

VOLVO CONSTRUCTION EQUIPMENT

SERVICE PROGRAMME

Machine Model Serial No. Operating hours Delivery Date page

3(3)

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Replace Oil Pan and Level Gauge Parts ListDocument2 paginiReplace Oil Pan and Level Gauge Parts ListBurik8Încă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Um3ab1 Head CoverDocument2 paginiUm3ab1 Head CoverBurik8Încă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Um2kc1 ElectricalDocument2 paginiUm2kc1 ElectricalBurik8Încă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

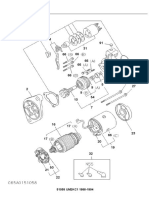

- Um2kc1 StarterDocument2 paginiUm2kc1 StarterBurik8Încă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Um2kc1 Sea Water PumpDocument2 paginiUm2kc1 Sea Water PumpBurik8Încă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Um2kc1 Fuel FilterDocument2 paginiUm2kc1 Fuel FilterBurik8Încă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Um2kc1 Sea Water PipeDocument2 paginiUm2kc1 Sea Water PipeBurik8Încă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- PARTS LISTDocument2 paginiPARTS LISTBurik8100% (1)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Um2kc1 Air DuctDocument2 paginiUm2kc1 Air DuctBurik8Încă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- Timing Chain CaseDocument3 paginiTiming Chain CaseBurik8Încă nu există evaluări

- Engine Electrical Control PartsDocument2 paginiEngine Electrical Control PartsBurik8Încă nu există evaluări

- Um2kc1 GeneratorDocument4 paginiUm2kc1 GeneratorBurik8Încă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- 0-50A Oil Cooler and Oil FilterDocument2 pagini0-50A Oil Cooler and Oil FilterBurik8Încă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Um2kc1 Fuel PumpDocument2 paginiUm2kc1 Fuel PumpBurik8Încă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- UM2KC1 ThermostatDocument2 paginiUM2KC1 ThermostatBurik8Încă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- 0-33A Fan and Fan BeltDocument2 pagini0-33A Fan and Fan BeltBurik8Încă nu există evaluări

- UM2KC1 Water PipingDocument2 paginiUM2KC1 Water PipingBurik8Încă nu există evaluări

- Um2kc1 Fuel InjectionDocument6 paginiUm2kc1 Fuel InjectionBurik8Încă nu există evaluări

- Water Pump and Corrosion ResistorDocument2 paginiWater Pump and Corrosion ResistorBurik8Încă nu există evaluări

- 0-22A Engine MountingDocument2 pagini0-22A Engine MountingBurik8Încă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Um2kc1 Oil PanDocument2 paginiUm2kc1 Oil PanBurik8Încă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

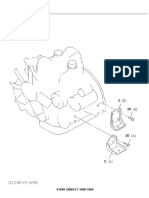

- Timing Gear Case and Flywheel HousingDocument3 paginiTiming Gear Case and Flywheel HousingBurik8Încă nu există evaluări

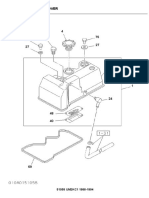

- Um2kc1 Cylinder Head CoverDocument2 paginiUm2kc1 Cylinder Head CoverBurik8Încă nu există evaluări

- Crankshaft, Piston and FlywheelDocument3 paginiCrankshaft, Piston and FlywheelBurik8Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Um2kc1 Oil PanDocument2 paginiUm2kc1 Oil PanBurik8Încă nu există evaluări

- Sea water pipe parts for 1988-1994 Honda 2KC1 marine enginesDocument2 paginiSea water pipe parts for 1988-1994 Honda 2KC1 marine enginesBurik8Încă nu există evaluări

- Umkc1 CamshaftDocument3 paginiUmkc1 CamshaftBurik8Încă nu există evaluări

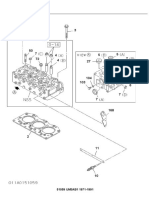

- Um2kc1 Cylinder HeadDocument3 paginiUm2kc1 Cylinder HeadBurik8Încă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Um2kc1 Air DuctDocument2 paginiUm2kc1 Air DuctBurik8Încă nu există evaluări

- Um2kc1 Sea Water PumpDocument2 paginiUm2kc1 Sea Water PumpBurik8Încă nu există evaluări

- CAT - 3126B.Prefix 1BWDocument7 paginiCAT - 3126B.Prefix 1BWPhil B.Încă nu există evaluări

- Refrigeration and Air Conditioning NotesDocument11 paginiRefrigeration and Air Conditioning NotesBALAMUGUNDAN82% (51)

- Hydraulic System: 5.1 Location of Main Hydraulic ComponentsDocument53 paginiHydraulic System: 5.1 Location of Main Hydraulic ComponentsMinh TânÎncă nu există evaluări

- Seneca PA34 01Document2 paginiSeneca PA34 01Abhijith JayakumarÎncă nu există evaluări

- HSC Crane scx1800Document56 paginiHSC Crane scx1800Abdur RahimÎncă nu există evaluări

- Low Voltage Products: Switches Rotary Cam Switches, Enclosed Cam Switches OM, ON and OLDocument68 paginiLow Voltage Products: Switches Rotary Cam Switches, Enclosed Cam Switches OM, ON and OLFabianÎncă nu există evaluări

- Operation & Maintenance: A160-Om-C-May15Document66 paginiOperation & Maintenance: A160-Om-C-May15Thomas AliÎncă nu există evaluări

- 2000 HP SCR Drilling Rig SpecificationsDocument24 pagini2000 HP SCR Drilling Rig Specificationsfatehul alam100% (2)

- George Ferris Unit StudyDocument10 paginiGeorge Ferris Unit StudyNancy LozanoÎncă nu există evaluări

- Six simple machines that make work easierDocument4 paginiSix simple machines that make work easierRuel GuiangÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Perancangan Mesin Pengering Vertikal Dengan Pengadukan Mekanik Untuk Biji-BijianDocument8 paginiPerancangan Mesin Pengering Vertikal Dengan Pengadukan Mekanik Untuk Biji-BijianPribadyoÎncă nu există evaluări

- Freelander Electrical Circuit DiagramsDocument74 paginiFreelander Electrical Circuit DiagramsElenaBaciu100% (2)

- Wiring DiagramDocument100 paginiWiring Diagramirfan100% (4)

- FS 2000 3900 4000ENPLR1 - PartsDocument52 paginiFS 2000 3900 4000ENPLR1 - PartsRaymond ZhaoÎncă nu există evaluări

- National HVAC Commissioning Checklist ENERGY STAR Certified Homes, Version 3 / 3.1 (Rev. 10)Document2 paginiNational HVAC Commissioning Checklist ENERGY STAR Certified Homes, Version 3 / 3.1 (Rev. 10)Gokulan LoganathanÎncă nu există evaluări

- Free PistonDocument7 paginiFree PistonpaulwaÎncă nu există evaluări

- Rov Dredge Pump Excavation Jetting Tritech MerlinDocument2 paginiRov Dredge Pump Excavation Jetting Tritech MerlinCleoÎncă nu există evaluări

- Advantages of HFSR Soft Starters Over Traditional StarterDocument1 paginăAdvantages of HFSR Soft Starters Over Traditional StartergagaresantoshÎncă nu există evaluări

- Otating Ontrol Evices: T M S ADocument11 paginiOtating Ontrol Evices: T M S ANeme VasquesÎncă nu există evaluări

- Turbine User Manual - Super Smelters LTD (1) - W. O.no. C-2567Document200 paginiTurbine User Manual - Super Smelters LTD (1) - W. O.no. C-2567snehasish sowÎncă nu există evaluări

- Bronze Safety Relief Valve: SV-B27 SVP-B27 SV-B29 SVP-B29Document1 paginăBronze Safety Relief Valve: SV-B27 SVP-B27 SV-B29 SVP-B29Shishan Ahmad100% (1)

- Flywheel Function and Engine DynamicsDocument118 paginiFlywheel Function and Engine DynamicsSathiez SathishÎncă nu există evaluări

- Klinger Marine Valves & GasketsDocument279 paginiKlinger Marine Valves & GasketsAndy Luthor100% (1)

- VG7 XVS - M PDFDocument1 paginăVG7 XVS - M PDFluis acostaÎncă nu există evaluări

- Vertical Machining Center: SMEC Co., LTDDocument8 paginiVertical Machining Center: SMEC Co., LTDsunhuynhÎncă nu există evaluări

- Agg Power ProfileDocument16 paginiAgg Power ProfileHENRYÎncă nu există evaluări

- Lhani 207 Scan 1Document2 paginiLhani 207 Scan 1max netÎncă nu există evaluări

- INTERNAL EXPANDING BRAKE DESIGN AND WORKING (39Document5 paginiINTERNAL EXPANDING BRAKE DESIGN AND WORKING (39Karansingh KhatriÎncă nu există evaluări

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDe la EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestEvaluare: 4 din 5 stele4/5 (28)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsDe la EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsÎncă nu există evaluări

- How to Design and Install In-Car Entertainment SystemsDe la EverandHow to Design and Install In-Car Entertainment SystemsEvaluare: 5 din 5 stele5/5 (1)

- Making Toys, Revised Edition: Heirloom Cars & Trucks in WoodDe la EverandMaking Toys, Revised Edition: Heirloom Cars & Trucks in WoodEvaluare: 4 din 5 stele4/5 (3)

- ASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersDe la EverandASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersÎncă nu există evaluări