Documente Academic

Documente Profesional

Documente Cultură

US5775921 - Electrical Slip Ring Plug

Încărcat de

devheadbot0 evaluări0% au considerat acest document util (0 voturi)

9 vizualizări7 paginiSlip Ring

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentSlip Ring

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

9 vizualizări7 paginiUS5775921 - Electrical Slip Ring Plug

Încărcat de

devheadbotSlip Ring

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 7

USOO5775921A

United States Patent [19] [in Patent Number: 5,775,921

Chou [45] Date of Patent: Jul. 7, 1998

[54] ELECTRICAL PLUG Primary Examiner—Gary F. Paumen

Attomey, Agent, or Firm—Bacon & Thomas

[76] Inventor: Jonie Chou. 9F-4. No. 232. Chung Ho

Road. Chung Ho City. Taipei Hsien. [57] ABSTRACT

Talwan An electrical plug which includes an insulative bottom shell

which holds a metal sleeve at the center. a first annular metal

[21] Appl‘ NO‘: 630574 cushion spaced around the metal sleeve. and second annular

[22] Filed; Apr. 10, 1996 metal cushion spaced around the ?rst annular metal cushion;

an insulative upper shell covered on the bottom shell and

Int Cl.6 ................................................... .. having a Circular opcning; and clccuical cable having [W0

[52] US. Cl. 439/21 electrical wires respectively connected to the metal sleeve

[58] Field of Search ................................ .. 439/18. 20-26. and the ?rst annular metal cushion. and a grounding wire

439/11. 13. 27. 28. 106 connected to the second annular metal cushion: and a rotary

cap revolvably mounted within the circular opening of the

[56] References Cited upper shell which holds two metal contact blades. which are

maintained in contact with the metal sleeve and the ?rst

U'S' PATENT DOCUMENTS annular metal cushion. and a grounding prong. which is

1,613,647 l/19Q7 Davies et al. ........................... .. 439/22 maintained in contact with the second annular metal cush

2,542.935 2/195l McElroy .. .. 439/27 ion; wherein the metal contact blades and grounding prong

2,570,784 10/1951 Ferguson -- 439/27 of the rotary cap are respectively and constantly maintained

21654369 10/1953 M‘fddi J5 - 439/27 in contact with the metal sleeve and the annular metal

312E‘: ' ' ' ' ' ' ' ''' ' cushions when the rotary cap is turned within the circular

51249970 10/1993 Jennings . . . . . . . . . . . . . . . .. 439/11 Opcmng of the upper shell‘

5.399.093 3/1995 Schneider et a1. . 439/21

5595503 [/1997 Pittman et a]. ......................... .. 439/11 8 Claims, 3 Drawing Sheets

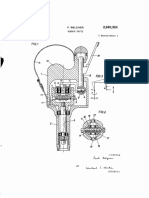

US. Patent Jul. 7, 1998 Sheet 1 of 3 5,775,921

US. Patent Jul. 7, 1998 Sheet 2 0f 3 5,775,921

US. Patent Jul. 7, 1993 Sheet 3 of 3 5,775,921

5.775.921

1 2

ELECTRICAL PLUG annular groove de?ned within the second upright annular

?ange around the ?rst upright annular ?ange. a plurality of

BACKGROUND OF THE INVENTION second upright rods disposed in the second annular groove.

and a second annular metal cushion mounted within the

The present invention relates to electrical plugs. and

second annular groove and supported on the second upright

relates more particularly to such an electrical plug which can

be conveniently adjusted to change the positions of the metal rods; the electrical cable further comprises a grounding wire

contact blades and the grounding prong so as to ?t diiferent

inserted through the side opening of the second upright

annular ?ange and connected to the second annular metal

installation conditions.

cushion: the rotary cap further comprises a third slot. and a

The contact metal blades of a regular electrical plug are grounding prong mounted in the third slot and having a

commonly disposed in line with the electrical cable thereof. T-shaped tail disposed in contact with the second annular

Therefore. the electrical cable must be bent in a particular metal cushion.

direction when the electrical plug is installed in an electrical

socket in a narrow area or behind a furniture. However. the BRIEF DESCRIPTION OF THE DRAWINGS

insulator tends to be broken if the electrical cable is 15

deformed. thereby causing a short circuit. US. Pat. No. FIG. 1 is an exploded view of an electrical plug according

4.927.376. issued to Dickie. disposes an electrical plug to the present invention;

adapted for installation in a narrow space. However. this FIG. 2 is a sectional assembly view of the electrical plug

structure of electrical plug ?ts only one particular direction. shown in FIG. 1'.

FIG. 3 is an exploded view of an alternate form of the

SUMMARY OF THE INVENTION electrical plug of the present invention; and

The present invention has been accomplished to provide FIG. 4 is an elevational view of of the electrical plug

an electrical plug which eliminates the aforesaid problem. It according to the present invention.

is one object of the present invention to provide an electrical

plug which is suitable for installation in a narrow area. It is 25 DETAILED DESCRIPTION OF THE

another object of the present invention to provide an elec PREFERRED EMBODIMENT

trical plug which can be conveniently adjusted to change the

positions of the metal contact blades and the grounding Referring to FIGS. 1 and 2. an electrical plug in accor

prong so as to ?t different installation conditions. According dance with the present invention is generally comprised of

to one aspect of the present invention. the electrical plug a bottom shell 1. an electrical cable 2. a rotary cap 3. and an

comprises an insulative bottom shell. the bottom shell com upper shell 4.

prising an upright stub tube on the inside. the upright stub The bottom shell 1 is an insulative covering comprising

tube having a side opening. a metal sleeve mounted within an upright smb tube 11 on the inside. the upright stub tube

the upright stub tube. a ?rst upright annular ?ange on the 11 having a side opening 111. a metal sleeve 12 mounted

inside around the upright stub tube. the ?rst upright annular 35 within the upright stub tube 11. a ?rst upright annular ?ange

?ange having a ?rst side opening corresponding to the side 13 on the inside around the upright stub tube 11. the ?rst

opening of the upright stub tube and a second side opening upright annular ?ange 13 having a ?rst side opening 133

134. a ?rst annular groove de?ned within the ?rst upright corresponding to the side opening 111 of the upright stub

annular ?ange around the upright stub tube. a plurality of tube 11 and a second side opening 134. a ?rst annular groove

?rst upright rods disposed in the ?rst annular groove. a ?rst 131 de?ned within the ?rst upright annular ?ange 13 around

annular metal cushion mounted within the ?rst annular the upright stub tube 11. a plurality of ?rst upright rods 132

groove and supported on the ?rst upright rods. and a cable disposed in the ?rst annular groove 131. a ?rst annular metal

hole at one end; an insulative upper shell covered on the cushion 14 mounted within the ?rst annular groove 131 and

bottom shell. the upper shell comprising a circular opening. supported on the ?rst upright rods 132 and having a con

an inward coupling ?ange suspending above and spaced 45 necting tip 141. a plurality of inside locating pins 15 on the

around the circular opening. and a cable hole at one end inside. a cable hole 16 at one end. two clamping ?anges 17

matched with the cable hole of the bottom shell; a rotary cap bilaterally disposed in the cable hole 16 and having respec

turned within the circular opening of the upper shell. the tive ribs 171. a second upright annular ?ange 18 on the

rotary cap comprising a ?rst slot. a ?rst metal contact blade inside around the ?rst upright annular ?ange 13. the second

mounted in the ?rst slot and having an arched tail disposed upright annular ?ange 18 having a side opening 183. a

in contact with the ?rst annular metal cushion of the bottom second annular groove 181 de?ned within the second

shell. a second slot. a second metal contact blade mounted upright annular ?ange 18 around the ?rst upright annular

in the second slot and having a rounded coupling end ?tted ?ange 13. a plurality of second upright rods 182 (not shown)

into the metal sleeve of the bottom shell. and an outward disposed in the second annular groove 181. and a second

coupling ?ange raised around the periphery and coupled to 55 annular metal cushion 19 mounted within the second annular

the inward coupling ?ange of the upper shell; and an groove 181 and supported on the second upright rods 182

electrical cable inserted through the cable hole of the bottom and having a connecting tip 191.

shell and the cable hole of the upper shell. comprising a ?rst The electrical cable 2 is inserted through the cable hole 16

electrical wire inserted through the ?rst side opening of the into the bottom shell 1 and held in place by the clamping

?rst upright annular ?ange and connected to the metal ?anges l7. comprised of a ?rst electrical wire 21. a second

sleeve. and a second electrical wire inserted through the electrical wire 22. and a grounding wire 23. The ?rst

second side opening of the ?rst upright annular ?ange and electrical wire 21 is inserted through the side opening 183 of

connected to the ?rst annular metal cushion. According to the second upright annular ?ange l8 and the ?rst side

another aspect of the present invention. the bottom shell opening 133 of the ?rst upright annular ?ange l3 and the

further comprises a second upright annular ?ange on the side opening 111 of the upright stub tube 11. and then

inside around the ?rst upright annular ?ange. the second connected to the metal sleeve 12. The second electrical wire

upright annular ?ange having a side opening. a second 22 is inserted through the side opening 183 of the second

5.775.921

3 4

upright annular ?ange 18 and the second side opening 134 with the metal sleeve 12. Therefore. the rotary cap 3 can be

of the ?rst upright annular ?ange 13. and then connected to turned within the circular opening 41 of the upper shell 4 to

the connecting tip 141 of the ?rst annular metal cushion 14. change the positions of the metal contact blades 33. 34 and

The grounding wire 23 is inserted through the side opening the grounding prong 37 to ?t the angular position of the

183 of the second upright annular ?ange 18. and then electrical socket.

connected to the connecting tip 191 of the second annular Referring to FIG. 4 and FIG. 1 again. two tie holes 44 are

metal cushion 19. made on the upper shell 4 at two opposite locations. and a

The rotary cap 3 is a circular insulative plate comprising lifting handle 45 is fastened with its two opposite ends to the

a ?rst slot 31. a ?rst metal contact blade 33 mounted in the tie holes 44. Through the lifting handle 45. the electric plug

?rst slot 31 and having an arched tail 331 raised at one end can be conveniently disconnected from the electric socket.

at right angles and adapted for ?tting over the ?rst annular FIG. 3 shows an alternate form of the present invention.

metal cushion 14. a second slot 32. a second metal contact in which the metal wall of the ?rst annular metal cushion 14

blade 34 mounted in the second slot 32 and having a rounded is made of hollow structure having a substantially U-shaped

coupling end 341 adapted for ?tting into the metal sleeve 12. cross section. and adapted for ?tting into the ?rst annular

an outward coupling ?ange 35 raised around the periphery groove 131; the metal wall of the second annular metal

and adapted for engagement with the upper shell 4. a third cushion 19 is made of hollow structure having a substan

slot 36. and a grounding prong 37 mounted in the third slot tially U-shaped cross section. and adapted for ?tting into the

36 and having a T-shaped tail 371 adapted for contact with second annular groove 181; the depth of the arched tail 331

the second annular metal cushion 19. of the ?rst metal contact blade 33 and the depth of the

The upper shell 4 is an insulative covering ?tting over the T-shaped tail 371 of the grounding prong 37 are relatively

20

bottom shell 1. comprising a circular opening 41. which increased so that they can be positively maintained in

receives the rotary cap 3. an inward coupling ?ange 411 contact with the ?rst annular metal cushion 14 and the

adapted for engagement with the outward coupling ?ange 35 second annular metal cushion 19.

of the rotary cap 3. a plurality of pin holes 42 adapted for It will be understood that the drawings are designed for

engagement with the locating pins 14 of the bottom shell 1. purposes of illustration only. and are not intended as a

25

a cable hole 43 at one end adapted for matching with the de?nition of the limits and scope of the invention disclosed.

cable hole 16 of the bottom shell 1 for the passing of the What the invention claimed is:

electrical cable 2. 1. An electrical plug comprising:

Furthermore. a plurality of spring members 10 are respec an insulative bottom shell. said bottom shell comprising

tively mounted around the ?rst upright rods 132 and the 30 an upright stub tube. said upright stub tube having a

second upright rods 182 to support the ?rst annular metal ?rst side opening; a metal sleeve mounted within said

cushion l4 and the second annular metal cushion 19 above upright stub tube; a ?rst upright annular ?ange extend

the ?rst upright rods 132 and the second upright rods 182. ing around said upright stub tube. said ?rst upright

and to force the ?rst annular metal cushion 14 and the annular ?ange having a second side opening corre

second annular metal cushion 19 into contact with the 35 sponding to the ?rst side opening of said upright stub

arched tail 331 of the ?rst metal contact blade 33 and the tube and a third side opening. a ?rst annular groove

T-shaped tail 371 of the grounding prong 37 respectively. de?ned between said ?rst upright annular ?ange and

The rotary cap 3 further comprises a plurality of raised said upright stub tube; a plurality of ?rst upright rods

portions 38 raised from the inside wall and adapted for disposed in said ?rst annular groove; a ?rst annular

pressing on the ?rst annular metal cushion 14 and the second metal cushion mounted within said ?rst annular groove

annular metal cushion 19 respectively. and supported on said ?rst upright rods; and a ?rst cable

Referring to FIG. 4 and FIGS. 1 and 2 again. the assembly hole at one end;

process of the electrical plug is simple and outlined herein an insulative upper shell covering said bottom shell. said

after. The metal contact blades 33. 34 and the grounding upper shell comprising a circular opening; an inward

prong 37 are respectively fastened to the respective slots 31. 45 coupling ?ange spaced around said circular opening;

32. 36 of the rotary cap 3. then the rotary cap 3 is revolvably and a second cable hole at one end located adjacent to

coupled to the circular opening 41 of the upper shell 4. and said ?rst cable hole;

then the spring members 10 are respectively mounted on the a rotary cap rotatably located within the circular opening

upright rods 132. 182. and then the metal sleeve 12 and the of said upper shell. said rotary cap comprising a ?rst

annular metal cushions 14. 19 are respectively fastened to slot; a ?rst metal contact blade mounted in the rotating

the electrical wires 21. 22 and grounding wire 23 of the cap and extending through said ?rst slot. the ?rst metal

electrical cable 2 and mounted in the upright stub tube 11. contact blade having an arched tail disposed in contact

?rst annular groove 131 and second annular groove 181 of with the ?rst annular metal cushion of said bottom

the bottom shell 1. and then the upper shell 4 is fastened to shell; a second slot; a second metal contact blade

the bottom shell 1 by ?tting the locating pins 15 into the pin 55 mounted in said rotary cap and extending through said

holes 42. permitting the electrical cable 2 to extend out of the second slot. the second metal contact blade having a

bottom shell 1 and the upper shell 4 through the cable holes rounded coupling end in contact with the metal sleeve

16. 46. and then the connecting area between the bottom of said bottom shell; and an outward coupling ?ange

shell 1 and the upper shell 4 are sealed by a high-frequency around a periphery and coupled to the inward coupling

heat sealing apparatus. When the rotary cap 3 is turned ?ange of said upper shell; and

within the circular opening 41 of the upper shell 4 through an electrical cable inserted through the ?rst and second

any desired angle. the arched tail 331 of the ?rst metal cable holes. comprising a ?rst electrical wire inserted

contact blade 33 is maintained in contact with the ?rst through the second side opening of said ?rst upright

annular metal cushion 14. the T-shaped tail 371 of the annular ?ange and connected to said metal sleeve. and

grounding prong 37 is maintained in contact with the second 65 a second electrical wire inserted through the third side

annular metal cushion 19. and the rounded coupling end 341 opening of said ?rst upright annular ?ange and con

of the second metal contact blade 34 is maintained in contact nected to said ?rst annular metal cushion.

5.775.921

5 6

2. The electrical plug of claim 1 wherein said upper shell mounted in the rotary cap and extending through said third

has a plurality of pin holes: and said bottom shell has a slot. the grounding prong having a T-shaped tail in contact

plurality of upright locating pins respectively ?tted into the with said second annular metal cushion.

pin holes of said upper shell. 5. The electrical plug of claim 4 wherein said bottom shell

3. The electrical plug of claim 1 wherein said bottom shell further comprises a plurality of spring members respectively

further comprises two clamping ?anges bilaterally disposed mounted around said ?rst upright rods and said second

in the ?rst cable hole. said clamping ?anges having ribs upright rods and supporting said ?rst annular metal cushion

con?gured to clamp on said electrical cable. and said second annular metal cushion above said ?rst

4. The electrical plug of claim 1 wherein said bottom shell upright rods and said second upright rods.

further comprises a second upright annular ?ange extending 6. The electrical plug of claim 4 wherein said rotary cap

around said ?rst upright annular ?ange. said second upright further comprises a plurality of raised portions located so as

annular ?ange having a fourth side opening. a second to press on said ?rst annular metal cushion and said second

annular groove formed between said second upright annular annular metal cushion.

?ange and said ?rst upright annular ?ange; a plurality of 7. The electrical plug of claim 1 wherein said upper shell

second upright rods disposed in said second annular groove: 15 further comprises a plurality of tie holes disposed on an

and a second annular metal cushion mounted within said outside at spaced apart locations; and a lifting handle having

second annular groove and supported on said second upright portions engaging said tie holes.

rods; wherein said elec’n-ical cable further comprises a 8. The electrical plug of claim 4 wherein said ?rst annular

grounding wire inserted through the fourth side opening of metal cushion and said second annular metal cushion each

said second upright annular ?ange and connected to said have a U-shaped cross section.

second annular metal cushion; and wherein said rotary cap

further comprises a third slot. and a grounding prong * * * * *

S-ar putea să vă placă și

- Pen TurningDocument2 paginiPen TurningdevheadbotÎncă nu există evaluări

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pagini@341 A É'Wqkammm: Filed July 28-, 1944devheadbotÎncă nu există evaluări

- US6953298 - Pinstripe Painting Device, 2005Document8 paginiUS6953298 - Pinstripe Painting Device, 2005devheadbotÎncă nu există evaluări

- Anodising - Aluminium Anodising DyesDocument4 paginiAnodising - Aluminium Anodising DyesdevheadbotÎncă nu există evaluări

- US1994497 - Indicator - Winters For Gladwin, 1935Document5 paginiUS1994497 - Indicator - Winters For Gladwin, 1935devheadbotÎncă nu există evaluări

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pagini@341 A É'Wqkammm: Filed July 28-, 1944devheadbotÎncă nu există evaluări

- US1157800 - Universal Test-Indicator - Oslund, 1915Document3 paginiUS1157800 - Universal Test-Indicator - Oslund, 1915devheadbotÎncă nu există evaluări

- US2466380 - Precision Centering Device - Leland Clark, 1949Document5 paginiUS2466380 - Precision Centering Device - Leland Clark, 1949devheadbotÎncă nu există evaluări

- US2940324 - Wobble Mechanism (Scraper)Document4 paginiUS2940324 - Wobble Mechanism (Scraper)devheadbotÎncă nu există evaluări

- US3230631 - Optical Center PunchDocument6 paginiUS3230631 - Optical Center PunchdevheadbotÎncă nu există evaluări

- US2579903 - Periscopic Sextant - Kollsman, 1951Document9 paginiUS2579903 - Periscopic Sextant - Kollsman, 1951devheadbot100% (1)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Magna 3Document36 paginiMagna 3mercruiserÎncă nu există evaluări

- Owner'S Manual: Safety and ReferenceDocument16 paginiOwner'S Manual: Safety and ReferenceMark RobsonÎncă nu există evaluări

- Service Manual: LCD TVDocument78 paginiService Manual: LCD TVlivinggood58Încă nu există evaluări

- P2571-LG 24MP77HMDocument39 paginiP2571-LG 24MP77HMpramudutaÎncă nu există evaluări

- LDL Parkside Ontozesidozito Hasznlati Utasitas HUDocument140 paginiLDL Parkside Ontozesidozito Hasznlati Utasitas HUjoaquim fernandesÎncă nu există evaluări

- Vestel Alva B Na-127vb3 Na-147vb3 SMDocument40 paginiVestel Alva B Na-127vb3 Na-147vb3 SMjoseÎncă nu există evaluări

- VN2EA700-MA-24.0E Robot Yushin Manual de Mantenimiento 750Document163 paginiVN2EA700-MA-24.0E Robot Yushin Manual de Mantenimiento 750Roberto Domínguez G100% (4)

- SG25 30 33 36 40 50CX-P2-User-ManualDocument115 paginiSG25 30 33 36 40 50CX-P2-User-ManualMahmood AhmedÎncă nu există evaluări

- Msi H310i Pro ManualDocument165 paginiMsi H310i Pro ManualgusgrafÎncă nu există evaluări

- Appendix - Pcmc2Document8 paginiAppendix - Pcmc2Siva PÎncă nu există evaluări

- Istar User Manual P9Document34 paginiIstar User Manual P9Markoov8350% (2)

- Midas Heritage 4000 ManualDocument78 paginiMidas Heritage 4000 ManualMaxReboÎncă nu există evaluări

- RD-9120 Qi 1-0-0Document52 paginiRD-9120 Qi 1-0-0aminshamsÎncă nu există evaluări

- FM 801 User ManualDocument46 paginiFM 801 User Manualanhhp8x100% (1)

- AQ 101 Manual EN1.3 PDFDocument59 paginiAQ 101 Manual EN1.3 PDFYvesÎncă nu există evaluări

- 400hz Aircraftplugs Technicalsheet-1Document1 pagină400hz Aircraftplugs Technicalsheet-1angelÎncă nu există evaluări

- Ltb-E1 BLKDocument190 paginiLtb-E1 BLKMichael Læsø50% (2)

- SSL40 Series: Single OutputDocument2 paginiSSL40 Series: Single OutputPierre-Emmanuel AUBERTELÎncă nu există evaluări

- Sec01 ZDocument33 paginiSec01 Zsinou.25Încă nu există evaluări

- Led TV: ServiceDocument43 paginiLed TV: ServicesunnyÎncă nu există evaluări

- Epp 1718 10 - 09Document6 paginiEpp 1718 10 - 09Yilber Briceño Carrero100% (2)

- Lenovo g470 g475 g570 g575 Disassembly ManualDocument36 paginiLenovo g470 g475 g570 g575 Disassembly Manualpetedetroit0% (1)

- BIOBASE Blood Thaw Machine WGH-III User ManualDocument9 paginiBIOBASE Blood Thaw Machine WGH-III User Manualsoporte03Încă nu există evaluări

- 185 ManualDocument12 pagini185 ManualZay Min HtetÎncă nu există evaluări

- s71500 Cpu1511 1 PN DTC Manual en-US en-USDocument49 paginis71500 Cpu1511 1 PN DTC Manual en-US en-USAlberto Fernández MarínÎncă nu există evaluări

- Citroen C4Document18 paginiCitroen C4marinhoucebÎncă nu există evaluări

- Display, 19 Color TFT Monitor DSC 1913-D DC CSTD CT02-023.805.02 TD00-000.841.46Document102 paginiDisplay, 19 Color TFT Monitor DSC 1913-D DC CSTD CT02-023.805.02 TD00-000.841.46Klaus BöhmdorferÎncă nu există evaluări

- QRP SuperRM Assembly ManualDocument26 paginiQRP SuperRM Assembly ManualBenjamin DoverÎncă nu există evaluări

- QCX 5W CW Transceiver Kit Assembly InstructionsDocument152 paginiQCX 5W CW Transceiver Kit Assembly Instructionsfox7878Încă nu există evaluări

- GK Build Instructions v2 PDFDocument9 paginiGK Build Instructions v2 PDFCarecaIIIÎncă nu există evaluări