Documente Academic

Documente Profesional

Documente Cultură

Dge LGW

Încărcat de

Abhishek BasakTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Dge LGW

Încărcat de

Abhishek BasakDrepturi de autor:

Formate disponibile

D G E

FR-68274 Wittenheim CH-3613 Steffisburg

Dr.-Ing. Günther Engineering GmbH

Dokumentation Laborgaswäscher Typ DGE-LGW

Documentation laboratory gas scrubber type DGE-LGW

Documentation laveur de gaz de laboratoire type DGE-LGW

Laborgaswäscher

Kompaktanlage mit fahrbaren Tisch für

eine industrielle Anwendung im ex-

Bereich

Abluftmenge : 100 m³/h

Schadstoff : Amine, HN3

Chemosorption mit 20%-iger

Schwefelsäure

Laboratory gas scrubber

Compact plant with mobile table for an

industrial application in the ex-area.

Exhaust air quantity: 100 m3/hr

Pollutant: amine, NH3

Chemisorption using 20 % sulfuric acid.

Laveur de gaz de

laboratoire

Installation compacte avec la table

mobile à l’usage d’ex-domaine.

Quantité d’air d’échappement: 100 m3/h

Pollutant : amine, NH3

Sorption chimique avec d’acide

sulfurique de 20 %.

DGE-LGW Laboratory gas scrubber documentation in English

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: +49-3491-661841 Fax: +49-3491-661842

DGE GmbH Tattenkofener Str. 25 82538 Geretsried Tel.: +49-8171-90051 Fax: +49-8171-90052

EMail: DGE-INFO@t-online.de Internet: http://www.dge-wittenberg.com

D G E

FR-68274 Wittenheim CH-3613 Steffisburg

Dr.-Ing. Günther Engineering GmbH

Contents

1. Introduction

1.1 Field of application

2. Description

2.1 Design

2.2 Function principle

2.3 Capacity parameters

3. Design types

3.1 Basic type

3.2 Additional equipment

3.3 Execution

3.3.1 Mobile design type fitted with a mobile table

3.3.2 Stationary design type in a laboratory case

4. Field of application

4.1 Chemisorption

4.2 Absorption

5. Application examples

5.1 Chemisorption

5.2 Absorption

6. Equipment designs

6.1 Common design

7. Laboratory gas scrubber – type series

8. Safety instructions

8.1 Safety regulations

9. Maintenance instructions

9.1 Service partners

10. List of spare parts

Enclosure

Instruction

All data, illustrations and specifications contained in this documentation are information

valid in the time of their publication. We are reserving the right to make changes at any

time.

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: +49-3491-661841 Fax: +49-3491-661842

DGE GmbH Tattenkofener Str. 25 82538 Geretsried Tel.: +49-8171-90051 Fax: +49-8171-90052

EMail: DGE-INFO@t-online.de Internet: http://www.dge-wittenberg.com

D G E

FR-68274 Wittenheim CH-3613 Steffisburg

Dr.-Ing. Günther Engineering GmbH

1. Introduction

The laboratory gas scrubbers are scrubbers serving for purifying exhaust

waste air for small quantities of air and they are designed to serve for

exhausting air from workplaces, laboratories and for industrial use.

The scrubber system developed by DGE GmbH firm can be realized as a

single apparatus separately or as a built-in variant into a laboratory case.

The developed laboratory scrubbers make it possible to maintain also

specified limit values given by law for exhausting the drawn off waste gas

directly in the place of occurrence, therefore, it is possible in this way to

maintain MAK values below a permissible limit value.

In spite of a simple design and construction the laboratory gas scrubber

is fitted with an measuring instrumentation, which guarantees for

personnel a safety course of work in all cases.

1.1 Field of application

The field of application of the gas scrubbers covers many fields of

industry and municipal economy system.

As the main field of application in industry they are considered to be

laboratory equipments. In this case it is possible to install the gas

scrubbers as mobile gas scrubbers or as an equipment installed firmly in

a chapel.

Further fields of application are in industry, e.g. at exhausting drawn off

air from reaction boiler storage tank at charge production in chemical and

pharmaceutical industry or at purifying the air exhausted from storage

tanks.

In view of the fact that the laboratory scrubbers are used often under

extreme conditions they are made of appropriate materials and fitted with

necessary safety equipment.

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: +49-3491-661841 Fax: +49-3491-661842

DGE GmbH Tattenkofener Str. 25 82538 Geretsried Tel.: +49-8171-90051 Fax: +49-8171-90052

EMail: DGE-INFO@t-online.de Internet: http://www.dge-wittenberg.com

D G E

FR-68274 Wittenheim CH-3613 Steffisburg

Dr.-Ing. Günther Engineering GmbH

2. Description

2.1 Design

The laboratory scrubber consists of a two-stage scrubbing system

formed by a jetting gas scrubber and a subsequently installed gas

scrubber filled with small solid bodies. In this way it is guaranteed a high

gas scrubbing capacity and very often there is no need to carry out any

additional treatment of the drawn off air. Both the gas scrubbing systems

are arranged as a one compact system making it possible to carry out

maintenance service work simply. Into the washing circuit there is

included a cooler serving for heat exchanging and reaction heat

dissipation. It is possible to install a circular adsorber after the laboratory

gas scrubber to remove components, which can not be removed by the

gas scrubbing.

2.2 Function principle

A scrubbing solution necessary for the scrubbing process is at disposal

in the washing agent storage tank. It is made up through filling branches.

State of filling can be checked visually. By switching in the laboratory gas

scrubber a circulating pump is put into operation and both the gas

scrubbers are supplied with washing liquid. The jetting gas scrubber has

been designed so that inside the gas scrubber there is underpressure,

therefore, on workplace there is not necessary to install any other

additional fan for exhausting air. In case of need, however, it is possible

to include in the system a piping fan.

With the use of a conductivity measuring probe installed in the washing

circuit and with the help concentration measuring in the clean gas it is

possible to monitor continuously the gas scrubbing capacity of the table

gas scrubber. An additionally installed working hours counter makes it

possible to monitor time of using the washing solution.

In this way they are installed three mutually independent control criteria

of capacity of the laboratory gas scrubber.

2.3 Capacity parameters

The laboratory gas scrubbers are high-capacity gas scrubbers for small

flow-rates of air. They do exist 4 basic types for rates of flow of exhaust

air from 5 to 250 m³/h. In comparison with the table gas scrubbers the

laboratory gas scrubbers can be operated with a markedly higher

unpurified gas charge.

Attainable separation capacities at chemisorption are higher than 99.9 %

and at the same time the acid or lye proportioning and discharge of

washing solution consumed are carried out continuously.

A pressure increase for exhausting the drawn off air is of about 3-5 mbar.

In addition, by installing a drawn off fan it is possible to increase the

exhausting capacity.

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: +49-3491-661841 Fax: +49-3491-661842

DGE GmbH Tattenkofener Str. 25 82538 Geretsried Tel.: +49-8171-90051 Fax: +49-8171-90052

EMail: DGE-INFO@t-online.de Internet: http://www.dge-wittenberg.com

D G E

FR-68274 Wittenheim CH-3613 Steffisburg

Dr.-Ing. Günther Engineering GmbH

3. Design type

The laboratory gas scrubber consists of a base plate on which the gas

scrubber system is installed.

3.1 Basic types

The basic type of the laboratory gas scrubber consists of the following

structural members:

Jetting gas scrubber K01 A filling state control

Gas scrubber with small bodies K01 B

Sludge storage tank B01

Circulating pump P01 ON/OFF switch

Demister F01

The basic type can be delivered in four basic sizes and the sludge

storage tank dimensions are adapted to the gas scrubber operation and

space conditions (circular or rectangular execution).

3.2. Additional equipment

The following additional equipment can be installed as optional:

Instrumentation MSR

Fan pH measuring

Circular adsorber Conductivity measuring

Proportioning station Purified gas measuring

Heating recording Recorder

Other additional equipment or execution for more extreme conditions are

manufactured on request.

3.3 Execution

3.3.1 Mobile design type fitted with a mobile table

For a flexible use the laboratory gas scrubber can be installed on a

mobile table. The exhaustion can be easily connected with the use of

flexible hoses.

3.3.2 Stationary design type in a laboratory case

For this application the laboratory gas scrubbers are built directly in the

upper part of the laboratory case. The dimensions are about as follows:

800x600x400 mm (L x W x D). The sludge storage tank can be installed

into the bottom part of the laboratory case.

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: +49-3491-661841 Fax: +49-3491-661842

DGE GmbH Tattenkofener Str. 25 82538 Geretsried Tel.: +49-8171-90051 Fax: +49-8171-90052

EMail: DGE-INFO@t-online.de Internet: http://www.dge-wittenberg.com

D G E

FR-68274 Wittenheim CH-3613 Steffisburg

Dr.-Ing. Günther Engineering GmbH

4. Field of application

The laboratory gas scrubber is suitable above all for purifying smaller

flow rates of waste gas with high concentrations which is contaminated

with inorganic or organic substances as acids and lyes.

4.1 Chemisorption

The laboratory gas scrubber is equipped with two stages of washing, i.e.

a jetting gas scrubber and a scrubber filled with small bodies.

The calculation of a necessary number of theoretical stages NTU for a

given separation capacity is carried out in the following way:

NTU = ln (YE/YA)

YE - inlet concentration of components in the waste gas

YA - outlet concentration of components in the waste gas

The high separation degree of a gas scrubber fitted with small body filling

is calculated in the following way:

Z = NTU * HTU

Z - design height of the gas scrubber fitted with small body fillings

expressed in m

NTU - number of necessary theoretical separation stages

HTU - height of theoretical separation degree

By installing before a jetting gas scrubber it is already attained one NTU

as a minimum, therefore, it is possible to realize using a table gas

scrubber in total 3-5 NTU .

4.2 Absorption

Good results of absorption can be obtained in such cases when the

scrubbing process is nit equipped with a closed water circuit, however, in

cases when the laboratory gas scrubber is operated with the use of fresh

water. The attainable separation capacity corresponds to a value of

about 1 NTU. During operation with a closed circuit it is necessary,

however, into consideration absorption and desorption effects.

As opposed to the method of calculation for chemisorption it is necessary

at absorption to take into consideration additionally also phase

equilibrium

YE,A = CE,A * Hi

C - concentration of components in liquid phase

Hi - Henry’s coefficient of component i

By this limitation it is obvious that with the use of absorption it is possible

to attain a good separation capacity only in substances well water-

soluble as for example ammonia.

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: +49-3491-661841 Fax: +49-3491-661842

DGE GmbH Tattenkofener Str. 25 82538 Geretsried Tel.: +49-8171-90051 Fax: +49-8171-90052

EMail: DGE-INFO@t-online.de Internet: http://www.dge-wittenberg.com

D G E

FR-68274 Wittenheim CH-3613 Steffisburg

Dr.-Ing. Günther Engineering GmbH

5. Application examples

5.1 Chemisorption

A flow rate of the exhaust air is of 250 m³/h and the air is NH3 saturated

in a concentration of 100 mg/m³. A limit of odour disturbance is of 3

mg/m³.

For solving the task it is necessary to use the following theoretical

number of stages:

NTU = ln (100/3) = 3.5

As a washing agent it is used 20 % sulphuric acid. With the help of trials

the following separation stages have been found for DGE-LGW 300-150

type:

Jetting gas scrubber 2,0

Gas scrubber with small solid bodies 3,0

In this way it is possible to solve the given task with the use of the

laboratory gas scrubber so that the waste gas with 5 NTU is washed to a

value of 0,7 mg/m³.

Transfer fluids connected with a substance form a firm know how and it is

used in any design.

5.2 Absorption

The explanation of absorption can be presented in advance only

approximately for the reason of a complex mass transfer. It is purposeful

to carry out a pilot trial to find a separation efficiency. When starting from

the maximum theoretical transfer unit NTU = 1 it is possible to realize

with water absorption a maximum separation efficiency of about 60%.

In this case it is not necessary to install any circulating pump. The jetting

gas scrubber and gas scrubber filled with small solid bodies are supplied

directly with fresh water. The saturated scrubbing water is discharged

directly from a common sludge storage tank.

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: +49-3491-661841 Fax: +49-3491-661842

DGE GmbH Tattenkofener Str. 25 82538 Geretsried Tel.: +49-8171-90051 Fax: +49-8171-90052

EMail: DGE-INFO@t-online.de Internet: http://www.dge-wittenberg.com

D G E

FR-68274 Wittenheim CH-3613 Steffisburg

Dr.-Ing. Günther Engineering GmbH

6. Equipment designs

The basic structure of the complete laboratory gas scrubber is shown on

the method diagrammatic plan included as a part of the enclosure. The

equipment consists of the following assemblies:

- Jetting gas scrubber K 01 A

- Gas scrubber filled with small solid bodies K 01 B

- Washing water storage tank and relaxation tank B 01

- Demister F01

- Circulating pump P 01

- MSR instrumentation

By means of these assemblies the automatic operation of the waste gas

purification can be realized.

6.1 Common design

For fully automatic operation of the table gas scrubber it is necessary to

apply only both filling state control and protection of the circulating pump

against idle running. Additionally, it is possible to install the following

equipment:

pH measuring

Conductivity measuring

Purified gas measuring

7. Laboratory gas scrubbers – type series

For the use of the laboratory gas scrubbers they do exist 4 different

assemblies for purifying exhaust gas with a flow rate of 5 to 250 m³/h.

Type designation of the laboratory gas scrubber is formed in accordance

with the following scheme:

DGE-LGW-D1/D2-A-B

It means in this case as follows:

DGE firm name

LGW laboratory gas scrubber

D1/D2 FKW/SW -type

S/T stationary or mobile execution

A material used

B year of manufacture

With the use of that classification the equipment – laboratory gas

scrubbers – can be unequivocally classified and their service ensured.

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: +49-3491-661841 Fax: +49-3491-661842

DGE GmbH Tattenkofener Str. 25 82538 Geretsried Tel.: +49-8171-90051 Fax: +49-8171-90052

EMail: DGE-INFO@t-online.de Internet: http://www.dge-wittenberg.com

D G E

FR-68274 Wittenheim CH-3613 Steffisburg

Dr.-Ing. Günther Engineering GmbH

8. Safety instructions

In principle, with the exception of instructions stated in the handed over

documentation the user shall observe also local regulations in force in

the place of the equipment application. Operators and personnel shall be

acquainted with the documentation and shall be provided with an

authorization for carrying out necessary appropriate activities. The user

undertakes to use for operating laboratory gas scrubbers an instructed

personnel only.

8.1 Safety regulations

Regulations, which shall be observed are included in the documentation

of the appropriate equipment. In addition to it, it is necessary to observe

regulations specific according to place of application of the equipment.

Above all, it is necessary to check whether:

- Operating instructions are kept close to the appropriate equipment.

- The equipment is handled and operated by an authorized personnel

only and that the appropriate personnel has been instructed.

- The cleaning of the equipment is carried in regular time intervals.

- Safety devices and equipments are checked after each 6 months.

- For operation of the equipment have been created no other

conditions than those stated in the contract.

Change in design can be carried out only when approved by the

equipment manufacturer.

Instruction

The observance of safety instructions and safety regulations is a precondition of trouble-

free operation.

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: +49-3491-661841 Fax: +49-3491-661842

DGE GmbH Tattenkofener Str. 25 82538 Geretsried Tel.: +49-8171-90051 Fax: +49-8171-90052

EMail: DGE-INFO@t-online.de Internet: http://www.dge-wittenberg.com

D G E

FR-68274 Wittenheim CH-3613 Steffisburg

Dr.-Ing. Günther Engineering GmbH

9. Maintenance instruction

It is necessary to observe maintenance time intervals as stated in the

maintenance instruction manual.

The maintenance work can be carried out with the appropriate equipment

switched off.

9.1 Service partners

When concluding a contract it is necessary to appoint a partner

responsible for service of the equipment.

Before the service has been carried out it is necessary to be supplied

well with necessary spare parts.

10. Spare parts

For ensuring trouble-free operation of the laboratory gas scrubber it is

necessary to have on stock a minimum amount of spare parts. This is,

however, very necessary in view of a long delivery time in case of special

spare parts. These special spare parts are as follows:

1 gas measuring sensing element

1 liquid for pH value and conductivity measuring

Other spare parts are always given by a specific mode of use.

Instruction

Regular maintenance and a stock of spare parts are necessary for ensuring troublefree

operation and for increasing applicability of the equipment.

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: +49-3491-661841 Fax: +49-3491-661842

DGE GmbH Tattenkofener Str. 25 82538 Geretsried Tel.: +49-8171-90051 Fax: +49-8171-90052

EMail: DGE-INFO@t-online.de Internet: http://www.dge-wittenberg.com

D G E

FR-68274 Wittenheim CH-3613 Steffisburg

Dr.-Ing. Günther Engineering GmbH

Enclosure

1. Basic flow diagram/block diagram

2. P&I-diagram of laboratory gas scrubber

2.1 Basic variant of laboratory gas scrubber

2.2 Laboratory gas scrubber with a circular adsorber

3. Lay-out

3.1 Lay-out with a circular sludge storage tank

3.2 Lay-out with an angular sludge storage tank

4. Laboratory gas scrubber for special applications, mobile

5. Data sheet

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: +49-3491-661841 Fax: +49-3491-661842

DGE GmbH Tattenkofener Str. 25 82538 Geretsried Tel.: +49-8171-90051 Fax: +49-8171-90052

EMail: DGE-INFO@t-online.de Internet: http://www.dge-wittenberg.com

App. 4

Laboratory gas scrubber for special use

Transportable

· Environmental Protection

· Process Engineering

· Plant Engineering

überwacht

überwacht

Dr.-Ing. Günther Engineering GmbH

DGE’s Standard Series DGE-LGW

for laboratory gas washers for exhaust air decontamination

DGE’s laboratory gas washers are high-perform-

ance washers for combined exhaust air decontami-

nation. DGE’s laboratory gas washers consists of

a combination of self-suctioning jet gas washers

and packed washers from the DGE-LGW series.

Using self-suctioning jet gas washers makes the

use of additional exhaust air fans superfluous.

DGE’s laboratory gas washers are suited to use

in the following areas:

dust and aerosol separation with small parti-

cles and precleaning for absorption and

chemosorption

in jet gas washers

absorption and chemosorption in packed wash-

ers

A heat exchanger may be mounted in the washing

cycle for cooling off the exhaust gas and dissipat-

ing the solution and reaction heat.

A packed washer can be designed with multiple

stages or with a rinsable mist separator. The wash-

ing cycle mode depends upon the task and may

be operated acidically or alkaline monitored for the

pH-value. An activated carbon filter may be in-

cluded downstream to the laboratory gas washer DGE’s laboratory gas washers

as a ringsorber for special tasks. We also offer spe- model series DGE-LGW

cial applications for use in the explosive area.

1 – the self-suctioning jet gas washer

DGE’s laboratory gas washers are made of steel, 2 – the FKW packed washer

stainless steel or plastics such as PE, PP, PVDF 3 – the movable tank sump

and GFK. Plastic designs are resistant to corro- 4 – the cycle pump

sive media. The structure of the column is designed

to allow the customer to do simple service work.

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: 0049-03491-661841 Fax: 0049-03491-661842

DGE GmbH Tattenkofenerstraße 25 D-82538 Geretsried Tel.: 0049-8171-90051 Fax: 0049-8171-90052

eMail: DGE-INFO@t-online.de Internet: http://www.Wittenberg-DGE.com

· Environmental Protection

· Process Engineering

· Plant Engineering

überwacht

überwacht

Dr.-Ing. Günther Engineering GmbH

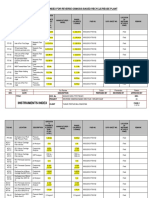

There are the following standard subassemblies for using DGE’s LGW laboratory gas washers for

exhaust air decontamination:

subassembly exhaust air decontamination

DN DN quantity of exhaust air water

FKW SWS m3/h m3/h

DGE-LGW 125 60 10 – 35 1

DGE-LGW 150 80 20 – 65 2

DGE-LGW 200 100 40 – 100 3

DGE-LGW 300 150 80 – 250 7

The dimension stated are based upon the standard round design. We produce other designs upon

request. We supply liquid reservoir tanks in a round or rectangular design depending upon the task.

model designation for DGE’s model

DGE produces its own laboratory gas

DGE-LGW laboratory gas washers washers. We can supply all column acces-

sories such as the

DGE GmbH

distribution levels, jets

laboratory gas washers

pH measured sections

DN-FKW metering containers

DN-SS mist separators

column workshop as component parts upon request.

year

DGE has its own cleaning techniques for

special area in exhaust air decontamination

as well as many years of know-how and

comprehensive references.

DGE – LGW – A – B – C – D

We would be glad to advise you as a sup-

plier of systems and together with you we

will work out the most favourable plant strat-

egy for your needs. We optimise operating

resource consumption and lower disposal

costs. We especially investigate existing

DGE’s laboratory gas washers are suited to possibilities for process development with

separating dusts, solid matter and aerosols in closed material cycles.

combination with absorption or chemosorption. If

We offer our customers a service for

required, DGE’s laboratory gas washers can be

especially sensitive plant systems with our

supplemented with acid or lye metering stations.

mobility guarantee and repair guarantee

Furthermore, we can integrate measuring and analysis

within 24 hours.

equipment for ascertaining separation performance.

The readings are stored on files that allow evaluation.

DGE GmbH Hufelandstraße 33 06886 Wittenberg Tel.: 0049-03491-661841 Fax: 0049-03491-661842

DGE GmbH Tattenkofenerstraße 25 D-82538 Geretsried Tel.: 0049-8171-90051 Fax: 0049-8171-90052

eMail: DGE-INFO@t-online.de Internet: http://www.Wittenberg-DGE.com

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- ASME Boiler & Pressure Vessel Code Companion Guide Volume 1Document1 paginăASME Boiler & Pressure Vessel Code Companion Guide Volume 1Sumit PrasadÎncă nu există evaluări

- Mechanical Works: Item Unit Cost Total Cost No. S.R S.R Div. Description of Material Unit Quantity RemarksDocument4 paginiMechanical Works: Item Unit Cost Total Cost No. S.R S.R Div. Description of Material Unit Quantity RemarksjatinÎncă nu există evaluări

- Types of Pressure Relief ValvesDocument22 paginiTypes of Pressure Relief ValvesFaraz MichÎncă nu există evaluări

- Power Plant ChemistryDocument16 paginiPower Plant ChemistrythanhhuyenÎncă nu există evaluări

- EN Folder Watersupply ILF PDFDocument12 paginiEN Folder Watersupply ILF PDFMishealÎncă nu există evaluări

- ISO TS 22002-2 Programa de Prerequisitos CateringDocument26 paginiISO TS 22002-2 Programa de Prerequisitos CateringRodrigo Díaz López80% (5)

- 06 - KBR Ammonia Revamp Technology PDFDocument30 pagini06 - KBR Ammonia Revamp Technology PDFMufadhzil MÎncă nu există evaluări

- Philippines School Implements Waste Segregation ProgramDocument11 paginiPhilippines School Implements Waste Segregation ProgramAnna CrisolÎncă nu există evaluări

- BP220 AmendedDocument43 paginiBP220 AmendedMarites BalmasÎncă nu există evaluări

- Twill Dutch Weave Wire MeshDocument1 paginăTwill Dutch Weave Wire MeshAbhishek BasakÎncă nu există evaluări

- Ms 01 22Document12 paginiMs 01 22Abhishek BasakÎncă nu există evaluări

- Steady-State Modeling of A Loop Heat Pipe in Gravity-Assisted Operation - ATEDocument33 paginiSteady-State Modeling of A Loop Heat Pipe in Gravity-Assisted Operation - ATEAbhishek BasakÎncă nu există evaluări

- An Experimental Study of A Slab Wick Heat Pipe ForDocument9 paginiAn Experimental Study of A Slab Wick Heat Pipe ForAbhishek BasakÎncă nu există evaluări

- Notes11 Floating Ring Seals 09 PDFDocument18 paginiNotes11 Floating Ring Seals 09 PDFsaravananknpcÎncă nu există evaluări

- MatISSE 2015 Comparison of RCC MRX and ASME Hyeong Yeon LeeDocument46 paginiMatISSE 2015 Comparison of RCC MRX and ASME Hyeong Yeon LeeAbhishek BasakÎncă nu există evaluări

- IMP Selection GuideDocument30 paginiIMP Selection GuideAbhishek BasakÎncă nu există evaluări

- TablDocument4 paginiTablAbhishek BasakÎncă nu există evaluări

- Notes15 Gas Film LubricationDocument58 paginiNotes15 Gas Film LubricationAKHIL PASULAÎncă nu există evaluări

- General Hairpin NomenclatureDocument1 paginăGeneral Hairpin NomenclatureAbhishek BasakÎncă nu există evaluări

- B.5 Wet Scrubbers For Gaseous Control: Review DRAFTDocument70 paginiB.5 Wet Scrubbers For Gaseous Control: Review DRAFTsafar bahariÎncă nu există evaluări

- Tender 2526Document18 paginiTender 2526Abhishek BasakÎncă nu există evaluări

- 054 PaperDocument14 pagini054 PaperAbhishek BasakÎncă nu există evaluări

- Delpech ReprocessingDocument60 paginiDelpech ReprocessingAbhishek BasakÎncă nu există evaluări

- Parker - Frameless MotorsDocument12 paginiParker - Frameless MotorsAbhishek BasakÎncă nu există evaluări

- How To Select Turbomachinery For Your Application PDFDocument10 paginiHow To Select Turbomachinery For Your Application PDFrafieeÎncă nu există evaluări

- Literature Review On Poor Drainage SystemDocument7 paginiLiterature Review On Poor Drainage Systemafdtsadhr100% (1)

- Aircraft Hydraulic SystemsDocument17 paginiAircraft Hydraulic SystemssushantreshmaÎncă nu există evaluări

- Gate Valves in IndustryDocument3 paginiGate Valves in IndustryKogulan SubramaniamÎncă nu există evaluări

- Ugc Net Paper-1 Weekly Magazine (Current Affairs, Mock Test, Reasoning) For December Exam Download PDFDocument65 paginiUgc Net Paper-1 Weekly Magazine (Current Affairs, Mock Test, Reasoning) For December Exam Download PDFDiwakar Entertainment DoseÎncă nu există evaluări

- Review On The Factors Affecting Ultrafiltration Hollow Fiber Membrane Operational Performance in Water TreatmentDocument16 paginiReview On The Factors Affecting Ultrafiltration Hollow Fiber Membrane Operational Performance in Water Treatmentभूषण लोहारÎncă nu există evaluări

- Bod KineticsDocument18 paginiBod KineticsNeda AarabiÎncă nu există evaluări

- Types of Pipes: Ar. Kiran PatilDocument6 paginiTypes of Pipes: Ar. Kiran PatilShweta PuriÎncă nu există evaluări

- B-4-Multi Grade Filter BrochureDocument2 paginiB-4-Multi Grade Filter BrochureSaurabh ChaudhariÎncă nu există evaluări

- Tuas South Incineration PlantDocument2 paginiTuas South Incineration Plantijaz fazilÎncă nu există evaluări

- Instruments Index RO Plant YTMDocument8 paginiInstruments Index RO Plant YTMSswahyudiÎncă nu există evaluări

- Air Pockets: Invisible Threat to Sprinkler SystemsDocument3 paginiAir Pockets: Invisible Threat to Sprinkler SystemsvhlactaotaoÎncă nu există evaluări

- Tyco Drenchers - TFP807 - 07 - 2014Document14 paginiTyco Drenchers - TFP807 - 07 - 2014Sanitaristu100% (1)

- Alternatives to Hydrazine in Water TreatmentDocument5 paginiAlternatives to Hydrazine in Water TreatmentjycortesÎncă nu există evaluări

- Proper Design ConsiderationsxDocument4 paginiProper Design ConsiderationsxLTE002Încă nu există evaluări

- Soil Physical Properties and Oil Palm Productivity in Peatlands with Different Water LevelsDocument8 paginiSoil Physical Properties and Oil Palm Productivity in Peatlands with Different Water LevelsTjandra LiemÎncă nu există evaluări

- Product Summary Catalogue: Creating Solutions For ConstructionDocument46 paginiProduct Summary Catalogue: Creating Solutions For Constructionpiyu114Încă nu există evaluări

- Case Study Mundra Thermal PlantDocument13 paginiCase Study Mundra Thermal PlantParth GhanekarÎncă nu există evaluări

- PollutionDocument2 paginiPollutionLaramaÎncă nu există evaluări

- Evs ProjectDocument11 paginiEvs ProjectUmesh TyagiÎncă nu există evaluări

- Are Golf Courses Bad For The EnvironmentDocument4 paginiAre Golf Courses Bad For The EnvironmentKyle M. SantosÎncă nu există evaluări

- Earthwork Support ShoringDocument3 paginiEarthwork Support Shoringabdella.whateverÎncă nu există evaluări

- Measuring and Monitoring The Efficiency of Central Chiller PlantsDocument14 paginiMeasuring and Monitoring The Efficiency of Central Chiller PlantsAqilaAndiÎncă nu există evaluări

- Worksheet 3 Reading ActivitiesDocument2 paginiWorksheet 3 Reading ActivitiesDella OktaviaÎncă nu există evaluări