Documente Academic

Documente Profesional

Documente Cultură

Duroxite-200 Data-Sheet Web En-2019 PDF

Încărcat de

Graylab TechnologiesTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Duroxite-200 Data-Sheet Web En-2019 PDF

Încărcat de

Graylab TechnologiesDrepturi de autor:

Formate disponibile

DUROXITE™ 200

DUROXITE™ 200

General Product Description

Duroxite™ 200 consists of specially formulated abrasive materials deposited on mild steel backing plate that is suitable for

extremely severe abrasive wear and high to moderate impact applications. The overlay material is composed of primary

chromium-rich carbides and refined multiple-alloy complex carbides dispersed evenly in a ductile eutectic austenite matrix.

Duroxite™ 200 is available in single and double layers.

Key Benefits

• Multiple-alloy complex carbides are harder and finer than chromium carbides and interlock between the primary

chromium carbides to provide better wear resistance

• Longer service life and better wear resistance compared to traditional chromium carbide overlay plate

• Double-layer overlay maintains full wear resistance up to 600° C (1100° F)

Typical Applications

Duroxite™ 200 is widely used many industries including mining, cement, and steel. Some specific applications include:

Mining Chutes, liner plates, conveyors sides, underground mine skips

Cement furnace components, sinter plant parts, fan blades, mixer blades, crews, gyratory mantles, coal and cement

Cement

pulverizer rolls, raw material crushing components, molding panels

Steel Ore sintering, crushing, riddling, blast furnace hoppers, throats, and ovens

For more information on applications see the Duroxite™ Product brochure.

DATA SHEET DUROXITE™ 200 | WWW DUROXITE.COM | 2019-03-11

DUROXITE™ 200

Standard Dimensions

Standard overlay thicknesses

Standard plate sizes

Single pass Multiple passes

Metric unit Imperial unit Metric unit Imperial unit Metric unit Imperial unit

3 mm on 6 mm 1/8’’ on 1/4’’ 6 mm on 6 mm 1/4’’ on 1/4’’ 1.2 m x 2.4 m 4’ x 8’

1.5 m x 3.0 m 5’ x 10’

6 mm on 10 mm 1/4’’ on 3/8’’ 1.8 m x 3.0 m 6’ x 10’

2.4 m x 3.0 m 8’ x 10’

10 mm on 10 mm 3/8’’ on 3/8’’ 1.4 m x 3.0 m 4.6’ x 10’

Other plate sizes and custom thicknesses can be produced upon request.

Mechanical Properties

Surface Hardness

Number of overlay passes Typical surface hardness 1)

Single pass 57 to 60 HRC (630 to 700 HV)

Double passes 60 to 65 HRC (700 to 850 HV)

1)

Surface hardness is measured on machined flat surface just below overlay surface.

Wear Properties

ASTM G65 – Procedure A weight loss 2)

Number of overlay passes

Surface 75% depth of overlay 3)

Single pass 0.19 g maximum 0.19 g maximum

Double passes 0.12 g maximum 0.12 g maximum

2)

ASTM G65 is a standard test measuring sliding abrasion resistance using a dry sand/rubber wheel apparatus. ASTM G65–Procedure A is the most severe test method.

3)

ASTM G65 wear test is conducted at 75 % depth of the overlay materials to ensure consistently good wear resistance from top surface through to the depth of 75 % of the overlay.

Microstructure

Primary chromium-rich carbide

The microstructure of Duroxite™ 200 contains primary chromium-rich

carbides and refined multiple-alloy complex carbides with a typical hardness

of 2500 to 3000 HK4) dispersed evenly in a ductile eutectic austenite matrix.

The typical volume fraction of primary chromium-rich carbides is maintained

between 30 to 40% with 7 to 10% of multi-alloy complex carbides.

4)

HK is the Knoop microhardness used primarily for very brittle materials or thin sheets.

Austenite matrix Refined multi-alloy carbides

DATA SHEET DUROXITE™ 200 | WWW DUROXITE.COM | 2019-03-11

DUROXITE™ 200

Tolerances

Thickness

Overall and overlay thickness tolerances can be guaranteed within ±10% of specified thickness.

Flatness

Plate flatness tolerance can be guaranteed within ±3 mm (±1/8”) over 1.5 m (5’) plate length for plate dimensions equal to or less

than 1.5 m (5’) x 3.0 m (10’). For plates greater than 1.5 m (5’) wide by 3.0 m (10’) long, the following flatness guarantees apply.

Flatness tolerance

Standard overlay thicknesses

1.8 m x 3.0 m (6’ x 10’) 2.4 m x 3.0 m (8’ x 10’)

Metric unit Imperial unit Metric unit Imperial unit Metric unit Imperial unit

5 mm on 7 mm 3/16” on 5/16” 25 mm 1” 41 mm 1-5/8”

6 mm on 6 mm 1/4” on 1/4’’ 25 mm 1” Not available

10 mm on 10 mm 3/8” on 3/8” 12 mm 1/2” 25 mm 1”

For custom sizes, please consult your local sales representative or local Hardox Wearparts center for flatness guarantees.

Delivery Conditions

Duroxite™ 200 is normally supplied in an as-welded condition, but can also be supplied in a ground condition upon request.

Fabrication and Other Recommendations

Welding, cutting, forming and machining

Recommendations can be found in the Duroxite™ Product brochure, or consult your local technical support representative.

The English version of this document shall prevail in case of discrepancy. Download the latest version of this document at www.ssab.com.

SSAB, Strenx™, Hardox®, Docol®, GreenCoat®, Toolox®, Armox®, Domex®, Raex® and Duroxite™ are trademarks owned by the SSAB group of companies.

DATA SHEET DUROXITE™ 200 | WWW DUROXITE.COM | 2019-03-11

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Duroxite-300 en Data-Sheet PDFDocument3 paginiDuroxite-300 en Data-Sheet PDFGraylab TechnologiesÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- SSAB Shape ToprailDocument2 paginiSSAB Shape ToprailGraylab TechnologiesÎncă nu există evaluări

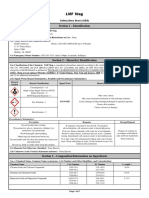

- 027LMF Slag SDS SSAB005 102018Document9 pagini027LMF Slag SDS SSAB005 102018Graylab TechnologiesÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Ssab Hardox Wearparts Duroxite Nov2017Document12 paginiSsab Hardox Wearparts Duroxite Nov2017Graylab TechnologiesÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Duroxite-201 en Data-SheetDocument3 paginiDuroxite-201 en Data-SheetGraylab TechnologiesÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Duroxite-400 en Data-Sheet WebDocument2 paginiDuroxite-400 en Data-Sheet WebGraylab TechnologiesÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Bradken Fixed Plant BrochureDocument29 paginiBradken Fixed Plant BrochurepinkypachoÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Duroxite-101 Data-Sheet Web enDocument3 paginiDuroxite-101 Data-Sheet Web enGraylab TechnologiesÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Duroxite-300 en Data-SheetDocument3 paginiDuroxite-300 en Data-SheetGraylab TechnologiesÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- 39 Duroxite Overlay Productslingyuen WeiExtranetDocument29 pagini39 Duroxite Overlay Productslingyuen WeiExtranetGraylab TechnologiesÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Duroxite-200 Data-Sheet Web En-2019Document3 paginiDuroxite-200 Data-Sheet Web En-2019Graylab TechnologiesÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Cement Plants Located in India 3Document4 paginiCement Plants Located in India 3Graylab TechnologiesÎncă nu există evaluări

- Norma - Dureza E140Document21 paginiNorma - Dureza E140JeffersonCruzÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Jindal Africa 2014 Corporate BrochureDocument43 paginiJindal Africa 2014 Corporate BrochureGraylab TechnologiesÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- (Elearnica) - Hardfacing Technologies For Improvement of Wear Characteristics of Hot WorkDocument13 pagini(Elearnica) - Hardfacing Technologies For Improvement of Wear Characteristics of Hot WorkelmiraÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Rolling Capacity Chart - PEE20Document1 paginăRolling Capacity Chart - PEE20Graylab TechnologiesÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- CDQ PresentationDocument10 paginiCDQ PresentationGraylab TechnologiesÎncă nu există evaluări

- Assembly 01 VundefinedDocument13 paginiAssembly 01 VundefinedGraylab TechnologiesÎncă nu există evaluări

- GGGDocument2 paginiGGGGraylab TechnologiesÎncă nu există evaluări

- Test One VundefinedDocument10 paginiTest One VundefinedGraylab TechnologiesÎncă nu există evaluări

- CDQ PresentationDocument10 paginiCDQ PresentationGraylab TechnologiesÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- A. O. Univ.-Prof. Dipl.-Ing. Dr. Mont. Erich Folkhard (Auth.) - Welding Metallurgy of Stainless Steels-Springer-Verlag Wien (1988)Document288 paginiA. O. Univ.-Prof. Dipl.-Ing. Dr. Mont. Erich Folkhard (Auth.) - Welding Metallurgy of Stainless Steels-Springer-Verlag Wien (1988)Graylab Technologies100% (1)

- The Influence of The Matrix Microstructure On Abrasive WearDocument12 paginiThe Influence of The Matrix Microstructure On Abrasive WearGraylab TechnologiesÎncă nu există evaluări

- The Comparative Effect of Sugarcane Juice On The Abrasion-Corrosion BehaviorDocument9 paginiThe Comparative Effect of Sugarcane Juice On The Abrasion-Corrosion BehaviorGraylab TechnologiesÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Cement Plants Located in India 2Document4 paginiCement Plants Located in India 2Graylab TechnologiesÎncă nu există evaluări

- Cement Plants Located in India 1Document4 paginiCement Plants Located in India 1Graylab Technologies0% (1)

- KalamDocument8 paginiKalamRohitKumarSahuÎncă nu există evaluări

- Vce Smart Task 1 (Project Finance)Document7 paginiVce Smart Task 1 (Project Finance)Ronak Jain100% (5)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Lista Agentiilor de Turism Licentiate Actualizare 16.09.2022Document498 paginiLista Agentiilor de Turism Licentiate Actualizare 16.09.2022LucianÎncă nu există evaluări

- RSA ChangeMakers - Identifying The Key People Driving Positive Change in Local AreasDocument29 paginiRSA ChangeMakers - Identifying The Key People Driving Positive Change in Local AreasThe RSAÎncă nu există evaluări

- All Zone Road ListDocument46 paginiAll Zone Road ListMegha ZalaÎncă nu există evaluări

- Project TitleDocument15 paginiProject TitleadvikaÎncă nu există evaluări

- 60617-7 1996Document64 pagini60617-7 1996SuperhypoÎncă nu există evaluări

- Speaking Test FeedbackDocument12 paginiSpeaking Test FeedbackKhong TrangÎncă nu există evaluări

- Roman Roads in Southeast Wales Year 3Document81 paginiRoman Roads in Southeast Wales Year 3The Glamorgan-Gwent Archaeological Trust LtdÎncă nu există evaluări

- Genomics - FAODocument184 paginiGenomics - FAODennis AdjeiÎncă nu există evaluări

- A Beautiful Mind - Psychology AnalysisDocument15 paginiA Beautiful Mind - Psychology AnalysisFitto Priestaza91% (34)

- (Methods in Molecular Biology 1496) William J. Brown - The Golgi Complex - Methods and Protocols-Humana Press (2016)Document233 pagini(Methods in Molecular Biology 1496) William J. Brown - The Golgi Complex - Methods and Protocols-Humana Press (2016)monomonkisidaÎncă nu există evaluări

- Visual Images of America in The Sixteenth Century: Elaine BrennanDocument24 paginiVisual Images of America in The Sixteenth Century: Elaine Brennanjoerg_spickerÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- IBM Unit 3 - The Entrepreneur by Kulbhushan (Krazy Kaksha & KK World)Document4 paginiIBM Unit 3 - The Entrepreneur by Kulbhushan (Krazy Kaksha & KK World)Sunny VarshneyÎncă nu există evaluări

- Curriculum Vitae Mukhammad Fitrah Malik FINAL 2Document1 paginăCurriculum Vitae Mukhammad Fitrah Malik FINAL 2Bill Divend SihombingÎncă nu există evaluări

- Employer'S Virtual Pag-Ibig Enrollment Form: Address and Contact DetailsDocument2 paginiEmployer'S Virtual Pag-Ibig Enrollment Form: Address and Contact DetailstheffÎncă nu există evaluări

- Conceptual Diagram of Ways To Increase SalesDocument1 paginăConceptual Diagram of Ways To Increase SalesO6U Pharmacy RecordingsÎncă nu există evaluări

- Standard - Bronze Age - World History Human Legacy TextbookDocument11 paginiStandard - Bronze Age - World History Human Legacy TextbookChris ChiangÎncă nu există evaluări

- DLP No. 10 - Literary and Academic WritingDocument2 paginiDLP No. 10 - Literary and Academic WritingPam Lordan83% (12)

- Port of Surigao Guide To EntryDocument1 paginăPort of Surigao Guide To EntryNole C. NusogÎncă nu există evaluări

- Karnu: Gbaya People's Secondary Resistance InspirerDocument5 paginiKarnu: Gbaya People's Secondary Resistance InspirerInayet HadiÎncă nu există evaluări

- Field Assignment On Feacal Sludge ManagementDocument10 paginiField Assignment On Feacal Sludge ManagementSarah NamyaloÎncă nu există evaluări

- Launchy 1.25 Readme FileDocument10 paginiLaunchy 1.25 Readme Fileagatzebluz100% (1)

- Impact Grammar Book Foundation Unit 1Document3 paginiImpact Grammar Book Foundation Unit 1Domingo Juan de LeónÎncă nu există evaluări

- Special Warfare Ma AP 2009Document28 paginiSpecial Warfare Ma AP 2009paulmazziottaÎncă nu există evaluări

- 23 East 4Th Street NEW YORK, NY 10003 Orchard Enterprises Ny, IncDocument2 pagini23 East 4Th Street NEW YORK, NY 10003 Orchard Enterprises Ny, IncPamelaÎncă nu există evaluări

- Student Worksheet Task 1 - Long Reading: Fanny Blankers-KoenDocument2 paginiStudent Worksheet Task 1 - Long Reading: Fanny Blankers-KoenDANIELA SIMONELLIÎncă nu există evaluări

- Government College of Engineering Jalgaon (M.S) : Examination Form (Approved)Document2 paginiGovernment College of Engineering Jalgaon (M.S) : Examination Form (Approved)Sachin Yadorao BisenÎncă nu există evaluări

- Chapin Columbus DayDocument15 paginiChapin Columbus Dayaspj13Încă nu există evaluări

- BP TB A2PlusDocument209 paginiBP TB A2PlusTAMER KIRKAYA100% (1)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisDe la EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisEvaluare: 5 din 5 stele5/5 (1)

- Workbook to Accompany Maintenance & Reliability Best PracticesDe la EverandWorkbook to Accompany Maintenance & Reliability Best PracticesEvaluare: 3.5 din 5 stele3.5/5 (3)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsDe la EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsEvaluare: 4 din 5 stele4/5 (11)

- A Complete Guide to Safety Officer Interview Questions and AnswersDe la EverandA Complete Guide to Safety Officer Interview Questions and AnswersEvaluare: 4 din 5 stele4/5 (1)

- Plutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersDe la EverandPlutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersEvaluare: 4 din 5 stele4/5 (32)