Documente Academic

Documente Profesional

Documente Cultură

Electronic Load Fundamentals

Încărcat de

Miguel PenarandaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Electronic Load Fundamentals

Încărcat de

Miguel PenarandaDrepturi de autor:

Formate disponibile

W H I T E PA P E R

Electronic Load Fundamentals

What is an electronic load?

An electronic load is a test instrument designed to sink current and absorb power out of

a power source. If a power supply is used to power a device, an electronic load is used

to test the power supply by emulating the device under test (DUT). Power supplies and

electronic loads are complementary test equipment. The power supply tests electronic

circuits under specific sourcing conditions. The electronic load tests the energy sources

or energy conversion blocks under specific loading constraints. An electronic load is a

programmable instrument that offers the user various modes of control such as constant

voltage (CV), constant current (CC), constant power (CP) or constant resistance (CR).

Figure 1 shows the voltage and current diagram of an electronic load.

Voltage

+I

o+ +60 V

Max power contour

200 W/100 W

E-load V

+5 V

Current

o– +16 V

+3.33 V +40 A

+1.67 A +20 A

Figure 1. Polarity convention and input characteristic of an electronic load

Find us at www.keysight.com Page 1

Most electronic loads specify a maximum power level they can absorb as shown by the

max power contour in Figure 1. The user can operate the load only within the voltage and

current combinations limited by the maximum power contour.

For example, it is not possible for an operator to sink 20 A out of a 48 V test device. Both

voltage and current are within their respective ranges, while the power to absorb (960 W)

falls outside the load maximum power dissipation limit of 200 W.

Who uses electronic loads?

Device manufacturers and design engineers use electronic loads to test numerous power

devices such as power supplies, DC-DC converters, chargers, adapters, batteries, solar

panels, fuel-cells, and more.

Why do engineers use electronic loads instead of a fixed value power

resistor?

In situations where you need a purely resistive load and no closed loop control is required,

it is sufficient to use a fixed value power resistor. A fixed value resistor presents many

limitations. It is not adequate for loading and testing power sources that have complex

testing requirements. Such tasks require sophisticated electronic load features to validate

the various states of operation.

Adapting to changes with fixed resistors is a time-consuming task that requires many

resistors, switching matrixes, and the appropriate control software. There is no way

to control or limit the voltage or the current that the load consumes. The user needs

to handle critical safety and device protection concerns in order to avoid any potential

damage to the device.

An electronic load offers higher flexibility by allowing you to sink various levels of power

profiles in multiple modes. The most common operating modes of an electronic load are

constant current (CC), constant voltage (CV), constant resistance (CR), and constant

power (CP).

The electronic load emulates various scenarios and actual devices that connect to your

power source. An electronic load is an effective solution to test devices rather than using

a fixed value resistor. A fixed resistor makes it difficult to automate and to emulate the

dynamic behavior of a real device. It also makes it difficult to adapt to changes in test

requirements.

Find us at www.keysight.com Page 2

DC Electronic Load Operation Modes

Constant current operation mode

Constant current (CC) is the most frequent mode in which an electronic load is used. In

constant current mode, the load will sink the programmed current independently from

the output voltage which is typically forced by the voltage source connected to it (for

example a battery).

How and where to use CC mode

Suppose you have a 3 V battery and would like to discharge it with a constant current

of 1 A; see Figure 2. The operating point is the (voltage and current) setpoint where

the battery output voltage intersects the programmed constant current load line of the

electronic load.

+ Voltage

External DUT

voltage source

characteristic

Operating point

V-in

= +3 V

Constant

current

load line

+ Current

CC setting = 1A

Figure 2. Electronic load I-V diagram in constant current operation

Find us at www.keysight.com Page 3

Figure 3 shows how an electronic load regulates its resistance to achieve the

programmed current when it is connected to a voltage source.

Electronic load External DUT

I-in = 1 A

3V

R FET

Load

FET

P amp

1V 1V

— V-in = 3 V

R shunt + Voltage source

0V 1A 1Ω — to be loaded

I-in +

1V

reference

I in * R shunt +

—

Figure 3. Electronic load circuit in constant current operation

When the load operates in CC mode, it loads the output of an external voltage source

(for example, a 3 V battery), with a variable resistor to reach the desired programmed

current. Most electronic loads use power transistors, FET’-s or IGBT’-s that act as a

variable resistor to regulate the current flowing into the load. The transistors are typically

arranged in a parallel array configuration to handle more power.

The current flowing into the load is monitored via a shunt resistor (for example 1 Ω). The

voltage drop proportional to I*Rshunt is fed to a current amplifier. The current amplifier

compares the voltage drop on the current shunt against the reference programmed

value (example 1 A * 1 Ω = 1 V). The amplifier output signal regulates the FET resistance

and electronic load’s input current. This feedback configuration allows the load to

dynamically change the resistance and maintain the programmed current independent

of the voltage change of your sourcing device.

The minimum voltage where the load can sink the desired current is limited by the input

current level and the low voltage behavior characteristic of the FET. Figure 4 illustrates

the minimum voltage as a function of the programmable sink current for a 100 W and

200 W module with a programmable short resistance of 80 mΩ and 40 mΩ.

Find us at www.keysight.com Page 4

Derated current detail

Voltage +100 W +200 W

+3

+2.5

+2

+1.6 V

+1.5

0.08 Ω 0.04 Ω

+1

+0.5

Current

0

+5 +10 +15 +20 +25 +30 +35 +40

Figure 4. Minimum output voltage where the load sinks the full-scale programmed current

The ability to sink high currents at exceptionally low voltages is challenging and a highly

required feature for electronic loads. Sinking at low voltages is mandatory when testing

fuel cells, power management ICs, or other devices operating at low voltages and high

currents. The 200 W electronic load characterized by Figure 4 offers a programmable

short resistance of 40 mΩ and allows you to sink up to 1 A at an input voltage down to

40 mV and 10 A at an input voltage as low as 0.4 V.

Constant voltage operation mode

In constant voltage (CV) mode the electronic load sets a fixed programmable voltage

across its terminals independently from the input current. In CV mode, the current is

set by the current source connected to it – for example, a current charging circuit or a

LED current driver. The load adjusts its resistance dynamically to attain the programmed

voltage at any current established by the current source under test.

Find us at www.keysight.com Page 5

How and where to use CV mode

Testing a battery charger operating in constant current mode is an example of how

you would use a load in CV mode. You can use the load as a battery sinking current to

test the behavior of the charging circuit at various battery voltages corresponding to a

specific state of charge.

For example, say you have a constant current charger sourcing 0.5 A and need to load

it with a constant voltage of 3.8 V to emulate the charging of a lithium ion battery. The

operating point is the setpoint where the current source level intersects the programmed

constant voltage load line of the electronic load as shown in Figure 5.

+ Voltage

Constant voltage

load line

CV setting

= +3.8 V

Operating point

External DUT

voltage source

characteristic

+ Current

I in = 0.5 A

Figure 5. Electronic load I-V diagram in constant voltage operation

Figure 6. Shows how an electronic load regulates its resistance to maintain its terminal

voltage when connected to a current source.

Find us at www.keysight.com Page 6

Electronic load External DUT

Vp = 5 V In + I-in = 0.5 A

Programmed

voltage

R FET

Load R2

FET 4 kΩ

P amp 0.5 A

1V

+ VM = 1 V I-in = 5 V

0V Voltage Current source

divider to be loaded

— R1

V in 1V

1 kΩ

reference

1 +

V in —

5 —

In –

Figure 6. Electronic load circuit in constant voltage operation

The electronic load is operated In CV mode to typically test and load a current source

device – for example, a current charging circuit. The electronic load modulates its resistance

to reach the programmed voltage. The load monitors the input voltage through a voltage

divider. The voltage amplifier compares the potential of the voltage divider (proportional to

the terminal voltage) against a reference voltage (proportional to the programmed value). If

the measured voltage is higher than the reference voltage, the amplifier activates the FET

proportionally to decrease its resistance RFET to match the programmed voltage.

This feedback configuration allows the load to dynamically change its resistance and

maintain the programmed voltage regardless of the current variation of the sourcing device.

The load adjusts its terminal potential for voltages and current within its range up to the

maximum voltage achievable by the sourcing device.

The load regulates its terminal voltage at the programmed value if the input current remains

within the current limit setting. A CV status flag indicates the output current is within the limit

settings.

When the input current reaches the current limit, the load no longer operates in CV mode

and the input voltage is no longer held constant. The electronic load now regulates the input

current at its current limit setting. A negative current limit status flag is set to indicate that a

current limit is met. If the voltage exceeds the allowable voltage or maximum power contour

for the specified current, the overvoltage protection trips and the load input turns off.

Find us at www.keysight.com Page 7

Constant resistance operation

In constant resistance (CR) mode, the load acts as a fixed programmable power resistor.

An electronic load’s CR mode is well-suited for loading a power source that is either a

voltage or current source. When the load connects to a voltage source it sinks a current

equal to the source potential divided by the programmed resistance value.

When the load connects to a current source, its terminal voltage is equal to the imposed

current multiplied by the programmed resistance value. Figure 7 depicts the I-V diagram of

an electronic load in CR mode when loading a voltage or current source.

A 5 Ω load on a 3 V voltage source will result in a 0.6 A sink current. Alternatively, the same

load on a 0.6 A current source results in a 3 V load voltage.

+ Voltage

Operating point 5 Ω resistive

V in load line

= +3 V

External DUT

current source

characteristic

+ Current

I in = 0.6 A

Figure 7. Electronic load I-V diagram in constant resistance operation

How and where does an electronic load’s CP mode work?

Discharging a battery with a precise resistive load for creating a specific battery profile is

how you would use an electronic load in CR mode.

Figure 8. illustrates an electronic load operating in CR mode. For example, you want

to load a 5 V voltage source with a 5 Ω power resistor. In CR mode, the load needs to

measure both voltage and current to adjust the FET resistance. In order to achieve a

programmable resistance of 5 Ω the ratio between voltage and current V / I should be 5.

Find us at www.keysight.com Page 8

A voltage divider is necessary to measure the voltage source, while the shunt resistor

measures the current. The control amplifier compares the input voltage against the input

current (voltage drop on the shunt times the programmed resistance) to regulate the

load input at a constant resistance value. Figure 8. shows the current sensing at 1 V / A

(1 Ω shunt resistor) and the voltage sensing at 0.2 V / V (for the voltage divider). The 0 V

error occurs for a current of 1 A and input resistance of 5 Ω (5 V / 1 A).

Electronic load External DUT

5 V I-in = 1 A

R

Load FET

FET

R amp

1V 1V

— X R2 V-in = 5 V

R shunt +

4 kΩ Voltage source

0V 1A 1Ω — to be loaded

+ Voltage

1V 1V divider

R-in

reference + R1

1

R in —

5 — 1 kΩ

Figure 8. Electronic load circuit in constant resistance operation

If the load needs to emulate a 10 Ω resistive load on the 5 V voltage source this would result

in a 0.5 A current flowing into the load. The voltage drop across the shunt is now 0.5 V. A

factor of 2 is necessary to achieve the same 1 V voltage drop across the feedback amplifier.

The R-in reference value that you program (10 × 1/5 = 2) controls the multiplying factor.

You can also program and dynamically adjust the load resistance to any value within the

load range.

Constant power operation

In constant power mode, the load module absorbs a constant power out of the DUT. It

regulates the power drawn according to the programmed power value. The DUT can be either

a voltage or current source. When testing a voltage source in CP mode, the load regulates

the sink current to absorb the programmed power level. When testing a current source in CP

mode the load regulates its terminal voltage to absorb the programmed power level.

Find us at www.keysight.com Page 9

Figure 9 shows the I-V diagram when loading a voltage source in CP mode. Loading a 5 V

voltage source with 1 W constant power result in a 0.2 A sink current. In contrast, loading

a 0.2 A current source with the same constant power results in a 5 V load voltage.

+ Voltage

Operating point

External DUT

voltage source

characteristic

V in

= +5 V

1W power

load curve

+ Current

I in = 0.2 A

Figure 9. Electronic load I-V diagram in constant power operation

How and where does an electronic load’s CP mode work?

Discharging a battery with constant power to obtain battery life information is how you

would use an electronic load in CP mode. The load discharges the battery with constant

power and emulates the behavior of a DC-DC converter. Figure 10. shows the operation

of the load in CP mode.

For example, if you have a 5 V battery and want to discharge it with a fixed constant

power of 1 W to emulate the behavior of a Dc-to-Dc converter. The load in CP mode

needs to measure both voltage and current to adjust the FET resistance to maintain a

constant power of 1 W.

The load monitors the input voltage through a voltage divider, while the shunt resistor

measures the current. The load measures power consumption by multiplying both

voltage and current (voltage drop on the shunt). The multiplication result feeds into the

control amplifier.

Find us at www.keysight.com Page 10

Electronic load External DUT

5V I-in = 1 A

R FET

Load

FET

P amp

1V 1V

— X R2 V-in = 5 V

R shunt +

4 kΩ Voltage source

0V 1A 1Ω — to be loaded

+ Voltage

1V 1V divider

P-in

reference R1

1 +

P in — 1 kΩ

5 —

Figure 10. Electronic load circuit in constant power operation

The control amplifier compares the input power against the reference power value. The

amplifier output signal regulates the FET conductance that controls the current flowing

into the load. If the power measurement is lower than the reference power, the amplifier

activates the FET proportionally. The FET increases its conductance (current flowing into

the load) to match the power reference power level.

The feedback configuration allows the load to dynamically change its resistance/

conductance to adjust the sink current. It maintains the same power consumption

level regardless of the voltage variations of the sourcing device. The maximum power

the load can consume at low voltages is limited by the source voltage and the load

minimum programmable short resistance V2/Rshort.

Discharging a battery with constant power gives you battery life information. It allows

you to understand how the Dc-to-Dc converter discharges the battery in similar

conditions. A battery voltage usually decreases during discharge. The load in CP mode

sinks additional current to keep the power consumption constant.

For example, to discharge the 5 V battery down to 4 V in 1 W CP mode results in

an initial discharge current of 0.2 A. When the battery voltage decreases to 4 V the

discharge current increases up to 0.25 A.

Find us at www.keysight.com Page 11

E-load Applications

As technology advances, electrification of legacy mechanical drive energy significantly

increases the use of electrical power. Designers are racing to produce high energy-

efficient products. Rigorous testing on power source and power consumption devices

are increasing DC electronic load applications.

The following are typical applications and how electronic loads are used across

various industries:

Description

Power converter and inverter testing: This is a fast way to test

DC-DC and AC/DC converters. The electronic load helps to simulate

the power-on process of the device. You can test the minimum and

maximum input turn-on voltage level with different load levels. You can

carry out ripple, noise, load/line regulation, over voltage, and current

protection tests with the electronic load.

Uninterruptible power supply (UPS): This is a complete test that

requires an AC source, DC source, DC load, and AC load. The DC

load uses the load bank to test the backup battery and charger

within the UPS. An AC load tests the entire UPS system. A load

bank test indicates the UPS’s ability to provide the necessary power,

voltage stability, and efficiency of control systems under varying load

conditions.

Batteries and fuel cells: Use constant loading to reduce the test

time in comparison to resistor load banks. To test the capacity, use

the CP mode to provide a consistent power drain as the battery

voltage drops over time. The electronic load’s capability to program

different load profiles with a fast transition enables profile testing for

battery charge and discharge cycles.

Solar panels: This is a good solution for high-power photo voltaic

testing as solar panels can sink high current at a lower cost. Use

the CV mode to capture the I-V curve and incremental voltages to

measure the current. With portable devices, program the e-load

to simulate various device power states such as sleep, power

conservation, and full power modes for a power consumption test.

Portable devices: Use the electronic load to simulate various device

power states such as sleep, power conservation, and full power

modes to test power consumption.

Find us at www.keysight.com Page 12

How to Select the Right Electronic Load

Use these guidelines to help select an electronic load that best fits your test requirements.

• Form factor

-- Choose a modular, small form factor solution to give you the flexibility to scale for

future expansion for automated test equipment (ATE).

• Capacity rating

-- Ensure your electronic load safely manages the capacity of your power source.

-- Check that the electronic load range of operations cover your maximum voltage,

current and power requirements.

• Speed

-- Choose a load to emulate fast waveforms with the appropriate slew rate.

-- Verify the load can generate and measure the signals of your application with

adequate bandwidth.

-- Choose a load with a programmable slew rate and ON|OFF delays to control

sequencing.

-- Select a load with superior command processing time and output speed to improve

and maximize your system throughput.

• Operating modes

-- CC for a power consumption test

-- CR for replacing a resistor

-- CV to test current source

-- CP to test storage capacity

• Dynamic testing

-- Identify a dynamic load with arbitrary function generation capabilities and built-in

waveforms to test sine, pulse, step, ramp, or to import your profiles.

-- Ensure the load has sufficient sample rate to generate/ measure fast transient

signals and sufficient memory.

-- Verify the load generates the arbitrary dynamic waveforms for necessary modes,

• Flexibility

-- Choose a modular system to mix and match different modules – electronic load

and power modules – within the same unit.

-- Synchronize within a single environment to achieve a turnkey solution.

• Protection features

-- Confirm the load has built-in protection features for overvoltage, overcurrent,

overpower, and overtemperature.

-- Ensure shut down features to avoid hazardous conditions on your DUT.

• Computer control

-- Load connectivity interfaces for remote programming and controlling of your

instrument – GPIB, LAN, or USB.

Find us at www.keysight.com Page 13

Flexible Load Solutions for Automated Test Equipment

The Keysight N6790 Series DC electronic loads give you the flexibility to test power

supplies in a 1U footprint. The built-in measurement system offers you accuracy and

convenience. It eliminates the need for a digital multimeter (DMM), external shunts, and

wiring. The N6790A electronic load modules fit within a low profile for the N6700/01/02C

mainframe with 1U of rack space. The mainframe offers side air vents; it does not have

top or bottom air vents. Other instruments are mounted directly above or below.

The mainframe hosts up to four electronic load modules making the N6790 series

an ideal solution for automatic test equipment (ATE) systems, design validation, and

manufacturing. The low profile mainframes give system designers the flexibility to mix and

match different electronic loads and power modules within a single unit.

N6700/01/02C low profile high-density system solution

Benchtop Loads

The N6705C DC Power Analyzer provides unrivaled productivity gains for loading, sourcing,

and measuring DC voltage and current into the DUT. The system integrates up to four

load modules with a digital multimeter (DMM), scope, arb, and data logger features. The

N6705C eliminates the need for additional equipment for creating complex test setups,

including transducers. You can easily eliminate current probes and shunts to measure the

current into your DUT.

The DC power analyzer also eliminates the need to develop custom programs to control

multiple instruments. All functions and measurements are available at the front panel.

Keysight’s 14585A control and analysis software offers control and analysis functions.

When automated bench setups are necessary, the N6705C is fully programmable over

GPIB, USB, LAN and is LXI-compliant.

Find us at www.keysight.com Page 14

N6705C high-density bench solution

High Power DC Electronic Loads

Keysight’s N3300A modular load solution helps you with higher power requirements. The

N3300A is a full-rack width mainframe with 6-slots. It accepts combinations of N330x

user installable load modules (150 W to 600 W). The modular design provides easy

system configuration and future reconfigurations. The N3300A also allows up to 1,800

watts of total maximum power.

All outputs are measured simultaneously using the built-in measurement capabilities with

multiple single output power sources. The N330xA Series of DC electronic loads gives

you fast operation, accurate programming and read-back necessary for high volume DC

power supply test systems.

N3300A High power system solution

Find us at www.keysight.com Page 15

Summary

Testing the reliability of a power source or the efficiency of an energy conversion block

is a crucial step for various industries to ensure that the devices meet the required

compliance standards. Multiple devices with complex loading profiles require a high

density test system with advanced features. An electronic load is a programmable

instrument that offers various modes of control such as constant voltage, constant

current, constant power, and constant resistance. It comes in different footprints ideal

for automatic test equipment (ATE) systems, design validation, and manufacturing. It

emulates various scenarios and actual devices that connect to your power source.

An electronic load provides higher flexibility by allowing you to sink various levels of

power and arbitrary profiles. An electronic load is an effective solution to test power

devices. It reduces test time and cost by easily adapting to continuous changes in

device test requirements.

Learn more at: www.keysight.com

For more information on Keysight Technologies’ products, applications or services,

please contact your local Keysight office. The complete list is available at:

www.keysight.com/find/contactus

Find us at www.keysight.com Page 16

This information is subject to change without notice. © Keysight Technologies, 2019, Published in USA, May 11, 2019, 5992-3625EN

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Motion Less Electro-Magnetic GeneratorDocument21 paginiMotion Less Electro-Magnetic Generatormdayyub100% (1)

- 1000 Watt 12 To 48 Volt ZVS Induction Heater Troubleshooting GuideDocument4 pagini1000 Watt 12 To 48 Volt ZVS Induction Heater Troubleshooting GuideJoel Antonio Lopez LopezÎncă nu există evaluări

- Capacitive Sensor Operation and OptimizationDocument10 paginiCapacitive Sensor Operation and OptimizationMiguel PenarandaÎncă nu există evaluări

- Battery Performance Models in ADVISORDocument9 paginiBattery Performance Models in ADVISORMiguel PenarandaÎncă nu există evaluări

- PPF Solenoid Catalog PDFDocument109 paginiPPF Solenoid Catalog PDFMiguel PenarandaÎncă nu există evaluări

- Gate Drive Hexfet Power MosfetsDocument22 paginiGate Drive Hexfet Power MosfetsNacer MezghicheÎncă nu există evaluări

- Understanding and Identifying Ul Awm StylesDocument2 paginiUnderstanding and Identifying Ul Awm StylesMiguel PenarandaÎncă nu există evaluări

- Reducing Emissions in DC-DC Switched Mode Power Supplies by Gentex Corp.Document71 paginiReducing Emissions in DC-DC Switched Mode Power Supplies by Gentex Corp.Miguel PenarandaÎncă nu există evaluări

- Power Supply Test: Using The New Fully Loaded N6700 Power SystemDocument11 paginiPower Supply Test: Using The New Fully Loaded N6700 Power SystemMiguel PenarandaÎncă nu există evaluări

- Lithium-Ion BatteriesDocument1 paginăLithium-Ion BatteriesMiguel PenarandaÎncă nu există evaluări

- SMD Tantalio Capacitor Codes VishayDocument23 paginiSMD Tantalio Capacitor Codes VishayMiguel PenarandaÎncă nu există evaluări

- SMD Tantalio Capacitor Codes AvxDocument51 paginiSMD Tantalio Capacitor Codes AvxMiguel PenarandaÎncă nu există evaluări

- SMD Aluminum Electrolytic Capacitor Codes RubyconDocument4 paginiSMD Aluminum Electrolytic Capacitor Codes RubyconMiguel PenarandaÎncă nu există evaluări

- SMD Ceramic Capacitors Codes AvxDocument115 paginiSMD Ceramic Capacitors Codes AvxMiguel PenarandaÎncă nu există evaluări

- SMD Tantalio Capacitor Code AvxDocument44 paginiSMD Tantalio Capacitor Code AvxMiguel PenarandaÎncă nu există evaluări

- SMD Tantalio & Niobium Oxide Capacitor Codes AvxDocument238 paginiSMD Tantalio & Niobium Oxide Capacitor Codes AvxMiguel Penaranda100% (1)

- FLM0910 4FDocument4 paginiFLM0910 4FTribu Vaquero JimenezÎncă nu există evaluări

- ECE 240 - Project1-CMOS InverterDocument7 paginiECE 240 - Project1-CMOS InverterAbhishek Sthanik GubbiÎncă nu există evaluări

- KA5Q1265RFDocument17 paginiKA5Q1265RFLudwig Sohn GottesÎncă nu există evaluări

- An Industry-Based Survey of Reliability in Power e PDFDocument20 paginiAn Industry-Based Survey of Reliability in Power e PDFPaulo Sérgio RodriguesÎncă nu există evaluări

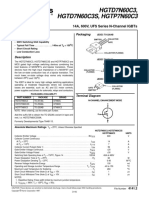

- Hgtd7N60C3, Hgtd7N60C3S, Hgtp7N60C3: 14A, 600V, Ufs Series N-Channel IgbtsDocument6 paginiHgtd7N60C3, Hgtd7N60C3S, Hgtp7N60C3: 14A, 600V, Ufs Series N-Channel IgbtsFábio Vitor MartinsÎncă nu există evaluări

- IRFP450 Mosfet 500V 14ADocument8 paginiIRFP450 Mosfet 500V 14AJunim CarvalhoÎncă nu există evaluări

- Placement Hand BookDocument191 paginiPlacement Hand BookSaurabh VermaÎncă nu există evaluări

- Concept VoltageDocument55 paginiConcept Voltagerajendra poudelÎncă nu există evaluări

- Quiz1 AnalogIC ECE4A - SetBDocument8 paginiQuiz1 AnalogIC ECE4A - SetBNiel Joshua I. LozadaÎncă nu există evaluări

- AN-478A TextDocument12 paginiAN-478A TextAl BenÎncă nu există evaluări

- Datasheet 13001Document6 paginiDatasheet 13001Thomas A. EDISSONÎncă nu există evaluări

- 2021irds BCDocument129 pagini2021irds BC蕭得軒Încă nu există evaluări

- Ee201 Notes 5Document46 paginiEe201 Notes 5adamwaiz100% (2)

- Bosch DS GCU3 1 EN RZDocument2 paginiBosch DS GCU3 1 EN RZInwards CenteredÎncă nu există evaluări

- Electronic Devices: 2 Marks 1. Define The Term Hybrid ParametersDocument4 paginiElectronic Devices: 2 Marks 1. Define The Term Hybrid ParametersMahendra BabuÎncă nu există evaluări

- TPC8053-H: Switching Regulator Applications Motor Drive Applications DC-DC Converter ApplicationsDocument7 paginiTPC8053-H: Switching Regulator Applications Motor Drive Applications DC-DC Converter ApplicationsGabriel EscamillaÎncă nu există evaluări

- Ecen 3103Document2 paginiEcen 3103gaurav kumarÎncă nu există evaluări

- Mini Project ReportDocument11 paginiMini Project ReportNurulAnisAhmad100% (1)

- Junction Field Effect TransistorDocument3 paginiJunction Field Effect TransistorAbril de VeraÎncă nu există evaluări

- Electronic Circuits - I: Lab ManualDocument85 paginiElectronic Circuits - I: Lab ManualKALAIMATHI80% (5)

- Design and Simulation of RF Energy Extracting Circuits and SystemDocument28 paginiDesign and Simulation of RF Energy Extracting Circuits and SystemHaresh SinghÎncă nu există evaluări

- An 9005Document15 paginiAn 9005MANOEL SAMPAIOÎncă nu există evaluări

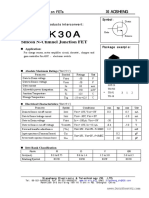

- K30a PDFDocument1 paginăK30a PDFVictorManuelBernalBlancoÎncă nu există evaluări

- Heat & Energy Answers To Workbook PagesDocument13 paginiHeat & Energy Answers To Workbook PageskarenÎncă nu există evaluări

- IRF630A: Advanced Power MOSFETDocument7 paginiIRF630A: Advanced Power MOSFETdragon-red0816Încă nu există evaluări

- 20240221104149-MR21 CSE B.tech Syllabus BookDocument210 pagini20240221104149-MR21 CSE B.tech Syllabus BookSyamkumarDuggiralaÎncă nu există evaluări

- Table of Electrical SymbolsDocument8 paginiTable of Electrical SymbolsIñigo Carlos AquinoÎncă nu există evaluări

- Tutorial On FetsDocument9 paginiTutorial On Fetsaishuvc1822Încă nu există evaluări