Documente Academic

Documente Profesional

Documente Cultură

JAC Truck HFC1061-1063-1083 PDF Service Manual

Încărcat de

Diego Alejandro QuinteroDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

JAC Truck HFC1061-1063-1083 PDF Service Manual

Încărcat de

Diego Alejandro QuinteroDrepturi de autor:

Formate disponibile

FOREWORD

Thank you for choosing JAC. We are pleased to welcome you to the growing number of discriminating people who drive

JAC truck. The advanced engineering and high-quality construction of each JAC we build is something of which we are

proud.

This Owner's Manual will introduce you to the features and operation of your new vehicle. If is suggested that you read it

carefully since the information it contains can contribute greatly to the satisfaction you receive from your new vehicle.

The manufacturer also recommends that all service and maintenance on your vehicle be performed by an authorized

JAC dealer. JAC dealers are prepared to provide high-quality service, maintenance and any other assistance that may

be required.

ANHUI JIANGHUAI AUTOMOBILE CO., LTD.

May. 2008

Downloaded from www.Manualslib.com manuals search engine

Contents

Page

I. Vehicle using 1

All information in this Owner's Manual is current at the time of publication. However JAC reserves the right to make

II. Engine 21

changes at any time so that our police of continual product improvement may be carried out.

III. Chassis 29

IV. Electrical equipment 63

This manual applies to all current JAC models and includes description and explanation of option as well as standard

V. Vehicle maintenance 71

equipment. As a result, you may find material in this manual that does not apply to your specific vehicle

VI.Troubles shooting 75

VII. Important information 91

Downloaded from www.Manualslib.com manuals search engine

Vehicle using

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

Use of instruments and ap鄄 Ignition switch the combination switch are as fol鄄 and the right turning lights and the releasing the handle, it goes out. Re鄄

Ignition switch is on the right side of lows: turning light indicator on the instru鄄 peating of the above action can con鄄

paratus in the cab

integrated switch. It has four func鄄 ment panel. Push the control handle trol the working condition of the high

Integrated switch and instru鄄

tions: LOCK尧ACC尧ON尧START. When forward in horizontal direction, the beam headlight to achieve the pur鄄

ment cluster left control handle

the key is on the 'LOCK' position, right turning light lights and there is pose of dimmer function when over鄄

Integrated switch (figure below),

the ignition switch has been connect鄄 荫 "OFF" indicates that neither small indication of turning right on the in鄄 taking at night.

which is composed of steering shaft

ed to the power source and lockup light nor headlight lights. strument panel. On the other hand, Combination switch (right control

lock seat尧ignition start lock and

of the steering gear has been disen鄄 荫 is the indication of small pull the control handle backwards, handle)

combination switch lies underneath Ignition switch

gaged. Turn the key to 'ACC' posi鄄 light. Turn the control handle clock鄄 the left turning light lights and there

the steering wheel.

tion clockwise, and circuit of acces鄄 Combination switch (left control han鄄 wise by 30o to lighten the front尧rear is indication of turning left on the in鄄

sories like radio and tape player is dle) small lights and the instrument light . strument panel. If the control handle

right control handle

connected. Turn the key to "ON' po鄄 Combination switch is under the 荫 is the indication of head鄄 is in the middle position, there will be

Integrated switch

sition, and the instrument circuit is control of the multifunctional handle, light. Keep on turning the left control no indication of turning. 荫 is the indication of syringe.

connected. If keep on turning the key which lies in the lower left and inferi鄄 handle clockwise by 30oto lighten 荫 Dimmer of headlight: Lift the left When the washer control button on

to 'START' position, engine can be or place of the steering wheel. It can the front headlight尧the rear small control handle upwards gently and the top of the control handle is

Ignition switch started. You should unlash handle of control small light尧headlight尧head鄄 light and the instrument light . do the "uplift -release" motion, which pressed, cleaning mixture (antifreeze

the key immediately after the engine light dimmer and left turning or right 荫 is the indication of steering. can control the dimmer function of should be used in winter) in the win鄄

starts. The key can return to "ON' turning by two different motion Forward and backward motion of the the headlight. If uplifting the handle dow washer which lies in the right

integrated switch position by the action of spring. modes. The symbols and functions of control handle can operate the left once, high beam headlight lights; if doorframe and underneath instru鄄

2 3

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

ment panel can be spouted to the and the indicator light on the instru鄄 pressed, the front尧 rear尧 left尧 right

windshield glass through the spout ment panel lights which shows that turning lights flash at the same time

under the window. exhaust throttle assistant braking and send out emergency signal for

Other electric appliance switch Danger alarm and fog lamp switch

荫 is the indication of wiper. works. If the accelerator pedal or the alarm indication. If pressed again,

Turning the control handle clockwise clutch pedal is depressed, the ex鄄 reset signal of the switch is discon鄄

in horizontal direction can control the haust assistant braking will be can鄄 nected.

wiper. Turn the control handle clock鄄 celled automatically and the indicator 3. is the indication of the fog

wise by 12o to the 'LO' position, the light on the instrument panel goes light. Press this button, the fog light

wiper works at a low speed. Keep on out. lights. Press it again, the switch re鄄

turning clockwise by another 12o, the Other electric appliance switches sets.

wiper can work at a high speed. Other electric appliance switches 4. Ceiling light signal indicates

When the control handle is on the o鄄 mainly include horn button, danger whether the door of the vehicle is

riginal position, the wiper will be dis鄄 warning switch, fog lamp switch and shut closely or not. If one door keeps

connected or return automatically. gating ceiling light switch. open or not shut closely, the ceiling

荫 is the indication of exhaust 1. Horn button is in the center of the light will light to remind the driver.

throttle assistant braking. Lift the steering wheel. When the button is

right control handle upward and do pressed, it can hoot.

the 'uplift-release' motion. Uplift the 2. is the indication of danger

handle, the switch can be connected warning switch. If the button is

4 5

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

Instrument cluster

New pattern of instrument cluster (air brake) Old pattern of instrument cluster (air brake)

New pattern of instrument cluster (hydraulic brake) Old pattern of instrument cluster(hydraulic brake)

Water temper鄄 Speedometer Speedometer

Indicator lamp Mileometer Fuel gauge Indicator lamp

Indicator lamp fuel gauge ature gauge Mileometer Fuel gauge

Air pressure

gauge Mileometer Tripmeter Speedometer

Tripmeter Tripmeter Electrical clock

Water temperature gauge

Button for returning to zero

Button for returning to zero

Air pressure gauge

Water temperature gauge

6 7

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

Integrated cluster when pulling up the parking brake light 渊 冤院when exhaust assistant Use of components in the equipped on the roof. There are

handle, the indicator light will light. braking operates, the indicator light three asbestos heat insulating

cab

5. Generator indicator light渊 冤院in will light. When exhaust assistant mattress on the upside of the engine.

Cab

dicates the working condition of brake is disconnected, the indicator Sealing of the door is double skin

Brief description of the structure:

generator. When the battery is light will go out. constructed. For safety, softening

The driver cab is constructed

discharged, the indicator light will light; 9. Fog light indication light 渊 冤院 has done for the main parts, which

enclosing with full metal. Window

otherwise, the indicator light will go out. press the switch to make it work. can appear knocking easily with

glass adopts panoramic camber

6.Oil pressure indicator light渊 冤院 10. Small light indicati0n light渊 冤院 passengers.

1. turn left 4. fuel alarm 7. oil pressure alarm 10.fog lamp windshield. In order to improve the

2. high beam 5.parking brake 8.braking fault 11.small light indicates low - pressure warning of When they work袁the indication light Air -conditioner system (choose

comfort, side panel with larger

3. tur right 6.charging 9.exhaust assistant brake engine oil pressure. When oil will light.

upside width and raised -roof cab

to pack)

Indicators : indicates that whether the headlight pressure is lower than 0.08-0.1Mpa , Brief introduction

have been adopted. Therefore, the

1. Turning indication light ( ) is under the working condition of the oil pressure indicator light will The automobile air -conditioner with

interior space of the cab can be

when the turning control handle is on high beam . When the headlight is light. When oil pressure is higher cold and warm machine is integrated

more commodious and comfortable.

the left (right) turning position, left on the high beam status, the than it, the oil pressure indicator light with automobile cluster panel. It has

Effective measures have taken in

(right) turning indicator light will flash. indicator light will light. will go out. many useful functions. For example,

reducing noise尧 heat insulation尧

If the warning switch is pressed, the 3. Fuel warning lamp ( ):used for 7. Braking fault indicator light渊 冤院 to make cold air, warm air and to

sound insulation and sealing. For

left and right turning indication light fuel level alarm, when fuel is in when braking fluid is not enough, the remove frost. The air -conditioner

instance, the section of roof forehead

will flash at the same time. shortage, fuel alarm light will light. indicator light will light.. system has four high and low

is enclosed and strengthening rib is

2. High beam indication light ( ) 4. Parking brake indicator light渊 冤院 8. Exhaust assistant brake indicator grades, which meets your need of

8 9

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

choosing different air speed and and the whole system works too. 2. Do not park the vehicle under protection, please do not switch

direction of air sending. 4. When using cold wind, please put the sun . on the system of air conditioner to

the Temperature adjusting handle 3 3. Close the door and windows of avoid accidents

to the COOL position. When using cab when using air-conditioner.

warm wind, put it to the HOT 4. Use compressed air and cold The top of cab's ventilating device

position.To have air sending from water to wash the condenser. (hot You can choose two ways to

different directions, please adjust water and steam are forbidden) ventilate the cab. Outdoor airiness

Handle 2. To use warm wind only, 5. Have the compressor worked and indoor airiness

please close Switch 5 of the air - for 5 minutes once a week in Outdoor airiness Door

Operation conditioner. winter to maintain the air condi - 1. Clockwise the rotary -knob on the 1. The cab door, which has three -

1. Start the engine. 5. Operate Handle 1 on natural wind tioner work normally. top of cab to make sure the top cab step opening, can improve the

2. Press Switch 4 of the air condi - conversion position to have natural 6. Make sure the temperature of closed. convenience for passengers to get

tioner to start air sender. The switch wind outside come into the cab. water used to cold the engine reach 2. Turn on the switch to "IN", then on or to get off. The partial opening

has four grades from left to right to Caution! turn on the rotary knob to "OPEN". angle can be 30益 and 57益 . And

to 70益above when using air heater

make the air speed more and more 1. Avoid putting the handle to the Outside door handle (left) Lock of

and you should use antifreeze fluid Indoor airiness the full opening angle can be 90益 ,

coldest position and pressing the

quick as well as making air stronger to avoid freezing radiator and inside 1. Clockwise the rotary knob to close on all of the three positions, the door door locking(right)

air speed switch on the lowest

and stronger. of air heater to be cracked. the ventilator louver. can be in stable condition. (figure Pull out the outside door handle to

position when using the air -

3. Operate air -conditioner Switch 5, 7. If you do not understand the 2. Turn the switch to "out "which is on above) open the door. Insert the starting

conditioner in order to prevent

then the compressor begins to work evaporative machine from frosting. structure and have no measures of the exhaust gear. switch key into the door lock and

10 11

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

rotate it to lock the door. 56益 .The maximum adjustable dist - When vehicle is in the progress of Notice flange of the wheel seriously before 3. The cab door must be fastened

2. The door can be locked outside ance of the seat is 160mm. maintenance, please clean the track tilting the cab. The notes are shown up. You should take away all the

without the key. First press the lock assembly of the driver seat, recoat in the figure above. goods on the instrument panel尧seat

button on the inner side of the doors the lithium base grease, and tighten Brief introduction of the structure: Use and maintenance and floor to avoid the damage of the

to the fixed position, then pull the all of the joint nuts again. If finding The cab has turnover functions with In order to tilt the cab and run the door and the front windshield.

outside door handle outwards and the sliding track shaking or blocking, turnover and lockup system. vehicle safely, please pay attention 4. Disengaged the locking function of

close the door at the same time. it should be repaired or be replaced Turnover system is composed of to the following contents. the cab locking mechanism at first

3. Pull out the inside door handle to with components. torsion bar, supporting -axle, cab's Cab tilting method and relative when tilting the cab.

open the door. Cab tilt lock mechanism rear bracket and so on. The cab to notices. 5. After the locking function diseng-

4. Press the lock button to lock the cab tilt locking device turnover is used by torsion power. 1. When stopping the vehicle on the aged, hold the tilting rod with hand

door after closing it. Lockup system is composed of right/ horizontal road, you should make and pull up the safety lock hook at

Cab seat left lock unit, turnover lock unit, short sure that there is enough space the same time to avoid the sudden

Cab seat can be classified as driver pull rod, long pull rod, rear bracket around the cab before tilting. Or else, uplift of the cab.

seat, assistant driver seat and rear 1. chuck rod of cab and so on .All of these are to the cab may be damaged while 6. Raise the cab slowly until it tilts to

row seat. Driver back seat adopts lock the cab too tightly and to make tilting. the highest position, then lock it

2. overturn rod

upright seat. The angle of backrest 3. safe locking

sure the vehicle turnover automati - 2. Pull up the parking brake, push carefully with lock arm on the rear

and the fore-and-aft position of seat hook cally when driving in any situation. the shifting rod into the neutral bracket.

can be adjusted. The maximum Please read the tilting notes on the position to avoid the self -sliding of 7. When lowering the cab down, first,

adjustable angle of the backrest is left door of the cab and on the upper the vehicle. hold the tilting rod and disengage

12 13

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

the locking function of lock arm on Inspection and maintenance 荫 Remove the shaft pin connected the torsion rod and operate with the 荫 Tilt the cab forward until the bolt Starting and running of the

the rear bracket, then lower the cab 1. Check periodically the rubber pad the rear support rod and the following steps: hole on the torsion rod arm aimed at

vehicle

down slowly. After the safety lock be assemblies which are used to baseboard support of the cab. 荫 Put the tooth part of the spline the screwed hole on the right bracket

Starting of the vehicle

locked, fasten the locking mech - strengthen the front尧rear support, if 荫 Push the cab forward to some which is cut at the bottom on one end in the cab, screw the bolt and tighten i.

Starting of the engine

anism. found damaged, it should be angle until the bolt on the torsion rod of the torsion rod in alignment with "1" 荫 Put the cab down slowly, and

After making preparations for starting

replaced instantly. arm can be loosened. position on the support axle tube and check whether the cab is on the

engine, first, put the shift bar on the

2. Check periodically the locking 荫 After the bolt removed, the torsion the spline tube, and insert the torsion state of suspending in the horizontal

neutral position, turn on the ignition

situation of the locking mechanism, if rod cannot work. Now the cab can rod into the support axle tube ( for the direction after dropped down. If it

switch, then check horns尧instruments

found not work, it should be repaired be removed ( The torsion rod can not rod which is pulled out). works normally, lock the cab.

on the instrument panel尧turning

or replaced immediately. be pulled out). 荫 After mounting the cab with 6. If finding the torsion rod not work,

lamps尧braking lamps尧the angle and

3. If it is difficult to tilt up the cab and support axle tube and the left尧 right referring to (4)(5) when replacing it.

Note: The mentioned above work position of the rear view mirror.

put it down, the torsion rod cannot bracket together to the frame, put the

must be done by three persons 1. Routine start

work. Replace the torsion rod. "1" of hub splines on the torsion rod

at least because two or three Turn the key to the START position ( As

4. When repairing the chassis, before in alignment with the spline tooth

persons cannot push the cab shown on the right figure), the engine

removing the cab, disengage the which is cut at the bottom on the

forward after the force of the can start. After starting, loosen the

force of the torsion rod and operate other end of the torsion rod, cover

torsion rod disengaged. accelerator pedal immediately and

with the following steps. the hub splines on the torsion rod

keep the engine working in low speed.

荫 Disengage the locking state, and 5. Before reverting the cab to the and insert the spline axle tube into

Pressing the accelerator pedal

tilt up the cab to the highest position. original position, return the force of the right bracket in the cab.

14 15

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

violently is forbidden. 荫 Heat up the oil up to 80益 耀90益 , stably, uplift the clutch pedal slowly. clutch pedal. Do not keep the foot on After shifting, if not finding shortage

Running, swerving, turnaround, bac -

2. Start in winter and then add it into the oil pan. 4. Usually run the vehicle after the the pedal to avoid the burning out of of power and chattering of trans - king and braking of the vehicle

When it is very cold, referring to the After starting the engine, check the temperature of engine rising to 60益 the clutch friction disc. mission, the shifting operation can 1. Running:

following measures to start engine. operating state of the engine and and the operating (sound) of the be considered right. For safety, Keep enough distance to the

Note: Do not let the vehicle run in

instruments at different rotating engine and the reading of the first or the second gear for a when swerving, passing bridge foregoing vehicle when running on

speed. Especially check the oil instruments are normal. Do not run long time to prevent from increasing and meeting, the vehicle can run flat road. Select vehicle speed

pressure. Check whether there is the vehicle in low temperature to the wearing and the fuel in moderate speed. If the running according to the vehicle model,

leakage of water尧oil and gas, avoid wearing the engine. consumption. Loosen the clutch condition is better, the vehicle can mission and concrete condition of

whether the oil level is normal and Starting and shifting of the vehicle pedal rapidly or depress the run in high speed so as to make road, generally select the speed of

whether there is noise coming from After engine operates normally, press accelerator pedal insufficiently, the the speed higher and economize 50-70km/h.

the engine as well as checking the clutch pedal, shift into low gear, engine can stop. the fuel. Let the vehicle run in the first or

whether the color of exhaust is loosen the parking brake, and press When running the vehicle, shift the When shifting, do not just see the second gear when starting,

normal. the horn once. Make sure that the gear according to the change of shifting rod .You should watch upgrading under heavy load and

荫 Use hot water to take the place of 3. After starting the engine, do not vehicle can be operated safely, road and landform. If finding the forward and hold the steering wheel running on bumpy road or on the

cooling water, turn on the drainage press the accelerator pedal violently, loosen the clutch pedal slowly and engine power abundant and the steadily with your left hand, having road with obstacles. But the vehicle

rotating speed rises, it illustrates

switch when heating the water. When loosen the accelerator pedal to keep depress the accelerator pedal the hollow of the palm of your right cannot be run in the first or second

that the primary gear is not

the hot water flow out and the engine the engine operating on idle for some properly at the same time to start the hand stick to the top of the shifting gear too long. When upgrading with

appropriate, the vehicle should be

body become warm, close the time. After the temperature of engine vehicle. After starting the vehicle, the rod and push or pull it to the right heavy load, shift the shifting rod into

shifted to the next fast gear in time.

drainage switch. rising and the engine operates foot should be went away from the position with your right wrist. low gear to avoid overloading of the

16 17

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

engine. or loblolly, prevent the water from vehicle more carefully to avoid vehicle solely alongside the right When turning the vehicle around by have the vehicle run to the left side

When running, do not increase or entering into air intake lines of the decreasing the braking performance side of road. When swerving, turn the 180益 , select the square, large - of road slowly. When approaching

decrease the vehicle speed abruptly engine, rear axles and transmission of the brake because of moist. Do steering wheel uniformly according to scale crossing or flat broad which the roadside, return the steering

and do not shake the steering wheel case. Check rear axle and trans - not take emergency braking opera - the situation of road, the swerving have little traffic flux and turn around wheel rapidly. After observing the

without reason, listen whether there is mission case for entering water after tion to avoid the danger of skidding . track should be transited smoothly , the vehicle at a time along the situation behind the vehicle , start

abnormal noise or not, check the padding. If there is water, drain off it 2. Swerving the turning motion should not be too running direction. At the 50 -100 and turn around vehicle, turn the

reading and indicator lamp of all the and add specified quantity of gear Swerving of the vehicle produces great or too small. Do not turn or meters position in front of the turning steering wheel to the right extreme

instruments for normalization. If oil. The vehicle should not run at a centrifugal force which can be bigger return the steering wheel suddenly. spot, reduce the vehicle speed, shift position at the same time. When

finding abnormal noise or abnormal high speed after padding, brake when the vehicle speed becomes Try your best to avoid taking braking into low gear and send out turning approaching the roadside, return the

events, stop the vehicle immediately pedal should be depressed at higher. The force can bring turning operation while turning the steering around signal. steering wheel rapidly and stop the

and check it, take necessary intervals to resume the braking over in the transverse direction in wheel, especially emergency braking. When turning around with running vehicle. If the turning around

adjustment and repair. performance as soon as possible. serious condition. Therefore, in the When steering, if found skidding of forwards and backwards , send out a operation can not be done for once ,

When downgrading, do not stall the When running on icy or snowy road, 50 -100 meters position before the front wheels, put up the turning around signal at first, reduce repeat the operations above.

engine. When downgrading steep run at steady speed. Do not take swerving, you should ring the horn, accelerator pedal and turn the the vehicle speed and run towards 4. Backing 院

ramp, shift the shifting rod into low emergency braking and do not turn turn on the turning lamp and reduce steering wheel properly along the the right side of road . When The operation of shifting into reverse

gear and take braking operation at the steering wheel fiercely to avoid on the freezing and muddy road or in skidding direction, and correct the approaching the preset spot for gear or shifting from reverse gear to

intervals to avoid the over speeding skidding danger. Keep long safety the weather of heavy rain, fog, wind, running direction after the skidding turning around, observe the situation onward gear can be done after the

running distance from the foregoing vehicle. sand and reduce the vehicle speed stops. of road, turn the steering wheel to the vehicle stopped completely. After

When running across a shallow river When running in heavy rain, drive the to less than 10km/h, swerve the 3. Turning around院 left extreme position rapidly and shifting into the reverse gear, the

18 19

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

back -up light lights. The vehicle reasons, park the vehicle near the After parking, especially after the

speed must be less than 5 km/h roadside and do not park the vehicle engine operates with heavy load, do

when backing. If the driver cannot on the running lane. Under the not stall the engine immediately, and

discern the situation behind the exceptional condition like breaking keep the engine operating in low

vehicle because the vehicle is down in the middle of road, two speed for several minutes. After the

loading or because of other reasons, caution plates should be placed on temperature of water decreases to

the backing operation must be the position of 200 meters in front of less than 70益 , vehicle is going to

commanded by one person who is and behind the vehicle. stop.

not in the vehicle. Do not back the

vehicle without commanding.

Avoid parking on the ramp. If the

vehicle must be parked on the ramp,

When parking midway in winter, take

the heat preservation and anti freez鄄 Engine

5. Parking of the vehicle and stop of pull up the parking brake rod to the ing measures for the engine. Prevent

the engine. extreme position, shift into low gear the oil tank from isolation in summer.

When preparing to park the vehicle , and block the vehicle with triangular After the vehicle runs, routine service

the vehicle speed reduces or the chocks or stones to prevent it from and inspection should be done on

vehicle slides out of gear and sliding. Note: Make sure that the the entire vehicle噎噎

indicates with turning light. After the parking brake can work when

vehicle parked. Pull up the parking parking on the ramp at the same

brake rod . If the vehicle must be time, turn on the emergency warning

parked on the road for some signal indicator light.

20 21

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

Note院The details of the engine Air inlet and air exhaust 荫 Check nuts for looseness, when larger dust particle can be separated dry cloth. When cleaning , do not let Cooling system

tightening the nut on the inlet and from the air by the function of cy鄄 the water enter into the filter element. Brief description of the structure

structure尧 assembling尧 adjust鄄 systems

ment尧 using and maintenance can exhaust manifold, the torsion force clone vane, then can be thrown into 3. Clean the dust unloading valve to Cooling system adopts closed wa鄄

Inlet system includes air inlet pipe

be consulted in the operating should be equable, or else the air the dust gathering plate, the sepa鄄 make sure it isn't worn and can ter-cooling pressure cycle type. It is

assembly尧 air filter 尧branch pipe of

specification of relevant engines. leakage can occur. rated air keep on moving and enter work.

air inlet. Air exhaust system includes composed of radiator尧cooling fluid尧

Note: there is a signboard of en鄄 荫 Check the inlet and exhaust mani鄄 into the cylinder by the filtering func鄄 4. Check whether the rubber tube

exhaust pipe尧 muffler and exhaust thermostat尧fan gear尧connection hose

gine on the top or on the side of

fold for crack and hole, check the tion of the paper element. connected to brake is tight or not etc.

the cylinder. Marked with model of tailpipe etc.

engine, serial number when leav鄄 gasket for damage and erosion, if For every 1000km running , check and close it tightly . Maintenance of cooling system

Using and maintenance

ing the factory, date when leaving finding those phenomena, replace it and maintain the air filter. When run鄄 5. Clean the filter element of the filter. 1. It' s recommended to use long -

1. Service life of engine has the clos鄄

the factory, demarcated rotational with a new one. ning in the condition of excessive Use compressed air gun to remove term effective antifreeze preservative

est relationship with the working

speed etc. please find the exact Air filter dust, the running mileage interval for the dry dirt or dust (air pressure

condition of air filter. It is forbidden to liquid of glycol base as cooling fluid.

position so as to use and repair our The function of air filter is to filtrate inspection and maintenance should should be less than 690kpa), remem鄄

use the engine without air filter or In the north, it can avoid damage to

product.

out the dust and the sand in the air be shortened suitably. ber to blow from inner side to outer the engine due to solidification of

with air filter that cannot work. Taking

The signboard of engine entering into the engine. Cleaning of the air cleaner: side of the filter element to clear

the air inlet port of air filter as the ini鄄 cooling fluid in winter; in the south, it

Air filter is cyclone dust gathering air 1. Remove the dish shaped nut from away the dirt or dust . Patting or can increase the boiling point of

tial air inlet port is also forbidden.

cleaner with paper filter element. Af鄄 the covering lid. Get the filter element knocking are forbidden. cooling fluid in summer to avoid

2. Check the inlet manifold and ex鄄

ter external air entering into the air fil鄄 after opening the covering lid. damage to engine due to air resis鄄

haust manifold for every 1000km run鄄

ter through the air entering into the 2. Clean the covering lid and inside tance in high temperature.

ning.

air filter through the air inlet pipe, of the outer covering with clean and 2. Every time before driving, check

22 23

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

the liquid level in the radiator, if the speed for 5 -10 minutes, then after anti-freezing liquid is green or blue, Accelerating transmission system the hand throttle drawing wire; struc鄄

liquid is found insufficient, it should engine stop working for 10-12 hours, if the liquid is deteriorated, the color Schematic diagram of accelerating transmission device ture of the pedal adopts injected

be added to specified level. restart the engine and run for 10-15 will become deep red because of in鄄 molding type, which makes the as鄄

Hand throttle

3. Drainage of cooling system. In minutes. Then drain the cooling sys鄄 filtration of impurity. 1. Braking pedal bracket sembly convenient and causes little

cold region and in winter, for long - tem with cleaned water. Adjusting of tension degree of fan belt 2. Manual throttle drawing wire operating noise.

3. Accelerator drawing wire

time parking or finishing using the Items in using long-term effective an鄄 pulley 4. Accelerator assembly 2. Accelerating wire drawing:

5. Accelerator pedal assembly

vehicle everyday without using anti - ti-freezing preservative liquid 1. Too tight or too loose fan belt does 6. Acceleration oscillating arm

It is operated with soft drawing wire

freezing preservative liquid, the cool鄄 1. Choose suitable antifreeze accord鄄 no good to operate the engine . of the engine and has a safe structure; it's char鄄

7. Frame

ing system must be drained and the ing to the lowest temperature of the Consult engine assembly for details acterized with convenient layout尧 lit鄄

water filler cap of the radiator must region, if the lowest temperature of of adjusting methods. tle frictional resistance and stable

be opened to avoid the incomplete the region is -25益 , antifreeze of 2. Adjusting methods: Adjust the fan transmission.

drainage of cooling water. which solidifying point is -30益 belt with adjusting bolts first, then do Brief description of the structure: drawing wire and controls the open鄄

4. After engine operating for a long should be chosen. accurate adjusting with the tension Accelerating transmission device is ing extent of the accelerator to in鄄

time , furring can be produced in the 2. Anti-freezing preservative liquid of rod; adjust degree of tension of the composed of accelerator pedal crease or decrease the speed

cooling water and it should be the same type should be used in V -belt with fingers, press each belt mechanism尧 accelerator drawing wire 1. Accelerator pedal mechanism:

cleaned in time .Clean it with the fol鄄 adding in case of deposition. with 98N force. Length of crankshaft and speed governor handle of the en鄄 This mechanism adopts the latest

lowing method: mix 700 -800gram 3. If finding deterioration of the anti- belt pulley-belt tension pulley is 10- gine. (As shown in the figure above) structure of ISUZU truck. It operates

kerosene, add the mixture liquid into freezing preservative liquid, replace 15 mm and length of belt tension pul鄄 When pressing the pedal, driving simply and safely and is connected

the cooling water , run in medium it entirely at once. Normal color of the ley-fan belt pulley is 7-8mm. device of the mechanism pulls the to the accelerating drawing wire and

24 25

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

3 Manual throttle drawing wire: Fuel supply system Using and maintenance of rough fil鄄

Using with the foot throttle can quick鄄 Brief description of the structure: ter:

en the preheating of the engine or in鄄 Fuel supply system is composed of 1. Check the chucking position of

crease the idling speed. fuel tank尧 fuel filter尧 fuel pump尧fuel pipeline interface for sealing ,reliabil鄄

Using and adjustment injection pump尧 fuel inlet pipe and ity and air leakage.

1. Check the chucking position of the fuel return pipe. 2. Check DX150T type precipitator

linkage rod and the accelerator The function of the fuel supply sys鄄 for water -proofing maintenance for

mechanism for rightness and reliabil鄄 tem is to inject specified quantity of every 1000km or 200hs'working . It's

ity, check the direction of the wire diesel well atomized into the cylinder Rough filter: fuel supply pipe is unnecessary to change the filter ele鄄

drawing for straight and check on regularly with definite interval of in鄄 mounted with DX15OT type spin-on ment.

the cornering for smooth transition. jection and under definite pressure precipitator. Its flow volume is 1.5L/

2. The pedal should be depressed according to engine -operating re鄄 min. It can filter big foreign particles

easily and to the extreme position quirement as well as making the and can separate oil from water.

without jamming. When released, it diesel mix with the air well and Fuel tank: oil filler is mounted with fil鄄

should return freely. rapidly. Operating state of fuel sup鄄 tering screen so as to prevent big

3. When pressing the pedal, if the ply system has great influence on foreign particles from entering into fu鄄

free play is too large or the opening power and economic performance of el tank. The lowest position of bottom

degree of the accelerator is insuffi鄄 the engine. of fuel tank is mounted with oil bolt to

cient, adjust the position of bolts. clear the deposit and water away.

26 27

Downloaded from www.Manualslib.com manuals search engine

Chassis

29

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

Clutch tate the end of the push rod to con鄄 to 3-5mm eral times, fill the master cylinder and burnout of the release bearing can

Brief description of the structure: tact gently with piston of the master 4. Bleed air from wheel cylinder of hydraulic pipeline with brake fluid, even result in the abnormal operation

The clutch equipped for this series cylinder, then rotate the push rod for the clutch then loosen the air bleed screw. Air of the clutch. When doing mainte鄄

truck is single -plate dry type di鄄 3/4 circle in the contrary direction, Air or oil leakage in the hydraulic bubble can be puffed from the oil nance, all kinds of clearances of the

aphragm spring clutch. Clutch facing tighten the locknut of the push rod, pipeline of the clutch is not allowed, ring if there is air in the pipeline. Be鄄 clutch must be adjusted. When doing

is composed of two friction discs and and the clearance or else, it can result in the disability fore the pedal reaches the floor, class -three maintenance, clean the

clutch facing riveted with rivet. between the push rod and the piston of the pedal, deficiency of the effec鄄 tighten the air bleed screw. Repeat master pump and distributor pump

Clutch pressure plate presses friction is about 0.5耀1mm. tive travel and incomplete release of the operation mentioned above until and liquid reservoir tank, filling the

discs on pillar by using pressure 3. Adjust the clutch release pump: the clutch etc., which make the there is no air bubble releasing. new lubrication into the inside of re鄄

produced by diaphragm spring to rotate the adjusting nut on pump's clutch not work normally. The work of Maintenance and adjustment of clutch lease bearing.

1. release fork 2. dust cover

produce jointing force. push rod and have the clutch release air bleeding should be completed by 3. copper washer 4. release cylinder Long time use or incorrect adjust鄄

Adjustment of the clutch operating finger touch the clutch release bear鄄 two persons . One person presses 5. wrench 6. soft plastic pipe ment and incomplete air bleeding of

ing. Then rotate adjusting nut in the the clutch pedal and the other 7. container 8. braking the clutch can cause incomplete re鄄

system:

1. Adjust the limit screw of the clutch contrary direction and make the free bleeds the air. Take off the rubber cap of the air lease of the clutch and make the

pedal to make sure that the free play play of clutch release fork reach to bleed screw on the wheel cylinder, clutch in half contact state for a long

of the pedal is 3耀5mm. 2-3mm. Tighten the nut at last. Part link a plastic pipe on the air bleed time, which aggravate wearing of the

2. Adjust the master cylinder of the of the vehicle model use clutch screw, put the other end of the pipe clutch pressure plate and friction lin鄄

clutch: Loosen the locknut on the booster. Adjust the free play of the into the container filled with brake ings. Decrepitating, burning and ex鄄

push rod of the master cylinder, ro鄄 rocker arm end on clutch release fork fluid, press the clutch pedal for sev鄄 foliation of the friction lining, and

30 31

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

Transmission worked by transmission gear shifting the gear selecting/ shifting can be Using and maintenance:

Transmissions equipped for the control mechanism, controlled by completed. There are marks of the 1. If finding the gear shifting cannot

chassis of this series of truck are long-distance soft shaft and rod. transmission, which is shown in the operate or operates difficultly when

LC5T97, LC5T30, LC6T46. Among Shifting control device of transmis鄄 figure below. the engine is not working, it shows

these, LC5T97 and LC5T30 are man鄄 sion. Control handle of transmission that the gear shifting rod (or the flex鄄

ual fixed axle with stages. There are Shifting control device of transmis鄄 Schematic diagram of the transmis鄄 ible shaft) has maladjustment or the

five forward gears and one back sion is controlled by long -distance sion gear shift control device bolt becomes loose, now you must

gear. The second, third, fourth and soft high -floor short rod, using two adjust the control rod (or the flexible

fifth gear has synchronizer that is flexible shafts to choose and shift shaft), check and tighten every bolt

synchromesh. The first and back gear. It is composed by control bar and every nut.

gear are constant mesh. Transmis鄄 base assembly and gear selecting/ 2. If finding out-of -gear when run鄄

sion uses synchronizer to make gear shifting and prop stand. The inner ning on the rough road, the control

shifting convenient. It can reduce core shaft of flexible shaft is steel rod (or the flexible shaft) has malad鄄

wear and tear of tooth and shock, wire rope. Gear selecting /shifting is justment, and it should be adjusted

prolong the life of gear linkage, short鄄 accomplished by steer wire rope's 1. gear shift control rod 7. side bracket for gear shifting correctly.

pulling and pushing motion. The ball 2.dust cover 8. flexible shaft for gear shifting 3. If finding free play of the control

en the time of gear shifting , improve

3. handle 9. fixed bracket of the gear shifting flexible

the average vehicle and reduce labor on the flexible shaft and adjusting rod is too large, check and tighten

4.floor of the cab shaft

intensity etc. screw are used for adjusting the total every bolt and every nut.

5. flexible shaft for gear selecting 10. rear cover of the clutch

Gear shifting of transmission is length of the flexible shaft to ensure 6. transmission rocker arm for gear selecting 11. transmission rocker arm for gear shifting 4. Do not take gear shifting operation

32 33

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

when the engine works at an over age of the over-speed gear resulting chronizer, so the lubricating oil transmission and the flange of the anism. Drive shaft

fast speed to avoid accelerating the from over loading . should be replaced after the break鄄 second shaft for tightening and 14. Gear selecting/shifting should be Brief description of structure:

wear of the synchronizer. 8. During driving, if there is any ab鄄 ing-in period of the new vehicle ex鄄 working condition of the components arranged well. The smallest bending Drive shaft of this loaded truck is ex鄄

5. When shifting, the force should be normal noise in the transmission, pires. Under general condition, re鄄 in the transmission frequently. Be鄄 radius should be 200mm or larger posed cardan shaft. The front flange

gentle. The hand force must be act鄄 stop the vehicle and check it to elimi鄄 place the lubricating oil once for ev鄄 cause the vent plug is easy to block than that. yoke of drive shaft assembly is con鄄

ed on the control rod until the gear nate the malfunction. ery 6000 km running. When replac鄄 by dust, which causes increasing nected with transmission, while the

reaches the correct position. Shifting 9. When sliding on the downgrade, ing the lubricating oil, first drain off pressure in the transmission, oil rear flange yoke is connected with

with flap of push and loosening is in鄄 stalling of the engine is not allowed; the oil in the transmission, prop up seepage or leakage, so the vent plug rear driving gear flange.

appropriate and the shifting opera鄄 starting the engine with the inertia of the rear axle, shift the transmission should be cleaned periodically.

tion cannot be accomplished easily sliding on the downgrade is forbid鄄 into the reverse gear, add kerosene, 13. The movement part of shifting

in this way. den in case of damage of the gear keep the transmission rotating for 2耀 operation component should be lu鄄

6. You can shift from forward gear to and the synchronizer. 3 minutes, then drain off kerosene, bricated well, or else, it will be hard

reverse gear or from reverse gear to 10. During breaking-in period of the add pure gear oil. to shift because of the wearing of the

forward gear only after the vehicle new vehicle, because the metal 11. Check the oil level in the trans鄄 movement parts. If the position of 1. intermediate driving shaft

stops stably, or else, the gear can be chipping which is produced by the mission frequently, if the oil level is gear selecting is found incorrectly, or 2. rear axle driving shaft

damaged. frictional function between new parts under the lower edge surface of the gear shifting is difficult or the trans鄄 Using and maintenance:

7. The fifth gear is over-speed gear, does harm to components in the oil filler bolt hole, sufficient oil should mission is out of gear automatically 1. Drive shaft has been counter鄄

it can be used when the vehicle transmission, especially to the dura鄄 be added. in using, firstly you should readjust poised in factory, it should be en鄄

speed is over 50 km/h to avoid dam鄄 bility of the conical rings of the syn鄄 12. Check the outside bolt of the the gear selecting and shifting mech鄄 sured not to impact in use and not to

34 35

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

knock and stack when doing disas鄄 of universal joint, check and tighten ative mark on the flange so as to Rear axle Driven gear is also called crown gear 15-30N.

sembly and assembly work or carry鄄 drive shaft and the connecting bolt in mount on the original position. After Brief description of structure: and is fixed to left half flange of the 2. The adjustment of drive gear bea-

ing. Replace for a new one if the every position of intermediate sup鄄 finishing all the maintenance items, Rear axle is single reduction driving differential case with bolts. Differen鄄 ring's pre-tension force is a process

shaft is distorted or the balancer is port. having balanced check again is bet鄄 axle, which is composed of final tial is a kind of device that is com鄄 of adding and reducing number of

desquamated, otherwise, there will When doing class-two maintenance, ter. The standard of dynamic bal鄄 drive and differential and axle hous鄄 posed of differential case, cross adjusting shim. When adjusting shim

be vibration, noise, and extra impact check whether the dust cap drop ance is 2750 turn per minute and the ing. It is medium and final class shaft and four planetary pinions is a adds, friction moment will be re鄄

in running, which can damage other and whether the universal joint's free unbalanced volume is less than speed reduction driving mechanism device that makes the left wheel and duced. When adjusting shim re鄄

assemblies and even endangered rotate motion get stuck. When the 144g/cm in driving system. Final drive can not the right wheel run at a different duces, friction moment will be

running. cross shaft lies in the needle bear鄄 only change the direction of driving speed when necessary. Rear axle added. Thickness of friction moment

2. Check oil seals of center support鄄 ing, tear down the universal joint if force, but also reduce the rotate housing is an integrated axle housing has three norms of 0.40mm, 0.45mm,

ing bearing, needle bearing of cross the radial play is too wide. Replace speed. It's composed of drive pinion that is made of welding punched ar鄄 0.50mm.

shaft, sliding spline regularly, replace the needle bearing or cross shaft ac鄄 and driven gear and final drive. The mor plate. 3. Check final drive for meshing be鄄

invalid oil seals instantly cording to your requirement drive pinion is connected with drive Final drive's tooth face meshing and tween drive pinion and driven gear .

3. When doing class -one mainte鄄 When doing class -three mainte鄄 shaft, whose end with spline is con鄄 adjustment of gear lash The contact area and side play be鄄

nance, lubricate the universal joint, nance, disassembling the drive shaft nected with universal joint assembly 1. Check drive gear bearing's pre - tween drive pinion and driven gear

slide spine and intermediate bearing. is necessary, pay attention to making by coupling flange. Driving bevel tension level. The pre -tension force can be adjusted by means of adjust鄄

When adding lubrication to the uni鄄 the mutual mark for the flange yoke, gear's toe end axle journal is mount鄄 of drive gear bearing should be ad鄄 ing shim and adjusting collar of dif鄄

versal, extrude the oil pistol quickly cross shaft and connecting yoke. For ed on guiding cylindrical roller bear鄄 justed. When measuring bearing ferential bearing. There are four kind

to fully lubricate the needle bearing slide spline shaft, make the cooper鄄 ing and bears radial force only. case's bolt hole , tangential stress is of shims according to thickness,

36 37

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

0.30mm,0.40mm, 0.45 and 0.5mm. To adjust tooth contact area, driven tooth top, as figure(c). beyond the specified value or the thinness has taken place. Frame

Normally, the clearance between gear should be coated with red lead Adjustment of rear axle's hub bear鄄 bearing axial clearance is too large, 5. Dismantle the rear cover when do鄄 Brief description of structure:

these two gears is 0.15 -0.25mm, in three points, and 2-3 teeth should ing: tighten the bearing lock nut to a or the damaged parts must be re鄄 ing class -three maintenance. Clean Truck of this series is of side-mem鄄

while the side play ranges under coated in every point. Then rotate certain force moment and release 1/ placed. the inner cavity and final drive as鄄 ber structure.

0.07mm. To adjust side play, mea鄄 gears clockwise and anti -clockwise 3 -1/4 circle. Pre -tightening force 3. Clean the vent plug regularly, dis鄄 sembly, screw bolt and nut referring Using and maintenance

sure four points with equal angle to get the trace of contact area. (see moment is 490-588N.m assemble it when doing class -one to the specified force moment. Side member, cross member and

every component fixed on the frame

around the driven gear, and the the right figure). If tooth contact area Maintenance of rear axle: maintenance to make sure ventilation

are connected using rivet or thread

gauge outfit of micrometer should be doesn't conform to the requirement 1. Hyperbola bevel gear requires a expedite. A jammed air drain can

and welding. Only when all the com鄄

in a vertical position. showed in figure (a), adjust it to con鄄 strict standard of lubricating, only bring higher air pressure in the rear

ponents are in perfect condition, can

form to the requirement. If trace devi鄄 can be filled with specified gear oil. axle, which will result in lubricant leak the frame be used well. Having over鄄

ate from convex or concave tooth Don't use or mix with other gear oil, from the drive pinion seal and other all check when doing class -three

root, add adjusting shim. If trace de鄄 or else, it will result in quickened welding line. Check the level of lubri鄄 maintenance. Tighten the rivet and

viate from convex or concave tooth scratch and wear. cant in axle housing. thread if they loose and renovate the

top, reduce adjusting shim. 2. Don't remove or adjust the conical 4. For a new vehicle, lubricant should cross member in time if there are

Correct contact trace should deviate gears and bearings of final drive, for be replaced when doing class -two crack and shape distortion on it.

Shape distortion and damage of

from toe end of tooth, as figure (a), they have been matched and adjust鄄 maintenance. Afterwards, check the

frame have close relationship with

trace deviate from convex or con鄄 ed in factory. Removing and adjust鄄 quality of lubricant during class -two

overloading and parking location and

cave tooth root, as figure (b), trace ing should be done only as the gears maintenance every time. Replace driving condition (vehicle speed and

deviate from convex or concave are worn and the gear clearance is new lubricant if color -change or road condition).

38 39

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

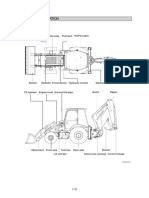

Suspension trucks is composed of leaf spring and stabilizer mounted forward and back鄄

Brief introduction of the structure: bi -directional hydraulic telescopic ward. The next figure shows our front

The suspension of this series of shock absorber. There is transverse suspension assembly.

1. front bumper bracket assembly 7. engine front support assembly 15. frame's rear spring front rein鄄 21. additional spring support

2. the first cross beam 8. front steel spring limit stop forced plate 22. the sixth cross beam coupling

3. the first cross beam reinforced 9. engine front support outer sup鄄 16. frame's reinforced plate plate

plate port 17. the fifth cross beam reinforced 23. the sixth cross beam

4. the second cross beam as鄄 10. cab's rear support assembly plate 24. frame's rear spring rear rein鄄

sembly 11. front spring shackle bracket 18. the fifth cross beam forced plate

5. front spring fixed support as鄄 12. cab's rear support assembly 19. rear shock absorber's support 25. frame's reinforced plate 1.front leaf spring 4.shock absorber

sembly 13. the third cross beam assembly assembly 26. spare-tire carrier cross member 2.front saddle clamp bolt 5.front shock absorber supporter

6. side member 14. the fourth cross beam 20. rear spring fixed support 27. rear cross member 3.damping ring

40 41

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

The next figure shows rear suspension assembly. 3. Tighten U - type bolt on leaf replace new ones. much lower temperature than the absorber is damaged or lack in oil.

spring with specified torque when ve鄄 7. When replacing leaf spring and symmetrical one, the lower one's re鄄 Repair and replace parts and add

hicle is fully loaded for running for dismantling or assembling center sistance is much more smaller. Low鄄 absorber oil in time to avoid serious

2000km-3000km. bolt, pay attention to the assembling er resistance result from lacking in oil damage.

4. Check and tighten exposed bolts direction of front and rear steel plate. or from damage of some important 4. If it's necessary to replace ab鄄

and nuts of the suspension (with ve鄄 When tightening leaf spring U -type parts, and the absorber that lack in sorber rod, replace oil sealing at the

hicle fully loaded) when doing class- bolt and nut, screw it using well-dis鄄 resistance should be removed to in鄄 same time. If necessary, don't dis鄄

one maintenance. Check rubber tributed force at first, then screw front spect. mantle valve parts casually.

parts of the suspension, if the rubber U -type nut according to specified 2. Check the shock absorber for oil 5. When doing class -three mainte鄄

parts are worn greatly, replace them force moment and screw rear ones. leak if continuous abnormal vibration nance, dismantle and clean the ab鄄

instantly. Using and inspection of shock ab鄄 is detected in running.Oil leak should sorber,replace the absorber oil.Don't

1. frame 4. rear absorber

2. rear leaf spring 5. secondary spring bracket 5. When doing class -two mainte鄄 sorber: be dealt with in time, so that the forget cleaning when adding oil.

3. rear center bolt 6. rear shackle clamp

nance, carry out class -one items 1. Check the absorber for tempera鄄 shock absorber can work normally.

Using and maintenance of leaf spring 2. After break -in period, tighten U - and dismantle the leaf spring as well ture after running a certain length on 3. Check absorber when maintaining

1. When vehicle runs for 200km and type bolt on leaf spring with speci鄄 as lubricating it, check the transverse bad road surface (usually more than vehicle. To check absorber, stick up

500km during the beginning of fied torque when vehicle is fully stabilizer rod at the same time. 10km) There is no resistance if the it and hold its lower end by vise,

break -in period, check and tighten loaded. Do it also when leaf spring is 6. When doing class -three mainte鄄 temperature is low ( lower than air then pull and press it for several

U-type bolt on leaf spring with spec鄄 replaced or reset for running every nance, carry out class-two items and temperature) and shock absorption times. Normally the resistance is

ified torque under load bearing state. 2000-3000km. dismantle all the rubber parts and doesn't function. If one absorber has bigger when pulled, otherwise the

42 43

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

Front axle 2. Adjustment of clearance between pin and bush. 荫 Use thrust plate to adjust steering

Brief description of structure: knuckle and front axle: The clearance 2. When doing class -two mainte鄄 knuckle and front axle if the clear鄄

Front axle assembly is composed of is adjusted via adjusting shim, it nance, carry out class -one mainte鄄 ance between them become wide,

front axle, steering knuckle, left should be less than 0.1mm. Use nance items as well as doing some keep the clearance less than 0.1mm.

&right steering knuckle arms, king thrust washer to adjust its clearance. checking. Check whether there is 荫 Replace king pin or bush if the

pin, front brake and tie rod etc. 3. Adjustment of toeing -in. The toe鄄 damage and crack on steering clearance between steering knuckle

Adjustment of front axle:

ing -in can be adjusted via adjusting knuckle, steering knuckle bending king pin and bush reach 0.15mm.

1. Adjusting of the front wheel hub

tie rod. Park the vehicle on a flat arm and left and right steering Replace king pin if its diameter has

bearing: To adjust front hub bearing

ground, jack up its header and orient knuckle arm. Check the fitness of worn to 0.07mm.

in axial retightening force, tighten

fastening nut with wrench, and front wheel just as vehicle run for鄄 steering knuckle king pin and bush. 荫 Replace ball pin or ball cup of

loosen knuckle nut for about 120益 . ward. Loosen locking nuts of tie rod, Check the wearing situation of longi鄄 steering longitudinal rod have worn a

Rotate the hub clockwise and anti - rotate the tie rod till the toeing -in fit tudinal and tie rod connector. Adjust lot and the clearance can not be re鄄

clockwise, make sure that roller a鄄 the specified size. Then tighten the toe -in and dismantle hub according moved.

gainst the tapered contact the bear鄄 locking nuts. to the formulation as well as lubricat鄄 荫 Replace hub oil seal if there is

ing outer race properly, then tighten 1.tire nut 7.lock plate 14.bush 20.thrust bearing

Using and maintenance: ing hub gearing and adding lubrica鄄 damage and aging of cutting edge.

nut to the position where the rabbet 2.front hub bolt 8.hub outside gearing 15.king pin 21.steering knuckle king

3.front hub and brake 9.hub inside gearing 16.king pin latch pin lid 1. When doing class -one mainte鄄 tion.

aims the split pin hole. Check the

drum assembly 10.oil seal 17.nut 22.steering bending arm nance, check tightening situation of 3. When doing class -three mainte鄄

hub if it can rotate freely and don't

4.front hub inside nut 11.oil seal carrier 18.steering stop bolt 23.tie rod assembly

swing a lot. Now, distort the split pin each nut. Lubricate longitudinal and nance, disassemble to clean and

5.hub cap 12.oil guard 19.steering knuckle pin 24. front axle

and fix it. 6.steering knuckle 13.brake bottom plate bolt bush assembly

tie rod ball pin, steering knuckle king check it, then assemble it again .

44 45

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

Steering system Power steering system nism, unitized power -steering gear, Power steering system adopts driv鄄 play of steering wheel is 15 -35mm. 3. Rotate steering wheel to left and

The steering system of this series of It is composed of steering control power steering pump and power - er's physical power and engine Rotate adjusting screw clockwise to right pole for several times.

truck is power steering system. mechanism, transmission mecha鄄 steering pipeline etc. power as steering energy. It can be decrease the free play, while rotate 4. Check oil level of power -steering

steering solely driven by driver if the anti-clockwise to increase it. oil tank, add steering oil if there is

boost device do not work. So com鄄 4. Rotational force of steering wheel not enough oil. Check whether oil lev鄄

pared with common mechanical is around 19.6N when engine runs in el is in normal temperature scope.

steering system, power-steering sys鄄 idle speed. 5. Start engine, rotate steering wheel

tem is acuter and safer, easing fa鄄 5. Check working condition of all of to left and right pole for several times

tigue of driver to a large extent. the switches including starter switch, if engine runs in idle speed. During

Checking procedures of power -steer鄄 rain wiper switch, exhaust brake the process of exhausting air, add

ing system's working state: switch, horn switch and combination steering oil constantly into oil tank to

1. Put front wheel on the steering switch. ensure power-steering oil tank full.

platform. Procedures of air exhausting in power 6. Rotate steering wheel to make

2. Turn the steering wheel to left and steering system: wheel confront forward.

right pole to check if the steering 1. Add steering oil (specified oil ) in鄄 7. After switching off engine, check

wheel has phenomenon of getting to oil tank. oil level and add steering oil if neces鄄

1. steering gear fuel inlet nipple 5. power-steering oil container assembly 9. oil pump inlet flexible pipe stuck and getting impeded. 2. After standing up the front axle by sary.

2. steering gear fuel outlet nipple 6. power-steering oil container supporter 10. hose clamp

3. Check free play of steering wheel using jack, use prop stand to sup鄄 Note: check whether steering oil is

3. power-steering fuel return flexible pipe 7. oil pump outlet bolt 11. wire clip

4. power-steering flexible pipe assembly 8. oil pump inlet nipple

when engine runs in idle speed. Free port frame. in high temperature scope, if stee-

46 47

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

ring oil has been cooled, check line, check it to prevent air from enter鄄 4. When power -steering system port power -engine steering gear or nance that is " preventing mainly, 因 Make sure cross shaft and steering

whether it is at normal temperature. ing into oil outlet pipeline of oil pump. doesn't work, driver can use hand de鄄 steering pump. ( referring to Ameri鄄 check and measure periodically and cross and straight pull rod rotate flexible

Start engine to make it run in idle pending on mechanical steering part. can General Motors Corporation maintain obligatorily ". Obey Ministry and tight

If finding problem, repeat step4

speed and add oil into oil tank. If the However, using mechanical steering standard ) of Communication standard JT/ 因 Check the tightening condition of every

and step5. If the problem still ex鄄

system has not been poured enough only for a long time is forbidden. Using and maintenance: T201-95 connection point to make sure them tight.

ists, repair power-steering pump.

Check and maintenance: oil, rotate steering wheel repeatedly 5. Power -steering system has a 1. Using of power -engine steering " Norm of vehicle maintenance craft " 因 Check connection point of pipeline to

1. Replace steering gear oil in time left and right to extreme position and function of spot turn. Be sure to system and Ministry of city Construction make sure there is no leakage.

and clean &replace filtering screen in add oil into oil tank at the same time avoid rotating steering wheel to ex鄄 荫 Rotating steering wheel to extreme standard CJ17-86 " city bus repair in 荫 Class -two maintenance 渊10000要

oil tank when a new truck runs for until oil level in oil tank doesn't drop treme position to prevent decreasing position for 5s is forbidden. technique condition ". 15000km冤

3000 -4000km and runs every 5000 and has no air bubble. Add oil until oil life of components. 荫 Continuing rotating steering wheel 荫 Make inspection and adjustment 因 Replace power-steering oil.

km afterwards. level is marked. When adding, check 6. Add liquid oil according to pre鄄 after rotating to dead space is forbid鄄 on steering system before driving, 因 Clean filtering screen of power-steer鄄

ing oil tank.

2. Check oil volume and oil quality in oil tank and pipeline connector of scription. If surrounding temperature den. during driving and after driving to

因 Check slack of steering-wheel and ad鄄

oil cylinder often, adding or replacing steering system to make sure them is 0益 above, use L -HM464# anti鄄 荫 Rotating steering wheel when guarantee driving safety.

just it to allowable value.

if oil goes bad. clean, having no impurity. Specific wear hydraulic oil.If surrounding tem鄄 wheels stand still is forbidden. 荫 Class -one maintenance ( 2000-

因 Make flaw detection on front shaft, ball

3. Pay attention to the mark of oil inlet connect are as follows: perature is 0益 below, use L-LM32# 荫 Rotating steering wheel for more 3000km)

pin, steering knuckle , steering knuckle

and outlet in pipeline connecting 荫 Connect oil outlet to oil inlet of antiwear hydraulic oil or 8# hydraulic than 90r/min is forbidden. 因 Add lubrication periodically in to every

arm, steering drop arm and steering gear

when strip and re-assemble steering steering oil pump. automatic steering oil. (mixture of 2. Maintenance of power -engine lubricating point and add power-steering

support frame.

mechanism to make sure it is con鄄 荫 Connect oil return hole of steering different oil type is forbidden). Use steering system oil in time when power -steering system

因 Disassemble cross and straight pull

nected right. After connecting pipe - gear to oil return hole of oil tank. DEXRON域 type hydraulic oil for im鄄 Carry out principle of vehicle mainte鄄 oil is not enough.

48 49

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

rod, clean and check each component to 因 When doing left and right steering, Braking system 2. Structure and theory (referring to the following diagram).

make sure there is no crack on the body steering straight pull rod should not be in鄄 Braking systems of trucks of this se鄄 Interface for low fressure alarming

of cross and straight pull rod as well as terfered in steering gear support frame Interface for air inlet

ries are: parking brake system(center

making sure screw thread on two ends limit arm. If it results in the damage of

drum) and running brake system (air Interface for clutch booster

not worn and limit wearing scope to 2mm straight, replace it in time.

brake, hydraulic brake)

for cotter pin hole of cross and straight

pull rod , 0.5mm for spheri cal surface. Running brake system

Also make sure spring can work well. Air brake

因 Referring to JT 辕 T 201要95 for oth er 1. Brief description of this system:

non-mentioned part. Compared with hydraulic brake, air

荫 For vehicle mounted steering drop brake can bring greater braking

arm limit bolt : force under the condition that force

on the pedal is not great and the

因 Make sure limiting reliability

pedal stroke is not long; at the same

因 Do instant replacement if finding dam鄄

time, dual-circuit air -pressure driv鄄

age on steering gear support frame

ing braking device is equipped to

check arm.

front and rear wheel separately, so

因 Check connection bolt connecting the braking is safe, reliable, labor - 1.air compressor 6.pressure control valve 11.front quick-release valve

steering gear and support frame as well saving, and more effective; even if 2.front brake cha-mber 7.barometer 12.rear brake valve

3.front cavity on main gas cylinder 8.brake valve 13.rear quick-release valve

as checking support frame and vehicle one of the brakes does not work, the 4.rear cavity on main gas cylinder 9.additional gas cylinder;

frame to make sure them tight. vehicle can still brake safely. 5.safety valve 10.one-way valve

50 51

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

Brake pipeline is arranged as fol鄄 valves 10 installed on ends of the air al is released, compressed air in Brake assembly absorb kinetic energy of vehicle to mainly composed of brake chamber,

lows: compressed air produced by inlet pipes of the front chamber 9 of front and rear brake chambers go in鄄 The function of brake is to utilize decelerate or stop the vehicle. Front brake arm and brake

air compressor 1 comes into the the auxiliary air reservoir and the rear to the atmosphere by front and rear power produced by friction between and rear brakes of this brake system

main air reservoir 3 (namely wet air chamber 4 of the main air reservoir in air-deflating valves 11 and 13. brake drum and brake shoe slice to adopt imbalanced structure and are

reservoir); and then the air is separat鄄 case that compressed air in the air

ed into two and come into the front reservoir flows backwards. There are

chamber 9 of the auxiliary air reser鄄 interfaces for air pressure gauge 7

voir and the rear chamber 4 of the and pressure -adjusting valve 6.

main air reservoir, the front chamber When air pressure reaches 0.74 -

9 of the auxiliary air reservoir and the 0.84Mpa, compressed air props up

rear chamber 4 of the main air valve of the pressure -adjusting 1. return spring locating pin 10. hex bolt

2. roller shaft-brake shoe 11. front brake air chamber support

reservoir. Compressed air in the front valve, and comes into upper cover of

3. roller-brake shoe frame with liner assembly

chamber 9 of the auxiliary air reser鄄 the air compressor to make air inlet 4. gripping ring -brake shoe roller 12. front left brake air chamber as鄄

voir and the rear chamber 4 of the valve open and the air compressor shaft sembly

5/18. front brake shoe with liner as鄄 13. hex bolt

main air reservoir come into upper idles. When brake valve 8 is de鄄

sembly 14. front brake adjusting arm as鄄

and lower chambers of brake valve pressed, front and rear brake cham鄄 6/19. front brake friction plate sembly

8, and then the air is transported ber 2 and 12 operate at the same 7. brake cam 15. shoe shaft fixed bolt

8. front brake baseboard with liner 16. front brake shoe-shoe shaft;

separately to rear brake chamber 12 time, which makes front and rear

assembly 17. front and rear brake shoe

and front brake chamber 2. Check brakes operate. When the brake ped鄄 9. front brake dust cap shaft-liner; 18. return spring

52 53

Downloaded from www.Manualslib.com manuals search engine

OWNER爷S MANUAL for

HFC1061,HFC1063,HFC1083

series trucks

Adjusting arm Brake Full adjustment 5. Test drive after adjustment, check end is 0.45mm. and deal with the problems in time. If

1冤Lubrication: mount oil month on Front brake has the same structure 1. Loosening fixed nut of brake shoe working condition of brake, whether Brake valve the air pressure is lower than

adjusting arm, use lithium base with the rear brake. It is shoe brake bearing pin and nut of binding bolt the brake drum get hot and whether Brake valve is a mechanism with 0.45Mpa but the annuciator does not

grease periodically to lubricate ad鄄 with camshaft with fixed sustainer. on cam bracket. braking distance is proper. If not, which the whole air brake system warn, check the annuciator, replace

justing arm (maximum lubrication in鄄 When braking, front and rear shoe 2. Rotate brake shoe bearing pin so readjust it controls the brake. it if necessary.

terval is limited to 10000km), or else, slices of the brake press to the rotat鄄 as to make clearance between front Partial adjustment Using and Maintenance: 3. If the brake shoe slice is damaged

life of adjusting arm will decrease. ing brake drum by the action of the shoe and bearing pin end the same Turn worm of the brake arm to adjust routine inspection or over worn, replace for new one;

2冤Check adjusting arm's counter鄄 same push force; so the rear brake as that between rear shoe and bear鄄 clearance between friction disc at the 1. Before running, air pressure in the surface of the new liner should be

clockwise force moment periodically: shoe is called power-reducing brake ing pin. camshaft end of the brake assembly pipeline should be checked, when grinded, and there should be no oil

rotate adjusting nut of adjusting arm shoe. All above lead to imbalance of 3. Start braking, make brake shoe and the brake drum. Adjusting meth鄄 the air pressure is more than dirt, scratches, chap on the surface.

counterclockwise when running every forces that front and rear brake friction disc lean against brake drum ods are as follows: Face to the worm, 0.6Mpa, the vehicle can start, and Friction disc must be made of the

20000km and measure whether the shoes press on the brake drum, so closely and brake camshaft auto鄄 turn the worm clockwise, at the same the normal running air pressure is same material.

rotary moment is bigger than 18Nm, this kind of brake is called simple matic positioned and tighten nut of time, rotate the brake drum come - 0.74 -0.84Mpa; if the air pressure is 4. Replacing friction disc or rein鄄