Documente Academic

Documente Profesional

Documente Cultură

Under Screed Piping

Încărcat de

Visakh VijayanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Under Screed Piping

Încărcat de

Visakh VijayanDrepturi de autor:

Formate disponibile

Domestic Gas Pipework

Part 2 - Installation and Testing

Copper tube and fittings be fitted before the meter is Installing tube in walls and floors

Copper tube to EN 1057 can be used disconnected, dust caps fitted, and the Typical methods of installing gas

for gas installations. It can be jointed using end of the pipework sealed. The existing piping in walls and floors are shown in

EN 1254 capillary or compression fittings. pipes should be purged out of service to Figure 3. Where copper tube is to be

According to BS 6891 compression remove fuel gas before using a blow buried in solid floors or walls, the number

fittings should only be used where they lamp. Any open ends of pipework must of joints should be kept to a minimum.

are readily accessible for tightening and be sealed before the work is left Ideally the tube should be run in a

inspection. This means that they cannot unattended. preformed duct with a suitable

be buried underground, buried in the

structure or used in ducts or under floors. Screed

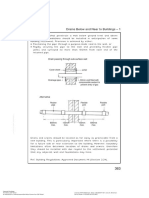

Pipe in screed Pipe in brick or block wall

Corrosion

Jointing protected pipe

When using capillary fittings it is

important to visually examine every joint T

to ensure that the solder has run. The

flux used must only be corrosive during Gas pipe in chase in plastered wall

heating and any residue should be Maximum chase depth: T÷3 vertical pipes

Base concrete T÷6 horizontal pipes

removed after making the joint. Apply a

thin coating of flux to the outside of the Pipe behind plasterboard on dabs

cleaned tube only, not into the mouth of Pipe in ground

the fitting. Twist the tube as it is bearing slab Adhesive dabs

assembled into the cleaned fitting to Soft copper tube

spread the flux and then wipe off any in plastic sleeve

Gas pipe behind plasterboard

excess before completing the joint. Use

only EN 751 approved non-setting

jointing compound on threads or the Individual

thicker type of approved PTFE adhesive dabs

Insulation

tape wrapped with a 50% overlap,

as in Figure 2. Concrete slab

Pipe in precast Chipboard over

PTFE tape beam & block insulation Continuous dabs

Pipe laid in to surround pipe

insulation layer

Pipe behind plasterboard on battens

Full length

50% overlap Precast beam timber batten

Figure 2

& block

Pipe in raft Gas pipe behind plasterboard

Installation Chipboard over

During installation prevent dirt and insulation

Pipe in timber wall

water entering the tube by use of Pipe laid in

insulation layer Ply sheathing

adhesive tape over the ends. Remove

burrs left by tube cutters to minimise Vapour barrier

pressure drop due to turbulent flow.

Full length

If work has to be done on existing timber blocking piece

Timber studs

pipes already connected to a meter, a Figure 3 Gas pipe behind plasterboard

temporary earth continuity bond should

protective cover. Use plastic sheathed point. Slowly turn on the gas

copper laid on top of the base concrete and note the reading; this

and soundness test the installation piping should be 20mbar or a little

before wrapping any joints and covering above. If the pressure reading

with a suitable screed. is above 25mbar the meter

governor may be faulty and

Alternatively, pass plastic sheathed the gas supplier should be

soft coiled copper through a larger tube informed. The reading should

Solid or cavity wall

that has been previously set into the Flexible mastic then be checked with the

concrete.Try to run vertical pipes in walls appliances operating, this

in ducts, with access if possible, never gives the meter outlet

inside the cavity. If the wall is thick enough working pressure. If the

to provide proper cover the pipe can be pressure drop across the

run in a chase. If the pipe is to be installed meter and governor is

behind plasterboards, timber battens or greater than 1.25mbar there

continuous adhesive dabs should be used could be a problem, due

Sleeve

to surround the pipe. Cement mortar Tube perhaps to overloading the

meter or an inadequate or

Flexible mastic

Where tube is to be laid in timber partially blocked service pipe.

floors running across the joists, these Consider extending In any event the gas supplier

sleeve above floor in

should be notched or drilled to areas like kitchens should be informed.

accommodate the tube. Care should be

taken to mark floor boards so that fixing Checking the installation

nails and screws do not damage the piping for pressure drop

tube.Tubes installed parallel to the joists Once the meter outlet

should be properly supported. If tube Sleeve working pressure is known,

has to be installed in purpose-designed Solid Floor Figure 4

ducts, these must be sealed to prevent the installation pipework can

the passage of gas into the wall cavity. If person before the meter is connected. If be checked for pressure drop. Attach a

the duct has a cross-sectional area of work is to be carried out on an existing manometer to the inlet pressure test

more than 10,000mm2 it should be installation it must be tested before point before the appliance governor and,

vented at high level to allow any escape starting and any faults traced and with the appliances lit, take a reading. If

of natural gas to dissipate into the rectified or the installation made safe. On this is more than 1mbar below the meter

rooms, and if possible cover the duct completion of the work a further test outlet working pressure, the pipework is

with a metal plate to minimise the risk must be carried out and if satisfactory either too small in diameter for its length,

from nail punctures. the installation purged into service. The or a section of piping may have been

testing and purging of domestic crushed or be partially blocked by debris.

Sleeves installations must be carried out in

Always sleeve the pipe where it accordance with BS 6891. Whatever the cause, the problem is

passes through solid walls or floors. Build within the installation. If the installation

the sleeve into the wall or floor and seal Dynamic performance testing gas pressure drop is satisfactory, and the

the gap between the gas pipe and sleeve installations burner pressure cannot be achieved,

with flexible fire-resistant compound at Note that once the gas piping then the problem lies within the

at least one end, as in Figure 4. installation is completed and the appliance, possibly in the appliance

installation has been tightness tested, governor.

Other services purged and brought into service the gas

Keep a gap of at least 25mm appliances must also be tested to make Brian Curry: March 2008.

between gas pipes and other services sure that they operate in accordance

and keep at least 150mm away from with the manufacturer’s instructions and

electricity meters and fuse boxes. Where the Gas Safety Regulations. In cases

electrical cross bonding is necessary, a where the correct burner pressure or

clamp is used to connect the protective gas rate cannot be achieved, taking

conductor near (ideally within 600mm) pressure readings at the meter and the

the outlet side of the meter in inlet pressure test points on the

accordance with BS 7671 Requirements appliances can identify the likely source

for Electrical Installations. of the problem.

Checking the service entry piping

Testing for soundness and meter installation for pressure

The Gas Safety Regulations require drop

that new installations be installed and Turn off all appliances and connect a

tested for gas tightness by a competent mano-meter to the meter outlet test

www.copperplumbing.org.uk

S-ar putea să vă placă și

- Figure 10-10 Pipe Cast in ConcreteDocument1 paginăFigure 10-10 Pipe Cast in Concretenorman moralesÎncă nu există evaluări

- Specification Data Sheet For Pipe InsulationDocument1 paginăSpecification Data Sheet For Pipe InsulationTalha BaigÎncă nu există evaluări

- D1.12 Hyliner AKS HDPE LiningDocument4 paginiD1.12 Hyliner AKS HDPE LininglmiitobnykhpvdwuzyÎncă nu există evaluări

- Rubber Lining of Pipes (p167-p171)Document5 paginiRubber Lining of Pipes (p167-p171)Marine SleimanÎncă nu există evaluări

- MS For AC Pipe InsulationDocument14 paginiMS For AC Pipe InsulationTruong Quoc Bao100% (1)

- SECTION 15083: Pipeing Insulation 15083Document8 paginiSECTION 15083: Pipeing Insulation 15083fatREVITÎncă nu există evaluări

- Fire Stop FoamDocument1 paginăFire Stop FoammikkyÎncă nu există evaluări

- Thermafiber Res Install Instructions-FinalDocument2 paginiThermafiber Res Install Instructions-Finalasanz1983Încă nu există evaluări

- Boiler Tube Plugging PDFDocument3 paginiBoiler Tube Plugging PDFCarlos Anibal OrtizÎncă nu există evaluări

- Domestic Gas Installation TestingDocument2 paginiDomestic Gas Installation TestingKosala KamburadeniyaÎncă nu există evaluări

- ACPPA TechSeries 03 Tunnel Installations 1Document4 paginiACPPA TechSeries 03 Tunnel Installations 1padmajareddyÎncă nu există evaluări

- Fatima de Guzman Part 1Document10 paginiFatima de Guzman Part 1Frances Dale CapulongÎncă nu există evaluări

- Staple Stakes SpecDocument1 paginăStaple Stakes SpecashwinÎncă nu există evaluări

- FL - Sleeves and Sleeve Seals For Plumbing Piping - BudDocument5 paginiFL - Sleeves and Sleeve Seals For Plumbing Piping - BudAntonius HarrisÎncă nu există evaluări

- Fusion Bonded EpoxyDocument28 paginiFusion Bonded EpoxyMahdiÎncă nu există evaluări

- HVAC Specs - ComplianceDocument32 paginiHVAC Specs - ComplianceArchanaShenoyÎncă nu există evaluări

- Supreme Beam and Block FloorDocument7 paginiSupreme Beam and Block FloorhemendraengÎncă nu există evaluări

- Drains Below and Near To BuildingsDocument1 paginăDrains Below and Near To BuildingsMoh'd KhadÎncă nu există evaluări

- Rehab Bro WebDocument16 paginiRehab Bro WebaapennsylvaniaÎncă nu există evaluări

- SleeveDocument16 paginiSleeveengsamerhozinÎncă nu există evaluări

- Project Title: Al Ula Primary & Childhood School Client Name: Royal Commission For Al UlaDocument2 paginiProject Title: Al Ula Primary & Childhood School Client Name: Royal Commission For Al Ulathahar ali syedÎncă nu există evaluări

- Draft Wadi Sarami Roof Deck Inspection 06 Dec 2017Document8 paginiDraft Wadi Sarami Roof Deck Inspection 06 Dec 2017WilfredoEnghoyÎncă nu există evaluări

- Oof Concr Ete Cons Tructions: 5 WolfDocument19 paginiOof Concr Ete Cons Tructions: 5 WolfMark Roger II HuberitÎncă nu există evaluări

- Running ManualDocument25 paginiRunning ManualArnel SolisÎncă nu există evaluări

- EAN-70M Portable Tiltmeter Manual - R01Document3 paginiEAN-70M Portable Tiltmeter Manual - R01rahuldevpatel5Încă nu există evaluări

- Cast Iron Soil PipeDocument10 paginiCast Iron Soil PipeFronda Jerome BlasÎncă nu există evaluări

- Edison Welding Institute Hot Tap WeldingDocument19 paginiEdison Welding Institute Hot Tap WeldingShikhar JainÎncă nu există evaluări

- Proceso de Soldadura PVC George FisherDocument10 paginiProceso de Soldadura PVC George FisherMarco Antonio Hernandez MotaÎncă nu există evaluări

- Wall Stabilisation Cintec Anchor SystemDocument4 paginiWall Stabilisation Cintec Anchor Systemmarin_sÎncă nu există evaluări

- D-5) Piping InstallationDocument8 paginiD-5) Piping InstallationfbellimamÎncă nu există evaluări

- Duct (HVAC) - Wikipedia, The Free EncyclopediaDocument4 paginiDuct (HVAC) - Wikipedia, The Free Encyclopediasaurabhjerps231221Încă nu există evaluări

- SECTION 15081: Duct Insulation 15081Document5 paginiSECTION 15081: Duct Insulation 15081fatREVITÎncă nu există evaluări

- ICU DesignDocument3 paginiICU DesignhyreepktÎncă nu există evaluări

- Csti - HDLDDocument6 paginiCsti - HDLDQuang Kien NguyenÎncă nu există evaluări

- 23 0511 - Builder's WorkDocument5 pagini23 0511 - Builder's WorkMohamed FawzyÎncă nu există evaluări

- Laying A New Water Supply Pipe: DuctingDocument4 paginiLaying A New Water Supply Pipe: DuctingvictorÎncă nu există evaluări

- Basement Waterproofing PDFDocument1 paginăBasement Waterproofing PDFFaisal NasimÎncă nu există evaluări

- PU Foam PresentationDocument2 paginiPU Foam PresentationDuongthithuydungÎncă nu există evaluări

- Veneer Masonry: SectionDocument22 paginiVeneer Masonry: SectionOuali HaceneÎncă nu există evaluări

- Gyplyner: Internal Wall Insulation (Iwi) Installation GuideDocument16 paginiGyplyner: Internal Wall Insulation (Iwi) Installation Guidesamuel rondon upeguiÎncă nu există evaluări

- Case Studies of Innovative Cable Bolt TechnologyDocument6 paginiCase Studies of Innovative Cable Bolt TechnologyMauricio GutierrezÎncă nu există evaluări

- Q-A Result ConclusionDocument1 paginăQ-A Result ConclusionAbdul MoizÎncă nu există evaluări

- Barrier & Membrane InterruptionsDocument1 paginăBarrier & Membrane InterruptionsRolando CostaÎncă nu există evaluări

- Elec Specifications PDFDocument166 paginiElec Specifications PDFام حورÎncă nu există evaluări

- Chiller Tech3 - EIL DelhiDocument3 paginiChiller Tech3 - EIL DelhibmanojÎncă nu există evaluări

- Pipe SleeveDocument2 paginiPipe Sleevepaansaeng_hotmailÎncă nu există evaluări

- TDSCLGB PFC Corofil Linear Gap Blocks CLGB Rev 1.3Document6 paginiTDSCLGB PFC Corofil Linear Gap Blocks CLGB Rev 1.3tellpatryanÎncă nu există evaluări

- Concrete Construction Article PDF - Construction Details For Earth-ShelteringDocument3 paginiConcrete Construction Article PDF - Construction Details For Earth-ShelteringCharlie GrazebrookÎncă nu există evaluări

- Peter Cox - Anchorbond Wall Stabilisation - Datasheet LeafletDocument4 paginiPeter Cox - Anchorbond Wall Stabilisation - Datasheet LeafletPaul LawlessÎncă nu există evaluări

- GRP Pipe JointsDocument5 paginiGRP Pipe JointsIlija Runjajic100% (1)

- BCA Design External Wall PDFDocument15 paginiBCA Design External Wall PDFSiow TingÎncă nu există evaluări

- Manual Instalacion Lineas Calentadas pn50035Document8 paginiManual Instalacion Lineas Calentadas pn50035Fredy Vázquez VelázquezÎncă nu există evaluări

- Silencio Price ListDocument12 paginiSilencio Price ListmohindarÎncă nu există evaluări

- Construction TerminologiesDocument4 paginiConstruction Terminologiesahrelje99Încă nu există evaluări

- Castellated BeamDocument3 paginiCastellated BeamSoham SatamÎncă nu există evaluări

- Types of InsulationDocument14 paginiTypes of Insulationnathan eyasuÎncă nu există evaluări

- 2.end Seal Tape - 1 Jul 2012 - PDSDocument3 pagini2.end Seal Tape - 1 Jul 2012 - PDSUbaidah JarrahÎncă nu există evaluări

- The Little Book of Vacuum Tube Pre-Amplifier ProjectsDe la EverandThe Little Book of Vacuum Tube Pre-Amplifier ProjectsÎncă nu există evaluări

- Scientific American Supplement, No. 470, January 3, 1885De la EverandScientific American Supplement, No. 470, January 3, 1885Încă nu există evaluări

- Construction Document Sheet Numbers and Sheet OrderDocument5 paginiConstruction Document Sheet Numbers and Sheet Orderkajale_shrikant2325Încă nu există evaluări

- Midea Atom B Series VRF 8 To 16kw ENDocument2 paginiMidea Atom B Series VRF 8 To 16kw ENa.guessoum.hvacÎncă nu există evaluări

- BoreAid Product Fact Sheet 011426Document2 paginiBoreAid Product Fact Sheet 011426Ana MariaÎncă nu există evaluări

- Thesis RCCDocument16 paginiThesis RCCcricketloversiitÎncă nu există evaluări

- SCE - Innovative Design of Storage Bins: #Think DifferentDocument21 paginiSCE - Innovative Design of Storage Bins: #Think DifferentMALELA70Încă nu există evaluări

- Surrey ENGM030 Unit 1 PresentationDocument44 paginiSurrey ENGM030 Unit 1 PresentationPhilip YapÎncă nu există evaluări

- Three Storey Commercial Building (Concrete) - 18-009 - PinagsamaDocument21 paginiThree Storey Commercial Building (Concrete) - 18-009 - PinagsamaJohn Michael TalanÎncă nu există evaluări

- Asme Sec I PT PWT 2005 PDFDocument5 paginiAsme Sec I PT PWT 2005 PDFarlyÎncă nu există evaluări

- 31003Document4 pagini31003Elliott RussellÎncă nu există evaluări

- Daynamic Analysis of FloorDocument11 paginiDaynamic Analysis of FloorBashar AlshathirÎncă nu există evaluări

- ASTM C494, PDF PDFDocument9 paginiASTM C494, PDF PDFMuhammad Zaini Gani100% (10)

- Katalog 2020 enDocument148 paginiKatalog 2020 enAlejandro BoccoÎncă nu există evaluări

- Napa Air Compressor ENDocument26 paginiNapa Air Compressor ENTenny SupÎncă nu există evaluări

- Modelling of Structures and Numerical SimulationDocument17 paginiModelling of Structures and Numerical SimulationObinna ObiefuleÎncă nu există evaluări

- POLB-Wharf Design (Version 2.0)Document103 paginiPOLB-Wharf Design (Version 2.0)mediannaÎncă nu există evaluări

- Espresso Coffee Machine PDFDocument104 paginiEspresso Coffee Machine PDFStrugaru GheorgheÎncă nu există evaluări

- 2e-Aruana 40 Efi 2017Document57 pagini2e-Aruana 40 Efi 2017costinbalca46Încă nu există evaluări

- Imp PSC DesignDocument107 paginiImp PSC DesignTouseef Ahemed Attar50% (2)

- Design HallDocument11 paginiDesign HallCherie Joy100% (1)

- Uttar Pradesh Power Transmission Corporation LTD.: Construction 400 KV Substation, JaunpurDocument207 paginiUttar Pradesh Power Transmission Corporation LTD.: Construction 400 KV Substation, JaunpurJai PrakashÎncă nu există evaluări

- Table 6 1 AWS D1 1 D1 1M 2010 PDFDocument1 paginăTable 6 1 AWS D1 1 D1 1M 2010 PDFFu AdÎncă nu există evaluări

- Assignment-Ii Geotech HydraulicsDocument2 paginiAssignment-Ii Geotech Hydraulicspat cruzÎncă nu există evaluări

- Manual For Design Using Etabs PDFDocument46 paginiManual For Design Using Etabs PDFPankaj Sardana100% (1)

- Book 01 - Specification - ArchitecturalDocument164 paginiBook 01 - Specification - ArchitecturalTarique NomaniÎncă nu există evaluări

- Instrument TubingDocument11 paginiInstrument Tubingbab_ooÎncă nu există evaluări

- Hexoloy Enhanced Sa Sic en 1008 Tds 215399Document1 paginăHexoloy Enhanced Sa Sic en 1008 Tds 215399Pedro Tavares MurakameÎncă nu există evaluări

- RomanDocument14 paginiRomanbharat vermaÎncă nu există evaluări

- NTN Bearings CatalogueDocument412 paginiNTN Bearings Cataloguemfulgosi1231Încă nu există evaluări

- AGPT04J-08 Aggregate and Source RockDocument34 paginiAGPT04J-08 Aggregate and Source RockSteveÎncă nu există evaluări

- NAASRA Guide HighwayBridgeDesign 1970Document245 paginiNAASRA Guide HighwayBridgeDesign 1970Angga Alfiannur100% (3)