Documente Academic

Documente Profesional

Documente Cultură

Friction Coefficient Test Machine

Încărcat de

AMBUJSHARMADrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Friction Coefficient Test Machine

Încărcat de

AMBUJSHARMADrepturi de autor:

Formate disponibile

SimTest Dynamics LLP

FRICTION

CO-EFFICIENT

TEST MACHINE

(Brake Lining Test Machine)

Test as per the SAE-J661 /

IS-2472 Standards

Automatic Controlled

System.

Customizable Software.

Power Failure Backup.

User Friendly Software.

No. 5E, 1stFloor, Block A,Sector-80, Phase-2, Noida, U.P. India-201301

Email: contact@simtestdynamics.in, Phone: -0120-424514

Website- www.simtestdynamics.in

SimTest Dynamics LLP

INTRODUCTION:

The friction coefficient test rig is designed to test the friction material as per - IS2742 and SAE J661

standard, speed sensitivity, road sensitivity, temperature sensitivity and in static condition. It can also

simulate user conditions, which can be programmed by the user for R&D and Quality use. It is fully

computerized and is programmable to study friction reaction and wear against speed, load, and

temperature. Software also provides report unit mode –MKS system.

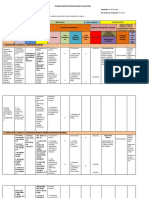

MONITORING (BY SOFTWARE)

Drum Speed

Drum Temperature

Load

Reactive force

Dynamic Friction coefficient

Friction coefficient

Wear

Application all time and OFF time Display

Elapsed time

Application Counter

Application ON/OFF Indicator

Heater ON/OFF Indicator

Blower ON/OFF Indicator

Test Schedule Information

MECHANICAL/MEASURMENT SYSTEM:

Main Structural Frame is fabricated by steel tube with suitable cross section and plates.

Bed is fabricated of machined MS (FE410E) with Nickel plating.

Spindle and pulley(Driver and Driven) is dynamically balanced for smooth operation.

Spindle is driven by a variable speed 15kW, 415V, 3 Phase, 1515 RPM AC motor through a

double groove V-belt with drive ratio of 1:1.

Belt tensioning device has been provided to adjust and tighten the belt.

Drum Heating: Commissioned by four 1.75kW, 415V, 3 Phase incoloy tubular heating

element.

Rate of heating of Drum: Adjusted by continuously variable transformers.

Drum Cooling: Maintained by a dynamically balanced 3 Phase Centrifugal Blower : 1.5Kw,

415V, AC, 3 Phase.

No. 5E, 1stFloor, Block A,Sector-80, Phase-2, Noida, U.P. India-201301

Email: contact@simtestdynamics.in, Phone: -0120-424514

Website- www.simtestdynamics.in

SimTest Dynamics LLP

Temperature measurement : Done by a ‘K’ – Type thermocouple mounted at suitable place

of the drum connected to the measurement system through Rotary switch.

Loading : Achieved through single double acting cylinder.

Load applied is controlled by an electro-pneumatic regulator , regulated by software.

Loading arm is provided with 4 point support , Three are high precision rod ends to give

smooth frictionless tangential movement to measure reactive force.

Load cells : Used to measure applied load and reactive force in Kgf.

Drum Speed Measurement : By VFD, calibrated for required RPM( displays in the software).

Automatic thickness measurement system: LVDT to read the wear of the test sample in mm.

PNEUMATIC SYSTEM:

The pneumatic system is provided with

Air Receiver Tank

Load Pressure Accumulator

Pressure Regulator : Maintains system pressure

Electrically Operated Pressure Regulator : Controls Applied load

Read Switch : Detects Piston position

Electrically Operated Solenoid Valve

Single Pneumatic cylinder : Controls loading, lift and run condition on specimen.

ELECTRICAL/CONTROL PANEL:

A separate ergonomically designed standard control panel is provided to house Electronics,

Electrical and Computer System.

Computer monitor placed on the control panel at suitable height to provide the best viewing

angle for both sitting and standing position.

The computer CPU unit is fixed inside the control panel.

All the Electrical Controls for automatic/manual operations are provided at the Front panel.

Variable Speed 15Kw AC VFD motor drive is housed inside the electrical panel with cooling

fan.

Heating Control Rate variable transformers are mounted on the side of electrical panel.

No. 5E, 1stFloor, Block A,Sector-80, Phase-2, Noida, U.P. India-201301

Email: contact@simtestdynamics.in, Phone: -0120-424514

Website- www.simtestdynamics.in

SimTest Dynamics LLP

ELECTRONICS, COMPUTER & INTERFACE:

The power electronics for controlling the blower, heater, AC Motor, Load Increase/Decrease

are provided inside the electrical panel.

A computer with a hard disk, DVD drive and 15” LED color monitor is provided with NI cDAQ

interface card to monitor and control the working of the test rig in manual and auto mode.

Windows 10 and the Brake Lining Test Rig Control Software (Lab view Based) is preloaded in

the system

MECHANICAL CALIBRATION DEVICES:

Calibrated 10kg and 6kg dead weight.

Applied Load calibration arm ratio 1:6.

Force calibration arm ratio 1:1.

SOFTWARE:

A User friendly menu driven control system, SimTest Dynamics software is provided.

The software is preprogrammed to run IS2742 or SAE J661 test schedule.

1. Control Software:

1.1 IS 2742or SAE J661 including 3rd fade.

1.2 Speed sensitivity

1.3 Load sensitivity

1.4 Temperature sensitivity

2. In-built tools to generate the graphs of the test reports including the standard:

2.1 IS2742 format.

2.2 Or SAE J661

When a test is run by IS2742or SAE J661, Software also determines the rating of test sample.

When the test is running, User is provided with a screen which displays all the monitored

values.

No. 5E, 1stFloor, Block A,Sector-80, Phase-2, Noida, U.P. India-201301

Email: contact@simtestdynamics.in, Phone: -0120-424514

Website- www.simtestdynamics.in

SimTest Dynamics LLP

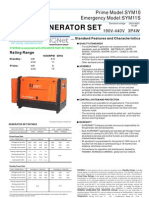

PRODUCT SPECIFICATIONS

1 Electrical Supply 3 phase, 420V AC, 50Hz.

2 Air supply 7 kg/cm² (100 PSI) dry air (incoming).

3 Working Pressure 6kg/cm² dry air (system pressure).

4 Drum Size (as per 277 mm (10.9’’) to 280 mm (10.02’’) inner diameter.

SAE-J661 standard)

5 Main Shaft Speed 100 to 1500 RPM.

6 Spindle Motor AC motor 15kW, 1500 RPM.

7 Drum Speed 100 RPM to 750RPM

8 Load on sample up to 170kg(max)

9 Reactive Force 100 kg (220lbs) Maximum.

10 Speed Conrol AC VFD 15Kw , 415V, 50Hz

11 Heater System 7.0 kW (1.75 KW each).

12 Cooling System 1.5kW centrifugal blower.

13 Drum Temperature Up to 500deg Celsius

14 Thickness Measurement Automatic by L.V.D.T.

15 Static Friction Measurement Manual attachment of adapter and manual operation with

software data collection.

16 Sample Size 25 mm x 25mm x 6mm.

17 Load Measurement 200Kg Load cell.

18 Temperature Measurement K-Type Thermocouple on drum, output through rotary switch

19 Speed Measurement Magnetic pickup.

20 Measurement Accuracy ±2% of full scale.

21 Spindle Nose Suitable for Indian and Imported Drum

22 Rig Size 742X 1622 X1440mm (WXDXH).

23 Rig Height 1050mm (Up to Table)

24 Mass 650 Kg. (approx.) (without packing)

No. 5E, 1stFloor, Block A,Sector-80, Phase-2, Noida, U.P. India-201301

Email: contact@simtestdynamics.in, Phone: -0120-424514

Website- www.simtestdynamics.in

SimTest Dynamics LLP

User Friendly Standard Reporting Formats

Output mode (MKS) Inbuilt standard report option

User Programmable Schedules Report Output to Printer

Preprogrammed standards Graph Output to Printer

Easy to learn programming interface Calibration Aid Utility with full online instructions

No. 5E, 1stFloor, Block A,Sector-80, Phase-2, Noida, U.P. India-201301

Email: contact@simtestdynamics.in, Phone: -0120-424514

Website- www.simtestdynamics.in

S-ar putea să vă placă și

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDe la EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisEvaluare: 4 din 5 stele4/5 (2)

- Diesel GenSet Specifications-1Document8 paginiDiesel GenSet Specifications-1Nahid KashmoulaÎncă nu există evaluări

- Dynamometer: Theory and Application to Engine TestingDe la EverandDynamometer: Theory and Application to Engine TestingÎncă nu există evaluări

- DKG 509 - UserDocument56 paginiDKG 509 - Userhackerland_1Încă nu există evaluări

- Variable Frequency DriveDocument2 paginiVariable Frequency Drivenksuthar5399Încă nu există evaluări

- EXTENDED PROJECT-Shoe - SalesDocument28 paginiEXTENDED PROJECT-Shoe - Salesrhea100% (5)

- Digital Automatic Voltage RegulatorDocument2 paginiDigital Automatic Voltage RegulatorPedro BancayanÎncă nu există evaluări

- 721 DSCDocument4 pagini721 DSCMatt WrightÎncă nu există evaluări

- Interoperability Standards For Voip Atm Components: Volume 4: RecordingDocument75 paginiInteroperability Standards For Voip Atm Components: Volume 4: RecordingjuananpspÎncă nu există evaluări

- Moog ServoDrives DS2000 Manual enDocument142 paginiMoog ServoDrives DS2000 Manual enBojan MarkovićÎncă nu există evaluări

- 7PCC1301Document20 pagini7PCC1301gsantosh06100% (4)

- The Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageDocument5 paginiThe Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageHenny ZahranyÎncă nu există evaluări

- A1000Document8 paginiA1000monikaÎncă nu există evaluări

- On CatiaDocument42 paginiOn Catiahimanshuvermac3053100% (1)

- Office Storage GuideDocument7 paginiOffice Storage Guidebob bobÎncă nu există evaluări

- Daraman vs. DENRDocument2 paginiDaraman vs. DENRJeng GacalÎncă nu există evaluări

- MMA1201PDocument8 paginiMMA1201Pnobita18tÎncă nu există evaluări

- Deep Sea Electronics PLC Telephone Email: Your Local DistributorDocument4 paginiDeep Sea Electronics PLC Telephone Email: Your Local DistributornanocycleÎncă nu există evaluări

- EEMDocument17 paginiEEMSandaruwan සුජීවÎncă nu există evaluări

- Automotive GoniometerDocument6 paginiAutomotive GoniometerifofanahÎncă nu există evaluări

- 5 - Control System TrainerDocument50 pagini5 - Control System TrainerGadam Siva Charan DasÎncă nu există evaluări

- Diesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PDocument4 paginiDiesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PYashveer TakooryÎncă nu există evaluări

- Converter Station Water-Cooled Pump Vibration Monitoring and Condition Assessment System Based On LabVIEWDocument6 paginiConverter Station Water-Cooled Pump Vibration Monitoring and Condition Assessment System Based On LabVIEWInternational Journal of Research in Engineering and ScienceÎncă nu există evaluări

- Transformer Monitoring Systems - MRDocument4 paginiTransformer Monitoring Systems - MRKelly chatingÎncă nu există evaluări

- Form 6 Pole Mount Recloser Control Specification Ps280005enDocument12 paginiForm 6 Pole Mount Recloser Control Specification Ps280005enLuis Francisco Calderon EspinozaÎncă nu există evaluări

- 1295 Specifications 2010Document0 pagini1295 Specifications 2010Timu OvidiuÎncă nu există evaluări

- ITCC in Riyadh Residential Complex J10-13300 16269-1 Variable Speed DrivesDocument7 paginiITCC in Riyadh Residential Complex J10-13300 16269-1 Variable Speed DrivesuddinnadeemÎncă nu există evaluări

- Wjcs-Ii Microcomputer System Technical Instructions: I. OverviewDocument12 paginiWjcs-Ii Microcomputer System Technical Instructions: I. OverviewQuangÎncă nu există evaluări

- Installation, Wiring, Operation Manua: Form 2844 Edition 11 © August 1993 Updated March 1997Document72 paginiInstallation, Wiring, Operation Manua: Form 2844 Edition 11 © August 1993 Updated March 1997kmpoulosÎncă nu există evaluări

- User's Manual: FDC 4100 / 7100 / 8100 / 9100 Auto-Tune Fuzzy / PID Process / Temperature ControllerDocument60 paginiUser's Manual: FDC 4100 / 7100 / 8100 / 9100 Auto-Tune Fuzzy / PID Process / Temperature ControllerkmpoulosÎncă nu există evaluări

- Manual-Motor de Gasolina Cm11 MkiiDocument4 paginiManual-Motor de Gasolina Cm11 MkiiNallely MassoÎncă nu există evaluări

- Automatic Control Panel: 1.1 System DescriptionDocument6 paginiAutomatic Control Panel: 1.1 System DescriptionRakib HasanÎncă nu există evaluări

- Firetrol SBP1100JDocument13 paginiFiretrol SBP1100JJlavieraÎncă nu există evaluări

- Dkg-509 Automatic Mains Failure Unit With J1939 Port: FeaturesDocument59 paginiDkg-509 Automatic Mains Failure Unit With J1939 Port: FeaturesAziz ArrahalÎncă nu există evaluări

- Tea Sensor de VelocidadeDocument6 paginiTea Sensor de VelocidadeValmaq Prestação Serviço LdaÎncă nu există evaluări

- BFGS User Manual 6Document17 paginiBFGS User Manual 6hevenessa0% (1)

- F 1821 DigitalControls enDocument7 paginiF 1821 DigitalControls enalbertooliveiraÎncă nu există evaluări

- INJkon 00 ManualDocument27 paginiINJkon 00 ManualJam AnjumÎncă nu există evaluări

- 10 KvaDocument4 pagini10 KvaLeonardusHSijabatÎncă nu există evaluări

- Commander SE: Simple and EasyDocument8 paginiCommander SE: Simple and EasyRitesh SharmaÎncă nu există evaluări

- Compacte Handleiding V7Document60 paginiCompacte Handleiding V7gui9871Încă nu există evaluări

- 6210 Thrust & de MonitorDocument5 pagini6210 Thrust & de Monitorerwin hpÎncă nu există evaluări

- 507 DataDocument2 pagini507 DatavasilimertzaniÎncă nu există evaluări

- DKG207 PDFDocument2 paginiDKG207 PDFRoberto MerizaldeÎncă nu există evaluări

- AC Inverter Drive: A1000 SeriesDocument8 paginiAC Inverter Drive: A1000 Seriesabhi_0302Încă nu există evaluări

- EE24 Design of Variable Speed Drive For Induction Motor Using VF ControlDocument4 paginiEE24 Design of Variable Speed Drive For Induction Motor Using VF ControlMechWindNaniÎncă nu există evaluări

- DG Application AMF / Synchroniser: Conzerv Systems PVT LTDDocument4 paginiDG Application AMF / Synchroniser: Conzerv Systems PVT LTDjaikolangaraparambilÎncă nu există evaluări

- Control: Monitoring With IntelligenceDocument4 paginiControl: Monitoring With IntelligenceyoeckoeÎncă nu există evaluări

- VC1100Document8 paginiVC1100SendhilKumarÎncă nu există evaluări

- What Is A Servo Stabilizer?: Single Phase Input & Single Phase OutputDocument5 paginiWhat Is A Servo Stabilizer?: Single Phase Input & Single Phase OutputHerman SalimÎncă nu există evaluări

- INJkon 01 4.0 ManualDocument93 paginiINJkon 01 4.0 ManualJansirani SelvamÎncă nu există evaluări

- 307 DataDocument2 pagini307 DataynadeemÎncă nu există evaluări

- Dkg-307 Automatic Mains Failure Unit: DescriptionDocument2 paginiDkg-307 Automatic Mains Failure Unit: DescriptionThao Nguyen XuanÎncă nu există evaluări

- 6875 SpecificationsDocument8 pagini6875 SpecificationsTimu OvidiuÎncă nu există evaluări

- Ic5 CatDocument20 paginiIc5 CatKỹ Sư TđhÎncă nu există evaluări

- SBP1100J (D)Document13 paginiSBP1100J (D)Eloy Alejandro Justiniano CoimbraÎncă nu există evaluări

- TDS3218 September 2016 B - KITE Technical Datasheet ENDocument4 paginiTDS3218 September 2016 B - KITE Technical Datasheet ENAnonymous srwHCpAÎncă nu există evaluări

- Ls Inverter Ic5Document20 paginiLs Inverter Ic5lamonahÎncă nu există evaluări

- SP1100 50Document6 paginiSP1100 50M-BasicÎncă nu există evaluări

- Eddy Current DynamometerDocument10 paginiEddy Current DynamometerbavinrajÎncă nu există evaluări

- DKG 545 EnglishDocument49 paginiDKG 545 EnglishrogerioÎncă nu există evaluări

- C17 C28D5 X2.5Document4 paginiC17 C28D5 X2.5Pritesh Kumar100% (1)

- Company ProfileDocument17 paginiCompany ProfilehappyharrÎncă nu există evaluări

- Pti1000 Esd5100 SeriesDocument2 paginiPti1000 Esd5100 SeriesRamon Thales DomeniconiÎncă nu există evaluări

- Down-Hole Sensor Package: Data SheetDocument2 paginiDown-Hole Sensor Package: Data SheetRonald LlerenaÎncă nu există evaluări

- Getting StartedDocument45 paginiGetting StartedMuhammad Owais Bilal AwanÎncă nu există evaluări

- Apm p5 Course NotesDocument267 paginiApm p5 Course NotesMusumbulwe Sue MambweÎncă nu există evaluări

- Chapter 5Document3 paginiChapter 5Showki WaniÎncă nu există evaluări

- RENCANA KERJA Serious Inspeksi#3 Maret-April 2019Document2 paginiRENCANA KERJA Serious Inspeksi#3 Maret-April 2019Nur Ali SaidÎncă nu există evaluări

- Doterra Enrollment Kits 2016 NewDocument3 paginiDoterra Enrollment Kits 2016 Newapi-261515449Încă nu există evaluări

- Escario Vs NLRCDocument10 paginiEscario Vs NLRCnat_wmsu2010Încă nu există evaluări

- Innovations in Land AdministrationDocument66 paginiInnovations in Land AdministrationSanjawe KbÎncă nu există evaluări

- Methodical Pointing For Work of Students On Practical EmploymentDocument32 paginiMethodical Pointing For Work of Students On Practical EmploymentVidhu YadavÎncă nu există evaluări

- Government of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Document2 paginiGovernment of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Satyaki Prasad MaitiÎncă nu există evaluări

- 1 PBDocument14 pagini1 PBSaepul HayatÎncă nu există evaluări

- Production - The Heart of Organization - TBDDocument14 paginiProduction - The Heart of Organization - TBDSakshi G AwasthiÎncă nu există evaluări

- Review of Related LiteratureDocument4 paginiReview of Related LiteratureCarlo Mikhail Santiago25% (4)

- Powerpoint Presentation: Calcium Sulphate in Cement ManufactureDocument7 paginiPowerpoint Presentation: Calcium Sulphate in Cement ManufactureDhruv PrajapatiÎncă nu există evaluări

- Draft Contract Agreement 08032018Document6 paginiDraft Contract Agreement 08032018Xylo SolisÎncă nu există evaluări

- Multispan LC 2046 Length Counter PDFDocument2 paginiMultispan LC 2046 Length Counter PDFvinod kumarÎncă nu există evaluări

- Building Program Template AY02Document14 paginiBuilding Program Template AY02Amy JaneÎncă nu există evaluări

- SILABO 29-MT247-Sensors-and-Signal-ConditioningDocument2 paginiSILABO 29-MT247-Sensors-and-Signal-ConditioningDiego CastilloÎncă nu există evaluări

- Banjara EmbroideryDocument34 paginiBanjara EmbroideryKriti Rama ManiÎncă nu există evaluări

- Elastic Modulus SFRCDocument9 paginiElastic Modulus SFRCRatul ChopraÎncă nu există evaluări

- Abu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationDocument27 paginiAbu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationPaulWolfÎncă nu există evaluări

- Fidp ResearchDocument3 paginiFidp ResearchIn SanityÎncă nu există evaluări

- Computer First Term Q1 Fill in The Blanks by Choosing The Correct Options (10x1 10)Document5 paginiComputer First Term Q1 Fill in The Blanks by Choosing The Correct Options (10x1 10)Tanya HemnaniÎncă nu există evaluări

- Amerisolar AS 7M144 HC Module Specification - CompressedDocument2 paginiAmerisolar AS 7M144 HC Module Specification - CompressedMarcus AlbaniÎncă nu există evaluări

- SME-Additional Matter As Per Latest Syllabus Implementation WorkshopDocument14 paginiSME-Additional Matter As Per Latest Syllabus Implementation WorkshopAvijeet BanerjeeÎncă nu există evaluări