Documente Academic

Documente Profesional

Documente Cultură

Chapter7 5

Încărcat de

Balaji PrasathDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Chapter7 5

Încărcat de

Balaji PrasathDrepturi de autor:

Formate disponibile

BUILDING FRAMING SYSTEMS AND BEST PRACTICES 7

7.3.1 Roof Sheathing

Roof sheathing is the first structural component in the load path between the roof system and the

foundation. The first envelope components (i.e., the roof covering and roof underlayment) are typically

non-structural and are discussed in detail in Chapter 8, Roof Covering and Best Practices.

The roof sheathing supports gravity loads, such as the roof live load, snow load, and vertical-uplift loads

created by wind pressures. Also, the roof sheathing (working in conjunction with the roof framing) must

function as a diaphragm to transfer lateral loads to the building’s shear walls.

The IBC, IRC, WFCM, and ICC-600 all contain prescriptive requirements for fastening roof sheathing.

The fastening requirements are those required to resist uplift forces from wind pressures and shear forces

from lateral loads.

Most codes and standards allow the use of common nails to connect sheathing to supporting members

for sites where basic wind speeds are less than 100 mph (110 mph in non-hurricane-prone regions)

but require ring-shank nails in higher-wind zones. Ring-shank nails have higher withdrawal capacities

(expressed in ratings) and are needed because they provide resistance to the high forces acting on the

sheathing panels from the roof pressures in higher-wind zones. Another option is to use wood screws

in place of nails because they tend to have higher withdrawal capacities. Best practices recommend the

use of wood screws—particularly in the eaves and corner zones of the roof, where winds can create

large uplift (suction) pressures. Unless directed otherwise by design professionals, wood screws should

have (at a minimum) the same diameter as the nails prescribed by the codes or standards and should

be located according to the same spacing interval (or be even more closely spaced). It is also important

to note that the density of the roof framing member must be taken into account when determining

fastener spacing. Relatively dense framing (such as is achieved with Southern Yellow Pine members) holds

fasteners better than lower-density framing (such as Spruce Pine Fir members) and may allow for wider

spacing of fasteners.

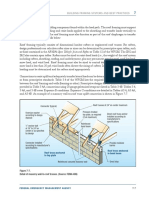

The fasteners securing roof sheathing must penetrate into the supporting roof framing to prove effective.

“Shiners” (i.e., nails that miss roof framing when hammered into place and whose metal surfaces “shine”

when viewed from the attic space below) provide no strength and no withdrawal capacity and constitute

a discontinuity within the load path (see Figures 7-5 and 7-6). Also, fasteners should not be overdriven.

Overdriving the fasteners increases the potential for the roof sheathing to tear around the heads of the

fasteners as the nail head penetrates into the wood sheathing. The overdriving of nails frequently occurs

when pneumatic or gas-powered nailers are used without proper settings. This issue can be addressed

onsite by a contractor by properly calibrating the tools being used.

FEDERAL EMERGENCY MANAGEMENT AGENCY 7-5

S-ar putea să vă placă și

- Components: ComponentDocument1 paginăComponents: ComponentBalaji PrasathÎncă nu există evaluări

- Test 1Document4 paginiTest 1Balaji PrasathÎncă nu există evaluări

- db0f 5Document1 paginădb0f 5Balaji PrasathÎncă nu există evaluări

- Chapter7 7Document1 paginăChapter7 7Balaji PrasathÎncă nu există evaluări

- Chapter7 2Document1 paginăChapter7 2Balaji PrasathÎncă nu există evaluări

- db0f 4Document1 paginădb0f 4Balaji PrasathÎncă nu există evaluări

- db0f 3Document1 paginădb0f 3Balaji PrasathÎncă nu există evaluări

- Chapter7 6Document1 paginăChapter7 6Balaji PrasathÎncă nu există evaluări

- db0f 2Document1 paginădb0f 2Balaji PrasathÎncă nu există evaluări

- Arches: A Neglected Topic in Structural Analysis CoursesDocument1 paginăArches: A Neglected Topic in Structural Analysis CoursesBalaji PrasathÎncă nu există evaluări

- Chapter7 3Document1 paginăChapter7 3Balaji PrasathÎncă nu există evaluări

- Chapter7 8Document1 paginăChapter7 8Balaji PrasathÎncă nu există evaluări

- BookChapters2018-19 2Document1 paginăBookChapters2018-19 2Balaji PrasathÎncă nu există evaluări

- RefDocument1 paginăRefBalaji PrasathÎncă nu există evaluări

- Chapter7 4Document1 paginăChapter7 4Balaji PrasathÎncă nu există evaluări

- 72Document4 pagini72Balaji PrasathÎncă nu există evaluări

- Chapter7 1Document1 paginăChapter7 1Balaji PrasathÎncă nu există evaluări

- Strength of Materials RefDocument1 paginăStrength of Materials RefBalaji PrasathÎncă nu există evaluări

- Guidelines For Design of Protective Structures Subjected To Unconfined ExplosionsDocument1 paginăGuidelines For Design of Protective Structures Subjected To Unconfined ExplosionsBalaji PrasathÎncă nu există evaluări

- Fact SoilDocument1 paginăFact SoilBalaji PrasathÎncă nu există evaluări

- BookChapters2018-19 1Document1 paginăBookChapters2018-19 1Balaji PrasathÎncă nu există evaluări

- 1645-2916-1-SM 9Document1 pagină1645-2916-1-SM 9Balaji PrasathÎncă nu există evaluări

- TechnicalPopularArticlesReviewArticles 2 PDFDocument1 paginăTechnicalPopularArticlesReviewArticles 2 PDFBalaji PrasathÎncă nu există evaluări

- Строительство уникальных зданий и сооружений, 2015, №3 (30) Construction of Unique Buildings and Structures, 2015, №3Document1 paginăСтроительство уникальных зданий и сооружений, 2015, №3 (30) Construction of Unique Buildings and Structures, 2015, №3Balaji PrasathÎncă nu există evaluări

- TechnicalPopularArticlesReviewArticles 1Document1 paginăTechnicalPopularArticlesReviewArticles 1Balaji PrasathÎncă nu există evaluări

- Calculus For The Ambitious: T. W. K OrnerDocument1 paginăCalculus For The Ambitious: T. W. K OrnerBalaji PrasathÎncă nu există evaluări

- SeismicDocument1 paginăSeismicBalaji PrasathÎncă nu există evaluări

- SFD-SP-16-13330-2011 80Document1 paginăSFD-SP-16-13330-2011 80Balaji PrasathÎncă nu există evaluări

- SFD-SP-16-13330-2011 80 PDFDocument1 paginăSFD-SP-16-13330-2011 80 PDFBalaji PrasathÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- BTech Admission 2024-UCSWorld GrowmoreDocument8 paginiBTech Admission 2024-UCSWorld GrowmoreUCSWorldGrowMoreÎncă nu există evaluări

- Shiroli Midc Companies ListDocument27 paginiShiroli Midc Companies ListRandy Lee67% (3)

- EGS 2200 Governor SystemDocument2 paginiEGS 2200 Governor Systemredchaoz0% (1)

- 5 Switch Dan RelayDocument35 pagini5 Switch Dan RelayNadiaRahmaNoorSalsabilaÎncă nu există evaluări

- BOQ - Secondary ContainmentDocument3 paginiBOQ - Secondary Containmentrehan7777Încă nu există evaluări

- N Top Hyd All 12oct2012 F480RB of 1940RB DDocument14 paginiN Top Hyd All 12oct2012 F480RB of 1940RB DArun TalluriÎncă nu există evaluări

- PASCHAL Formwork Manual PDFDocument279 paginiPASCHAL Formwork Manual PDFmodarth100% (1)

- Samhita IyerDocument1 paginăSamhita IyerSamhita IyerÎncă nu există evaluări

- 01 08 Handbook of The Management of Creativity and InnovationDocument399 pagini01 08 Handbook of The Management of Creativity and InnovationArbresh RaveniÎncă nu există evaluări

- P&ID Check ListDocument2 paginiP&ID Check ListHadi ShahsavanÎncă nu există evaluări

- Integrated Rapid Visual Screening of Buildings For Seismic HazardDocument43 paginiIntegrated Rapid Visual Screening of Buildings For Seismic HazardPADMA RAOÎncă nu există evaluări

- The Art of Strategic Leadership Chapter 2 - The BusinessDocument6 paginiThe Art of Strategic Leadership Chapter 2 - The BusinessAnnabelle SmythÎncă nu există evaluări

- Fundamentals of Bridge Design Note (Repaired)Document73 paginiFundamentals of Bridge Design Note (Repaired)Awoke Aschale75% (4)

- Rotating EquipmentDocument3 paginiRotating EquipmentSathish DesignÎncă nu există evaluări

- Inter Chang IbilityDocument20 paginiInter Chang IbilityKumarChirraÎncă nu există evaluări

- Hatflex ChinaDocument31 paginiHatflex ChinaedgarmerchanÎncă nu există evaluări

- Team - 01 Engineering Analysis Report PDFDocument21 paginiTeam - 01 Engineering Analysis Report PDFRupak GhawghaweÎncă nu există evaluări

- Combustion Engineering SyllabusDocument6 paginiCombustion Engineering SyllabusCyrene May BueÎncă nu există evaluări

- Articulo Standar Ashrae 15Document17 paginiArticulo Standar Ashrae 15fmlomaÎncă nu există evaluări

- High Pressure Piping System Procedure PDFDocument4 paginiHigh Pressure Piping System Procedure PDFBudi PrasetyoÎncă nu există evaluări

- Manhole AnalysisDocument15 paginiManhole Analysishasan_kygsz100% (4)

- NRC 2018 R & R Open CategoryDocument7 paginiNRC 2018 R & R Open CategorySiti Nadiah OthmanÎncă nu există evaluări

- Analysis & Design of Structural ElementsDocument15 paginiAnalysis & Design of Structural ElementsNamrata PalÎncă nu există evaluări

- List of BS CodeDocument8 paginiList of BS CodeCC OoiÎncă nu există evaluări

- Under Water Human Detection DeviceDocument21 paginiUnder Water Human Detection DeviceSnehal VarbheÎncă nu există evaluări

- The Effect of Masonry Infill WallsDocument8 paginiThe Effect of Masonry Infill WallsJose ManuelÎncă nu există evaluări

- El47500-Psb DDocument26 paginiEl47500-Psb DWahyu WidartoÎncă nu există evaluări

- Asif Ali: Current Position: Electrical EngineerDocument3 paginiAsif Ali: Current Position: Electrical EngineerMohammed AbdulmuqeetÎncă nu există evaluări

- Bukit Merah c39b PDF File (Non Cast-In) 28.11.2022Document15 paginiBukit Merah c39b PDF File (Non Cast-In) 28.11.2022kk. yulwinnÎncă nu există evaluări

- Steel Module 2 Part 1Document33 paginiSteel Module 2 Part 1Pyro Villanueva100% (1)