Documente Academic

Documente Profesional

Documente Cultură

20 Steps For Manufacturing Excellence

Încărcat de

Dharmvir Uppal0 evaluări0% au considerat acest document util (0 voturi)

38 vizualizări2 paginiTitlu original

20 steps for Manufacturing Excellence

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

38 vizualizări2 pagini20 Steps For Manufacturing Excellence

Încărcat de

Dharmvir UppalDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

Lean Manufacturing Implementation:

A 20-Step Road Map

Lean manufacturing is being utilized by businesses of all sizes today. Although it took a few

years to become mainstream, the success stories from mid-size to large corporations have

pushed lean manufacturing down to very small organizations.

Most of the large corporations employ a few lean experts. Many mid-size and most small

businesses do not have lean manufacturing expertise in the company. It is common that a

few individuals have attended a lean manufacturing seminar or read a few books, but lack

the expertise to develop a road map.

The reason most courses and seminars do not teach a “road map” is because the tools are

best applied to problems or bottlenecks, rather than forcing the tool use on the opportunity.

For example, a machine that sets up once per week in 30 minutes probably doesn't warrant

a week of single minute exchange of dies (SMED) activity.

However, a road map can be used with common sense. Lean manufacturing has been

called “common-sense manufacturing”, although not always “common practice”.

Here are 20 steps that comprise a lean manufacturing road map:

1. Form team (mix of lean manufacturing and relevant business experience)

2. Develop communication and feedback channel for everyone

3. Meet with everyone and explain the initiative

4. Begin to train all employees (lean overview, eight wastes, standard

operations, kaizen, RCPS, PDCA)

5. Facility analysis – Determine the gap between current state and a state of “lean”

6. 5-S - It is the foundation of lean. Workplace organization is critical for any lean

initiative

7. TPM – Begin Total Productive Maintenance early (used throughout lean)

8. Value Stream Mapping – Determine the waste across the entire system

9. 7 (or 8) waste identification – Use with value stream mapping to identify system

waste

10. Process mapping – A more detailed map of each process

11. Takt time – Determine need to produce on all processes, equipment

12. Overall equipment effectiveness and six losses – Determine the losses on all

processes and equipment

13. Line balance – Use, if necessary, with takt time and OEE

14. SMED – Push setup times down to reduce cycle time, batch quantity and lower costs

15. Pull / one-piece flow / Continuous Flow Analysis – Utilize kanban and supermarkets

16. Analyze quality at the source application – Poor quality stopped at the source

17. Implement error-proofing ideas

18. Cellular manufacturing/layout and flow improvement – Analyze facility and each

process

19. Develop standardized operations – Concurrently with SMED, line balance, flow,

layouts

20. Kaizen – Continue improving operations, giving priority to bottlenecks within the

system

The specific implementation plan should be developed from the facility analysis. The

analysis identifies areas of opportunity in every area of the business, including sales,

service, engineering, maintenance, production, quality, shipping and administrative

functions.

Some lean manufacturing projects within a lean initiative require the tools of Six Sigma to

find the improvement answers. The lean manufacturing team needs to be trained to

understand when the lean tools must be supplemented to either solve the problem or

maximize the improvement.

Kaizen events may use all of the lean tools (and some Six Sigma tools) to meet the team's

objective. Kaizen events are conducted on an ongoing basis to achieve a state of “lean”.

For example, a process may need a quick throughput improvement. The kaizen blitz could

include focused SMED and OEE analysis. The kaizen might have an objective to reduce

setup time from 80 minutes to 60 minutes in four days.

It is important to keep an enterprise view with the analysis and road map. No single

operation should be improved at the expense of the entire system. For example, if a

bottleneck is happening at Process B, improving Process A prior to B only hurts the system

worse.

A larger-scale example is improving throughput if shipping cannot handle the volume.

Although many improvements cause bottlenecks elsewhere, forcing a larger known problem

is rarely a good idea.

The road map above is only one example. It could be shown with many different variations.

However, there is a logical sequence to many of the tools. Value stream mapping is almost

always conducted very early on in the process.

The 5-S system provides a foundation for most other tools. TPM is large and plays an

important role in OEE improvement and, therefore, must be started early.

The key is to have a plan and get started. The path to lean will not be straight and it never

ends. Don't let the pursuit of perfection get in the way of being “better” today.

S-ar putea să vă placă și

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsDe la EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsEvaluare: 4.5 din 5 stele4.5/5 (2)

- Tips For 5S On The Shop FloorDocument5 paginiTips For 5S On The Shop FloorAnonymous v5QjDW2eHxÎncă nu există evaluări

- Operational Excellence A Complete Guide - 2019 EditionDe la EverandOperational Excellence A Complete Guide - 2019 EditionEvaluare: 1 din 5 stele1/5 (1)

- Six Sigma Metrics and DMAICDocument21 paginiSix Sigma Metrics and DMAICzoyamalik27100% (1)

- Process Improvement Simplified: A How-to-Book for Success in any OrganizationDe la EverandProcess Improvement Simplified: A How-to-Book for Success in any OrganizationÎncă nu există evaluări

- Knowledge Management in Manufacturing SectorDocument22 paginiKnowledge Management in Manufacturing SectorVaishnavi PreranaÎncă nu există evaluări

- Total Quality ManagementDocument7 paginiTotal Quality ManagementmansoorliveÎncă nu există evaluări

- Agile Manufacturing CaseDocument3 paginiAgile Manufacturing CaseAngela Vesleño100% (1)

- Cost Of Poor Quality A Complete Guide - 2021 EditionDe la EverandCost Of Poor Quality A Complete Guide - 2021 EditionÎncă nu există evaluări

- SMED single minute exchange of die A Complete Guide - 2019 EditionDe la EverandSMED single minute exchange of die A Complete Guide - 2019 EditionÎncă nu există evaluări

- HeijunkaDocument6 paginiHeijunkajosegarreraÎncă nu există evaluări

- Simulation-based Lean Six-Sigma and Design for Six-SigmaDe la EverandSimulation-based Lean Six-Sigma and Design for Six-SigmaEvaluare: 3 din 5 stele3/5 (2)

- 142-5045 Lean ManufacturingDocument7 pagini142-5045 Lean Manufacturing2b-or-not2bÎncă nu există evaluări

- A3 Example 2-ColDocument1 paginăA3 Example 2-ColKrunal PandyaÎncă nu există evaluări

- DMAICDocument11 paginiDMAICGermán Huarte ZubiateÎncă nu există evaluări

- VSM ExerciseDocument1 paginăVSM ExerciseJacob EdwardsÎncă nu există evaluări

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsDe la Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsEvaluare: 5 din 5 stele5/5 (1)

- Project Quality Management A Complete Guide - 2019 EditionDe la EverandProject Quality Management A Complete Guide - 2019 EditionÎncă nu există evaluări

- KAIZEN: A Case Study in Small Scale OrganizationsDocument4 paginiKAIZEN: A Case Study in Small Scale OrganizationsijsretÎncă nu există evaluări

- Method Study: by Kunal PatelDocument28 paginiMethod Study: by Kunal PatelPatel KunalÎncă nu există evaluări

- 7 Slides Cell DesignDocument30 pagini7 Slides Cell DesignLuis Alberto Lamas LavinÎncă nu există evaluări

- Quiz Answers Kaizen Leadership PDFDocument1 paginăQuiz Answers Kaizen Leadership PDFJose OrtegaÎncă nu există evaluări

- Five Steps To Improve ProductivityDocument2 paginiFive Steps To Improve ProductivityManojÎncă nu există evaluări

- OEE Improvement and Root Cause Analysis of Marico LimitedDocument26 paginiOEE Improvement and Root Cause Analysis of Marico LimitedtanyaÎncă nu există evaluări

- Value Stream MappingDocument40 paginiValue Stream Mappingjinyue7302Încă nu există evaluări

- Cellular ManufacturingDocument25 paginiCellular ManufacturingApoorv Mathur100% (1)

- Basic 7 Tools of QualityDocument31 paginiBasic 7 Tools of Qualityapi-3835934100% (2)

- Routing - PPT by Gopal K. DixitDocument38 paginiRouting - PPT by Gopal K. DixitkaashniÎncă nu există evaluări

- Fundamentals of Manufacturing ExcellenceDocument8 paginiFundamentals of Manufacturing ExcellenceFadi Zaid AlkilaniÎncă nu există evaluări

- Six SigmaDocument35 paginiSix SigmaVeeresh Kumar RÎncă nu există evaluări

- Kaizen Case StudyDocument44 paginiKaizen Case StudyTanmoy ChakrabortyÎncă nu există evaluări

- SWOT - v1Document79 paginiSWOT - v1Alpha Excellence consultingÎncă nu există evaluări

- Agile ManufacturingDocument17 paginiAgile ManufacturingRaj KumarÎncă nu există evaluări

- Process Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDocument2 paginiProcess Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDouglasWilkinsÎncă nu există evaluări

- Lean IntroDocument27 paginiLean Introjitendrasutar1975Încă nu există evaluări

- Pre Read 5S Program GuideDocument27 paginiPre Read 5S Program GuideHerry Prakoso100% (1)

- Gemba Overview - Sheena Butts - IIESHS - WEBINAR v1Document35 paginiGemba Overview - Sheena Butts - IIESHS - WEBINAR v1Bryan OrdialesÎncă nu există evaluări

- Cellular LayoutsDocument10 paginiCellular Layoutssidd88Încă nu există evaluări

- Value Stream Mapping: Dr. Richard E. WhiteDocument19 paginiValue Stream Mapping: Dr. Richard E. WhiteSamir ChaudhariÎncă nu există evaluări

- 1 Lean GlossaryDocument7 pagini1 Lean GlossaryHilalAldemirÎncă nu există evaluări

- Staufen Polska One Piece Flow 2009Document4 paginiStaufen Polska One Piece Flow 2009tiwintli14Încă nu există evaluări

- Lean Dennis Summary ReviewDocument70 paginiLean Dennis Summary ReviewHector Leonel RivasÎncă nu există evaluări

- TPM TRNGDocument28 paginiTPM TRNGSwapan Kumar DasÎncă nu există evaluări

- What Is Your Company's Cost of Poor Quality (CoPQ) - Tools For Calculating and Reducing ItDocument4 paginiWhat Is Your Company's Cost of Poor Quality (CoPQ) - Tools For Calculating and Reducing ItfaidbÎncă nu există evaluări

- The Why Factor: Winning with Workforce IntelligenceDe la EverandThe Why Factor: Winning with Workforce IntelligenceÎncă nu există evaluări

- Lean Manufacturing 2014Document5 paginiLean Manufacturing 2014api-366590421Încă nu există evaluări

- Production Management Scope and ObjectiveDocument19 paginiProduction Management Scope and ObjectiveBhushan Chinchmalatpure100% (6)

- Week 11 - Numerical Analysis For Productivity ImprovementDocument34 paginiWeek 11 - Numerical Analysis For Productivity ImprovementNguyễn Ngọc Minh QuânÎncă nu există evaluări

- Quality Management ProcessDocument13 paginiQuality Management ProcessSukumar ReddyÎncă nu există evaluări

- Coca-Cola Quality PolicyDocument20 paginiCoca-Cola Quality PolicyDharmvir UppalÎncă nu există evaluări

- 5S Best Practices For Lean WarehousingDocument3 pagini5S Best Practices For Lean WarehousingDharmvir UppalÎncă nu există evaluări

- 5S Best Practices For Lean WarehousingDocument3 pagini5S Best Practices For Lean WarehousingDharmvir UppalÎncă nu există evaluări

- AdwrefDocument7 paginiAdwrefDharmvir UppalÎncă nu există evaluări

- Zed Activities PlannerDocument14 paginiZed Activities PlannerDharmvir UppalÎncă nu există evaluări

- B1 B1 RB1: Roof Framming PlanDocument1 paginăB1 B1 RB1: Roof Framming Plandomin domÎncă nu există evaluări

- Concrete Method Statement PDF FreeDocument14 paginiConcrete Method Statement PDF FreeAli KayaÎncă nu există evaluări

- ETABS 2016 Shear Wall Design: ETABS 2016 16.2.1 License # 1B2PQL2Z6AFQJAFDocument1 paginăETABS 2016 Shear Wall Design: ETABS 2016 16.2.1 License # 1B2PQL2Z6AFQJAFA&T. IngenieriaÎncă nu există evaluări

- Financial EnvironmentDocument20 paginiFinancial EnvironmentZahidul Islam SoykotÎncă nu există evaluări

- Norma AASHTO M 304Document9 paginiNorma AASHTO M 304Vianey MartinezÎncă nu există evaluări

- Engineer Sohail Tasawar: AddressDocument7 paginiEngineer Sohail Tasawar: AddresshaditakerÎncă nu există evaluări

- Design and Static Structural Analysis of Aircraft Floor BeamDocument5 paginiDesign and Static Structural Analysis of Aircraft Floor BeamGRD JournalsÎncă nu există evaluări

- Frameless Glazing Using Spider Fittins & Patch FittingsDocument22 paginiFrameless Glazing Using Spider Fittins & Patch FittingsJahnavi JayashankarÎncă nu există evaluări

- Mini Project TemplateDocument7 paginiMini Project TemplateAlain FlameÎncă nu există evaluări

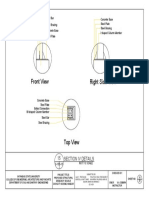

- Front View Right Side View: Section Iv Details 15Document1 paginăFront View Right Side View: Section Iv Details 15Darius Frane MarasiganÎncă nu există evaluări

- Aluminium Façade SystemsDocument20 paginiAluminium Façade SystemsMatjaž FerencÎncă nu există evaluări

- Cowdray Park QuoteDocument2 paginiCowdray Park QuoteJimmy MacloudÎncă nu există evaluări

- Shelterproject: Guidelines For The Construction of Emergency Relief InfrastructureDocument32 paginiShelterproject: Guidelines For The Construction of Emergency Relief InfrastructuretomasfebreroÎncă nu există evaluări

- Kelompok 1 Bored PileDocument22 paginiKelompok 1 Bored PileVernondo HorseÎncă nu există evaluări

- OM - Double Twist ProductsDocument27 paginiOM - Double Twist ProductsRoshanRSVÎncă nu există evaluări

- Foundation For Roller Press in A Cement Plant - A Case Study PDFDocument3 paginiFoundation For Roller Press in A Cement Plant - A Case Study PDFRajKumarÎncă nu există evaluări

- Ar Ged 04 001 0Document1 paginăAr Ged 04 001 0Bahaa MohamedÎncă nu există evaluări

- Damage Limit State MasonryDocument7 paginiDamage Limit State MasonryDaniel Ortega CotrinaÎncă nu există evaluări

- Basic Rules of Concrete Mix DesignDocument2 paginiBasic Rules of Concrete Mix DesignBijaya RaulaÎncă nu există evaluări

- GB T1591 Q345B Carbon and Low Alloy High Strength Steel PlateDocument1 paginăGB T1591 Q345B Carbon and Low Alloy High Strength Steel Platejcvalencia100% (1)

- Tower Structure: Ow Skyscrapers Work?Document5 paginiTower Structure: Ow Skyscrapers Work?Mar Kenneth Dela CruzÎncă nu există evaluări

- Schedule of Beam and Slab For Ground Floor Top-ModelDocument1 paginăSchedule of Beam and Slab For Ground Floor Top-Modeldhiraj patilÎncă nu există evaluări

- FABM1 Lesson1-3 Function of AccountingDocument11 paginiFABM1 Lesson1-3 Function of AccountingKassandra KayÎncă nu există evaluări

- DPWHDocument128 paginiDPWHdanilo m.sampagaÎncă nu există evaluări

- Curtain WallsDocument50 paginiCurtain WallsMayyage LokayaÎncă nu există evaluări

- Analysis and Design of A Multi-Storey Reinforced Concrete BuildingDocument40 paginiAnalysis and Design of A Multi-Storey Reinforced Concrete BuildingAbinayaÎncă nu există evaluări

- Two Way Slab DesignDocument16 paginiTwo Way Slab DesignMandar NadgaundiÎncă nu există evaluări

- Un Manual de Proyectos y Planos para Hacer Gabinetes de Cocina en MaderaDocument142 paginiUn Manual de Proyectos y Planos para Hacer Gabinetes de Cocina en MaderaEsteban Yepes0% (1)

- Resume Titian Damai Mandiri PDFDocument8 paginiResume Titian Damai Mandiri PDFBernard RiaulanÎncă nu există evaluări

- Masonry Methodology 2 FinalDocument4 paginiMasonry Methodology 2 FinalMarielÎncă nu există evaluări