Documente Academic

Documente Profesional

Documente Cultură

Job Sheet 3

Încărcat de

Melita-Mely Baco PallarcoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Job Sheet 3

Încărcat de

Melita-Mely Baco PallarcoDrepturi de autor:

Formate disponibile

JOB SHEET 3.

1-7

Title: Operating Electrical Power and Hydraulic Tools

Performance Objective: Given the necessary equipment, you should be able

to operate each of the selected electrical power and

hydraulic tools in accordance with the prescribed

standard.

Alloted Time : 1 hour and 30 minutes

Supplies/Materials :

Equipment :

A. Portable hand drill

B. Portable grinder

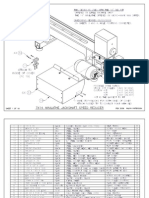

C. Hydraulic pipe bender

D. Hydraulic knotout set

ELECTRICAL Document No. MC-EIMNCII-01

Date Developed: Issued by :

INSTALLATION DECEMBER 2019 MEDINA

AND COLLEGE

MAINTENANCE

NC II Developed by :

Espirato C. Revision # 00

Leyson Jr.

Steps/ Procedure :

A. Portable hand drill

1. Always center punch or make a starting indentation in the material

being drilled to get an accurate starting point for the drill bit.

2. Tighten the drill bit by rotating the chuck key to all three holes in the

chuck. This will help to keep the drill bit centered.

3. Apply moderate even pressure to the drill during the drilling operation.

4. Maintain good balance at all times when drilling.

5. Use slow drill speeds for drilling metal and fast speeds for drilling wood.

6. To obtain holes that are placed accurately, drill a small pilot first then

drill the final hole.

B. Portable grinder

1. Tighten the grinding disk snuggly when mounting it on the portable disc

grinder.

2. Be sure to hold the portable disc grinder firmly when the off/on switch is

turned on.3.

3. Make sure that the cord is sufficiently large in size for the grinder being

used.

4. Keep the electrical and extension cords positioned away from the

grinding area.

5. Before using the switch lock on the portable disc grinder always check to

make sure the lock is functioning properly.

6. Hold the portable disc grinder so that sparks and grit are thrown away

from the operator and from others who are working in the area.

C. Hydraulic pipe bender

1. Raise the handle.

2. Raise the upper wing plate.

3. Select the suitable bending die for the pipe to be bent and slip it on the

end of the cylinder ram.

4. Select the positions of the swaging blocks for the pipe.

5. Turn the swaging blocks so the notch that best fits the diameter of the

pipe to be bent faces in the direction of the bending die.

6. Place the pipe you are going to bend.

ELECTRICAL Document No. MC-EIMNCII-01

Date Developed: Issued by :

INSTALLATION DECEMBER 2019 MEDINA

AND COLLEGE

MAINTENANCE

NC II Developed by :

Espirato C. Revision # 00

Leyson Jr.

7. Lower the upper wing plate.

8. Close the release valve by turning clockwise.

9. Pump the handle to bend the pipe.

D. Hydraulic knotout set

1. Match the punch, die, draw stud, adapter (if needed), and spacer(s) as

required for the size hole to be punched.

2. After marking the hole location, drill a hole approximately 1⁄32" to 1⁄16"

larger than the draw stud or adapter being used.

3. When using 3⁄4" through 3" punch and die, thread the end of the 3⁄4"

draw stud with the shortest thread length into the ram until snug.

4. Determine spacer(s) needed (if any) and install.

5. Slide the die onto the draw stud with the open end of the die facing away

from the ram.

6. Complete the punching process by activating the hand pump.

Assessment Method:

1. Demonstration

2. Direct observation and questioning

Performance Criteria Checklist 3.1-7

CRITERIA YES NO

A. Portable hand drill

1. Properly made center punch or made a starting indentation in the

material being drilled to get an accurate starting point for the drill

bit ?

ELECTRICAL Document No. MC-EIMNCII-01

Date Developed: Issued by :

INSTALLATION DECEMBER 2019 MEDINA

AND COLLEGE

MAINTENANCE

NC II Developed by :

Espirato C. Revision # 00

Leyson Jr.

2. Properly tightened the drill bit by rotating the chuck key to all

three holes in the chuck ?

3. Properly applied moderate even pressure to the drill during the

drilling operation ?

4. Properly maintained good balance at all times when drilling?

5. Properly used slow drill speeds for drilling metal and fast speeds

for drilling wood?

6. Properly obtained holes that are placed accurately and drill a

small pilot first then drill the final hole ?

B. Portable grinder

1. Properly tightened the grinding disk snuggly when mounting on

the portable disc grinder ?

2. Properly held the portable disc grinder firmly when the off/on

switch is turned on ?

3. Properly sure that the cord was sufficiently large in size for the

grinder being used ?

4. Properly keep the electrical and extension cords positioned away

from the grinding area ?

5. Properly checked Before using the switch lock on the portable

disc grinder and make sure the lock was functioning ?

1. Properly hold the portable disc grinder so that sparks and grit are

thrown away from the operator and from others who are working

in the area ?

C. Hydraulic pipe bender

1. Properly raised the handle?

2. Properly raised the upper wing plate ?

3. Properly selected the suitable bending die for the pipe to be bent

ELECTRICAL Document No. MC-EIMNCII-01

Date Developed: Issued by :

INSTALLATION DECEMBER 2019 MEDINA

AND COLLEGE

MAINTENANCE

NC II Developed by :

Espirato C. Revision # 00

Leyson Jr.

and slip it on the end of the cylinder ram ?

4. Properly selected the positions of the swaging blocks for the pipe

?

5. Properly turned the swaging blocks so the notch that best fits the

diameter of the pipe to be bent faces in the direction of the

bending die ?

6. Properly placed the pipe you are going to bend?

7. Properly lowered the upper wing plate ?

8. Properly closed the release valve by turning clockwise ?

9. Properly pump the handle to bend the pipe ?

D. Hydraulic knotout set

1. Properly matched the punch, die, draw stud, adapter (if needed),

and spacer(s) as required for the size hole to be punched.

2. Properly marked the hole location and drilled a hole

approximately 1⁄32" to 1⁄16" larger than the draw stud or

adapter being used ?

3. Properly used 3⁄4" through 3" punch and die, thread the end of

the 3⁄4" draw stud with the shortest thread length into the ram

until snug ?

4. Properly determined spacer(s) needed (if any) and installed ?

5. Properly slide the die onto the draw stud with the open end of the

die facing away from the ram ?

6. Completed the punching process by activating the hand pump ?

Overall Performance

Satisfactory Not Satisfactory

Feedback to trainees:

ELECTRICAL Document No. MC-EIMNCII-01

Date Developed: Issued by :

INSTALLATION DECEMBER 2019 MEDINA

AND COLLEGE

MAINTENANCE

NC II Developed by :

Espirato C. Revision # 00

Leyson Jr.

Trainee’s Signature: Date:

Trainer’s Signature: Date:

ELECTRICAL Document No. MC-EIMNCII-01

Date Developed: Issued by :

INSTALLATION DECEMBER 2019 MEDINA

AND COLLEGE

MAINTENANCE

NC II Developed by :

Espirato C. Revision # 00

Leyson Jr.

S-ar putea să vă placă și

- TVE8 IA EPAS Tools Week2 2022 2023corro No Answer KeyDocument8 paginiTVE8 IA EPAS Tools Week2 2022 2023corro No Answer KeyStacieÎncă nu există evaluări

- Eim 11 Q4 Las 1Document6 paginiEim 11 Q4 Las 1Rey RolunaÎncă nu există evaluări

- Perform Basic Preventive Maintenance of Electronic Tools and Equipment Performance StandardsDocument4 paginiPerform Basic Preventive Maintenance of Electronic Tools and Equipment Performance StandardsDominick Paul DizonÎncă nu există evaluări

- Q1 Mod 3 EIM GRADE 12 NewDocument15 paginiQ1 Mod 3 EIM GRADE 12 NewRhenan LoseoÎncă nu există evaluări

- CP Gun Operation ManualDocument12 paginiCP Gun Operation ManualThaibinh NguyenÎncă nu există evaluări

- Q1 Mod 5 EIM GRADE 12 LRMDSDocument16 paginiQ1 Mod 5 EIM GRADE 12 LRMDSRhenan LoseoÎncă nu există evaluări

- Technical Education and Skills Development AuthorityDocument5 paginiTechnical Education and Skills Development AuthorityRenniel DingcongÎncă nu există evaluări

- Electrical Power ToolsDocument32 paginiElectrical Power ToolsMa Cecelia Borja100% (1)

- Expt 13Document6 paginiExpt 13Williard VälduezaÎncă nu există evaluări

- Written Test: I. Multiple ChoiceDocument4 paginiWritten Test: I. Multiple ChoicejojoÎncă nu există evaluări

- Method Statement: Location: JV GAS in Amenas. Costumer: KBRDocument30 paginiMethod Statement: Location: JV GAS in Amenas. Costumer: KBRhicham boutoucheÎncă nu există evaluări

- TLE EIM Worksheet 1Document3 paginiTLE EIM Worksheet 1Jerome Ayala BermundoÎncă nu există evaluări

- EIM 7 Lesson PlanDocument10 paginiEIM 7 Lesson Plannoy50% (2)

- Internacional Colegio de TecnologiaDocument19 paginiInternacional Colegio de TecnologiaCristal GumalangÎncă nu există evaluări

- Pentaksiran Teori-Assignment (k1)Document8 paginiPentaksiran Teori-Assignment (k1)adibÎncă nu există evaluări

- P Electric DrillDocument9 paginiP Electric DrillMoid Aretaño Mesa100% (1)

- Method Statement - Marmul Fire Ground r1Document17 paginiMethod Statement - Marmul Fire Ground r1United East Projects TradingÎncă nu există evaluări

- PDF Q1 Mod 8 EIM GRADE 12 LRMDSDocument16 paginiPDF Q1 Mod 8 EIM GRADE 12 LRMDSRenante GalauraÎncă nu există evaluări

- 8TVEEIM q1 Module5 Faustino For Printing SheilaDocument10 pagini8TVEEIM q1 Module5 Faustino For Printing SheilaParamintaramaha ParamintaramahaÎncă nu există evaluări

- Competency Assessment Tool (Recovered)Document13 paginiCompetency Assessment Tool (Recovered)Egghead YTCÎncă nu există evaluări

- Electrical General Ipcl-Mgcc SMP No: NC/MAINT/ELE/2041 Battery ChargingDocument2 paginiElectrical General Ipcl-Mgcc SMP No: NC/MAINT/ELE/2041 Battery ChargingFarooq SiddiquiÎncă nu există evaluări

- Grade 9 TLE EIM Electrical Installation Maintenance LASDocument25 paginiGrade 9 TLE EIM Electrical Installation Maintenance LASmanolito mercado jr.Încă nu există evaluări

- Workshop Practical ManualDocument111 paginiWorkshop Practical ManualMat E-darÎncă nu există evaluări

- Use of Handtools (Common)Document30 paginiUse of Handtools (Common)Edwin SanbuenaventuraÎncă nu există evaluări

- Institutional Assessment NC IIDocument7 paginiInstitutional Assessment NC IIDonnald YambaÎncă nu există evaluări

- M S Ramaiah Institute of Technology - Civil Engineering DepartmentDocument15 paginiM S Ramaiah Institute of Technology - Civil Engineering Departmentharis_gunda3786Încă nu există evaluări

- Pipeline Maintenance Section: IndexDocument55 paginiPipeline Maintenance Section: Indextenneti CHALAPATHY RAOÎncă nu există evaluări

- Offshore-Onshore Institute of Technology, Inc.: Pre-Test Electrical Installation and Maintenance NC IIDocument7 paginiOffshore-Onshore Institute of Technology, Inc.: Pre-Test Electrical Installation and Maintenance NC IIOFFSHORE-ONSHORE INSTITUTE OF TECHNOLOGY INCÎncă nu există evaluări

- EPAS 8 MODULE 1 - Week 2Document20 paginiEPAS 8 MODULE 1 - Week 2manolito mulatÎncă nu există evaluări

- CBLM or Learning MaterialsDocument38 paginiCBLM or Learning MaterialsMaximalistaÎncă nu există evaluări

- Lesson Plan 2 4aDocument7 paginiLesson Plan 2 4aanonymous102798Încă nu există evaluări

- MMM Lab 18mel47bDocument47 paginiMMM Lab 18mel47bSachin PrabhaÎncă nu există evaluări

- M3LB-001 - Wire StrippingDocument4 paginiM3LB-001 - Wire Strippingashleyanne.bantayÎncă nu există evaluări

- Grade 7 2nd Quarter ExamDocument3 paginiGrade 7 2nd Quarter ExamBILLY JOE ARELLANOÎncă nu există evaluări

- DJJ10022 REPORT (Machining)Document6 paginiDJJ10022 REPORT (Machining)Muhd Imran Kasyidi OmarÎncă nu există evaluări

- WeldingDocument8 paginiWeldingmukesh201094Încă nu există evaluări

- Icopress: MODEL 5606 Battery Powered Compression ToolDocument10 paginiIcopress: MODEL 5606 Battery Powered Compression ToolSatyam KumarÎncă nu există evaluări

- TLE-EIM9 - Q4M5WEEK6 - OKDocument10 paginiTLE-EIM9 - Q4M5WEEK6 - OKglazykimjorquiaÎncă nu există evaluări

- Learner's Module in Technology and Livelihood Education 10 Electronics Product Assembly and Servicing (EPAS)Document7 paginiLearner's Module in Technology and Livelihood Education 10 Electronics Product Assembly and Servicing (EPAS)Chard VascoÎncă nu există evaluări

- Rev - 08 - Ms - Installation of UpsDocument8 paginiRev - 08 - Ms - Installation of Upsanon_534254691Încă nu există evaluări

- Tugas Laporan Bhs - Inggris SeriusanDocument6 paginiTugas Laporan Bhs - Inggris SeriusanFalak EntodÎncă nu există evaluări

- Q2 Wk1 Wk2 Summative AssessmentDocument2 paginiQ2 Wk1 Wk2 Summative AssessmentBrylai GabrielÎncă nu există evaluări

- 6.drain PipingDocument2 pagini6.drain PipingPramod BhintedeÎncă nu există evaluări

- MOS Precast PilingDocument5 paginiMOS Precast PilingPuzzelsProductionÎncă nu există evaluări

- Module Week 4Document4 paginiModule Week 4geronimoalvin400Încă nu există evaluări

- Experiment - Arc WeldingDocument5 paginiExperiment - Arc WeldingAl Anood Al AmeriÎncă nu există evaluări

- Method Statement For Installation of SMDB, DB & IsolatorDocument14 paginiMethod Statement For Installation of SMDB, DB & IsolatorProjects INTSÎncă nu există evaluări

- Chapter 1: Introduction: PKM Smts SPM 2010Document9 paginiChapter 1: Introduction: PKM Smts SPM 2010yeopsagorÎncă nu există evaluări

- Project Plan FLIP FLOPDocument5 paginiProject Plan FLIP FLOPClark Linogao FelisildaÎncă nu există evaluări

- Antenna Feeder System InstallationDocument24 paginiAntenna Feeder System InstallationAbdul RahimÎncă nu există evaluări

- 3rd Quater EimDocument3 pagini3rd Quater EimJoyce Anne UmbaoÎncă nu există evaluări

- BRY-MSG-02-EN-C MICROPILE - 20181106 (EN Version - Updated)Document21 paginiBRY-MSG-02-EN-C MICROPILE - 20181106 (EN Version - Updated)Minh TruongÎncă nu există evaluări

- STD-InSP-0003 (Coded Marking Procedures LATEST)Document3 paginiSTD-InSP-0003 (Coded Marking Procedures LATEST)airbroomÎncă nu există evaluări

- Sample LASDocument14 paginiSample LASJoseph Joram SabrosoÎncă nu există evaluări

- Set Batter BoardDocument24 paginiSet Batter Boardirishmae101795100% (1)

- EPAS 11 - Q1 - W7 - Mod5Document40 paginiEPAS 11 - Q1 - W7 - Mod5Alberto A. FugenÎncă nu există evaluări

- I&c FundamentalsDocument232 paginiI&c Fundamentalskumar shivamÎncă nu există evaluări

- MOS Panel InstallationDocument10 paginiMOS Panel InstallationEm NiaxÎncă nu există evaluări

- Universiti Kuala Lumpur: Assessment Brief and Verification Cover SheetDocument12 paginiUniversiti Kuala Lumpur: Assessment Brief and Verification Cover SheetNaim NizamÎncă nu există evaluări

- 71 Electrical & Electronic Porjects (With Cd): For beginners, intermediate and engineering studentsDe la Everand71 Electrical & Electronic Porjects (With Cd): For beginners, intermediate and engineering studentsEvaluare: 5 din 5 stele5/5 (3)

- Foredom CC S SR ManualDocument16 paginiForedom CC S SR ManualStevenÎncă nu există evaluări

- Dewalt - Tools Catalog - Buy DirectDocument22 paginiDewalt - Tools Catalog - Buy DirectShopHomeOnlineÎncă nu există evaluări

- P Electric DrillDocument9 paginiP Electric DrillMoid Aretaño Mesa100% (1)

- Dsa 5500Document12 paginiDsa 5500Nguyen Van ToanÎncă nu există evaluări

- Ojt M Aziz Fikri (Xii Pem B-21)Document88 paginiOjt M Aziz Fikri (Xii Pem B-21)RifkiÎncă nu există evaluări

- Metal Turning, Short Course inDocument13 paginiMetal Turning, Short Course inJim100% (15)

- 2018 External Fixation Catalogue PDFDocument55 pagini2018 External Fixation Catalogue PDFNikhil CÎncă nu există evaluări

- Lathe Diagram With ExplanationDocument3 paginiLathe Diagram With ExplanationEnrico959Încă nu există evaluări

- Variable Speed Mini Lathe Operation ManualDocument15 paginiVariable Speed Mini Lathe Operation ManualDaniel AndradeÎncă nu există evaluări

- Rebel V65E LE Servo ManualDocument86 paginiRebel V65E LE Servo Manualhung100% (1)

- Miyano Evolution Line: CNC Turning Center With 2 Spindles, 2 Turrets and 1 Y-Axis SlideDocument8 paginiMiyano Evolution Line: CNC Turning Center With 2 Spindles, 2 Turrets and 1 Y-Axis SlidealdiÎncă nu există evaluări

- HikokiDocument132 paginiHikokilabedduÎncă nu există evaluări

- Mahek SPM Automation File - 2Document118 paginiMahek SPM Automation File - 2Mamta ParmarÎncă nu există evaluări

- Machine Shop 1Document11 paginiMachine Shop 1Ozen AnchetaÎncă nu există evaluări

- Getting Started With Mastercam LatheDocument132 paginiGetting Started With Mastercam LatheshawntsungÎncă nu există evaluări

- Lec2 Lathe MachineDocument70 paginiLec2 Lathe MachineFELIX KEUYAÎncă nu există evaluări

- Art Jewelry Corrugated Knot Chain Bracelet Howard SiegelDocument6 paginiArt Jewelry Corrugated Knot Chain Bracelet Howard SiegelAlexa Miha100% (3)

- Metre Eater Neumatica AQ PDFDocument19 paginiMetre Eater Neumatica AQ PDFGloria Mojonero AguilarÎncă nu există evaluări

- Ralph Patterson Speed Reducer 2Document27 paginiRalph Patterson Speed Reducer 2kokiskoÎncă nu există evaluări

- GENRALDocument274 paginiGENRALRavi BhaskarÎncă nu există evaluări

- 11 New PEO TurningDocument7 pagini11 New PEO TurningmichalÎncă nu există evaluări

- ME2258 Manufacturing Technology Lab IIDocument14 paginiME2258 Manufacturing Technology Lab IIதியாகராஜன் அரிதாஸ்Încă nu există evaluări

- Makita HR2410 User ManualDocument16 paginiMakita HR2410 User ManualSilviu MotÎncă nu există evaluări

- Jig Fixture Final ProjectDocument20 paginiJig Fixture Final ProjectRizky Candra50% (2)

- Spare Parts List: Pusher Leg RockdrillsDocument24 paginiSpare Parts List: Pusher Leg RockdrillsMatheus TavaresÎncă nu există evaluări

- Compact Air Drive IIDocument40 paginiCompact Air Drive IIManuel FloresÎncă nu există evaluări

- 360 Degree Flexible Drilling MachineDocument24 pagini360 Degree Flexible Drilling MachineDHINESH IT67% (3)

- Lathe ReportDocument16 paginiLathe ReportMuhammad Aisamuddin88% (8)

- DHR242 DHR243 ManualDocument64 paginiDHR242 DHR243 ManualTjell KeunÎncă nu există evaluări

- Maxi ManualDocument47 paginiMaxi ManualB Gary AcostaÎncă nu există evaluări