Documente Academic

Documente Profesional

Documente Cultură

KEC Calculation Sheet SDC

Încărcat de

subhaschandraTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

KEC Calculation Sheet SDC

Încărcat de

subhaschandraDrepturi de autor:

Formate disponibile

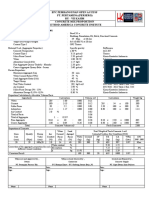

UltraTech Cement Limited

Unit : Ultra Tech Concrete

Bangalore

Mix Design Report

Project : KEC INTERNATIONAL

Location : GODREJ REFLECTION

Client : GODREJ

Date of Submission : 27-01-2020

Mix Design as per IS 10262 - 2009 / IS 456 - 2000

A1 Stipulations for Proportioning

Grade designation M40 SDC

Type of Cement OPC 53 Grade

Type of Mineral Admixture GGBS

Maximum nominal size of Aggregate 20 MM

Minimum Cement Content Specified 360 Kg/Cum

Maximum W/C ratio 0.40

Workability (FLOW) 600 +- 50 mm

Exposure Condition Moderate

Method of Concrete Placing Pumping

Degree of Quality Control Good

Type of Aggregate Cubical

Maximum Cement Content 450 Kg/Cum

Chemical Admixture Type Super - Plasticiser

A2 Test Data for Materials

Cement Used UltraTech OPC 53 G

Specific Gravity of Cement 3.13

Specific Gravity of GGBS 2.81

Chemical Admixture BASF MASTEREASE 3711

Specific Gravity

Coarse Aggregate 2.63

Fine Aggregate 2.61

Water Absorption

Coarse Aggregate 0.41%

Fine Aggregate 4.49%

Free (Surface )Moisture

Coarse Aggregate Nill

Fine Aggregate Nill

Sieve Analysis

Coarse Aggregate Confirming to IS 383

Fine Aggregate Confirming to Zone II as per IS 383

Ratio of CA : FA Based on Gradation 51 : 49

Ratio of 20 : 12.5 Based on Gradation 13 : 87

A3 Target Strength for Mix Proportioning

Fck = fck + 1.65 s 48.25 N/mm2

where Fck = Target average Compressive strength at 28 Days

Fck = Characteristic Compressive strength at 28 Days

s = Standard Deviation

From Table 1 , Standard Deviation , s = ##

A4 Selection of Water - Cement Ratio

From Table 5 of IS 456, Maximum water cement ratio 0.4

Based on Experience, adopt Water-Cement ratio as 0.336

0.33<0.40 hence, Ok

A5 Selection of Water Content

Specified Water - Cementitious ratio = 0.336

Hence Water Content = 500 x 0.34 = 168 L

As superplasticiser used ,the water content can be reduced upto 20 %

Super Plasticiser used @ 0.70 % of Cement Content

A6 Calculation of Cement Content

Cement Content Specified = 500 Kg Cement 350 kg

Assuming GGBS % = 30 % GGBS 150 kg

A7 Proportioning of Coarse and fine Aggregate Content

From Table 3, Volume of Coarse Aggregate corresponding to 20mm size Aggregate

and Fine aggregate (Zone II) for Water - Cement ratio of 0.50 = 0.62

Since Manufactured Sand is used and

as per Gradation results the ratio of CA : FA is 51 : 49

As per IS 10262-2019 Cl 5.2 Table 3 entrapped air is taken as 1% for 20mm maximum size of aggregate

A8 Mix Calculation

For Fine Aggregate Content

V = ( W + (C / Sp. C+MA / Sp. C + 1 / P.fa x FA /Sp.fa x 1 / 1000)

where W is Water Content

C is Cement Content

Sp.C is Specific Gravity of Cement

FA is Fine Aggregate Content

p.fa is Percentage of Fine aggregate

Sp.fa is Specific Gravity of Fine Aggregate

C MA 1 FA 1

0.99

= ( W +

Sp.C

+

Sp.C

+

P.fa

x

Sp.fa ) x 1000

350 150 1 FA 1

0.99

= ( 168 +

3.13

+

2.81

+

0.49

x

2.61 ) x 1000

990 = ( 168 + 111.82 + 53.38 + 0.77 x FA )

:. FA 990 - 333.202

= = 849.83

0.773

For Coarse Aggregate Content

V = ( W + C / Sp. C + 1 / P.ca x CA /Sp.ca x 1 / 1000)

where W is Water Content

C is Cement Content

Sp.C is Specific Gravity of Cement

CA is Fine Aggregate Content

p.ca is Percentage of Fine aggregate

Sp.ca is Specific Gravity of Fine Aggregate

C MA 1 CA 1

0.99

= ( W +

Sp.C

+

Sp.C

+

P.ca

x

Sp.fa ) x 1000

350 150 1 CA 1

0.99

= ( 168 +

3.13

+

2.81

+

0.51

x

2.63 ) x 1000

990 = ( 168 + 111.82 + 53.38 + 0.75 x CA )

:. CA 990 - 333.202

= = 873.88

0.75

Total Coarse Aggregate is 873.88

:. 20mm = 873.88 x 13 % = 109.93

:. 12.5mm = 873.88 x 87 % = 763.62

:. The Mix Constituents are

Cement GGBS 20mm 12.5mm M Sand Water Admixture Remarks

350 150 110 764 850 168 3.50 Mix is cohesive

Remark : The

above Mix Design is on the basis of our approved sources/suppliers of the material. The same may require alteration in

proportioning of materials,within limits, in case of source changes by keeping the performance requirements intact.

Q C Incharge For UltraTech RMC

UltraTech Cement Limited

Unit : Ultra Tech Concrete

Bangalore

Mix Design Report

Project : KEC INTERNATIONAL

Location : GODREJ REFLECTION

Client : GODREJ

Date of Submission : 27-01-2020

Mix Design as per IS 10262 - 2009 / IS 456 - 2000

A1 Stipulations for Proportioning

Grade designation M30SDC

Type of Cement OPC 53 Grade

Type of Mineral Admixture GGBS

Maximum nominal size of Aggregate 20 MM

Minimum Cement Content Specified 320 Kg/Cum

Maximum W/C ratio 0.45

Workability (FLOW) 600 +- 50 mm

Exposure Condition Moderate

Method of Concrete Placing Pumping

Degree of Quality Control Good

Type of Aggregate Cubical

Maximum Cement Content 450 Kg/Cum

Chemical Admixture Type Super - Plasticiser

A2 Test Data for Materials

Cement Used UltraTech OPC 53 G

Specific Gravity of Cement 3.13

Specific Gravity of GGBS 2.81

Chemical Admixture BASF MASTEREASE 3711

Specific Gravity

Coarse Aggregate 2.63

Fine Aggregate 2.61

Water Absorption

Coarse Aggregate 0.41%

Fine Aggregate 4.49%

Free (Surface )Moisture

Coarse Aggregate Nill

Fine Aggregate Nill

Sieve Analysis

Coarse Aggregate Confirming to IS 383

Fine Aggregate Confirming to Zone II as per IS 383

Ratio of CA : FA Based on Gradation 51 : 49

Ratio of 20 : 12.5 Based on Gradation 20 : 80

A3 Target Strength for Mix Proportioning

Fck = fck + 1.65 s 38.25 N/mm2

where Fck = Target average Compressive strength at 28 Days

Fck = Characteristic Compressive strength at 28 Days

s = Standard Deviation

From Table 1 , Standard Deviation , s = 5.0

A4 Selection of Water - Cement Ratio

From Table 5 of IS 456, Maximum water cement ratio 0.45

Based on Experience, adopt Water-Cement ratio as 0.389

0.33<0.40 hence, Ok

A5 Selection of Water Content

Specified Water - Cementitious ratio = 0.389

Hence Water Content = 450 x 0.39 = 175 L

As superplasticiser used ,the water content can be reduced upto 20 %

Super Plasticiser used @ 0.65 % of Cement Content

A6 Calculation of Cement Content

Cement Content Specified = 450 Kg Cement 315 kg

Assuming GGBS % = 30 % GGBS 135 kg

A7 Proportioning of Coarse and fine Aggregate Content

From Table 3, Volume of Coarse Aggregate corresponding to 20mm size Aggregate

and Fine aggregate (Zone II) for Water - Cement ratio of 0.50 = 0.62

Since Manufactured Sand is used and

as per Gradation results the ratio of CA : FA is 51 : 49

As per IS 10262-2019 Cl 5.2 Table 3 entrapped air is taken as 1% for 20mm maximum size of aggregate

A8 Mix Calculation

For Fine Aggregate Content

V = ( W + (C / Sp. C+MA / Sp. C + 1 / P.fa x FA /Sp.fa x 1 / 1000)

where W is Water Content

C is Cement Content

Sp.C is Specific Gravity of Cement

FA is Fine Aggregate Content

p.fa is Percentage of Fine aggregate

Sp.fa is Specific Gravity of Fine Aggregate

C MA 1 FA 1

0.99

= ( W +

Sp.C

+

Sp.C

+

P.fa

x

Sp.fa ) x 1000

315 135 1 FA 1

0.99

= ( 175 +

3.13

+

2.81

+

0.49

x

2.61 ) x 1000

990 = ( 175 + 100.64 + 48.04 + 0.78 x FA )

:. FA 990 - 323.732

= = 855.20

0.779

For Coarse Aggregate Content

V = ( W + C / Sp. C + 1 / P.ca x CA /Sp.ca x 1 / 1000)

where W is Water Content

C is Cement Content

Sp.C is Specific Gravity of Cement

CA is Fine Aggregate Content

p.ca is Percentage of Fine aggregate

Sp.ca is Specific Gravity of Fine Aggregate

C MA 1 CA 1

0.99

= ( W +

Sp.C

+

Sp.C

+

P.ca

x

Sp.fa ) x 1000

315 135 1 CA 1

0.99

= ( 175 +

3.13

+

2.81

+

0.51

x

2.63 ) x 1000

990 = ( 175 + 100.64 + 48.04 + 0.75 x CA )

:. CA 990 - 323.732

= = 891.04

0.75

Total Coarse Aggregate is 891.04

:. 20mm = 891.04 x 20 % = 178.21

:. 12.5mm = 891.04 x 80 % = 712.12

:. The Mix Constituents are

Cement GGBS 20mm 12.5mm M Sand Water Admixture Remarks

315 135 178 712 855 175 2.93 Mix is cohesive

Remark : The

above Mix Design is on the basis of our approved sources/suppliers of the material. The same may require alteration in

proportioning of materials,within limits, in case of source changes by keeping the performance requirements intact.

Q C Incharge For UltraTech RMC

UltraTech Cement Limited

Unit : Ultra Tech Concrete

Bangalore

Mix Design Report

Project : KEC INTERNATIONAL

Location : GODREJ REFLECTION

Client : GODREJ

Date of Submission : 27-01-2020

Mix Design as per IS 10262 - 2009 / IS 456 - 2000

A1 Stipulations for Proportioning

Grade designation M40 SDC

Type of Cement OPC 53 Grade

Type of Mineral Admixture GGBS

Maximum nominal size of Aggregate 20 MM

Minimum Cement Content Specified 360 Kg/Cum

Maximum W/C ratio 0.40

Workability (FLOW) 600 +- 50 mm

Exposure Condition Moderate

Method of Concrete Placing Pumping

Degree of Quality Control Good

Type of Aggregate Cubical

Maximum Cement Content 450 Kg/Cum

Chemical Admixture Type Super - Plasticiser

A2 Test Data for Materials

Cement Used UltraTech OPC 53 G

Specific Gravity of Cement 3.13

Specific Gravity of GGBS 2.81

Chemical Admixture BASF MASTEREASE 3711

Specific Gravity

Coarse Aggregate 2.63

Fine Aggregate 2.61

Water Absorption

Coarse Aggregate 0.41%

Fine Aggregate 4.49%

Free (Surface )Moisture

Coarse Aggregate Nill

Fine Aggregate Nill

Sieve Analysis

Coarse Aggregate Confirming to IS 383

Fine Aggregate Confirming to Zone II as per IS 383

Ratio of CA : FA Based on Gradation 51 : 49

Ratio of 20 : 12.5 Based on Gradation 20 : 80

A3 Target Strength for Mix Proportioning

Fck = fck + 1.65 s 48.25 N/mm2

where Fck = Target average Compressive strength at 28 Days

Fck = Characteristic Compressive strength at 28 Days

s = Standard Deviation

From Table 1 , Standard Deviation , s = 5.0

A4 Selection of Water - Cement Ratio

From Table 5 of IS 456, Maximum water cement ratio 0.4

Based on Experience, adopt Water-Cement ratio as 0.340

0.33<0.40 hence, Ok

A5 Selection of Water Content

Specified Water - Cementitious ratio = 0.340

Hence Water Content = 500 x 0.34 = 170 L

As superplasticiser used ,the water content can be reduced upto 20 %

Super Plasticiser used @ 0.65 % of Cement Content

A6 Calculation of Cement Content

Cement Content Specified = 500 Kg Cement 300 kg

Assuming GGBS % = 40 % GGBS 200 kg

A7 Proportioning of Coarse and fine Aggregate Content

From Table 3, Volume of Coarse Aggregate corresponding to 20mm size Aggregate

and Fine aggregate (Zone II) for Water - Cement ratio of 0.50 = 0.62

Since Manufactured Sand is used and

as per Gradation results the ratio of CA : FA is 51 : 49

As per IS 10262-2019 Cl 5.2 Table 3 entrapped air is taken as 1% for 20mm maximum size of aggregate

A8 Mix Calculation

For Fine Aggregate Content

V = ( W + (C / Sp. C+MA / Sp. C + 1 / P.fa x FA /Sp.fa x 1 / 1000)

where W is Water Content

C is Cement Content

Sp.C is Specific Gravity of Cement

FA is Fine Aggregate Content

p.fa is Percentage of Fine aggregate

Sp.fa is Specific Gravity of Fine Aggregate

C MA 1 FA 1

0.99

= ( W +

Sp.C

+

Sp.C

+

P.fa

x

Sp.fa ) x 1000

300 200 1 FA 1

0.99

= ( 170 +

3.13

+

2.81

+

0.49

x

2.61 ) x 1000

990 = ( 170 + 95.85 + 71.17 + 0.78 x FA )

:. FA 990 - 337.021

= = 837.29

0.780

For Coarse Aggregate Content

V = ( W + C / Sp. C + 1 / P.ca x CA /Sp.ca x 1 / 1000)

where W is Water Content

C is Cement Content

Sp.C is Specific Gravity of Cement

CA is Fine Aggregate Content

p.ca is Percentage of Fine aggregate

Sp.ca is Specific Gravity of Fine Aggregate

C MA 1 CA 1

0.99

= ( W +

Sp.C

+

Sp.C

+

P.ca

x

Sp.fa ) x 1000

300 200 1 CA 1

0.99

= ( 170 +

3.13

+

2.81

+

0.51

x

2.63 ) x 1000

990 = ( 170 + 95.85 + 71.17 + 0.75 x CA )

:. CA 990 - 337.021

= = 875.84

0.75

Total Coarse Aggregate is 875.84

:. 20mm = 875.84 x 20 % = 175.17

:. 12.5mm = 875.84 x 80 % = 700.85

:. The Mix Constituents are

Cement GGBS 20mm 12.5mm M Sand Water Admixture Remarks

300 200 175 701 837 170 3.25 Mix is cohesive

Remark : The

above Mix Design is on the basis of our approved sources/suppliers of the material. The same may require alteration in

proportioning of materials,within limits, in case of source changes by keeping the performance requirements intact.

Q C Incharge For UltraTech RMC

UltraTech Cement Limited

Unit : Ultra Tech Concrete

Bangalore

Mix Design Report

Project : KEC INTERNATIONAL

Location : GODREJ REFLECTION

Client : GODREJ

Date of Submission : 27-01-2020

Mix Design as per IS 10262 - 2009 / IS 456 - 2000

A1 Stipulations for Proportioning

Grade designation M30SDC

Type of Cement OPC 53 Grade

Type of Mineral Admixture GGBS

Maximum nominal size of Aggregate 20 MM

Minimum Cement Content Specified 320 Kg/Cum

Maximum W/C ratio 0.45

Workability (FLOW) 600 +- 50 mm

Exposure Condition Moderate

Method of Concrete Placing Pumping

Degree of Quality Control Good

Type of Aggregate Cubical

Maximum Cement Content 450 Kg/Cum

Chemical Admixture Type Super - Plasticiser

A2 Test Data for Materials

Cement Used UltraTech OPC 53 G

Specific Gravity of Cement 3.13

Specific Gravity of GGBS 2.81

Chemical Admixture BASF MASTEREASE 3711

Specific Gravity

Coarse Aggregate 2.63

Fine Aggregate 2.61

Water Absorption

Coarse Aggregate 0.41%

Fine Aggregate 4.49%

Free (Surface )Moisture

Coarse Aggregate Nill

Fine Aggregate Nill

Sieve Analysis

Coarse Aggregate Confirming to IS 383

Fine Aggregate Confirming to Zone II as per IS 383

Ratio of CA : FA Based on Gradation 50 : 50

Ratio of 20 : 12.5 Based on Gradation 20 : 80

A3 Target Strength for Mix Proportioning

Fck = fck + 1.65 s 38.25 N/mm2

where Fck = Target average Compressive strength at 28 Days

Fck = Characteristic Compressive strength at 28 Days

s = Standard Deviation

From Table 1 , Standard Deviation , s = 5.0

A4 Selection of Water - Cement Ratio

From Table 5 of IS 456, Maximum water cement ratio 0.45

Based on Experience, adopt Water-Cement ratio as 0.380

0.33<0.40 hence, Ok

A5 Selection of Water Content

Specified Water - Cementitious ratio = 0.380

Hence Water Content = 450 x 0.38 = 171 L

As superplasticiser used ,the water content can be reduced upto 20 %

Super Plasticiser used @ 0.70 % of Cement Content

A6 Calculation of Cement Content

Cement Content Specified = 450 Kg Cement 270 kg

Assuming GGBS % = 40 % GGBS 180 kg

A7 Proportioning of Coarse and fine Aggregate Content

From Table 3, Volume of Coarse Aggregate corresponding to 20mm size Aggregate

and Fine aggregate (Zone II) for Water - Cement ratio of 0.50 = 0.62

Since Manufactured Sand is used and

as per Gradation results the ratio of CA : FA is 50 : 50

As per IS 10262-2019 Cl 5.2 Table 3 entrapped air is taken as 1% for 20mm maximum size of aggregate

A8 Mix Calculation

For Fine Aggregate Content

V = ( W + (C / Sp. C+MA / Sp. C + 1 / P.fa x FA /Sp.fa x 1 / 1000)

where W is Water Content

C is Cement Content

Sp.C is Specific Gravity of Cement

FA is Fine Aggregate Content

p.fa is Percentage of Fine aggregate

Sp.fa is Specific Gravity of Fine Aggregate

C MA 1 FA 1

0.99

= ( W +

Sp.C

+

Sp.C

+

P.fa

x

Sp.fa ) x 1000

270 180 1 FA 1

0.99

= ( 171 +

3.13

+

2.81

+

0.50

x

2.61 ) x 1000

990 = ( 171 + 86.26 + 64.06 + 0.76 x FA )

:. FA 990 - 321.319

= = 876.83

0.763

For Coarse Aggregate Content

V = ( W + C / Sp. C + 1 / P.ca x CA /Sp.ca x 1 / 1000)

where W is Water Content

C is Cement Content

Sp.C is Specific Gravity of Cement

CA is Fine Aggregate Content

p.ca is Percentage of Fine aggregate

Sp.ca is Specific Gravity of Fine Aggregate

C MA 1 CA 1

0.99

= ( W +

Sp.C

+

Sp.C

+

P.ca

x

Sp.fa ) x 1000

270 180 1 CA 1

0.99

= ( 171 +

3.13

+

2.81

+

0.50

x

2.63 ) x 1000

990 = ( 171 + 86.26 + 64.06 + 0.76 x CA )

:. CA 990 - 321.319

= = 884.59

0.76

Total Coarse Aggregate is 884.59

:. 20mm = 884.59 x 20 % = 176.92

:. 12.5mm = 884.59 x 80 % = 706.97

:. The Mix Constituents are

Cement GGBS 20mm 12.5mm M Sand Water Admixture Remarks

270 180 177 707 877 171 3.15 Mix is cohesive

Remark :

The above Mix Design is on the basis of our approved sources/suppliers of the material. The same may require alteration

in proportioning of materials,within limits, in case of source changes by keeping the performance requirements intact.

Q C Incharge For UltraTech RMC

UltraTech Cement Limited

Unit : Ultra Tech Concrete

Bangalore

Mix Design Report

Project : KEC INTERNATIONAL

Location : GODREJ REFLECTION

Client : GODREJ

Date of Submission : 27-01-2020

Mix Design as per IS 10262 - 2009 / IS 456 - 2000

A1 Stipulations for Proportioning

Grade designation M40 SDC

Type of Cement OPC 53 Grade

Type of Mineral Admixture GGBS

Maximum nominal size of Aggregate 20 MM

Minimum Cement Content Specified 360 Kg/Cum

Maximum W/C ratio 0.40

Workability (FLOW) 600 +- 50 mm

Exposure Condition Moderate

Method of Concrete Placing Pumping

Degree of Quality Control Good

Type of Aggregate Cubical

Maximum Cement Content 450 Kg/Cum

Chemical Admixture Type Super - Plasticiser

A2 Test Data for Materials

Cement Used UltraTech OPC 53 G

Specific Gravity of Cement 3.13

Specific Gravity of GGBS 2.81

Chemical Admixture BASF MASTEREASE 3711

Specific Gravity

Coarse Aggregate 2.63

Fine Aggregate 2.61

Water Absorption

Coarse Aggregate 0.41%

Fine Aggregate 4.49%

Free (Surface )Moisture

Coarse Aggregate Nill

Fine Aggregate Nill

Sieve Analysis

Coarse Aggregate Confirming to IS 383

Fine Aggregate Confirming to Zone II as per IS 383

Ratio of CA : FA Based on Gradation 50 : 50

Ratio of 20 : 12.5 Based on Gradation 20 : 80

A3 Target Strength for Mix Proportioning

Fck = fck + 1.65 s 48.25 N/mm2

where Fck = Target average Compressive strength at 28 Days

Fck = Characteristic Compressive strength at 28 Days

s = Standard Deviation

From Table 1 , Standard Deviation , s = 5.0

A4 Selection of Water - Cement Ratio

From Table 5 of IS 456, Maximum water cement ratio 0.4

Based on Experience, adopt Water-Cement ratio as 0.340

0.33<0.40 hence, Ok

A5 Selection of Water Content

Specified Water - Cementitious ratio = 0.340

Hence Water Content = 500 x 0.34 = 170 L

As superplasticiser used ,the water content can be reduced upto 20 %

Super Plasticiser used @ 0.70 % of Cement Content

A6 Calculation of Cement Content

Cement Content Specified = 500 Kg Cement 350 kg

Assuming GGBS % = 30 % GGBS 150 kg

A7 Proportioning of Coarse and fine Aggregate Content

From Table 3, Volume of Coarse Aggregate corresponding to 20mm size Aggregate

and Fine aggregate (Zone II) for Water - Cement ratio of 0.50 = 0.62

Since Manufactured Sand is used and

as per Gradation results the ratio of CA : FA is 50 : 50

As per IS 10262-2019 Cl 5.2 Table 3 entrapped air is taken as 1% for 20mm maximum size of aggregate

A8 Mix Calculation

For Fine Aggregate Content

V = ( W + (C / Sp. C+MA / Sp. C + 1 / P.fa x FA /Sp.fa x 1 / 1000)

where W is Water Content

C is Cement Content

Sp.C is Specific Gravity of Cement

FA is Fine Aggregate Content

p.fa is Percentage of Fine aggregate

Sp.fa is Specific Gravity of Fine Aggregate

C MA 1 FA 1

0.99

= ( W +

Sp.C

+

Sp.C

+

P.fa

x

Sp.fa ) x 1000

350 150 1 FA 1

0.99

= ( 170 +

3.13

+

2.81

+

0.50

x

2.61 ) x 1000

990 = ( 170 + 111.82 + 53.38 + 0.77 x FA )

:. FA 990 - 335.202

= = 850.75

0.770

For Coarse Aggregate Content

V = ( W + C / Sp. C + 1 / P.ca x CA /Sp.ca x 1 / 1000)

where W is Water Content

C is Cement Content

Sp.C is Specific Gravity of Cement

CA is Fine Aggregate Content

p.ca is Percentage of Fine aggregate

Sp.ca is Specific Gravity of Fine Aggregate

C MA 1 CA 1

0.99

= ( W +

Sp.C

+

Sp.C

+

P.ca

x

Sp.fa ) x 1000

350 150 1 CA 1

0.99

= ( 170 +

3.13

+

2.81

+

0.50

x

2.63 ) x 1000

990 = ( 170 + 111.82 + 53.38 + 0.76 x CA )

:. CA 990 - 335.202

= = 866.74

0.76

Total Coarse Aggregate is 866.74

:. 20mm = 866.74 x 20 % = 173.18

:. 12.5mm = 866.74 x 80 % = 693.05

:. The Mix Constituents are

Cement GGBS 20mm 12.5mm M Sand Water Admixture Remarks

350 150 173 693 851 170 3.50 Mix is cohesive

Remark : The

above Mix Design is on the basis of our approved sources/suppliers of the material. The same may require alteration in

proportioning of materials,within limits, in case of source changes by keeping the performance requirements intact.

Q C Incharge For UltraTech RMC

S-ar putea să vă placă și

- C - 25 Concrete Mix Design (Slab)Document14 paginiC - 25 Concrete Mix Design (Slab)Engineeri TadiyosÎncă nu există evaluări

- C - 15 Concrete Mix Design CementDocument6 paginiC - 15 Concrete Mix Design CementEngineeri TadiyosÎncă nu există evaluări

- C - 35 Concrete Mix Design (Pipe Culvert)Document24 paginiC - 35 Concrete Mix Design (Pipe Culvert)Engineeri TadiyosÎncă nu există evaluări

- FFC-MBR-QC-CON-01 A Oct. 03, 2018: 1500 Psi at 28 Day 20 0.8 GoodDocument4 paginiFFC-MBR-QC-CON-01 A Oct. 03, 2018: 1500 Psi at 28 Day 20 0.8 GoodjaymarÎncă nu există evaluări

- Design Mix Computation SheetDocument6 paginiDesign Mix Computation SheetAshutosh RawatÎncă nu există evaluări

- Concrete Mix Designs: Raw Materials Weight of Raw Materials Per Cubic Meter CMD-1 CMD-2 RemarksDocument13 paginiConcrete Mix Designs: Raw Materials Weight of Raw Materials Per Cubic Meter CMD-1 CMD-2 RemarksDzey IsorenaÎncă nu există evaluări

- Mix Design of Class C-24 (3500psi) ConcreteDocument3 paginiMix Design of Class C-24 (3500psi) ConcreteMd. Mahmudle HassanÎncă nu există evaluări

- Mamburao Project Concrete DesignDocument4 paginiMamburao Project Concrete DesignjaymarÎncă nu există evaluări

- M30 Easycrete Mix DesignDocument3 paginiM30 Easycrete Mix Designabir senguptaÎncă nu există evaluări

- Mix Design For PQCDocument20 paginiMix Design For PQCSasanka SekharÎncă nu există evaluări

- M30 Grade Concrete Mix Design With Fly Ash - IS10262Document5 paginiM30 Grade Concrete Mix Design With Fly Ash - IS10262scribdfree anytimeÎncă nu există evaluări

- Concrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)Document6 paginiConcrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)jishad_nalakath50% (2)

- Mix Design Calculations - DCIPL M40.Document14 paginiMix Design Calculations - DCIPL M40.AmirÎncă nu există evaluări

- PRISM JOHNSON LIMITED CONCRETE MIX DESIGN FOR M30 GRADEDocument3 paginiPRISM JOHNSON LIMITED CONCRETE MIX DESIGN FOR M30 GRADEabir senguptaÎncă nu există evaluări

- Concrete Mixed Design For C30Document2 paginiConcrete Mixed Design For C30raju_420034520Încă nu există evaluări

- M 35 With FlyashDocument54 paginiM 35 With FlyashCIVIL ENGINEERINGÎncă nu există evaluări

- Concrete Mix Design M-40 (RCC) GradeDocument6 paginiConcrete Mix Design M-40 (RCC) GradeAshok amlapureÎncă nu există evaluări

- Concrete Mix Design M-40 (RCC) GradeDocument6 paginiConcrete Mix Design M-40 (RCC) GradeAshok amlapureÎncă nu există evaluări

- Concrete Mix DesignDocument6 paginiConcrete Mix Designlewis kalataÎncă nu există evaluări

- Ready Mixed Concrete Mix Design for 35 N/mm2 StrengthDocument1 paginăReady Mixed Concrete Mix Design for 35 N/mm2 StrengthAung Naing Latt AungÎncă nu există evaluări

- PRISM JOHNSON LIMITED CONCRETE MIX DESIGN FOR M40 GRADEDocument3 paginiPRISM JOHNSON LIMITED CONCRETE MIX DESIGN FOR M40 GRADEabir senguptaÎncă nu există evaluări

- DESIGN MIX OF CONCRETE - 4000psi PCDDocument6 paginiDESIGN MIX OF CONCRETE - 4000psi PCDJohn Archie Dela CruzÎncă nu există evaluări

- Aggregate Type Source Dry Rodded Density KG Specific Gravity Water AbsorptionDocument5 paginiAggregate Type Source Dry Rodded Density KG Specific Gravity Water AbsorptionMatumbi NaitoÎncă nu există evaluări

- TM Concrete Mix Design M25PCCDocument11 paginiTM Concrete Mix Design M25PCCAnurag ChaturvediÎncă nu există evaluări

- M25 - Fluidic Mix Design With Trial MixDocument3 paginiM25 - Fluidic Mix Design With Trial Mixabir senguptaÎncă nu există evaluări

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument6 paginiTest Report: M/S Abhi Engg Corporation PVT LTDImran Khan100% (1)

- I. Stipulations For Proportioning of M35 Grade Concrete: Table 5-IS456Document5 paginiI. Stipulations For Proportioning of M35 Grade Concrete: Table 5-IS456scribdfree anytimeÎncă nu există evaluări

- Mix Design - M25 - CSDocument5 paginiMix Design - M25 - CSsatishÎncă nu există evaluări

- Calculation On C30 DesignsDocument3 paginiCalculation On C30 Designsanon_424198985100% (1)

- Stipulations For Proportions: - : Mix Design As Per IS 10262-2009Document7 paginiStipulations For Proportions: - : Mix Design As Per IS 10262-2009AslamMakandarÎncă nu există evaluări

- M30 Normal - Mix Design With Trial SheetDocument4 paginiM30 Normal - Mix Design With Trial Sheetabir senguptaÎncă nu există evaluări

- DATE OF CASTING - 2/1/2022: Epc Contractor Representative Concessinoaire Independent EngineerDocument37 paginiDATE OF CASTING - 2/1/2022: Epc Contractor Representative Concessinoaire Independent Engineerjitendra dixitÎncă nu există evaluări

- Mix Design M45 PDFDocument6 paginiMix Design M45 PDFHarsh PatelÎncă nu există evaluări

- Mix Design M40 Grade Per IS 10262 & IS 456Document6 paginiMix Design M40 Grade Per IS 10262 & IS 456Sanjoy RoyÎncă nu există evaluări

- Group 3Document10 paginiGroup 3Shivam SharmaÎncă nu există evaluări

- Masonry Mortar DesignDocument40 paginiMasonry Mortar Designp. kiran kuamrÎncă nu există evaluări

- Epc Pembangunan Open Access Pt. Pertamina (Persero) Ru - Vii Kasim Concrete Mix Proportion Method America Concrete InsituteDocument4 paginiEpc Pembangunan Open Access Pt. Pertamina (Persero) Ru - Vii Kasim Concrete Mix Proportion Method America Concrete InsituteBengkulu BetonÎncă nu există evaluări

- Concrete Mix DesignDocument10 paginiConcrete Mix Designkrishbist67% (3)

- M25 Mix Design & Trial SheetDocument3 paginiM25 Mix Design & Trial Sheetabir senguptaÎncă nu există evaluări

- Calculation of Design Mix: Fine Aggerates Coarse AggregatesDocument6 paginiCalculation of Design Mix: Fine Aggerates Coarse AggregatesVALIENT CANCERANÎncă nu există evaluări

- (As Per IS: 10262 - 2019) Trial Mix Date: A-1) Design StipulationDocument8 pagini(As Per IS: 10262 - 2019) Trial Mix Date: A-1) Design StipulationvamsiÎncă nu există evaluări

- Concrete Mix DesignDocument6 paginiConcrete Mix DesignWilliamray PabloÎncă nu există evaluări

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument10 paginiClient National Highways Authority of India Authority Engineer Epc ContractorDeepakÎncă nu există evaluări

- Report For Mix Design of Concrete Grade M-20: (With J.K.Lakshmi OPC 43G)Document9 paginiReport For Mix Design of Concrete Grade M-20: (With J.K.Lakshmi OPC 43G)artiÎncă nu există evaluări

- M40 Concrete Mix Design AppendixDocument3 paginiM40 Concrete Mix Design AppendixKunjbihari ParmarÎncă nu există evaluări

- M35 Revised Mix Design SheetDocument2 paginiM35 Revised Mix Design Sheetamol awateÎncă nu există evaluări

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument9 paginiClient National Highways Authority of India Authority Engineer Epc ContractorDeepakÎncă nu există evaluări

- PQC Mix DesignDocument60 paginiPQC Mix DesignAshok amlapure67% (9)

- M30 Design CalculationDocument6 paginiM30 Design Calculationjeffkarthick1Încă nu există evaluări

- Concrete Mix Design For - M5: (As Per IS 10262-2019)Document8 paginiConcrete Mix Design For - M5: (As Per IS 10262-2019)mahesh naikÎncă nu există evaluări

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument61 paginiTest Report: M/S Abhi Engg Corporation PVT LTDimran khanÎncă nu există evaluări

- 1) Summary of RequirementsDocument4 pagini1) Summary of RequirementsSolomon MehariÎncă nu există evaluări

- Mix Design CalculationDocument8 paginiMix Design CalculationEr Digvijay SinghÎncă nu există evaluări

- Pasig-Marikina River Channel Improvement Project Concrete Mix DesignDocument6 paginiPasig-Marikina River Channel Improvement Project Concrete Mix DesignVALIENT CANCERANÎncă nu există evaluări

- Mix Design Details For 40 MPaDocument1 paginăMix Design Details For 40 MPaTaposh PaulÎncă nu există evaluări

- M-30 Concrete Mix Design As Per IS-10262-2009Document4 paginiM-30 Concrete Mix Design As Per IS-10262-2009Vinod BabhaleÎncă nu există evaluări

- Aparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Document5 paginiAparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Kumar gsÎncă nu există evaluări

- ChenchuDocument3 paginiChenchuBhuvaneshwar ReddyÎncă nu există evaluări

- Bentonite Functionalised with 2-(3-(2-aminoethylthio)propylthio)ethanamine (AEPE) for the Removal of Hg(II) from Wastewaters: Synthesis, Characterisation and Hg(II) Adsorption PropertiesDe la EverandBentonite Functionalised with 2-(3-(2-aminoethylthio)propylthio)ethanamine (AEPE) for the Removal of Hg(II) from Wastewaters: Synthesis, Characterisation and Hg(II) Adsorption PropertiesÎncă nu există evaluări

- Progress in Nuclear Magnetic Resonance Spectroscopy: Volume 14De la EverandProgress in Nuclear Magnetic Resonance Spectroscopy: Volume 14Încă nu există evaluări

- Internal Audit Checklist (Insert Classification)Document30 paginiInternal Audit Checklist (Insert Classification)subhaschandraÎncă nu există evaluări

- QUALITY AgendaDocument1 paginăQUALITY AgendasubhaschandraÎncă nu există evaluări

- Bs 6699 For GgbsDocument22 paginiBs 6699 For Ggbssubhaschandra100% (1)

- Book 111Document8 paginiBook 111subhaschandraÎncă nu există evaluări

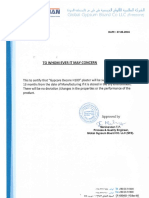

- Gypcore Gypsum Plaster Selflife CertificateDocument1 paginăGypcore Gypsum Plaster Selflife CertificatesubhaschandraÎncă nu există evaluări

- Morth - Section400Document34 paginiMorth - Section400sudhreddy72% (25)

- ALMA - Method Statement For STP Water ProofingDocument7 paginiALMA - Method Statement For STP Water ProofingsubhaschandraÎncă nu există evaluări

- QUALITY CONTROL REVIEW DASHBOARDDocument1 paginăQUALITY CONTROL REVIEW DASHBOARDsubhaschandraÎncă nu există evaluări

- NKM - Quality Assurance Review Dashboard - Working FileDocument27 paginiNKM - Quality Assurance Review Dashboard - Working FilesubhaschandraÎncă nu există evaluări

- NKM - Quality Assurance Review Dashboard 1.4Document1 paginăNKM - Quality Assurance Review Dashboard 1.4subhaschandraÎncă nu există evaluări

- Gypcore Gypsum Plaster MTC 2Document1 paginăGypcore Gypsum Plaster MTC 2subhaschandraÎncă nu există evaluări

- Calibration Details 1Document3 paginiCalibration Details 1subhaschandraÎncă nu există evaluări

- Curriculum Vitae: Dipen Sarkar Mobile: +91-8016913764Document2 paginiCurriculum Vitae: Dipen Sarkar Mobile: +91-8016913764subhaschandraÎncă nu există evaluări

- Hebel Tech Manual 3Document79 paginiHebel Tech Manual 3subhaschandraÎncă nu există evaluări

- Slab Formwork DesignDocument7 paginiSlab Formwork DesignRaja SundarapandianÎncă nu există evaluări

- 7GS 5000Document5 pagini7GS 5000subhaschandraÎncă nu există evaluări

- CV 6+ Years ElectricianDocument2 paginiCV 6+ Years ElectriciansubhaschandraÎncă nu există evaluări

- DR Satyanarayana HILDocument4 paginiDR Satyanarayana HILvaratharajank100% (1)

- 3greenseal Flexi 201Document3 pagini3greenseal Flexi 201subhaschandraÎncă nu există evaluări

- Eticketing PrintTicketDocument1 paginăEticketing PrintTicketsubhaschandraÎncă nu există evaluări

- DR Fixit Pidifin 2 KDocument3 paginiDR Fixit Pidifin 2 Ksubhaschandra100% (1)

- Technical Sheet and Installation Guide for Autoclaved Aerated Concrete PropertiesDocument12 paginiTechnical Sheet and Installation Guide for Autoclaved Aerated Concrete PropertiessubhaschandraÎncă nu există evaluări

- MYKSANIFLEXDocument2 paginiMYKSANIFLEXsubhaschandraÎncă nu există evaluări

- Brushbond TGPDocument2 paginiBrushbond TGPsubhaschandraÎncă nu există evaluări

- DR Fixit FastflexDocument3 paginiDR Fixit FastflexsubhaschandraÎncă nu există evaluări

- Renderoc RGDocument4 paginiRenderoc RGvenkatasuri999Încă nu există evaluări

- BRawnflex PrimeDocument1 paginăBRawnflex PrimesubhaschandraÎncă nu există evaluări

- Aerocon Blocks Product Literature FOLDER A4Document2 paginiAerocon Blocks Product Literature FOLDER A4subhaschandraÎncă nu există evaluări

- BlocksDocument4 paginiBlockssubhaschandraÎncă nu există evaluări

- 439 20140827 Method Statement of Tie-Ins For Portable Water and Sanitary Waste Water LineDocument16 pagini439 20140827 Method Statement of Tie-Ins For Portable Water and Sanitary Waste Water Linearshad iqbalÎncă nu există evaluări

- IS 7272.1.1974 - Labour Constants PDFDocument19 paginiIS 7272.1.1974 - Labour Constants PDFVenkatesh KakhandikiÎncă nu există evaluări

- Analisa-Prime MortarDocument14 paginiAnalisa-Prime Mortarirfan ikhsani wahyuÎncă nu există evaluări

- Astm C 87Document4 paginiAstm C 87mickyfelixÎncă nu există evaluări

- Analysis of Increasing of Concrete Compression Strength To Concrete'S Age Due To Adding Admixture of Sikament-163Document6 paginiAnalysis of Increasing of Concrete Compression Strength To Concrete'S Age Due To Adding Admixture of Sikament-163Mahnoor asadÎncă nu există evaluări

- George Washington Masonic National MemorialDocument89 paginiGeorge Washington Masonic National MemorialGarden Club of VirginiaÎncă nu există evaluări

- Piling SpecificationDocument25 paginiPiling SpecificationletuananhbÎncă nu există evaluări

- Epoxy CatalogDocument38 paginiEpoxy CatalogMohamed ElMahalaweyÎncă nu există evaluări

- Nitofill Ur63 PDFDocument3 paginiNitofill Ur63 PDFtalatzahoorÎncă nu există evaluări

- Masonry Testing 101 - 2018 04 12Document57 paginiMasonry Testing 101 - 2018 04 12Jeff LongoriaÎncă nu există evaluări

- The Reinforced Concrete Floor SystemDocument6 paginiThe Reinforced Concrete Floor SystemglendaÎncă nu există evaluări

- Introduction to Pavement Design PrinciplesDocument9 paginiIntroduction to Pavement Design PrinciplesRicky MeyerÎncă nu există evaluări

- Case Writing Lucky CementDocument20 paginiCase Writing Lucky CementM.TalhaÎncă nu există evaluări

- TDS - Rheomac 730Document2 paginiTDS - Rheomac 730Alexi ALfred H. TagoÎncă nu există evaluări

- Is 2250 1981 PDFDocument36 paginiIs 2250 1981 PDFChockalingamÎncă nu există evaluări

- West Bengal Schedule Rates of Building Works 2015Document399 paginiWest Bengal Schedule Rates of Building Works 2015Arunashish Mazumdar75% (8)

- Using Cathodic Protection To Control Corrosion in Marine EnvironmentsDocument12 paginiUsing Cathodic Protection To Control Corrosion in Marine EnvironmentsMark ByramÎncă nu există evaluări

- Schedule B Sub Estimate 1Document4 paginiSchedule B Sub Estimate 1Karanjit SigotÎncă nu există evaluări

- Submission of 7-Days Concrete Mix Design Test ResultsDocument2 paginiSubmission of 7-Days Concrete Mix Design Test ResultsAdyam YonasÎncă nu există evaluări

- STRUCTURE ANALYSIS REPORT FOR MAJALENGKA TOWER (TDD_INFILLPKU001Document34 paginiSTRUCTURE ANALYSIS REPORT FOR MAJALENGKA TOWER (TDD_INFILLPKU001rifkynetÎncă nu există evaluări

- Duracon Concrete DensifierDocument2 paginiDuracon Concrete Densifiertejas_tÎncă nu există evaluări

- BtechhDocument7 paginiBtechhcorbitecoÎncă nu există evaluări

- 2 - Paved Shoulder Comp. RevisedDocument7 pagini2 - Paved Shoulder Comp. RevisedUopEmptyÎncă nu există evaluări

- Slip Formwork Use For ConstructionsDocument87 paginiSlip Formwork Use For Constructionscoepcesa67% (3)

- A Study of Concrete Paver Block Using Crumb Rubber in InterlockingDocument4 paginiA Study of Concrete Paver Block Using Crumb Rubber in InterlockingEditor IJTSRDÎncă nu există evaluări

- Fosroc Tunnelling Brochure 2020Document12 paginiFosroc Tunnelling Brochure 2020aamerÎncă nu există evaluări

- Green ConcreteDocument11 paginiGreen ConcreteVaishnavi MundlodÎncă nu există evaluări

- Dam and Reservoir EngineeringDocument800 paginiDam and Reservoir Engineeringnongvanden2100% (8)

- TDS - Glenium 51Document3 paginiTDS - Glenium 51Alexi ALfred H. TagoÎncă nu există evaluări

- Project Ecs536 Mac Jun 2023Document6 paginiProject Ecs536 Mac Jun 2023Hairul AsyrafÎncă nu există evaluări