Documente Academic

Documente Profesional

Documente Cultură

Saic A 2011

Încărcat de

jerinDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Saic A 2011

Încărcat de

jerinDrepturi de autor:

Formate disponibile

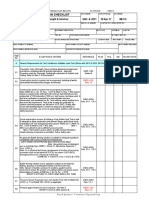

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.

00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pressure Test Preparation SAIC-A-2011 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Test Preparation - General Requirements ... USE SATR-A-2001, 2002, 2003, 2004, 2005 & SATR-A-2006 as req'd.

Pressure Test Package meets Attachment 1 minimum content

requirements. (Reviewed/approved/signed). See SAIC-A-2003. SAEP-1160,

A1 Note 1: Package contents were Section 8

reviewed carefully. Note 2: Document

deficiencies are noted in package for action.

Pre-Test Punchlisting is complete (per procedure). All "A" items are

cleared & accepted* (*Test Pkg Flow Chart is also signed off)

SAEP-1160,

A2 Section 8

Note: "A" items are Pre-test Punchlist items that must be complete

prior to safe pressure testing of systems per approved procedure.

Permanent Flange set installations are documented/accepted.

Note: Flanges that will not

SAEP-1160,

A3 be disturbed after the pressure test are marked/identified and

Section 8

tightened & QC records are per approved procedure & available. See

also SAIC-L-2014 & SATR-L-2001.

System Flushing and internal Cleanliness is complete. Test

SAES-A-004,

A4 Package Flow chart is signed-off. New systems and equipment in

Para. 8.1.2

Plants were cleaned per approved procedures per SAES-L-350.

Component Safeguards (temporary removals/test exclusions) exist

for new systems to prevent damage caused by filling, venting,

SAES-A-004,

draining, flushing or testing. These are itemized on Reinstatement

A5 Section 8

and Pre-Test Checklists and are found in Test Pkgs/Procedures.

See Safeguards listed in Attachment 2.

Temporary supports shall be installed prior to hydrostatic testing, and

SAES-A-004,

A6 flushing of the piping if they were determined to be required per

Para. 8.5.2

SAES-L-150.

Expansion joints and spring hangers or spring supports are provided

SAES-L-150,

A7 with temporary restraints where needed to prevent excessive travel

Para. 6.4

or deformation under the test loads. (Field Verify)

All joints including welded joints are accesible and left exposed for

visual leak detection during the strength test. External coating and SAES-L-150,

A8

priming of such joints are not allowed unless approved. Para. 7.3

Note: This excludes joints subject to 24-hr recorded test

Work permit is obtained for pressure testing and associated work G.I.-2.102,

A9

within restricted areas, as per G.I. 2.100, Work Permit System. Para. 5.1.6

Equipment & appurtenances (Attachments, auxilliary equipment, etc)

that are not adequate for test pressures are isolated from test. G.I.-2.102,

A10

Provisions made to ensure that no over pressuring can occur in Para. 5.1.7

equipment that is not being tested

Saudi Aramco: Company General Use

If an isolation valve is used for a test boundary, in lieu of test

blind, ensure that no overpressurization damage can occur in any

equipment beyond the isolation valve (due to valve leak-by) by:

a) Reduction of test pressure (rule = G.I.-2.102,

1.1 times valve press rating) b) Open isolation valve Para. 5.1.7,

A11 drain (or nearest adjacent low-point drain) c) SAES-A-004

Relief valves placed on both sides of isolation valve. (Para. 7.3) Para 8.3

d) Personnel are posted during testing to identify any valve

leak-by. e) Personnel control/stop pressurization

(Valve leak-by evidence). See

Remarks Section (Safety Note 1)

MSDS or Chemical Hazard Bulletins is available/reviewed for all

chemicals handled (corrosion inhibitor, bactericide, chlorine, oxygen G.I.-2.102,

A12

scavenger, etc). Written procedure to safely handle chemicals Para. 5.1.9

during testing & to ensure proper disposal after testing is approved.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pressure Test Preparation SAIC-A-2011 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Personal protective equipment (PPE) is available and utilized as G.I.-2.102,

A 13

shown on these sheets and bulletins for chemical handling. Para. 5.2.1

Access/Egress for Test areas is marked & warning signs posted to G.I.-2.102,

A 14

alert approaching personnel of pressure testing activities. Para. 5.1.11

Where a road parallels within 30 m (100 ft.) of an aboveground

pipeline being tested, traffic shall be diverted or stopped during the G.I.-2.102,

A 15

test. If this is not practical, the area Loss Prevention offices should be Para. 5.1.11

contacted to confirm that the test can be conducted safely.

If non-Saudi Aramco facilities will be exposed in a pressure test of SA

G.I.-2.102,

A 16 facilities, the proponent organization of the test shall so inform the

Para. 5.1.12

Saudi Aramco Affairs representative prior to the test.

Copy of the approved pressure testing procedure & the GI-2.102 are

SAES-A-004,

A 17 available at site. Test Personnel are safety trained/experienced.

Para. 5.6.1

B Verification of Actual Test Set-up & SIS Sheet Data:

Test Set-up* matches actual test arrangement (drawings).

Note 1: *Pressure Test Diagram

with an appropriate Legend for symbols, Test Manifold Arrangement

(& pressure hoses/piping) show all high points (vents), low points

(drains), gage locations & provide documentation that attests to the

SAEP-1160,

actual test as performed. In event of testing accident, Loss

Section 8

B1 Prevention Dept must be able to use diagrams & sketches to

Bullet

recreate actual test set-up/conditions. Note 2:

Item 2

Testing of multiple lines (test pkgs) on projects can be done by

proper hose arrangement, filling & venting to save time. Sketch &

show the actual hose arrangement(s) in test packages. Correct any

errors in arrangement found, initial & date sketches.

SIS Sheet Data (pressure, limiting factor, medium & temperature) is

checked* for accuracy against the test application and is correct. SAEP-1160,

*Note: Human error (test package calcs) is common. Section 8

B2

Inspectors responsible for testing are able to spot gross errors & Bullet

prevent unsafe testing & overpressurization of systems & Item 2

components.

C Test Manifold & Appurtanances (Piping, Fittings, Hoses)

Before employing the pressure testing manifold in the actual system

pressure test, it shall be separately pressure tested to at least 1.2

times the system test pressure but not less than the discharge

pressure of the pump used for the pressure testing. SAES-A-004

C1 The test manifold shall be designed and constructed to meet the Para 5.5.4,

minimum system requirements and approved by the Engineering 5.5.4.1, 5.5.4.2

Division head in operating facilities or responsible Project Inspection

Division head in new construction.

Test manifolds shall have 100% NDT of all welds.

Pressure rating or design of test manifold components* (isolation

valves, pipe nipples, fittings) exceed system test pressure by 20%. G.I.-2.102,

C2

See Safety Note 1 in Remarks for isolation Para. 5.1.5.5

valves

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pressure Test Preparation SAIC-A-2011 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Manifold Arrangement Drawings attest to the following:

A) Fabrication was per code construction with component

details listed such as Class, size, schedule, type isolation valve, etc.

B) Maximum Safe Test

Pressure Rating based on limiting factor. C)

G.I.-2.102,

C3 Each test manifold is identified with a unique number (certificate)

Para. 5.1.2.5

D) Shows actual arrangement including hose

configuration used Note 1:

Manifold permanent marking (unique ID #, pressure rating) is legible,

traceable & certified (Engineering support docs).

Manifolds proposed for use on projects without detailed code

construction certification (Engineering calcs & Inspection) must be

evaluated for fitness and safety. Provide necessary details and

G.I.-2.102,

C4 support test manifolds with any necessary calculations (SIS sheet)

Para. 5.1.5.5

and the appropriate visual Inspection and any necessary NDE.

Note: Unknown piping schedules can be determined by

using a UT Thickness meter. Weld quality is verified by VT or RT.

A blow down valve of adequate pressure rating is installed to G.I.-2.102,

C5

depressurize the system safely (easily accessible to operator). Para. 5.1.5.3

Test Manifold pressure tested to at least 20 percent above test

pressure of the system under test. (Exception: Final connection

between test manifold and system under test may be tested to G.I.-2.102,

C6

maximum system test pressure only if a higher test pressure is Section 5.1.5.5

impractical.) The test manifold test certificate shows the limiting factor

(lowest pressure rated component).

Paddles or spectacle blinds & other fabricated test items used to

isolate test sections are at least the same code class rating of SAES-A-004

C7

systems under test or are supported by appropriate code calcs. See Para. 8.3

Remarks, Critical Safety Note 2

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pressure Test Preparation SAIC-A-2011 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

D Test Relief Valve(s)

Relief valve is located in the system under test and near the test

G.I.-2.102,

D1 pump with Isolation valves on the inlet and outlet of the relief valve

Para. 5.1.5.1

sealed open during the test. (SAEP-1160, Bullet Item # 3)

Relief valve(s) of adequate capacity (*SIS Sheet & Calcs available)

are set to relieve at 5%* above the hydrotest pressure. SAES-A-004

D2

*Note: Test pressures less than 85% of SMYS can have Para 5.5.1

relief valves set at 10% above test pressure. Verify SIS sheets calcs.

Relief valve(s) are tested, dated, and tagged (as valid) for a period of SAES-A-004

D3

one week for project pressure tests. Stickers are legible & valid. Para 5.5.1

E Pressure Gages and Recorders

A minimum of two pressure gages are required for test systems, with

accuracy within 5% of one another.

Note 1: When large systems are tested, Inspection personnel will

determine the need for additional gages.

Note 2: Elevation changes (hydrostatic head SAES-A-004

E1

considerations) & hot weather create pressure testing problems with Para 8.1.5.4

frequent popping of relief valves. For this reason, gage accuracy

within 2% is best. Note 3: Careful handling of

delicate instruments like test gages is practiced by test crews. No

gage damage or mishandling is found.

Pressure gages and pressure recorders are calibrated within (1) SAES-A-004

E2

month prior to test. Stickers applied indicate latest calibration date. Para 8.1.5.2

G.I.-2.102,

Avoid the following typical examples of poor practices:Testing

Sec.4 &

E3 equipment with the test gauge located at the bottom of the equipment

SAES-A-004,

reading the test pressure,including the head of test water

Para 5.3

All gages have a range such that the test pressure is within 30% to SAES-A-004

E4

80% of the full range. Para 8.1.5.3

F Temperature Gages and Recorders (When Required, ie: 24-hr Recorded Tests)

Bubble Leak Test (associated with Pneumatic strength/service test)

surface metal temperatures shall be recorded and compatible with

test methods (including test solution used to detect leaks).

SAES-A-004

F1 Note: ASME V, Art 10, Man. App. 1, Table 1-1021

Para 5.6.3

requires surface metal temp measurements during testing (detailed

in procedure). Record maximum (direct sun) & minimum test

temperatures.

Thermocouples are installed to obtain accurate pipe metal

temperature measurements and to determine the acceptance of the SAES-L-150,

F2

pressure test where pressure variations due to test water Para. 11.3

temperature changes occur, such as in cross-country pipelines.

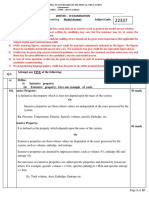

REMARKS: Critical Safety Note 1: Surveys of test manifolds used on projects have resulted in many findings of inadequate ratings for isolation

valves. Test manifolds for testing specific pressure rating Classes require isolation valves of the next higher class. Example: Manifolds for testing

Class 300 # systems require Class 600 # isolation valves as a general rule. For Pressure tests against closed seats follow the 110% rule for safe

test pressure calculation. See ASME B16.34, Para 7.2 as applicable. Also, this same requirement must be carefully considered when determining

test pressures where an isolation valve serves as a test boundary limit and the valve seat will be pressurized. Ensure system test pressures are

reduced to 110% as applicable and show the valve seat as the test "limiting factor". Safety Note 2: Fabricated test

implements of proper code construction receive inspection and properly identification/marking for pressure rating, inspection acceptance/fitness

(Insp Ok, initial, date). Never allow uninspected non-code test implement use or those that are unfit for testing (deteriorated, damaged, heavily

corroded). Unsafe/unfit test implements found are reported/removed ASAP from Company Projects.

REFERENCE DOCUMENTS:

1. SAES-A-004, General Requirements for Pressure Testing, (30-Jan-2011)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pressure Test Preparation SAIC-A-2011 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

2. GI-2.102, Saudi Aramco General Instruction-Pressure Testing Safely, (28 October, 2008)

3. SAES-L-150, Pressure Testing of Plant Piping and Pipelines, (24-Dec-2014)

4. Pro Forma Contract Schedule Q (Project Specific)

5. SAEP-1160-- Tracking and Reporting of Welding, NDT and Pressure Testing for Capital Projects (10-July-2011)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pressure Test Preparation SAIC-A-2011 30-Apr-17 MECH-

Attachment 1 - SAEP-1160 Test Pkg Minimum Requirements

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pressure Test Preparation SAIC-A-2011 30-Apr-17 MECH-

Attachment 2 - Component Safeguard Summary

Note: This Summary Checklist has been developed with concurrence of CSD

1. INSTALL THESE COMPONENTS IN LINE ONLY AFTER THOROUGH FLUSHING:

Soft seated valves & control valves (SAES-A-004, Para. 8.1.3)

2. INSTALL THESE COMPONENTS IN LINE AFTER FLUSHING & TEST COMPLETION (ON

REINSTATEMENT):

Components in new piping systems which interfere with filling, venting, draining or flushing shall not be installed until after line

flushing and pressure testing are completed. This includes Procedures/Test Package Instruction or details about specific

component care as listed below (SAES-A-004, Para 8.1.4):

a) Orifice plates -- Flow nozzles -- Sight glasses (incl. vessel trim) -- Venturies -- Meters (positive displacement,

turbine)

b) In-line equipment (as determined by Proponent) includes valve care (corrosion, cleaning, lay-up considerations). A list

shall be obtained by Contractor from COMPANY relative to Component Safeguards. Contractor shall request specific

instruction for specific component safeguards from Company (Proponent, SAPMT, SA Inspection)

3. INSTALL THESE COMPONENTS (EXCLUDED FROM PRESSURE TEST) ON FINAL REINSTATEMENT:

Note: The following list defines the equipment that shall be excluded from the in-situ pressure

testing of the tested system. Also, other unlisted sensitive equipment or as designated by SA Inspector can be added (SAES-A-

004-Para 8.2):

a) Rotating machinery, such as pumps, turbines and compressors;

b) Strainers and filter elements

c) Pressure relieving devices, such as rupture disks and pressure relief valves;

d) Locally mounted indicating pressure gauges, where the test pressure will exceed their scale range;

e) Equipment that cannot be drained (This includes valve cavities. See Valve Care below).

f) Instrument Devices.

g) Other unlisted sensitive equipment (propose exclusion in test package)

h) Equipment designated by Saudi Aramco Inspector (Approves procedures that list specific equipment in scope)

CSD VALVE SAFEGUARDS & CARE (TYPICAL FOR AMBIENT LAY-UP)

Valve Field Hydrotest Practice (separate from line/system testing) assures adequate preservation as listed below. Valves

or other equipment that are field tested prior to installation in a pipeline, plant, or other facility are likely to experience corrosion

damage if this is not performed with adequate diligence and precautions.

a) The following applies to valve trims Type 1, 4, 6, 7, 8, and 8A and all solid Type 400 SS (13 CR) valves.

b) Plan prior field testing of valves to minimize the length of time between test and installation in the system.

c) All critical isolation valves that are tested shall be tested with water containing less than 50 ppm chlorides. The water shall

contain 0.5% by weight (5 grams per liter) Cortec VpCI 609. (Note:Chemical cost would be about $0.30 per liter. VpCI 609 is

biodegradable so there are no problems with its use. (See Environmental Protection Dept.)

d) After hydrotesting, gate valves will have their gates raised to allow full draining of water. Allow adequate drainage time. All

traces of visible

e) Apply water shall

manufacturer be removed

approved from

lubricant the10%

plus valve bodyVpCI-329

Cortec and seat area.

(SAP Blow dry with clean

1000173887) addedcompressed

to all interiorair.

critical surfaces

such as seal areas. Ball valves shall be full operated to distribute inhibited lubricant between ball and body.

Constructed Piping Hydrotest Practice (Valve Safeguards)

a) Hydrotest plans for constructed field equipment shall be designed to minimize exposure of valves to hydrotest water. Unless

it is absolutely unavoidable, critical isolation valves (Field Hydrotested) shall be installed after completion of hydro.

b) Piping systems shall be thoroughly flushed before hydrotesting to remove wind-blown sand, construction debris, and any

other foreign matter. Flushing water shall be the same quality as the hydrotest water. Hydrotest shall be performed

immediately after flushing or the line shall be properly layed-up per SAES-A-007 Procedures (30-day rule).

c) If any 400 series (13 CR) trimmed valves are pre-installed & hydrotested in the line, utilize test gaskets and thoroughly drain

test water immediately after the test. Where complete draining is impossible (no valve body drain plug), valves shall be

removed immediately after test, dried with clean compressed air and re-lubricated before "ambient" lay-up. Ensure

that there is no debris in the seat area.

d) Any 400 series (13 CR) trimmed valves that are pre-installed and hydrotested in the line, and that have body or seat drains

and are in place when field pipework is hydrotested shall be treated with Cortec VpCI 609 by blowing into all possible valve

injection locations immediately after completion of the hydrotest and draining of all water.

e) Any 400 series (13Cr) trimmed valves that are pre-installed welded-in-place shall be liberally coated with inhibited lubricant

before final welding into the line.

f) Safeguards for 300 series (316 SS, etc) trimmed valves require similar care to assure complete cavity draining. Corrosion

inhibitors used shall be approved by CSD.

Saudi Aramco: Company General Use

S-ar putea să vă placă și

- Chapter 3 - Francis and Kaplan Turbine - Fluid MachineryDocument26 paginiChapter 3 - Francis and Kaplan Turbine - Fluid Machineryamanpreet2190100% (6)

- SAIC-L-2035 Rev 6Document2 paginiSAIC-L-2035 Rev 6biplabpal2009Încă nu există evaluări

- SAIC-L-2014 Rev. 5Document10 paginiSAIC-L-2014 Rev. 5Jagadeesh PuppalaÎncă nu există evaluări

- Saic Gi 2102Document3 paginiSaic Gi 2102jerin100% (3)

- Valves PDFDocument150 paginiValves PDFksvvijÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 paginiSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidÎncă nu există evaluări

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 paginiSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289Încă nu există evaluări

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 paginiSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWÎncă nu există evaluări

- SAIC-A-2015 Rev 7Document8 paginiSAIC-A-2015 Rev 7Bebin Mathew0% (1)

- Saic A 2011Document5 paginiSaic A 2011Anonymous 4e7GNjzGWÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingDocument5 paginiSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingpravinÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 paginiSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289Încă nu există evaluări

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 paginiSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14Document10 paginiSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14pravinÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechDocument6 paginiSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechEagle SpiritÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 paginiSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saic L 2008 PDFDocument4 paginiSaic L 2008 PDFHesham HelalÎncă nu există evaluări

- Saic RT 2007Document9 paginiSaic RT 2007munnaÎncă nu există evaluări

- Saic W 2003Document14 paginiSaic W 2003Mohammed IlliasuddinÎncă nu există evaluări

- Saudi Aramco Inspection ChecklistDocument23 paginiSaudi Aramco Inspection ChecklistjahaanÎncă nu există evaluări

- Saudi Aramco Inspection ChecklistDocument2 paginiSaudi Aramco Inspection ChecklistJoni Carino SuniÎncă nu există evaluări

- Saudi Aramco Inspection ChecklistDocument13 paginiSaudi Aramco Inspection ChecklistAli AhmedÎncă nu există evaluări

- Saic A 2001Document21 paginiSaic A 2001Dilshad AhemadÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacoDocument7 paginiSaudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacojahaanÎncă nu există evaluări

- SAIC-H-2010 Rev 7Document1 paginăSAIC-H-2010 Rev 7Satheesh Rama SamyÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 paginiSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanÎncă nu există evaluări

- Saic L 2003Document9 paginiSaic L 2003MAZHARULÎncă nu există evaluări

- Ir 175-010000Document2 paginiIr 175-010000Abu Anas M.SalaheldinÎncă nu există evaluări

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 paginiSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaÎncă nu există evaluări

- Saudi Aramco Inspection ChecklistDocument3 paginiSaudi Aramco Inspection ChecklistAbdul HannanÎncă nu există evaluări

- SAIC-A-2008 Rev 0Document3 paginiSAIC-A-2008 Rev 0Kristine Caye DatarioÎncă nu există evaluări

- 175 325100Document2 pagini175 325100sridhar100% (1)

- Satr-W-2010Document1 paginăSatr-W-2010Joni Carino SuniÎncă nu există evaluări

- SAIC L 2031 (Comments)Document2 paginiSAIC L 2031 (Comments)Anton Thomas PunzalanÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 paginiSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldDocument6 paginiSaudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldManoj KumarÎncă nu există evaluări

- Saudi Aramco Test ReportDocument4 paginiSaudi Aramco Test Reportkarthi51289Încă nu există evaluări

- SAIC-D-2005 Rev 2Document4 paginiSAIC-D-2005 Rev 2ரமேஷ் பாலக்காடுÎncă nu există evaluări

- SAIC-A-2009 Rev 2Document5 paginiSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுÎncă nu există evaluări

- SAIC-H-2014 Rev 7Document3 paginiSAIC-H-2014 Rev 7mohammed siddiqÎncă nu există evaluări

- SATIP H 002 08 Rev 4.unlockedDocument2 paginiSATIP H 002 08 Rev 4.unlockedMohamed Farhan B PositiveÎncă nu există evaluări

- SAIC-L-2136 Rev 0Document3 paginiSAIC-L-2136 Rev 0philipyapÎncă nu există evaluări

- 175 011100Document2 pagini175 011100Abu Anas M.SalaheldinÎncă nu există evaluări

- Saic LPT 2006Document12 paginiSaic LPT 2006jerinÎncă nu există evaluări

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 paginiSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 paginăSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWÎncă nu există evaluări

- SAIC W 2069 in Process Welding InspectionDocument8 paginiSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhÎncă nu există evaluări

- Saic-L-2010 Pmi Testing PDFDocument5 paginiSaic-L-2010 Pmi Testing PDFkarioke mohaÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 paginiSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocument2 paginiSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- Saudi Aramco Inspection ChecklistDocument2 paginiSaudi Aramco Inspection Checklistkarthi51289Încă nu există evaluări

- Saep 324Document13 paginiSaep 324Up WeldÎncă nu există evaluări

- 175 010300 PDFDocument2 pagini175 010300 PDFAbu Anas M.SalaheldinÎncă nu există evaluări

- Materials System SpecificationDocument22 paginiMaterials System SpecificationAwais CheemaÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldDocument1 paginăSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 paginiSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalÎncă nu există evaluări

- SAIC-W-2043 Rev 0Document3 paginiSAIC-W-2043 Rev 0philipyapÎncă nu există evaluări

- SATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)Document2 paginiSATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)deepa narayan100% (1)

- 175 091300Document2 pagini175 091300Abu Anas M.SalaheldinÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldDocument13 paginiSaudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldAnonymous S9qBDVky100% (1)

- SAIC-A-2011 Rev 6 Pressure TestDocument8 paginiSAIC-A-2011 Rev 6 Pressure Testpookkoya thangalÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 paginiSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshÎncă nu există evaluări

- SAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesDocument6 paginiSAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesAhdal NoushadÎncă nu există evaluări

- Saic H 2060Document11 paginiSaic H 2060jerinÎncă nu există evaluări

- Saic LPT 2006Document12 paginiSaic LPT 2006jerinÎncă nu există evaluări

- Saic G 2002Document32 paginiSaic G 2002jerinÎncă nu există evaluări

- Saic LPT 2004Document13 paginiSaic LPT 2004jerinÎncă nu există evaluări

- Saic e 2005Document13 paginiSaic e 2005jerinÎncă nu există evaluări

- Saic LPT 2001Document22 paginiSaic LPT 2001jerinÎncă nu există evaluări

- Saic H 2033Document6 paginiSaic H 2033jerinÎncă nu există evaluări

- Saic e 2002Document10 paginiSaic e 2002jerinÎncă nu există evaluări

- Saic M 1004Document2 paginiSaic M 1004jerinÎncă nu există evaluări

- Saic B 1002Document3 paginiSaic B 1002jerinÎncă nu există evaluări

- Saic B 1004Document2 paginiSaic B 1004jerinÎncă nu există evaluări

- Saic A 2013Document6 paginiSaic A 2013jerinÎncă nu există evaluări

- Saic D 2017Document2 paginiSaic D 2017jerinÎncă nu există evaluări

- Saic D 2025Document10 paginiSaic D 2025jerinÎncă nu există evaluări

- Satip N 110 01Document11 paginiSatip N 110 01jerinÎncă nu există evaluări

- Saic N 2026Document3 paginiSaic N 2026jerinÎncă nu există evaluări

- Satr M 1063Document3 paginiSatr M 1063jerin100% (1)

- Qpedia Apr09 Basic Principles of Wind Tunnel Design9Document3 paginiQpedia Apr09 Basic Principles of Wind Tunnel Design9Ryan FadhliÎncă nu există evaluări

- Cpsf-In-Lst-1-D179-01-00 Reva3Document33 paginiCpsf-In-Lst-1-D179-01-00 Reva3henriquezrsÎncă nu există evaluări

- Steam Injection in Fractured Carbonate Reservoirs PDFDocument2 paginiSteam Injection in Fractured Carbonate Reservoirs PDFlinda feibe rawisÎncă nu există evaluări

- Day 02 ESP Basic Design and Operational FactorsDocument113 paginiDay 02 ESP Basic Design and Operational FactorsMustafa Abdel-WahabÎncă nu există evaluări

- ASHRAE - Factsheet Refrigerant - 200424Document6 paginiASHRAE - Factsheet Refrigerant - 200424Hiei ArshavinÎncă nu există evaluări

- 2X70 Power Plant Technical SpecificationDocument53 pagini2X70 Power Plant Technical SpecificationChanna BasavaÎncă nu există evaluări

- Welding ProcessDocument9 paginiWelding ProcessrajuÎncă nu există evaluări

- Multicomponent Distillation Shortcut MethodDocument5 paginiMulticomponent Distillation Shortcut MethodDiegoAndréVegaDávalosÎncă nu există evaluări

- Lab 9 Air Conditioning 1Document8 paginiLab 9 Air Conditioning 1khairi_mohammadÎncă nu există evaluări

- Airlift PumpDocument3 paginiAirlift Pumpveliger2009Încă nu există evaluări

- Model Answer Winter 2019Document19 paginiModel Answer Winter 2019Mohit D MoreÎncă nu există evaluări

- Hydraulics Lecture Part I (Introduction)Document46 paginiHydraulics Lecture Part I (Introduction)Kristal AbalosÎncă nu există evaluări

- PDI-200 Water HammerDocument27 paginiPDI-200 Water HammerKumlachew Mengistu100% (1)

- 1-Oil & Gas Industry Trivia Questions & Answers - Earth ScienceDocument4 pagini1-Oil & Gas Industry Trivia Questions & Answers - Earth SciencewreckiebÎncă nu există evaluări

- Floating Bodies PDFDocument8 paginiFloating Bodies PDFQSQFÎncă nu există evaluări

- MEEG 630, Intermediate Fluid Mechanics: R U R If A Pressure GradientDocument2 paginiMEEG 630, Intermediate Fluid Mechanics: R U R If A Pressure GradientAditya KumarÎncă nu există evaluări

- b25d b30d Mkiii HydraulicsDocument28 paginib25d b30d Mkiii HydraulicsErmias100% (3)

- Glycol Dehydration Instrumentation and ControlsDocument3 paginiGlycol Dehydration Instrumentation and ControlsdndudcÎncă nu există evaluări

- Cap 03 Mecanica Dos Fluidos Fox Mcdonald 8a Edicao SolutionDocument166 paginiCap 03 Mecanica Dos Fluidos Fox Mcdonald 8a Edicao SolutionAlice LimaÎncă nu există evaluări

- ME 231 Montazami Whharris 10-2-18 Class Work SolutionDocument15 paginiME 231 Montazami Whharris 10-2-18 Class Work SolutionJoana ArielaÎncă nu există evaluări

- Centrifugal Pumps IntroductionDocument6 paginiCentrifugal Pumps IntroductionKhemiri Houssem EddineÎncă nu există evaluări

- SLB ESP With Packer and VentDocument1 paginăSLB ESP With Packer and VentwsgÎncă nu există evaluări

- Biogas Capture From Palm Oil Mill Effluent For Power Generation On 27.3.2014 (For MR CHIN)Document13 paginiBiogas Capture From Palm Oil Mill Effluent For Power Generation On 27.3.2014 (For MR CHIN)Wan Zahir100% (1)

- G-104 One-Piece Ball Valve: Parts ListDocument1 paginăG-104 One-Piece Ball Valve: Parts ListEnrique AssmannÎncă nu există evaluări

- A Fixed Quantity of Gas at 21Document8 paginiA Fixed Quantity of Gas at 21nonoytagupa3Încă nu există evaluări

- Technical Data Manual: Vitodens 100-WDocument32 paginiTechnical Data Manual: Vitodens 100-WRed SquerrelÎncă nu există evaluări

- Centac Fluid Techtrol Gold Fluid Analysis Program: DescriptionDocument2 paginiCentac Fluid Techtrol Gold Fluid Analysis Program: DescriptionAndrew Archie ArcherÎncă nu există evaluări

- Knowledge Management Series-Low Vacuum in Steam Turbine PDFDocument4 paginiKnowledge Management Series-Low Vacuum in Steam Turbine PDFMadhusudhan Pasumarty100% (1)