Documente Academic

Documente Profesional

Documente Cultură

Series 3 Electrical Minicargador CASE

Încărcat de

Mauricio DuranDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Series 3 Electrical Minicargador CASE

Încărcat de

Mauricio DuranDrepturi de autor:

Formate disponibile

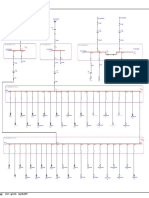

Electrical

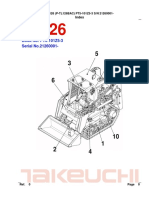

400 SERIES 3 EIC and

AIC Programming

1 of 15

“400” Series Skid Steer

Electrical

Startup of Unlocked Machine

I. Sit in seat

a. Operator must be in the seat to enable the pushbutton startup

b. All indicator lamps except the Engine Preheat lamp will illuminate briefly to

confirm operation

c. Audible alarm will sound briefly to confirm operation

d. All LCD segments will display briefly to confirm operation

e. POWER button will flash to prompt operator

f. Engine hours will display in text window regardless of display option

II. Press the flashing POWER button to power up the instrument panel

III. Await completion of engine preheat

a. Engine Preheat indicator lamp will illuminate

b. Text window will display a countdown of preheat time remaining

c. Preheat Time

i. NEF [440, 450, 465] – 30 seconds

ii. F5C [420, 430, 435, 445] – 30 seconds, 10 seconds during cranking

iii. ISM [410]

Above 68F/20C – 3 seconds

68F/20C – 4 seconds

59F/15C – 5 seconds

50F/10C – 7.5 seconds

41F/5C – 9 seconds

32F/0C – 10.5 seconds

23F/-5C – 13 seconds

Below 23F/-5C – 13 seconds

IV. Press the flashing START button to crank machine

V. Release START button once machine is started

VI. Press the flashing PARK button to enable the hydraulic system

a. The Control Handle Park Brake switch cannot be used for initial system enable

b. Instrument Panel PARK button and Control Handle Park Brake switch have

same functionality after initial system enable

2 of 15

“400” Series Skid Steer

Electrical

Startup of Locked Machine

I. Sit in seat

a. Operator must be in the seat to enable the pushbutton startup

b. All indicator lamps except the Engine Preheat lamp will illuminate briefly to

confirm operation

c. Audible alarm will sound briefly to confirm operation

d. All LCD segments will display briefly to confirm operation

e. POWER button will flash to prompt operator

f. Engine hours will display in text window regardless of display option

II. Press the flashing POWER button to power up the instrument panel

III. “UNLOC” will display briefly in the text window to prompt user

IV. “00000” will display with the left-most digit flashing to prompt user to enter

code

V. The power-tan numbers and symbols beneath each of the pushbuttons apply to

the lock codes

a. The START button is used to enter 1, 2, and 3

i. Press once for 1

ii. Press twice for 2

iii. Press thrice for 3

b. The AUX OVERRIDE button is used to enter 4, 5, and 6

i. Press once for 4

ii. Press twice for 5

iii. Press thrice for 6

c. The PARK button is used to enter 7, 8, 9, and 0

i. Press once for 7

ii. Press twice for 8

iii. Press thrice for 9

iv. Press four times for 0

d. The POWER button is used to enter each digit and enter the code

i. Press after each digit is entered to move to the next digit

ii. Press after all digits have been entered to unlock the machine

e. If code is incorrect, “ERROR” will be displayed briefly before display returns

to “00000” prompt to try code again

f. If code is correct, the panel will power up and engine preheat will begin

VI. Await completion of engine preheat

a. Engine Preheat indicator lamp will illuminate

b. Text window will display a countdown of preheat time remaining

c. Preheat Time

i. NEF [440, 440CT, 450, 450CT, 465] – 30 seconds

ii. F5C [420, 420CT, 430, 435, 445, 445CT] – 30 seconds, 10 seconds during

cranking

iii. ISM [410]

Above 68F/20C – 3 seconds

68F/20C – 4 seconds

59F/15C – 5 seconds

50F/10C – 7.5 seconds

3 of 15

“400” Series Skid Steer

Electrical

41F/5C – 9 seconds

32F/0C – 10.5 seconds

23F/-5C – 13 seconds

Below 23F/-5C – 13 seconds

VII. Press the flashing START button to crank machine

VIII. Release START button once machine is started

IX. Press the flashing PARK button to enable the hydraulic system

a. The Control Handle Park Brake switch cannot be used for initial system enable

b. Instrument Panel PARK button and Control Handle Park Brake switch have

same functionality after initial system enable

Machine Shutdown

1. Press the POWER button to turn off the machine’s engine

2. “LOCK?” will display in the text window

a. To lock machine, press the flashing AUX OVERRIDE button

i. “LOCKd” will display to confirm machine is locked

ii. Machine cannot be locked if a lock code has not been created

b. To leave machine unlocked, simply exit machine without pressing the AUX

OVERRIDE button

4 of 15

“400” Series Skid Steer

Electrical

SETUP Menu

The SETUP menu allows the user to create machine lockout codes, review machine faults,

perform onboard machine diagnostics, and change machine settings.

To enter the SETUP menu

I. Instrument Panel must be off

a. Panel will turn off 30 seconds after sitting in seat

b. Raise weight out of seat to turn off panel prior to 30 second timeout

II. Push and hold the AUX OVERRIDE button and the PARK button simultaneously for

5 seconds

III. SETUP will display in the text window

IV. User may sit in seat after entering SETUP

SETUP

a. “SETUP” will display as a top-level menu placeholder

b. Press the START button to move to the next selection [EXIT] in SETUP

EXIT is used to exit the setup menu

a. Press the POWER button to exit the setup menu

b. Press the START button to move to the next selection [LOCK] in SETUP

LOCK is used to create and modify codes to unlock a locked machine

a. Press the POWER button to enter LOCK

b. Press the START button to move to the next selection [FAULT] ]in SETUP

FAULT records machine fault history that can be viewed by the user

a. Press the POWER button to enter FAULT

b. Press the START button to move to the next selection [dIAG] in SETUP

dIAG allows the user to perform onboard diagnostics of the instrument panel and its

SSL system interface

a. Press the POWER button to enter dIAG

b. Press the START button to move to the next selection [UNITS] in SETUP

UNITS allows the user to select the units of measure for the digital temperature

display

a. Press the POWER button to enter UNITS

b. Press the START button to move to the next selection [dSPLY] in SETUP

dSPLY allows the user to select machine information to be displayed in the text

window during normal machine operation

a. Press the POWER button to enter dSPLY

b. Press the START button to move to the next selection [JTIME] in SETUP

JTIME provides a clearable machine usage timer separate from the engine hour meter

a. Press the POWER button to enter JTIIME

b. Press the START button to move to the next selection [ENGIN] in SETUP

ENGIN allows a technician to change the machine engine settings to match a given

machine

a. Press the POWER button to enter ENGIN

b. Press the START button to move to the next selection [SRVCE] in SETUP

SRVCE contains additional menus and machine information for use by a technician

in a service setting

a. Press the POWER button to enter SRVCE

b. Press the START button to move to the next selection, back around to EXIT

5 of 15

“400” Series Skid Steer

Electrical

LOCK

The first time entering LOCK, the user will be prompted to create an Owner

code.

An Owner code must be created to allow activation of the machine lockout

feature.

This Owner code is used to unlock a locked machine and allows access to

create and modify User codes.

To exit LOCK after entering, press and hold the PARK button for five

seconds from any sub-menu

To create an Owner code

Enter LOCK

I. “OWNCR” will be displayed briefly

II. “00000” will display with the left-most digit flashing to prompt user to create a

code

III. The power-tan numbers and symbols beneath each of the pushbuttons apply to

the lock codes

a. The START button is used to enter 1, 2, and 3

i. Press once for 1

ii. Press twice for 2

iii. Press thrice for 3

b. The AUX OVERRIDE button is used to enter 4, 5, and 6

i. Press once for 4

ii. Press twice for 5

iii. Press thrice for 6

c. The PARK button is used to enter 7, 8, 9, and 0

i. Press once for 7

ii. Press twice for 8

iii. Press thrice for 9

iv. Press four times for 0

d. The POWER button is used to enter each digit and enter the code

i. Press after each digit is entered to move to the next digit

ii. Press after all digits have been entered to unlock the machine

IV. The code will be saved and displayed back to the user for verification

V. The user will be returned to SETUP prompt

To view or modify an Owner code

Enter LOCK

I. “OWNER” will be displayed

II. Press the POWER button to enter OWNER

III. “OPEN” will display briefly to prompt the user for access code

IV. “00000” will display with the left-most digit flashing to prompt user to enter

access code

V. Enter the Owner code

6 of 15

“400” Series Skid Steer

Electrical

VI. The power-tan numbers and symbols beneath each of the pushbuttons apply to

the lock codes

a. The START button is used to enter 1, 2, and 3

i. Press once for 1

ii. Press twice for 2

iii. Press thrice for 3

b. The AUX OVERRIDE button is used to enter 4, 5, and 6

i. Press once for 4

ii. Press twice for 5

iii. Press thrice for 6

c. The PARK button is used to enter 7, 8, 9, and 0

i. Press once for 7

ii. Press twice for 8

iii. Press thrice for 9

iv. Press four times for 0

d. The POWER button is used to enter each digit and enter the code

i. Press after each digit is entered to move to the next digit

ii. Press after all digits have been entered to unlock the machine

VI. If code is incorrect

a. “ERROR” will be displayed briefly

b. “OPEN” will be displayed briefly

c. “00000” will display with the left-most digit flashing to prompt user to enter

access code

VII. If code is correct

a. “OWNCR” will be displayed briefly to prompt user that a new Owner code can

be created

b. The existing saved Owner code will be displayed with the left-most digit

flashing to prompt the user to over-write the current code with a new code

VII. The code will be saved and displayed back to the user for verification

VIII. The user will be returned to SETUP prompt

To create User codes

Ten independent User codes can be created, USER0-USER9. These codes will unlock a

locked machine. The Owner code must be entered to modify a User code.

Enter LOCK

I. “OWNER” will be displayed

II. Press the START button to move to the next LOCK selection, “USER”

III. Press the POWER button to enter USER

IV. “USER0” will display to indicate current User code selected

V. Press the POWER button to enter USER0

VI. “USRCR” will be displayed briefly to prompt user to create User code

VII. “00000” will display with the left-most digit flashing to prompt user to enter

access code

VIII. Create a User code using the pushbuttons to enter numbers

VIII. The code will be saved, displayed back to the user for verification

IX. The user will be returned to SETUP prompt

7 of 15

“400” Series Skid Steer

Electrical

X. Re-enter LOCK

XI. Press the START button to move to USER

XII. Press the POWER button to enter USER

XIII. Press the START button to move from USER0 to USER1

XIV. Press POWER to enter USER1

XV. “USRCR” will be displayed briefly to prompt user to create User code

XVI. Create USER1 code

XVII. Repeat for codes USER2 through USER9 as desired

To view or modify User codes

The Owner code must be entered to modify a User code.

Enter LOCK

I. “OWNER” will be displayed

II. Press the START button to move to the next LOCK selection, “USER”

III. Press the POWER button to enter USER

IV. “USER0” will display to indicate current User code selected

V. Press the POWER button to enter USER0

VI. “OPEN” will be displayed briefly to prompt user to enter Owner code for

access

VII. “00000” will display with the left-most digit flashing to prompt user to enter

access code

VIII. Enter the Owner code

IX. “USRCR” will be displayed briefly to prompt user to modify User code

X. The existing saved USER0 code will be displayed with the left-most digit

flashing to prompt the user to over-write the current code with a new code

XI. The new code will be saved, displayed back to the user for verification

XII. The user will be returned to SETUP prompt

XIII. Repeat for codes USER1 through USER9 as desired

8 of 15

“400” Series Skid Steer

Electrical

FAULT

FAULT stores information about machine system faults that have occurred.

Press and hold the PARK button for five seconds to exit FAULT from any sub-menu

level.

The FAULT menu structure is

EC001 [Charge Pressure] is recorded on a low charge pressure fault that

occurs while the engine is running

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC001 information

EC002 [Engine Oil Pressure] is recorded on a low engine oil pressure fault

that occurs while the engine is running

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC002 information

EC003 [Hydraulic Oil Filter] is recorded on an oil filter warning

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC003 information

EC004 [Air Filter/EGR Malfunction] is recorded on an air intake filter

warning or engine EGR control module warning

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC004 information

EC005 [Hydraulic Oil Temperature] is recorded on a high oil temperature

fault

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC005 information

EC006 [Engine Coolant Temperature] is recorded on a high engine coolant

temperature fault

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC006 information

EC007 [Over-voltage/Under-voltage] is recorded on a low voltage or high

voltage warning

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC007 information

EC008 [Accessory Fault] is recorded if the Accessory Relay output is on but

the load is disconnected

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC008 information

9 of 15

“400” Series Skid Steer

Electrical

EC009 [Fuel Solenoid Status] is recorded if the Fuel Solenoid output is on but

the load is disconnected

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC009 information

EC010 [Aux Override Status] is recorded if the Auxiliary Override output is

on but the load is disconnected

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC010 information

EC011 [Hydraulic Enable Fault] is recorded if the Hydraulic Enable output is

on but the load is disconnected

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC011 information

EC012 [Grid Heat Status] is recorded if the Engine Preheat output is on but

the load is disconnected

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC012 information

EC013 [Park Brake Status] is recorded if the Park Brake output is on but the

load is disconnected

o # # # # # number of occurrences

o # # # #.# engine hours of most recent occurrence

o CLEAR to erase all EC013 information

I. Press the POWER button to enter FAULT

II. If no faults have occurred, “NO EC” will be displayed

III. If a fault has occurred, the error code of the lowest number fault will be

displayed (The AUX OVERRIDE button can be pushed at this level to return to the top-

level menu items and move to “dIAG”

IV. Press the START button to select between different fault codes

V. Press the POWER button to select a fault, the number of occurrences will be

displayed

VI. Press the START button, the hour meter at which the most recent fault

occurred will be displayed

VII. Press the START button, “CLEAR” will be displayed to prompt the user to

erase this fault’s information

Press the POWER button to erase the fault information

Press the START button to display the number of occurrences again

Press the AUX OVERRIDE button to return to the list of fault codes

10 of 15

“400” Series Skid Steer

Electrical

DIAG

The diagnostic menu allows the user to evaluate the status and functionality of various

instrument panel displays and inputs and outputs from and to the machine electrical

system.

I. Press the POWER button to enter dIAG

II. “dIAGI” will be displayed, allowing user to select input diagnostics

III. Press the START button

IV. “dIAGO” will be displayed, allowing user to select output diagnostics

V. Press the START button again to return to dIAGI

VI. **From this level the AUX OVERRIDE button can be pushed to return to the

top-level menus

VII. Press the POWER button to enter dIAGI or dIAGO

INPUT DIAGNOSTICS

I. Press the POWER button to enter dIAGI

II. “dI IN” will be displayed, allowing user to select digital inputs

III. Press the START button

IV. “AN IN” will be displayed, allowing the user to select analog inputs

V. Press START again to return to dI IN

VI. **From this level the AUX OVERRIDE button can be pushed to return to

input/output selection menu

VII. Press the POWER button to enter dI IN or AN IN

Digital Inputs

I. Press the POWER button to enter dI IN

II. Press and hold the PARK button at any time to exit this menu level

III. The Main Power Relay will be turned on to provide power necessary to

measure some inputs

IV. Create a transition on any input to the instrument panel

a. The audible alarm will beep

b. The name of the triggered input will display in the text window to verify its

operation

V. Digital Input Features

a. IGNON

i. Will display when user selects digital inputs after Main Power Relay has been

turned on

ii. Verifies ignition input is functioning (Pins 23 and 24)

b. POWER – Verifies operation of the POWER button

c. START – Verifies operation of the START button

d. AUX – Verifies operation of the AUX OVERRIDE button

e. PARK – Verifies operation of the PARK button

11 of 15

“400” Series Skid Steer

Electrical

f. EOILP – Verifies the panel registers a high-to-low transition on the Engine Oil

Pressure ciruit input

g. CPRES – Verifies the panel registers a high-to-low transition on the Charge

Pressure ciruit input

h. AIRFL – Verifies the panel registers a high-to-low transition on the Air Intake

Filter or EGR Control Module fault circuit input

i. OILFL – Verifies the panel registers a high-to-low transition on the Hydraulic

Oil Filter circuit input

j. SEATb – Verifies the panel registers a low-to-high transition on the Lap Bar

switch circuit input

k. SEATS – Verifies the panel registers a low-to-high transition on the Seat

Switch circuit input

l. KEYST

i. Verifies the panel registers a low-to-high transition on the Key Start switch

circuit input

ii. A KEY SWITCH IS NOT OFFERED WITH THE DELUXE INSTRUMENT

PANEL OPTION

Analog Inputs

Press the POWER button to enter AN IN

Press and hold the PARK button at any time to exit this menu level

The Main Power Relay will be turned on to provide power necessary to measure

some inputs

“VbATT” is displayed

a. Displays the machine system voltage

b. “VbATT” displays alternately with the value of the system voltage

c. There is no decimal point, so, for example, 143 = 14.3 Volts

Press the START button

“HTEMP” is displayed

a. Displays Hydraulic Oil Temperature sender resistance

b. “HTEMP” displays alternately with the resistance value

c. This value does not require a decimel, so, for example, 500 = 500

Press the START button

“WTEMP” is displayed

a. Displays Engine Coolant Temperature sender resistance

b. “WTEMP” displays alternately with the resistance value

c. This value does not require a decimel, so, for example, 500 = 500

Press the START button

a. Displays Fuel Level gauge resistance

b. “FUEL” displays alternately with the resistance value

c. This value does not require a decimel, so, for example, 500 = 500

Press the START button to return to VbATT

12 of 15

“400” Series Skid Steer

Electrical

OUTPUT DIAGNOSTICS

I. Press the POWER button to enter dIAGO

II. Press and hold the PARK button at any time to exit this menu level

III. “LEd 0” is displayed

a. Press the POWER button

b. The Lap Bar indicator lamp will toggle on and off with the POWER button

c. Verifies operation of the Lap Bar indicator

IV. Press the START button

V. “LEd 1” is displayed

a. Press the POWER button

b. The Engine Oil Pressure indicator lamp will toggle on and off with the

POWER button

c. Verifies operation of the Lap Bar indicator

VI. Press the START button

VII. “LEd 2” is displayed

a. Press the POWER button

b. The Charge Pressure indicator lamp will toggle on and off with the POWER

button

c. Verifies operation of the Charge Pressure indicator

VIII. Press the START button

IX. “LEd 3” is displayed

a. Press the POWER button

b. The Engine Malfunction indicator lamp will toggle on and off with the

POWER button

c. Verifies operation of the Engine Malfunction indicator

X. Press the START button

XI. “LEd 4” is displayed

a. Press the POWER button

b. The Hydraulic Oil Filter indicator lamp will toggle on and off with the POWER

button

c. Verifies operation of the Hydraulic Oil Filter indicator

XII. Press the START button

XIII. “LEd 5” is displayed

a. Press the POWER button

b. The Engine Preheat indicator lamp will toggle on and off with the POWER

button

c. Verifies operation of the Engine Preheat indicator

XIV. Press the START button

XV. “LEd 6” is displayed

a. Press the POWER button

b. The Park Brake indicator lamp will toggle on and off with the POWER button

c. Verifies operation of the Park Brake indicator

XVI. Press the START button

13 of 15

“400” Series Skid Steer

Electrical

XVII. “PHEAT” is displayed

a. Press the POWER button

b. The Grid Heat Relay output will be turned on and off with the POWER button

to verify operation of instrument panel output circuit, machine harness, and relay.

XVIII. Press the START button

XIX. “bRAKE” is displayed

a. Press the POWER button

b. The Park Brake output will be turned on and off with the POWER button to

verify operation of instrument panel output circuit, machine harness, and valve solenoid.

XX. Press the START button

XXI. “FUEL” is displayed

a. Press the POWER button

b. The Fuel Solenoid output will be turned on and off with the POWER button to

verify operation of instrument panel output circuit, machine harness, and solenoid.

XXII. Press the START button

XXIII. “ACC O” is displayed

a. Press the POWER button

b. The Accessory Relay output will be turned on and off with the POWER button

to verify operation of instrument panel output circuit, machine harness, and relays.

XXIV. Press the START button

XXV. “AUXOV” is displayed

a. Press the POWER button

b. The Auxiliary Hydraulic Override output will be turned on and off with the

POWER button to verify operation of instrument panel output circuit, machine harness,

and solenoid.

XXVI. Press the START button

XXVII. “HYdEN” is displayed

a. Press the POWER button

b. The Hydraulic Enable output will be turned on and off with the POWER button

to verify operation of instrument panel output circuit, machine harness, and valve

solenoids.

XXVIII. Press the START button

XXIX. “LEd 7” is displayed

a. Press the POWER button

b. The AUX OVERRIDE button backlight will be toggled on and off with the

POWER button

XXX. Press the START button

XXXI. “LEd 8” is displayed

a. Press the POWER button

b. The PARK button backlight will be toggled on and off with the POWER button

XXXII. Press the START button

14 of 15

“400” Series Skid Steer

Electrical

XXXIII. “LEd 9” is displayed

a. Press the POWER button

b. The START button backlight will be toggled on and off with the POWER

button

XXXIV. Press the START button

XXXV. “LEd10” is displayed

a. Press the POWER button

b. The POWER button backlight will be toggled on and off with the POWER

button

XXXVI. Press the START button

XXXVII. “LEd11” is displayed

a. Press the POWER button

b. The AUX OVERRIDE indicator lamp will be toggled on and off with the

POWER button

XXXVIII. Press the START button

XXXIX. “bkLT0” is displayed

a. Press the POWER button

b. The text window backlight will be toggled on and off with the POWER button

XL. Press the START button

XLI. “bkLT1” is displayed

a. Press the POWER button

b. The hydraulic oil temperature backlight will be toggled on and off with the

POWER button

XLII. Press the START button

XLIII. “bkLT2” is displayed

a. Press the POWER button

b. The engine coolant temperature backlight will be toggled on and off with the

POWER button

XLIV. Press the START button

XLV. “bkLT3” is displayed

a. Press the POWER button

b. The fuel gauge backlight will be toggled on and off with the POWER button

XLVI. Press the START button

XLVII. “dTEST” is displayed

a. Press the POWER button

b. All LCD text segments and bar segments will be displayed to verify operation

15 of 15

“400” Series Skid Steer

S-ar putea să vă placă și

- CAT Antes de Usar TH460BDocument4 paginiCAT Antes de Usar TH460Bmiguel0% (1)

- Ems Tractionline Manual 4.0Document46 paginiEms Tractionline Manual 4.0John SanzanaÎncă nu există evaluări

- Plano Electrico 322D - JJG - DFPDocument2 paginiPlano Electrico 322D - JJG - DFPjonel mongeÎncă nu există evaluări

- Ajuste y Test Presiones Iniciales PDFDocument8 paginiAjuste y Test Presiones Iniciales PDFHugo Rivas ViedmanÎncă nu există evaluări

- Remove and Install High Pressure Fuel PumpDocument6 paginiRemove and Install High Pressure Fuel PumpWilfer GrainÎncă nu există evaluări

- Your Partner in Materials Handling.: CaterpillarDocument3 paginiYour Partner in Materials Handling.: Caterpillarjoao mariaÎncă nu există evaluări

- Reyco PDFDocument44 paginiReyco PDFJavier Yandun100% (1)

- Pruebas y Ajustes Trannmision 928gDocument23 paginiPruebas y Ajustes Trannmision 928gManuel RamosÎncă nu există evaluări

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document9 paginiInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Elie Abisaad100% (1)

- Transmision Retroexcavadora VilavilaDocument30 paginiTransmision Retroexcavadora VilavilaRZ Emi100% (1)

- Troubleshooting John Deere 510DDocument5 paginiTroubleshooting John Deere 510Denriquevazquez27Încă nu există evaluări

- 420D, 432D and 442D Hydraulic System Backhoe Loader: Fluid Power SymbolsDocument4 pagini420D, 432D and 442D Hydraulic System Backhoe Loader: Fluid Power Symbolsmilton murillo100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document9 paginiInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Denys Zhukov100% (1)

- Sist Elec. D6K PDFDocument16 paginiSist Elec. D6K PDFJose Luis Aguero PomachaguaÎncă nu există evaluări

- Steering Cylinder ( - 618133) - ST156245: Parts ListDocument3 paginiSteering Cylinder ( - 618133) - ST156245: Parts ListtallerÎncă nu există evaluări

- 3002 Slid Electr in Put Out PutDocument36 pagini3002 Slid Electr in Put Out Putyecner salvadorÎncă nu există evaluări

- Uenr0213uenr0213-01 Sis PDFDocument2 paginiUenr0213uenr0213-01 Sis PDFRaphael Ruiz Ramos100% (2)

- CASE 580N-Backhoe-Service-Manual-diagram-electricDocument1 paginăCASE 580N-Backhoe-Service-Manual-diagram-electricWuillians GuzmanÎncă nu există evaluări

- Service Instructions "P-1Nn" Single Pressure Compensator, Series F1U ControlDocument20 paginiService Instructions "P-1Nn" Single Pressure Compensator, Series F1U ControlCamilo BarreraÎncă nu există evaluări

- 005 Joystick 2Document8 pagini005 Joystick 2JonathanDavidDeLosSantosAdornoÎncă nu există evaluări

- Terex Genie RL4000 Operation Manual D2 PDFDocument68 paginiTerex Genie RL4000 Operation Manual D2 PDFjmbc_jbcÎncă nu există evaluări

- 416E Vs 416D Product Buletin (TEJB9168)Document36 pagini416E Vs 416D Product Buletin (TEJB9168)firman manaluÎncă nu există evaluări

- Power Riser NuevoDocument9 paginiPower Riser NuevoJaime ArreolaÎncă nu există evaluări

- Parts and Service Interval DD90HF M@SH PDFDocument2 paginiParts and Service Interval DD90HF M@SH PDFjrincon26Încă nu există evaluări

- MID 039 - CID 1847 - FMI 09: Pantalla AnteriorDocument6 paginiMID 039 - CID 1847 - FMI 09: Pantalla AnteriorWalterÎncă nu există evaluări

- 320 B Diagrama HidraulicoDocument11 pagini320 B Diagrama HidraulicoJimmyJavierTorresSalas100% (3)

- Bomba Vicker Triple 2520vqsv10s21a1155Document6 paginiBomba Vicker Triple 2520vqsv10s21a1155Angel DlsgÎncă nu există evaluări

- Caterpillar Cat 245 EXCAVATOR (Prefix 95V) Service Repair Manual (95V00001-00470)Document25 paginiCaterpillar Cat 245 EXCAVATOR (Prefix 95V) Service Repair Manual (95V00001-00470)rpoy9396615100% (1)

- Manual Motor Elantra 1993Document66 paginiManual Motor Elantra 1993oshdezÎncă nu există evaluări

- Oil Pressure Test SMCS 1304 081Document8 paginiOil Pressure Test SMCS 1304 081Danny M Hurtado TaypeÎncă nu există evaluări

- 310SK Backhoe Loader Engine 4045HT073 PIN 1T0310SK E219607 E277407 IntroductionDocument8 pagini310SK Backhoe Loader Engine 4045HT073 PIN 1T0310SK E219607 E277407 Introductionjose ignacio mora delgadoÎncă nu există evaluări

- Parts Manual TL126 PT5-101Z5-3Document183 paginiParts Manual TL126 PT5-101Z5-3АлексейÎncă nu există evaluări

- Motores Orbitais OMSDocument84 paginiMotores Orbitais OMSKarina RickenÎncă nu există evaluări

- Cb634c Elec SysDocument2 paginiCb634c Elec SysLuis Eduardo Corzo Enriquez100% (1)

- 4 Roadtec 600 Cummins QSXDocument24 pagini4 Roadtec 600 Cummins QSXdavidÎncă nu există evaluări

- D10T Track-Type Tractor Power Train System: Rjg1-UpDocument2 paginiD10T Track-Type Tractor Power Train System: Rjg1-UpJHOSMAR_22Încă nu există evaluări

- 432d Signal Resolver Network - CheckDocument6 pagini432d Signal Resolver Network - CheckDiego CatariÎncă nu există evaluări

- Partes JD 110 TLBDocument10 paginiPartes JD 110 TLBenriquevazquez27Încă nu există evaluări

- Beckett GeniSys 7505 ManualDocument12 paginiBeckett GeniSys 7505 ManualEdgardo GarridoÎncă nu există evaluări

- Extract of HEIL Old Manual Valve SectionsDocument10 paginiExtract of HEIL Old Manual Valve SectionsL.kolekar100% (1)

- Tractor de Cadenas D11T Plano HYD 2014 SISDocument14 paginiTractor de Cadenas D11T Plano HYD 2014 SISFabrizio JesúsÎncă nu există evaluări

- Transmission Assembly, Input Shaft, Two Wheel or Four Wheel DriveDocument4 paginiTransmission Assembly, Input Shaft, Two Wheel or Four Wheel DriveLUIS FERNANDO JOAQUINÎncă nu există evaluări

- Caterpillar Hammer Failure Analysis GuideDocument69 paginiCaterpillar Hammer Failure Analysis GuideVP ErickÎncă nu există evaluări

- Global Service Learning: PreliminaryDocument214 paginiGlobal Service Learning: PreliminaryOscar TelloÎncă nu există evaluări

- 416b Elec - TransDocument9 pagini416b Elec - TransFelix CruzÎncă nu există evaluări

- Bobcat Online Parts CatalogueDocument74 paginiBobcat Online Parts CatalogueHervé ChédruÎncă nu există evaluări

- Control Hidraulico de La Transmision D6NDocument7 paginiControl Hidraulico de La Transmision D6NDavid manjarresÎncă nu există evaluări

- Lower Tool Bushing: Tool Retaining Pins ToolDocument12 paginiLower Tool Bushing: Tool Retaining Pins Tooll_aguilar_mÎncă nu există evaluări

- D4EDocument11 paginiD4EMantenimiento U.C.O.100% (1)

- Kenway Txcr325Document24 paginiKenway Txcr325Mohamed RashedÎncă nu există evaluări

- TH360B Plano Electrico 1 PDFDocument15 paginiTH360B Plano Electrico 1 PDFCarlos Irabedra100% (1)

- 7 StepimpcosystemDocument2 pagini7 StepimpcosystemGuillermo Rueda Quevedo100% (2)

- Ge Remote Instruction Eg 24912Document31 paginiGe Remote Instruction Eg 24912Valentín MenaresÎncă nu există evaluări

- Samsung Option Code ACDocument4 paginiSamsung Option Code ACGhazwan Nabeel Al-Ehealy83% (6)

- Manual Remote Starter Compustar 2W901Document22 paginiManual Remote Starter Compustar 2W901cristianbachÎncă nu există evaluări

- User Manual of WINVIEW Controller (TK8070-SERIES)Document16 paginiUser Manual of WINVIEW Controller (TK8070-SERIES)Duong PhạmÎncă nu există evaluări

- Osiris Remote ManualDocument56 paginiOsiris Remote ManualRobert JohnsonÎncă nu există evaluări

- Nisse I Injection Moulding Machines OpDocument2 paginiNisse I Injection Moulding Machines Opweb312_twÎncă nu există evaluări

- Dacor Wall OvenDocument77 paginiDacor Wall OvenJim Harmke100% (2)

- Engine ImmobilizerDocument51 paginiEngine ImmobilizerYargen Gonzalez100% (4)

- Eaton Fuller RTX 14715Document43 paginiEaton Fuller RTX 14715Mauricio DuranÎncă nu există evaluări

- Pegasus Operator ManualDocument320 paginiPegasus Operator ManualMauricio Duran100% (1)

- O Pe Rating Instr U Ctio NDocument40 paginiO Pe Rating Instr U Ctio NMohan CharanchathÎncă nu există evaluări

- 8999 1838 00 Diagrams and Drawings PDFDocument144 pagini8999 1838 00 Diagrams and Drawings PDFMauricio DuranÎncă nu există evaluări

- Wilkinson Divider Even and Odd Mode AnalysisDocument14 paginiWilkinson Divider Even and Odd Mode AnalysistugasutomoÎncă nu există evaluări

- ADC Eco Dry ES-50 COIN SpecificationsDocument2 paginiADC Eco Dry ES-50 COIN Specificationsmairimsp2003Încă nu există evaluări

- Electrical Engineering Hand BookDocument22 paginiElectrical Engineering Hand Bookjicksonjohn100% (1)

- SY-1 Build Instructions: Erratas/preparationsDocument6 paginiSY-1 Build Instructions: Erratas/preparationsPepe CocaÎncă nu există evaluări

- Exp 1,2Document4 paginiExp 1,2NischayÎncă nu există evaluări

- Radar Systems - Delay Line CancellersDocument7 paginiRadar Systems - Delay Line Cancellersgajjala rakeshÎncă nu există evaluări

- Application of ABCDDocument15 paginiApplication of ABCDSantanu Nath50% (4)

- Matoshri College of Engineering and Research Center Nasik Department of Computer EngineeringDocument18 paginiMatoshri College of Engineering and Research Center Nasik Department of Computer EngineeringAditya DarekarÎncă nu există evaluări

- Isa RP16.4 1960Document10 paginiIsa RP16.4 1960OliverghÎncă nu există evaluări

- Most Often Needed: Radio DiagramsDocument191 paginiMost Often Needed: Radio DiagramsbrenodesenneÎncă nu există evaluări

- AIPHONE GH-1AD SpecDocument3 paginiAIPHONE GH-1AD SpecFeby ChristinaÎncă nu există evaluări

- Sabouni AdaptivecoverageforfutureltenetworksDocument158 paginiSabouni AdaptivecoverageforfutureltenetworksWided AhmadiÎncă nu există evaluări

- Pdfslide - Tips Astm-D7240Document4 paginiPdfslide - Tips Astm-D7240YosiichiHuapayaTamuraÎncă nu există evaluări

- Nibe GV HR110 Pliant 30 09 2013 enDocument4 paginiNibe GV HR110 Pliant 30 09 2013 envaliÎncă nu există evaluări

- K02ELBD005016P0Document16 paginiK02ELBD005016P0KhalidÎncă nu există evaluări

- GSTP011Document134 paginiGSTP011José Luis Morán HernándezÎncă nu există evaluări

- 10 Types of Electrical Tool1Document5 pagini10 Types of Electrical Tool1Noreen Dela cruzÎncă nu există evaluări

- How Do Wind Power Plants Work?: How Are Wind Turbines Connected To The Electricity Network ?Document3 paginiHow Do Wind Power Plants Work?: How Are Wind Turbines Connected To The Electricity Network ?Sección Uso CasinoÎncă nu există evaluări

- CEQ - Corrosion Studies KitDocument3 paginiCEQ - Corrosion Studies KitPong VongÎncă nu există evaluări

- LT ABC Line Isolation: (KE/TPRE/SOP/605)Document15 paginiLT ABC Line Isolation: (KE/TPRE/SOP/605)Shaharyar WaliullahÎncă nu există evaluări

- Distribution BoardsDocument5 paginiDistribution BoardssallammohamedÎncă nu există evaluări

- SCH MainDocument2 paginiSCH MainDjrichardMixÎncă nu există evaluări

- Hewlett-Packard - AN150-10 - Spectrum Analysis - Field Strenght MeasurementDocument2 paginiHewlett-Packard - AN150-10 - Spectrum Analysis - Field Strenght Measurementgbr123Încă nu există evaluări

- Wiring Headlight RelaysDocument20 paginiWiring Headlight RelaysFloris van EnterÎncă nu există evaluări

- 5parameter ListDocument86 pagini5parameter ListIsradani MjÎncă nu există evaluări

- Gea S1004 PDFDocument8 paginiGea S1004 PDFmeirangongÎncă nu există evaluări

- Genadvisor Partial Discharge Monitoring: Generator ServiceDocument2 paginiGenadvisor Partial Discharge Monitoring: Generator ServiceStefanos DiamantisÎncă nu există evaluări

- One-Line Diagram - OLV1 (Short-Circuit Analysis)Document20 paginiOne-Line Diagram - OLV1 (Short-Circuit Analysis)Yogesh MittalÎncă nu există evaluări

- Certificado EficienciaDocument7 paginiCertificado EficienciaRoy Muy GolfoÎncă nu există evaluări

- Westinghouse Lighting Rampliter III HID Airport Floodlight System Spec Sheet 8-72Document2 paginiWestinghouse Lighting Rampliter III HID Airport Floodlight System Spec Sheet 8-72Alan MastersÎncă nu există evaluări