Documente Academic

Documente Profesional

Documente Cultură

Scaffolding, Bolting Work & Working at Height at Security Building Area For Vehicle Parking Shed

Încărcat de

krishnakumar0 evaluări0% au considerat acest document util (0 voturi)

98 vizualizări3 paginiTitlu original

Scaffolding%2c Bolting work & working at height at Security Building area for vehicle parking shed

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

98 vizualizări3 paginiScaffolding, Bolting Work & Working at Height at Security Building Area For Vehicle Parking Shed

Încărcat de

krishnakumarDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

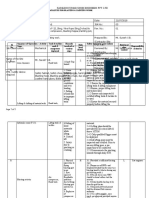

JOB SAFETY PLAN (JSP)

COMPANY: MAJEES TECHNICAL SERVICES LLC.

DATE: 26/12/2019

ACTIVITY: Working at height, Scaffolding TASK DESCRIPTION: Scaffolding, Bolting work & working at height at

Work at Security Building Area. Security Building area for vehicle parking shed.

WORK LOCATION: Daleel Security Building

- Vehicle parking shed area.

TASK HAZARD CONTROL ACTION *( )

PARTY

Mobilization of H2S and LEL a) H2S and LEL Gas detection within 15m

personnel & Personnel being perimeter from the live area if required.

Transporting Run over or struck b) Trailer driver have valid License

by moving vehicles c) Trailer banks man need to stay always with

equipment. Permit

Lack of site HSSE inside plant area operation

knowledge d) All personnel will receive the MTS - HSE holder

Accident Induction

vehicle movement e) Ensure all material/tools/ equipment /

plant is visually inspected before use to

ensure all safe guards are working

f) All personnel working in close proximity to

moving vehicles shall wear high visibility

vests

g) Correct PPE to be worn at all times

h) Un-authorized entry of personnel to

worksite must be restricted. Barriers and

safety signs to be used.

i) Thorough visual inspection of the area and

ground conditions to be carried out before

work starts

j) No personnel to stand behind reversing

k) Authorized Drivers drive the vehicle for

shifting and other materials.

General Working without Adequate Work Permit should be available

work permit. prior to the commencement of the job and shall

In-experienced be displayed at work place.

Improper planning

& communication Conduct Tool Box talks, JSP & Adequate PPE’s. Permit

Short cutting of Strict supervision has to be ensured. holder

activities

Proper planning to be done, Usage of home

Over confident

tools to be avoided.

Absent minded

Extreme high Use barrier cream from sunlight and use

Temperature & coverall (full suit).

humidity

Working without The supervisor to communicate with all parties

PPE, Toolbox talk.

Improper planning Ensure welfare facilities

of work and tools.

Fire hazard.

Majees Technical Services LLC.

Bolting work & Unbalance Ensure the PTW system in place

working at Fall of men & Continues Gas test by permit holder

height. material Ensure the bolts remove and placed one by

Striking one.

Permit

Striking ,Slip & Carefully or qualified person will be

trip engaged in activity. holder

Trapping of limbs Effective supervision and TBT

Crushing of body Isolate existing services and flow lines.

parts Ground conditions will be reviewed before

Environmental commencing activity.

impact Proper PPEs including safety harness to be

Spillage used and housekeeping should be done.

Personal injuries Bolt to be cleaned of any oils, slush,

Dehydration lubricants etc. that may cause a slip.

Noise Use of non-spark tools

Use of WD40 Soles of the Safety shoes need to be cleaned.

Required hot bolting will be carefully

handling & fixed up properly as per plan.

Use only color coded tools and tackles

which are in good condition.

During fixing of tools & tackles ensure

proper access, PPEs.

No loads will be pulled or dragged.

From work area & fire fighting equipment

to be provided like fire extinguisher, sand

bucket.

Scaffolding Personnel fall Tool box meeting being conducted before

erection & from height execution of the scaffold erection. Hazard

dismantling Personnel injured associated & precautionary measures will

by falling material be explained to the working crew.

Collapse of Only certified scaffolders erect the scaffold

Scaffold under the supervision of scaffolding Permit

Slip & trip inspector. Holder

Heat exhaustion Full body safety harness with double

lanyard being used by scaffolders.

Presence of Scaffolds are red tagged "Do not use" while

hydrocarbon in being erected.

the sterile area Work place barricaded & caution boards

Hydrocarbon will be displayed to avoid unauthorized

presence man entry.

Wearing hard hat is mandatory in work

site.

Slip & trip

Heat exhaustion

Before erection, ground level checked for

imposed load.

Material stacking on platform prohibited

Ladder sufficiently supported and tied

Access & egress will be kept clean

Not to work when temperature is high.

No entry inside the barricaded area.

Effective supervision and effective TBT

Majees Technical Services LLC.

Lifting activities to be taken care with

proper supervision

Gas testing

Shift rotation works

Follow PTW and follow signage

Use of Hand Breaking of Make regular inspection of hand tools Permit

Tools hacksaw blades / before use job. Holder

chisels etc.., TBT about safe hand tools use &

highlighting of hand tools hazards.

Use of incorrect

Must be use PPE’s

(wrong) tools.

Use the right type of hand tools for the right

Broken handles of jobs.

tools. Ensure proper inspection & conduct

Skilled person , using proper technique

Manual Shifting LTI/RWC/Property Ensure proper hauling of materials, get Permit

loss help if required. holder

Wear cotton gloves. Use the legs when

lifting object not the back muscles, keep

back straight “Don’t Twist”.

Never try to lift more than you can handle

safely. If you are in doubt, consult your

supervisor.

Ensure that workers are complying with

the minimum PPE’s requirement.

Trip Slip , a) Ensure adequacy of resources required and Permit

Manual Handling plan the work area properly to avoid holder

Wind up and accumulation of materials, spills, wastages,

House Keeping etc., that harm personnel at site.

b) Establish clearly maintained walkways and

for movement of vehicles / equipment,

wherever Access clear from unwanted

materials.

Work supervisor on site is to confirm (√) that all controls are in place prior to start the job

Permit Applicant: Signature: Date:

Responsible Supervisor: Signature: Date:

Permit Holder: Signature: Date:

Area authority: Signature: Date:

Majees Technical Services LLC.

S-ar putea să vă placă și

- Jha - For Manhole ConstructionDocument2 paginiJha - For Manhole ConstructionChinedu AchilikeÎncă nu există evaluări

- JSa For Operation of Jack HammeringDocument3 paginiJSa For Operation of Jack Hammeringyc safety0% (1)

- JSA For Concrete PouringDocument8 paginiJSA For Concrete Pouringfayaz fayazhotmail.com100% (1)

- Safety Data Sheet Acc. To OSHA HCSDocument11 paginiSafety Data Sheet Acc. To OSHA HCSTim BrownÎncă nu există evaluări

- Example JSA Job Safety AnalysisDocument13 paginiExample JSA Job Safety AnalysisSiti MaisarahÎncă nu există evaluări

- Jsa For Tie in of Fuel Gas LineDocument3 paginiJsa For Tie in of Fuel Gas LineMohammed Minhaj100% (1)

- Exavation Works PipercksDocument4 paginiExavation Works PipercksHRTYR100% (1)

- Workplace Hazards in ConstructionDocument2 paginiWorkplace Hazards in ConstructionDWi Uwee DejHeÎncă nu există evaluări

- JSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Document7 paginiJSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Marvin BerrensteinÎncă nu există evaluări

- Job Safety Analysis: Work Sequence Potential Hazards Recommended Action / Control MeasuresDocument3 paginiJob Safety Analysis: Work Sequence Potential Hazards Recommended Action / Control Measuresmuhammad imtiaz100% (1)

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 paginăJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaÎncă nu există evaluări

- Confined Space Hazard Evaluation Survey FormDocument2 paginiConfined Space Hazard Evaluation Survey FormEdward100% (1)

- Suroj Buildcon Pvt. LTD.: Job Safety AnalysisDocument6 paginiSuroj Buildcon Pvt. LTD.: Job Safety AnalysisKiran ChenchalaÎncă nu există evaluări

- Gas Cutting JsaDocument4 paginiGas Cutting JsaMohammed Minhaj100% (1)

- Motor Vehicle Mechanical Repair Workshop: Example Risk Assessment For ADocument5 paginiMotor Vehicle Mechanical Repair Workshop: Example Risk Assessment For AKimmy Lyons100% (1)

- Hse JsaDocument22 paginiHse JsaAnonymous y1pIqcÎncă nu există evaluări

- All ChecklistsDocument0 paginiAll Checklistsmalika_00Încă nu există evaluări

- JSA For Hydrotesting PDFDocument6 paginiJSA For Hydrotesting PDFMohammed Minhaj100% (1)

- Job Safety Analysis: JSA Reference #: DateDocument3 paginiJob Safety Analysis: JSA Reference #: DateLi QiÎncă nu există evaluări

- JSA For Manual Excavation Inside The Operation Area (Access Road)Document6 paginiJSA For Manual Excavation Inside The Operation Area (Access Road)Mohammed MinhajÎncă nu există evaluări

- JSA Formet New Structural Steel FabricationDocument7 paginiJSA Formet New Structural Steel Fabricationsakthi venkatÎncă nu există evaluări

- Step No. Sequence of Activities Hazard Who or What May Be Harmed? Control Measures / Recovery Measures Action / Responsible PartyDocument7 paginiStep No. Sequence of Activities Hazard Who or What May Be Harmed? Control Measures / Recovery Measures Action / Responsible PartyameeraliÎncă nu există evaluări

- SAFETY PLAN For Pilling Work at Making AreaDocument8 paginiSAFETY PLAN For Pilling Work at Making AreaBalogun Isaac100% (1)

- Hse FormDocument2 paginiHse FormPhilip Tcs100% (1)

- JSA For Coating and Raping Activity in TankDocument7 paginiJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatÎncă nu există evaluări

- Jsa Road BlockingDocument3 paginiJsa Road BlockingRam Krishna100% (1)

- 16.18 TBT - Gas Welding and CuttingDocument2 pagini16.18 TBT - Gas Welding and Cuttinggrant100% (1)

- 3054E and 3056E Industrial Engines-Engine SafetyDocument12 pagini3054E and 3056E Industrial Engines-Engine SafetySantiago Capiato33% (3)

- Confined Spaces ProcedureDocument10 paginiConfined Spaces Procedurezam110Încă nu există evaluări

- Pamphlet 88 - Edition 3 - March 2010Document44 paginiPamphlet 88 - Edition 3 - March 2010Jacques BlueqÎncă nu există evaluări

- Glossary of HSE Terms. IAGC & OGPDocument20 paginiGlossary of HSE Terms. IAGC & OGPxaviergomezmaza100% (1)

- Akk Jha Installation of Diesel TankDocument3 paginiAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Fall Protection and Ladder SafetyDocument56 paginiFall Protection and Ladder SafetyKAii Magno GuiaÎncă nu există evaluări

- JSA Formet New Blasting & PaintingDocument5 paginiJSA Formet New Blasting & Paintingsakthi venkatÎncă nu există evaluări

- Job Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdDocument3 paginiJob Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdTeodoro EsquilloÎncă nu există evaluări

- HSE-Method Statement ScaffoldingDocument32 paginiHSE-Method Statement ScaffoldingihsanÎncă nu există evaluări

- JSA Forklift PDFDocument2 paginiJSA Forklift PDFfauziÎncă nu există evaluări

- JSA For Erection Modification QSTECDocument7 paginiJSA For Erection Modification QSTECMohamed NouzerÎncă nu există evaluări

- Jsa For The Installation of I EamDocument5 paginiJsa For The Installation of I EamMohammed MinhajÎncă nu există evaluări

- HSE ALERT NO. 5-Safe Working at HeightDocument1 paginăHSE ALERT NO. 5-Safe Working at HeightClark Angelo JuanÎncă nu există evaluări

- JSA For Fab Erec of STRL Steel StackDocument5 paginiJSA For Fab Erec of STRL Steel StackkrishnakumarÎncă nu există evaluări

- Job Hazard AnalysisDocument35 paginiJob Hazard AnalysisMichael NullasÎncă nu există evaluări

- Working at Height - Hazard and ControlDocument31 paginiWorking at Height - Hazard and ControlDexter Daniel80% (5)

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 paginiTower Crane Dismantling JSA HSE ProfessionalsnabeelÎncă nu există evaluări

- How Chin Engineering: Job Safety AnalysisDocument5 paginiHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdÎncă nu există evaluări

- Electric Powered Bottom Sludge Scraper: User GuideDocument53 paginiElectric Powered Bottom Sludge Scraper: User GuideDelshad DuhokiÎncă nu există evaluări

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument11 paginiThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh kumar yadav100% (1)

- Nalco All MSDSDocument211 paginiNalco All MSDSSaravanan Swaminathan100% (6)

- Dry Bulk Product Safety SOPDocument14 paginiDry Bulk Product Safety SOPWan Sek ChoonÎncă nu există evaluări

- SBS Waterproofing ITP & ChecklistDocument27 paginiSBS Waterproofing ITP & Checklistlike saddamÎncă nu există evaluări

- Draft Proposal Wellness and Beauty SOPDocument15 paginiDraft Proposal Wellness and Beauty SOPMargueritteÎncă nu există evaluări

- JSA-Confined Space Activity - 05Document4 paginiJSA-Confined Space Activity - 05babjihanumanthuÎncă nu există evaluări

- 1st Periodic Test in CAREGIVINGDocument4 pagini1st Periodic Test in CAREGIVINGMelanie PradoÎncă nu există evaluări

- JSP - Manual & Mechanical ExcavationDocument6 paginiJSP - Manual & Mechanical ExcavationkrishnakumarÎncă nu există evaluări

- Hira - Excavation, PCC, RCCDocument6 paginiHira - Excavation, PCC, RCCPrithika AnbuÎncă nu există evaluări

- Confined Spaces Toolbox TalkDocument3 paginiConfined Spaces Toolbox TalkWaSim AKramÎncă nu există evaluări

- Step Activity Potential Hazards Hazard Controls NoDocument2 paginiStep Activity Potential Hazards Hazard Controls NoKazeneza BMÎncă nu există evaluări

- Excavation Safety Dos and DontsDocument4 paginiExcavation Safety Dos and DontsVidya SagarÎncă nu există evaluări

- 2.JOB SAFETY ANALYSIS Preparation of Temporary Yard Facility Project Title Installation of Wet Sprinkler System at Main WarehouseDocument4 pagini2.JOB SAFETY ANALYSIS Preparation of Temporary Yard Facility Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar GondalÎncă nu există evaluări

- Safety-Overhead CraneDocument2 paginiSafety-Overhead CraneaisyahÎncă nu există evaluări

- Method Statement For Worker WelfereDocument4 paginiMethod Statement For Worker WelfereMohamad Hidayat Zainul MasriÎncă nu există evaluări

- Hydration: The Importance of Water: Safety MomentDocument1 paginăHydration: The Importance of Water: Safety MomentSheri Diĺl100% (1)

- Construction Job Hazards Analysis: This Is A TEMPLATEDocument1 paginăConstruction Job Hazards Analysis: This Is A TEMPLATETamÎncă nu există evaluări

- Jha Confined SpaceDocument6 paginiJha Confined SpaceArun ArunbolluÎncă nu există evaluări

- Hand and Power ToolsDocument57 paginiHand and Power ToolsMarvin TriaÎncă nu există evaluări

- PPE AwarenessDocument23 paginiPPE AwarenessAjit BhosaleÎncă nu există evaluări

- Jsa For PCCDocument6 paginiJsa For PCCCICON EngineersÎncă nu există evaluări

- Job Safety Analysis Work SheetDocument16 paginiJob Safety Analysis Work Sheetjiks_i4uÎncă nu există evaluări

- Updated New IGC3 - SampleDocument9 paginiUpdated New IGC3 - SampleHossamKandil100% (1)

- Jsa Ducting Rev 00Document1 paginăJsa Ducting Rev 00SRR HSE Department, Sandvik Project,Încă nu există evaluări

- Octopus Jsa For Fusion WeldingDocument2 paginiOctopus Jsa For Fusion WeldingOgunwa EmmanuelÎncă nu există evaluări

- Elcb MCB RCCB Inspection Register 28-04-2016Document1 paginăElcb MCB RCCB Inspection Register 28-04-2016krishnakumarÎncă nu există evaluări

- JSP PCC ActivityDocument5 paginiJSP PCC ActivitykrishnakumarÎncă nu există evaluări

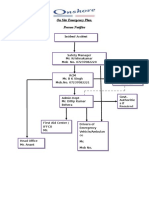

- On Site Emergency Plan. Person Notifies: Incident/ AccidentDocument1 paginăOn Site Emergency Plan. Person Notifies: Incident/ AccidentkrishnakumarÎncă nu există evaluări

- TU2004V ManualDocument80 paginiTU2004V Manualga6ba5Încă nu există evaluări

- White Distilled Vinegar MSDSDocument4 paginiWhite Distilled Vinegar MSDSJivendra KumarÎncă nu există evaluări

- COVID-19 Antigen Rapid Test KitDocument4 paginiCOVID-19 Antigen Rapid Test KitWai Lin PhyoÎncă nu există evaluări

- Fire Extinguisher Abc Multipurpose Dry Chemical Material Safety Data SheetDocument6 paginiFire Extinguisher Abc Multipurpose Dry Chemical Material Safety Data SheetspurscoukÎncă nu există evaluări

- Affluent HR Practices Followed and Implemented by Berger Paints Bangladesh LimitedDocument100 paginiAffluent HR Practices Followed and Implemented by Berger Paints Bangladesh LimitedSalman HaiderÎncă nu există evaluări

- The Noise Exposure of Working DiversDocument5 paginiThe Noise Exposure of Working DiversJDÎncă nu există evaluări

- Material Safety Data Sheet (Hydrazine)Document1 paginăMaterial Safety Data Sheet (Hydrazine)Talha JamilÎncă nu există evaluări

- Waterline Tie-In With Existing Service AHADocument2 paginiWaterline Tie-In With Existing Service AHALawrence adeleke OmisakinÎncă nu există evaluări

- Tra Offloading AndriggingDocument11 paginiTra Offloading AndriggingAjaz AhmedÎncă nu există evaluări

- Greases Multifakep2 PDFDocument8 paginiGreases Multifakep2 PDFCarlos Gabriel Quintero RodríguezÎncă nu există evaluări

- MSDS PetrolDocument6 paginiMSDS PetrolridgellÎncă nu există evaluări

- Az.342750 Manitowoc 999 250 T Farina Man Riding Safety ProceduresDocument17 paginiAz.342750 Manitowoc 999 250 T Farina Man Riding Safety Proceduresdan antonÎncă nu există evaluări

- COSHH Red Oxide PaintDocument2 paginiCOSHH Red Oxide PaintIonian TribeÎncă nu există evaluări

- Object:-Job Safety Analysis For PDB InstallationDocument1 paginăObject:-Job Safety Analysis For PDB Installationpushpanath reddyÎncă nu există evaluări

- Rescocast 17 MSDSDocument3 paginiRescocast 17 MSDSgroovercm15Încă nu există evaluări

- Oxivir Plus SDS SheetsDocument5 paginiOxivir Plus SDS SheetsSteven LeeÎncă nu există evaluări

- S&M 1Document8 paginiS&M 1Mohamed AlaaÎncă nu există evaluări

- Security Vs Corona (Duties)Document17 paginiSecurity Vs Corona (Duties)DIAL 4 GUARD Ajay Singh BhadoriaÎncă nu există evaluări

- Fairviewsafetysolutions - Dorinpetrenichi - Working at Height - 3665 - FeedbackDocument13 paginiFairviewsafetysolutions - Dorinpetrenichi - Working at Height - 3665 - FeedbackDorin PatrenichiÎncă nu există evaluări

- WD-40 3-In-One Drip Oil MSDSDocument5 paginiWD-40 3-In-One Drip Oil MSDSHai HaÎncă nu există evaluări