Documente Academic

Documente Profesional

Documente Cultură

MS - Hydraulic Jack-In Pile (Cylonix) - 240

Încărcat de

aniesbaek100%(1)100% au considerat acest document util (1 vot)

99 vizualizări2 paginiTitlu original

MS - Hydraulic Jack-in Pile (Cylonix)-240

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

99 vizualizări2 paginiMS - Hydraulic Jack-In Pile (Cylonix) - 240

Încărcat de

aniesbaekDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

CYLONIX GEOTECHNICS SDN. BHD.

Method Statement for Installation of Hydraulic Injection Pile

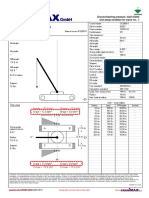

Machine Hydraulic Jacking Piling Machine YZY-240

Counterweights Steel / Concrete Counterweights – 40 ton

Machine Weight 140 ton

Total weight 140 + 40 = 180 ton

Machine Crew Foreman - 1 pax

Operator - 1 pax

Rig Assistant / Welder - 1 -2 pax

Crane Operator - 1 pax

______________________________________________________________________________

Method Statement of Installation

1. All movement of the rig to be only under the exclusive direction of the Rig foreman.

2. The foreman will move the rig over the survey point for the pile to be jack in.

3. The crane crew will sling and pitch the pile into to the machine, lowering into the grips.

4. The machine will grip the pile and lower the pile to ground level.

5. The machine operator will plumb the pile.

6. The foreman will ensure the rig is moved and adjusted over the survey point.

7. The pile is jacked an initial 2m.

8. The pile is checked for plumb with a 1m spirit level.

9. The pile is jacked to the required pressure as per the setting pressure conversion table for

the desired jacking force.

No RC Pile Size Working Jack In Force Setting Pressure Cylinders

(mm) Load (ton) (ton) (Mpa)

1 275 x 275 75 165 14.0 2 x 280mm cylinder

(2.2times WL) (172 ton)

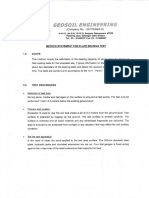

Pile setting criteria

The set pressure is held for 30seconds and the settlement after holding period shall not

exceeding 5mm in 2 consecutive cycles (1st & 2nd cycle).

The difference in settlement between 1st & 2nd cycle shall be less than 3mm.

The measurement of settlement will be manually recorded using graph paper and pencil

with a support (as shown in the following example).

CYLONIX GEOTECHNICS SDN. BHD.

Example of pile set measurement

Line draw at setting pressure

(after holding period) Settlement

Line draw at setting pressure

(before holding period)

Line draw at 0 pressure

(after unloading)

Line draw at 0 pressure

(before loading)

Pile Cut Off

If pile still exists above ground level, cut the pile off with air compressor breaker.

10. If jacking force is not achieved then a splice is required. Another pile segment is lowered

into the machine.

11. The pile is jack into until the splice is approximately 0.5m above ground level. The

alignment of the splice plate is checked.

12. The pile jacking sequence is stopped.

13. The splice is welded to be coated with anti-corrosion paints. (red oxide paints)

14. The pile jacking sequence is restarted, go to 8

15. The site clerk is to complete the Piling Record Sheet progressively from step 1.

S-ar putea să vă placă și

- Crusher Run - Type 1Document1 paginăCrusher Run - Type 1Rizlan AmirÎncă nu există evaluări

- 03-Ir Chow-Design and Execution of Jack-In Piles in Malaysia (31st August 2015)Document112 pagini03-Ir Chow-Design and Execution of Jack-In Piles in Malaysia (31st August 2015)freezefreezeÎncă nu există evaluări

- LI JKR Pasir MasDocument29 paginiLI JKR Pasir MasMiro BdkQlateÎncă nu există evaluări

- Push Pull Props RS PDFDocument24 paginiPush Pull Props RS PDFTerry CheungÎncă nu există evaluări

- Pu 300Document2 paginiPu 300marklester100% (1)

- Structure Inspection Manual Part 5 - NDT and PDT Testing Chapter 16 - Magnetic ParticleDocument6 paginiStructure Inspection Manual Part 5 - NDT and PDT Testing Chapter 16 - Magnetic ParticleSafeeruddin KhanÎncă nu există evaluări

- 4) JackinMethod Installation PDFDocument7 pagini4) JackinMethod Installation PDFOng George SammyÎncă nu există evaluări

- HIGHT - The Nicoll Highway CollapseDocument140 paginiHIGHT - The Nicoll Highway CollapseSeniorista Gunawan100% (1)

- Crawler CraneDocument11 paginiCrawler CraneidonotspammeÎncă nu există evaluări

- Velox Slab FormworkDocument15 paginiVelox Slab FormworkahmadsawalmahÎncă nu există evaluări

- Example Method Statement Jack in-PPCDocument4 paginiExample Method Statement Jack in-PPCLatifi AmirÎncă nu există evaluări

- How Do I Import A Geometry in PLAXIS 3D?Document1 paginăHow Do I Import A Geometry in PLAXIS 3D?NISHANT ROYÎncă nu există evaluări

- The Influence of Plugging On DriveabilityDocument12 paginiThe Influence of Plugging On DriveabilityDedy DharmawansyahÎncă nu există evaluări

- Rapid Load Testing of Foundation Piles in Barcelona:: IssueDocument5 paginiRapid Load Testing of Foundation Piles in Barcelona:: IssuebozarromegustaÎncă nu există evaluări

- Esq 540 - Piling Operation-AssignmentDocument11 paginiEsq 540 - Piling Operation-AssignmentMoffat KangombeÎncă nu există evaluări

- Lifting Systems Design CriteriaDocument8 paginiLifting Systems Design CriteriatfvnjyÎncă nu există evaluări

- Laterally Loaded Pile With Plaxis 3dDocument5 paginiLaterally Loaded Pile With Plaxis 3dteomalancuÎncă nu există evaluări

- Foundation Design For Vibrating MachinesDocument2 paginiFoundation Design For Vibrating MachinesEuÎncă nu există evaluări

- Retaining Structures and Special Foundations at The Platinum Tower, in MaputoDocument6 paginiRetaining Structures and Special Foundations at The Platinum Tower, in MaputoRuiFPTÎncă nu există evaluări

- Broms 1995-The Republic Plaza in Singapore-Foundation DesignDocument22 paginiBroms 1995-The Republic Plaza in Singapore-Foundation Designjcpchin2Încă nu există evaluări

- Bridge Bearing2Document10 paginiBridge Bearing2sandbad2Încă nu există evaluări

- Ground Improvement Technique - A View of Stone Column Method With The Case StudyDocument6 paginiGround Improvement Technique - A View of Stone Column Method With The Case StudymooolkaÎncă nu există evaluări

- Numerical Modelling of Deep Mixed Columns PDFDocument27 paginiNumerical Modelling of Deep Mixed Columns PDFvickneshj9406Încă nu există evaluări

- Behavior of Sbr-Latex Modified Polypropylene Fibre Einforced Railway SleepersDocument7 paginiBehavior of Sbr-Latex Modified Polypropylene Fibre Einforced Railway SleepersHasnain BukhariÎncă nu există evaluări

- CIVL6077 Ground Investigation and Soil Testing Lecture 4 In-Situ TestsDocument126 paginiCIVL6077 Ground Investigation and Soil Testing Lecture 4 In-Situ TestsHamza NadeemÎncă nu există evaluări

- Concrete PumpsDocument18 paginiConcrete Pumpswajid khanÎncă nu există evaluări

- YJACK Indonesia, Type C - June 2019Document61 paginiYJACK Indonesia, Type C - June 2019rizki afynÎncă nu există evaluări

- Design of PileDocument12 paginiDesign of PileAniket DÎncă nu există evaluări

- G&P Digest Issue 6Document8 paginiG&P Digest Issue 6Chua Chim HueeÎncă nu există evaluări

- Validation Bearing Capacity of Circular Footing 2016Document4 paginiValidation Bearing Capacity of Circular Footing 2016Jose Leo MissionÎncă nu există evaluări

- Wk9 Bearing Capacity From Field TestsDocument35 paginiWk9 Bearing Capacity From Field TestsAli Saeed100% (2)

- 17 Priebe 1998 Vibro Replacement To Prevent LiquefactionDocument4 pagini17 Priebe 1998 Vibro Replacement To Prevent LiquefactionGerman RodriguezÎncă nu există evaluări

- Annexure A Nimli Hydrological SurveyDocument23 paginiAnnexure A Nimli Hydrological SurveyUmesh MishraÎncă nu există evaluări

- PC PilesDocument12 paginiPC PilesBobby SetiawanÎncă nu există evaluări

- Jack in PileDocument56 paginiJack in PileArif Azizan0% (1)

- Pile Driving EquipmentsDocument23 paginiPile Driving EquipmentsAbhishek BhushanÎncă nu există evaluări

- Design of Prestressed Concrete Pile PDFDocument14 paginiDesign of Prestressed Concrete Pile PDFvindyavÎncă nu există evaluări

- Lateral Pile Load Test Oats JSPL Angul 20.10Document2 paginiLateral Pile Load Test Oats JSPL Angul 20.10DEEPAK KUMAR MALLICKÎncă nu există evaluări

- Compaction GroutingDocument10 paginiCompaction GroutingRainndrop FonnyryÎncă nu există evaluări

- SI & Load Tests - Req BCADocument3 paginiSI & Load Tests - Req BCAAzaleaLeeÎncă nu există evaluări

- Arindam Dey, RSS, Qip-Stc Gepd 2014Document147 paginiArindam Dey, RSS, Qip-Stc Gepd 2014AnÎncă nu există evaluări

- 010 019 InnovationDocument6 pagini010 019 InnovationG-SamÎncă nu există evaluări

- During Tremie Concreting The Following Precautions Are To Be Taken While Doing The WorkDocument2 paginiDuring Tremie Concreting The Following Precautions Are To Be Taken While Doing The WorkRaghavendraÎncă nu există evaluări

- A Comparison of Dynamic and Static Load Tests On Reinforced Concrete Driven Pile-2004 - 02Document7 paginiA Comparison of Dynamic and Static Load Tests On Reinforced Concrete Driven Pile-2004 - 02Hoo Yen HowÎncă nu există evaluări

- Subway Jakarta Mitsui-MorotakaDocument18 paginiSubway Jakarta Mitsui-MorotakaDionysius SiringoringoÎncă nu există evaluări

- Tunnelling in Bukit Timah Granite Formation - Challenges in Tunnelling From Newton To Stevens StationDocument14 paginiTunnelling in Bukit Timah Granite Formation - Challenges in Tunnelling From Newton To Stevens StationfreezefreezeÎncă nu există evaluări

- Well Foundation - RVNLDocument9 paginiWell Foundation - RVNLVenkateswarlu DanduÎncă nu există evaluări

- Types of Cast in Place PilesDocument11 paginiTypes of Cast in Place PilesWaqas SadiqÎncă nu există evaluări

- Standard Penetration TestDocument21 paginiStandard Penetration TestVenkatesh ThumatiÎncă nu există evaluări

- Application of Braced and Unbraced Frame in Reinforced Concrete StructureDocument2 paginiApplication of Braced and Unbraced Frame in Reinforced Concrete StructureNazmi DhiyauddinÎncă nu există evaluări

- Combextra GP ExtraDocument4 paginiCombextra GP ExtrailhamÎncă nu există evaluări

- SBC, BH-01Document15 paginiSBC, BH-01Kundan SinghÎncă nu există evaluări

- Design and Calculation Process of Friction PilesDocument63 paginiDesign and Calculation Process of Friction PilesDoughnut Chilli PiÎncă nu există evaluări

- Engg. Maths by Sridhar Sir PDFDocument152 paginiEngg. Maths by Sridhar Sir PDFDivanshu InsaÎncă nu există evaluări

- Column Design As Per BS 8110-1:1997: PHK/JSNDocument16 paginiColumn Design As Per BS 8110-1:1997: PHK/JSNMohammed ShafiÎncă nu există evaluări

- Method Statement of Jack-In Pile PDFDocument3 paginiMethod Statement of Jack-In Pile PDFAMIR ASYRAF ZAINUDIN100% (1)

- Method Statement of Jack-In Pile - Rev.1 PDFDocument3 paginiMethod Statement of Jack-In Pile - Rev.1 PDFAMIR ASYRAF ZAINUDIN100% (1)

- Mos TPZB 260 PDFDocument16 paginiMos TPZB 260 PDFThanesh ManogaranÎncă nu există evaluări

- Method Statement and Set CalculationDocument9 paginiMethod Statement and Set CalculationSham AranÎncă nu există evaluări

- Руководство По Эксплуатации На Термопласт Un-230epiiiDocument69 paginiРуководство По Эксплуатации На Термопласт Un-230epiiiДмитрий ТарасенкоÎncă nu există evaluări

- Analysis of The Effects of Intra-Urban Spatial Structures On Carbon Footprint PDFDocument7 paginiAnalysis of The Effects of Intra-Urban Spatial Structures On Carbon Footprint PDFaniesbaekÎncă nu există evaluări

- Mos PBTDocument3 paginiMos PBTaniesbaekÎncă nu există evaluări

- MOS Temporary HoardingDocument4 paginiMOS Temporary Hoardinganiesbaek88% (8)

- Mos Survey WorkDocument4 paginiMos Survey Workaniesbaek100% (1)

- Final List of AwardeesDocument12 paginiFinal List of AwardeesSamson Jerold Samuel CÎncă nu există evaluări

- Budget 2023hhhhDocument27 paginiBudget 2023hhhhMajid KhanÎncă nu există evaluări

- RNS Price ListDocument8 paginiRNS Price Listtheo vasileÎncă nu există evaluări

- Product Data Sheet Metco 6A Air Control Unit: 2 Features and Benefits N N NDocument2 paginiProduct Data Sheet Metco 6A Air Control Unit: 2 Features and Benefits N N Nlhphong021191Încă nu există evaluări

- Industrial Valve Cross Ref - Vickers VS Rexroth For Primary Metal Applications0309Document60 paginiIndustrial Valve Cross Ref - Vickers VS Rexroth For Primary Metal Applications0309Abelio TavaresÎncă nu există evaluări

- 113 EDDY CURRENT INSPECTION OF TWISTED TUBE HEAT EXCHANGERS AND FIELD TEST RESULTS - TimothyRushDocument25 pagini113 EDDY CURRENT INSPECTION OF TWISTED TUBE HEAT EXCHANGERS AND FIELD TEST RESULTS - TimothyRushDan ClarkeÎncă nu există evaluări

- How To Specify & Order Class 150 Stainless Steel Threaded Pipe FittingsDocument15 paginiHow To Specify & Order Class 150 Stainless Steel Threaded Pipe FittingsJoesmoÎncă nu există evaluări

- Weld Deposition Per Electrode/Fillerwire: S.No Type Quantity (No) Dia (MM) Length (MM) Deposition (GMS) ElectrodeDocument6 paginiWeld Deposition Per Electrode/Fillerwire: S.No Type Quantity (No) Dia (MM) Length (MM) Deposition (GMS) Electrodenms1968Încă nu există evaluări

- Waist Slab StaircaseDocument13 paginiWaist Slab StaircaseNidhi BhatÎncă nu există evaluări

- Workshop 1 Welding : Arc Welding & Spot WeldingDocument2 paginiWorkshop 1 Welding : Arc Welding & Spot Weldingsherif115040 BueÎncă nu există evaluări

- Fast Rescue Boat PROCEDURESDocument34 paginiFast Rescue Boat PROCEDURESDERELL DEL ROSARIOÎncă nu există evaluări

- A Report On Industrial Attachment AT Kuber Auto Works Pvt. LTD Dharan, SunsariDocument31 paginiA Report On Industrial Attachment AT Kuber Auto Works Pvt. LTD Dharan, Sunsarishanathkumar14Încă nu există evaluări

- API (American Petroleum Institute) Gages: Services Offered ProductsDocument1 paginăAPI (American Petroleum Institute) Gages: Services Offered ProductsGrant ClarkÎncă nu există evaluări

- AA Revised Instructions Connectors 9-25-14 BC 7-15-16Document3 paginiAA Revised Instructions Connectors 9-25-14 BC 7-15-16mohamed hamedÎncă nu există evaluări

- Slab DesignDocument38 paginiSlab Designmathewsujith31Încă nu există evaluări

- Full Loaded Condition Draft Displacement 9.016 M 17634.56 T Light Condition Draft Displacement 2.548 M 4500.00 T DEADWEIGHT (SEA WATER) 13134.56 TDocument1 paginăFull Loaded Condition Draft Displacement 9.016 M 17634.56 T Light Condition Draft Displacement 2.548 M 4500.00 T DEADWEIGHT (SEA WATER) 13134.56 TSalah Uddin MahmoodÎncă nu există evaluări

- Bosch GST 85 PbeDocument43 paginiBosch GST 85 Pbej_abendstern4688Încă nu există evaluări

- S&T TM (T14S10) PDFDocument13 paginiS&T TM (T14S10) PDFFrezgi BirhanuÎncă nu există evaluări

- dt325 SourcebookDocument2 paginidt325 SourcebookLuis Felipe Morales JaraÎncă nu există evaluări

- Manufacturing Process Lab ReportDocument9 paginiManufacturing Process Lab ReportEric ChangÎncă nu există evaluări

- Manual: Floor To Ceiling Tube Support Unit DM-FCT-1Document9 paginiManual: Floor To Ceiling Tube Support Unit DM-FCT-1Ho PhuÎncă nu există evaluări

- Riser Diagram E: "Construction of Tanauan Super Health Center"Document1 paginăRiser Diagram E: "Construction of Tanauan Super Health Center"Liana BantayanÎncă nu există evaluări

- 375 FT Jack Up Drilling Unit CJ46 BrochureDocument7 pagini375 FT Jack Up Drilling Unit CJ46 BrochureAshwani Yadav100% (1)

- Lopx 709 SFD-34Document56 paginiLopx 709 SFD-34Surajkumar KumaranÎncă nu există evaluări

- Herion Poppets PDFDocument20 paginiHerion Poppets PDFhamzaÎncă nu există evaluări

- Suez University Faculty of Petroleum &mining Engineering Mechanical Design Sheet # 2Document6 paginiSuez University Faculty of Petroleum &mining Engineering Mechanical Design Sheet # 2Flying KiteÎncă nu există evaluări

- Stock 06.01.19Document92 paginiStock 06.01.19Felipe Gamboa GálvezÎncă nu există evaluări

- Lubang Sampling Emisi CerobongDocument6 paginiLubang Sampling Emisi CerobongwijeckÎncă nu există evaluări

- Scotchman CatalogDocument44 paginiScotchman CatalogANIL KUMAR KÎncă nu există evaluări

- Company ProfileDocument15 paginiCompany ProfileUlla SlaluÎncă nu există evaluări