Documente Academic

Documente Profesional

Documente Cultură

Baking and Drying Temperature of Electrodes

Încărcat de

shisTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Baking and Drying Temperature of Electrodes

Încărcat de

shisDrepturi de autor:

Formate disponibile

CHAPTER A3:

AA/CQ/GL/011/ Part I-WM Rev Date WELDING MATERIAL

Page 37 of 154

WELDING MANUAL 00 SPECIFICATION AND

24/10/16 CONTROL

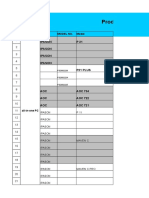

Drying and Holding Parameters

AWS Drying (*) Minimum Holding

Classification Temperature °C Time (Hours) Temperature °C (@)

E7018 250 - 300 2 150

E7018-1 250 - 300 2 150

E7018-A1 250 - 300 2 150

E8018-G 250 - 300 2 150

E8018-B2 250 - 300 2 150

E9018-B3 250 - 300 2 150

E9018-B23 250 - 300 2 150

E9015-B91 250 - 300 2 150

E9015-B92 250 - 300 2 150

E308, E309, E310 150

250 - 300 1

E316& E347

ENiCrFe-3 250 - 300 2 150

ENiCrFe-7 250 - 300 2 150

Note: (*) - Gu

followed.

(@) - Maintain the temperature in the oven till issue.

4.2.4 After issue, maintain the electrodes in a portable oven at a minimum temperature of

65°C till use. This is not applicable for E6013 (Rutile) electrodes, however the following

instruction shall be followed for E6013 electrodes:

(1) Rutile electrodes require some moisture in the coating and they would not require

drying. If they become damp, re-drying at around 120 to 150°C for 1 hour will be

sufficient.

(2) These electrodes with potassium silicate binder can be used on both DCEP/DCEN

polarities and on AC. E6013 electrodes generally have better arc striking and

stability characteristics with an easily detachable slag.

4.3 Unused, returned electrodes shall be segregated and reused only after repeating

drying and holding cycles.

S-ar putea să vă placă și

- Pipe Welding Traceability Record (Rev 01) As On 1st June 2018Document1.913 paginiPipe Welding Traceability Record (Rev 01) As On 1st June 2018gomathyselvi100% (1)

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 paginiN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliÎncă nu există evaluări

- Guidance To Prepare Wps PQR For WeldingDocument1 paginăGuidance To Prepare Wps PQR For WeldingHamid MansouriÎncă nu există evaluări

- 1662 15Document117 pagini1662 15RajamanikkamÎncă nu există evaluări

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 paginăWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadÎncă nu există evaluări

- Welding Repair ProcedureDocument4 paginiWelding Repair ProcedureRiky SumantriÎncă nu există evaluări

- Wps Mma PipeDocument2 paginiWps Mma PipeDimitris NikouÎncă nu există evaluări

- TopCoreBelco 101 FCDocument9 paginiTopCoreBelco 101 FCCesar ArellanoÎncă nu există evaluări

- Welding Consumables Control RegisterDocument1 paginăWelding Consumables Control RegisterAli MhaskarÎncă nu există evaluări

- T.C.L. Co. - Test & Control LaboratoriesDocument2 paginiT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταÎncă nu există evaluări

- Sample Forms WPS PQRDocument22 paginiSample Forms WPS PQRGMÎncă nu există evaluări

- Circularity Inspection Report: Shell Course (LW) CW CWDocument14 paginiCircularity Inspection Report: Shell Course (LW) CW CWaszlizaÎncă nu există evaluări

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 paginiAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Welding Parameters Control PipelineDocument1 paginăWelding Parameters Control PipelinemusheerÎncă nu există evaluări

- Attachment 22 - (SECL-PIP026) Welding Consumable Issue SlipDocument5 paginiAttachment 22 - (SECL-PIP026) Welding Consumable Issue SlipRjeb mohamedÎncă nu există evaluări

- Alishar SP 2Document84 paginiAlishar SP 2Alam MD SazidÎncă nu există evaluări

- WPS & SmawDocument12 paginiWPS & Smawnuke apriyaniÎncă nu există evaluări

- Welders ManagementDocument11 paginiWelders ManagementStanley AlexÎncă nu există evaluări

- PQR - PipeDocument3 paginiPQR - PipeAdvanced Quality Centre AQC100% (1)

- Welding Repair ProcdureDocument16 paginiWelding Repair Procdureprem nautiyal100% (1)

- ITP Fuel Fillter (J-1001) Rev10+Document9 paginiITP Fuel Fillter (J-1001) Rev10+DjokoÎncă nu există evaluări

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pagini2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanÎncă nu există evaluări

- SA 387 Grade 91 Class 2Document4 paginiSA 387 Grade 91 Class 2briang-2Încă nu există evaluări

- Bs Tech: Electrodes Issue and Return RegisterDocument1 paginăBs Tech: Electrodes Issue and Return RegisterRhannie GarciaÎncă nu există evaluări

- Lot Inspection Report For LPG New CylindersDocument3 paginiLot Inspection Report For LPG New CylindersJagannath MajhiÎncă nu există evaluări

- Electrode SelectionDocument1 paginăElectrode SelectionMel gibsonÎncă nu există evaluări

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Document21 paginiTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- Weld RepairDocument2 paginiWeld RepairAnurag YadavÎncă nu există evaluări

- WPS PQR 12 PDFDocument9 paginiWPS PQR 12 PDFVinay YadavÎncă nu există evaluări

- Aws N-1 WPS-PQR FormDocument2 paginiAws N-1 WPS-PQR FormEdwin MariacaÎncă nu există evaluări

- En 15085-2020-What Has ChangedDocument2 paginiEn 15085-2020-What Has ChangedBoran YelkenciogluÎncă nu există evaluări

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocument2 paginiWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisÎncă nu există evaluări

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 paginiProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabÎncă nu există evaluări

- Visual Inspection FormatDocument2 paginiVisual Inspection Formattuan mai vanÎncă nu există evaluări

- WFP 2 01 Procedure R1Document8 paginiWFP 2 01 Procedure R1leodavid87Încă nu există evaluări

- NDT MapDocument1 paginăNDT MapJuni OutsaidersÎncă nu există evaluări

- B H e L Limited RTDocument13 paginiB H e L Limited RTbhavin17850% (2)

- 12.6 Welding Procedures List (Li-002)Document31 pagini12.6 Welding Procedures List (Li-002)Ana GameroÎncă nu există evaluări

- Painting Report Cd3Document15 paginiPainting Report Cd3sivaÎncă nu există evaluări

- WPS 19Document15 paginiWPS 19Avishek Gupta100% (1)

- TDC-10B Heat Treatment For C12A Steel CastingsDocument2 paginiTDC-10B Heat Treatment For C12A Steel CastingsGohilakrishnan ThiagarajanÎncă nu există evaluări

- 1036330-23-349 Al 464 HV Hùng Smaw+fcaw Iso 9606 CS 6G (H-L045)Document2 pagini1036330-23-349 Al 464 HV Hùng Smaw+fcaw Iso 9606 CS 6G (H-L045)Nguyen Thanh BinhÎncă nu există evaluări

- Cold Tap Coating Report 2Document1 paginăCold Tap Coating Report 2Jamal BakhtÎncă nu există evaluări

- Ferrite Content ReportDocument2 paginiFerrite Content ReportJawad MunirÎncă nu există evaluări

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document1 paginăDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPÎncă nu există evaluări

- Welder ID Card BRE KarahaDocument5 paginiWelder ID Card BRE KarahaHerruSetiawan100% (1)

- Electrode Brand Name and Class MirfaDocument13 paginiElectrode Brand Name and Class MirfaAnonymous rYZyQQot55Încă nu există evaluări

- WPQ Template (Asme Ix) No LogoDocument4 paginiWPQ Template (Asme Ix) No LogorcpretoriusÎncă nu există evaluări

- Course Module 4Document6 paginiCourse Module 4Makise AghataÎncă nu există evaluări

- API 1104 ComplateDocument24 paginiAPI 1104 ComplateAwale UdinÎncă nu există evaluări

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 paginiNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityÎncă nu există evaluări

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocument1 paginăReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarÎncă nu există evaluări

- Electro-Motive Standard Welding Symbols AI01046Document9 paginiElectro-Motive Standard Welding Symbols AI01046eraman_meÎncă nu există evaluări

- VP16 PDFDocument13 paginiVP16 PDFKara WhiteÎncă nu există evaluări

- Offshore Marinetech PVT - LTD: Electrode Baking RegisterDocument3 paginiOffshore Marinetech PVT - LTD: Electrode Baking RegisterPrathamesh OmtechÎncă nu există evaluări

- WPS 2014-002 006 - 6G PipeDocument3 paginiWPS 2014-002 006 - 6G PipejeswinÎncă nu există evaluări

- Manual Joints (QW - 402) : Page 1 of 12Document12 paginiManual Joints (QW - 402) : Page 1 of 12miteshpatel191Încă nu există evaluări

- Veeyes Foundry Private Limited: COIMBATORE - 641 107Document1 paginăVeeyes Foundry Private Limited: COIMBATORE - 641 107mangalraj900Încă nu există evaluări

- SV 300 Spare Parts ListDocument33 paginiSV 300 Spare Parts ListAlaa AlauqyÎncă nu există evaluări

- Vigilance Awareness QuizDocument9 paginiVigilance Awareness QuizshisÎncă nu există evaluări

- Vigilance Awareness QuizDocument9 paginiVigilance Awareness QuizshisÎncă nu există evaluări

- ARJUN 10 ManualDocument20 paginiARJUN 10 Manualshis100% (1)

- Vigilance Awareness QuizDocument9 paginiVigilance Awareness QuizshisÎncă nu există evaluări

- ALL - INDIA - Map - TAG 2017Document1 paginăALL - INDIA - Map - TAG 2017shisÎncă nu există evaluări

- FIELD HANDLING TECH AND COMPARISSION PrintDocument15 paginiFIELD HANDLING TECH AND COMPARISSION PrintshisÎncă nu există evaluări

- Pipe Working Pressure Barlow's FormulaDocument2 paginiPipe Working Pressure Barlow's FormulashisÎncă nu există evaluări

- Map of West Bengal Showing Different Divisions: DarjeelingDocument1 paginăMap of West Bengal Showing Different Divisions: DarjeelingshisÎncă nu există evaluări

- Plan at El.2268 MM Tos: WBCD Support at El.45100, Buckstay Guide at El.50000Document1 paginăPlan at El.2268 MM Tos: WBCD Support at El.45100, Buckstay Guide at El.50000shisÎncă nu există evaluări

- Qualified Range I II III Qualified Range I II IIIDocument1 paginăQualified Range I II III Qualified Range I II IIIshisÎncă nu există evaluări

- Plan at El.2268 MM Tos: WBCD Support at El.45100, Buckstay Guide at El.50000Document1 paginăPlan at El.2268 MM Tos: WBCD Support at El.45100, Buckstay Guide at El.50000shisÎncă nu există evaluări

- Ga Irrsp Study GuideDocument7 paginiGa Irrsp Study Guidechesspupil100% (2)

- Six Sigma Black Belt PDFDocument557 paginiSix Sigma Black Belt PDFpepe100% (5)

- Material GradesDocument1 paginăMaterial GradesshisÎncă nu există evaluări

- 15ME11E - Solar PV - Question BankDocument15 pagini15ME11E - Solar PV - Question BankvigneshÎncă nu există evaluări

- How To Export Resource Assignment Data To Excel From P6Document9 paginiHow To Export Resource Assignment Data To Excel From P6artletÎncă nu există evaluări

- Transformer Secondary ConductorsDocument10 paginiTransformer Secondary ConductorsdskymaximusÎncă nu există evaluări

- Technical Data - Fan Model ECE152SM: Location: Designation: Performance - Required ActualDocument2 paginiTechnical Data - Fan Model ECE152SM: Location: Designation: Performance - Required ActualJÎncă nu există evaluări

- LabVIEW Project Report Complete HPK Kumar DetailedDocument62 paginiLabVIEW Project Report Complete HPK Kumar DetailedDanny Vu75% (4)

- Spare Parts List: Hand-Held Gas Saw DS HS80-14"Document20 paginiSpare Parts List: Hand-Held Gas Saw DS HS80-14"mayoo1986Încă nu există evaluări

- Accomplishment Report in ESPDocument7 paginiAccomplishment Report in ESPAldrin Perez85% (39)

- 11 443734731Document71 pagini11 443734731Prio ApÎncă nu există evaluări

- A88JY ManualDocument6 paginiA88JY ManualionmocanuÎncă nu există evaluări

- Ipason Product CatalogueDocument72 paginiIpason Product CatalogueithacaÎncă nu există evaluări

- Eaton Lumark Nightfalcon SpecDocument4 paginiEaton Lumark Nightfalcon Specluis torresÎncă nu există evaluări

- Cep Matlab CodeDocument5 paginiCep Matlab CodeMuhammad FurqanÎncă nu există evaluări

- Hoja de EspecificacionesDocument2 paginiHoja de Especificacionesacere18Încă nu există evaluări

- Unit 2Document3 paginiUnit 2lewlking123Încă nu există evaluări

- ASTM D1265-11 Muestreo de Gases Método ManualDocument5 paginiASTM D1265-11 Muestreo de Gases Método ManualDiana Alejandra Castañón IniestraÎncă nu există evaluări

- SAFMC 2023 CAT B Challenge Booklet - V14novDocument20 paginiSAFMC 2023 CAT B Challenge Booklet - V14novJarrett LokeÎncă nu există evaluări

- Fifths emDocument5 paginiFifths emcoolguy19895Încă nu există evaluări

- Convention On Cybercrime BudafestDocument26 paginiConvention On Cybercrime BudafestWinardiÎncă nu există evaluări

- Ad-All Ss Pressure GaugeDocument5 paginiAd-All Ss Pressure Gaugepankaj doshiÎncă nu există evaluări

- ValvesDocument1 paginăValvesnikhilÎncă nu există evaluări

- Manual M810Document38 paginiManual M810romiyuddinÎncă nu există evaluări

- Pre-Disciplinary and Post-Disciplinary Perspectives: Bob Jessop & Ngai-Ling SumDocument13 paginiPre-Disciplinary and Post-Disciplinary Perspectives: Bob Jessop & Ngai-Ling SumMc_RivÎncă nu există evaluări

- Scarabeo 200 I e 0910Document66 paginiScarabeo 200 I e 0910ΧΑΡΑΛΑΜΠΟΣΣΕΛΙΜΗΣÎncă nu există evaluări

- Logic Families and Their Characteristics CharacteristicsDocument26 paginiLogic Families and Their Characteristics CharacteristicsanunilaÎncă nu există evaluări

- Behringer FX2000-Product InfoDocument10 paginiBehringer FX2000-Product Infogotti45Încă nu există evaluări

- Director, Policy and Research (SEG 3 Et Al - Ministry of Culture, Gender, Entertainment and Sport PDFDocument12 paginiDirector, Policy and Research (SEG 3 Et Al - Ministry of Culture, Gender, Entertainment and Sport PDFvernon whiteÎncă nu există evaluări

- Tquins Resources Training Template For MT Work Programme SCS RevisedDocument12 paginiTquins Resources Training Template For MT Work Programme SCS RevisedLileth LagasimÎncă nu există evaluări

- Schlafhorst Texlab: Catalogue of ServicesDocument27 paginiSchlafhorst Texlab: Catalogue of ServicesvenkatspinnerÎncă nu există evaluări

- Table UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3Document7 paginiTable UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3MechanicalÎncă nu există evaluări

- Modern Love - The New York TimesDocument23 paginiModern Love - The New York TimesPearl Sky100% (1)