Documente Academic

Documente Profesional

Documente Cultură

Saic e 2005

Încărcat de

jerinTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Saic e 2005

Încărcat de

jerinDrepturi de autor:

Formate disponibile

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.

00 31-Mar-15

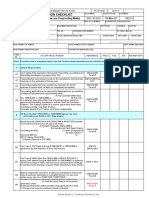

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Document Verification

Final Disposition Report was reviewed by the Contractor and Schedule "Q",

A1 submitted to Saudi Aramco within two weeks of acceptance of Att. III, Para.

material or equipment. 3.22

Final Disposition Report includes the following as a minimum:

a. Narrative details of Quality activities performed during

manufacturing and fabrication of the equipment or material.

b. Copies of SAUDI ARAMCO approved waivers to SAUDI Schedule "Q",

A2 ARAMCO’s requirements. Att. III, Para.

c. All SA-175 CONTRACTOR witnessed inspections. 3.24

d. Copies of supplier quality records as specified in SA-175.

e. Copies of all NCR's with final dispositions and resolutions.

f. Outstanding punch list items from pre-shipment inspections.

The Exchanger Manufacturer has submitted final records in 32-SAMMS-011,

A3

accordance with Form NMR-7922-2, Nonmaterial Requirements Para. 5.13

All materials for pressure and non-pressure components conform

32-SAMSS-011,

A4 with Data sheet & are in accordance with Table 1.

Para. 8.1.1

All materials, except carbon steels, is alloy (and verified by the 32-SAMSS-011,

A5

Exchanger Manufacturer in accordance with SAES-A-206). Para. 8.1.9

Exchangers have been Code stamped, with nameplates and

32-SAMSS-011,

A6 nameplate mounting brackets located such that they are not covered

Para. 10.5

by insulation, and are easily readable.

Clad exchangers conformed to 32-SAMSS-031 in addition to the 32-SAMSS-011,

A7

requirements of of 32-SAMSS-011. Para. 1.1.8

Exchangers in lube and seal oil services conformed to 32-SAMSS- 32-SAMSS-011,

A8

013 in addition to the requirements of 32-SAMSS-011. Para. 1.1.9

For Carbon or low-alloy steel the minimum nominal Tube/Plug

Sheets thickness is 20 mm including any corrosion allowance and for API 661 Para

A9

High-alloy steel or other material is 15mm excluding the corrosion 7.1.6.1.6

allowance. For Ref Att-1 Table-1

B Walkthrough of the equipment

Air cooled heat exchanger has no visible damage to the shell, fans or Schedule "Q",

B1

its appurtenances. Att IV,

Each tube bundle have one header free to move with thermal

32-SAMSS-011,

B2 expansion of the tubes and have teflon sliding plates at the moving

Para. 7.1.1.14

end both on structure and on bundle.

Steel used for slide plates is type 316 stainless steel. 32-SAMSS-011,

B3

(NOTE: Carbon steel slide plates shall not be used.) Para. 8.4.7

Plugs are coated with thread lubricant suitable for the design API 661

B4

conditions of the exchanger. Para. 9.5.1

Saudi Aramco: Company General Use

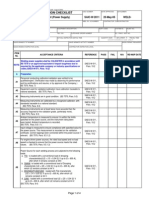

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Connections; where a process stream is likely to be stagnant,

projection is limited to 2.5 times connection nominal diameter for 32-SAMSS-011,

B5

vertical connections & 3.5 times connection nominal diameter for Para. 7.1.9.23

horizontal connections.

Integrally reinforced openings (with no reinforcing pads) are provided 32-SAMSS-011,

B6 Design

for all services and design conditions. Para. 7.1.9.24

All nozzles are attached to the header by full penetration full fusion 32-SAMSS-011,

B7 Design

welds. Para. 7.1.9.25

The maximum tube length is 15000 mm, unless otherwise approved 32-SAMSS-011,

B8 Design

by the Saudi Aramco Engineer. Para. 7.1.11.2

The fin type selection are as follows:

1) Fins shall be extruded (integral) type for process inlet temp of

up to and including 300°C.

2) Mechanically embedded fins may be used for a process fluid inlet

temperature of up to 400°C.

32-SAMSS-011,

B9 3) Welded fins, carbon steel on carbon steel, may be specified for a Design

Para. 7.1.11.7

process fluid inlet temperature of up to 450°C.

4) Embedded fins shall be used for cyclic service.

5) Fins, which are bonded to the outside surface of the tubes by hot-

dip galvanizing or brazing, shall not be used.

6) Other types of fins requires approval by the SA Engineer.

For grade mounted exchangers, headroom clearance below unit,

excluding driver arrangement, is not less than 2150 mm between fan 32-SAMSS-011,

B10

ring and grade for forced draft units and between tube bundle and Para. 7.3.1.9

grade for induced draft units.

Ensure the following:

1) The clearance between the fan tip and fan ring, the fan ring length

SAES-E-007,

B11 and the shape are acceptable.

Para. 9

2) The fan curves provided are valid for specific fan ring specified by

the Exchanger Manufacturer.

Actuators for auto-variable pitch fans are provided with maximum

32-SAMSS-011,

B12 pitch stops and the the design blade setting are marked on the hub

Para. 7.2.3.18

nameplate.

Removable fan guards are provided for both the forced and the 32-SAMSS-011,

B13

induced draft exchangers. Para. 7.2.6.1

32-SAMSS-011,

B14 Belt tensioning adjustment is possible without removal of fan guards.

Para. 7.2.8.2.14

Belt drives are provided with jack screws or an equivalent means of API 661

B15

initial belt-tensioning and/or retensioning. Para. 7.2.8.2.4

32-SAMSS-011,

B16 All control louvers are provided with side mounted hand wheels.

Para. 7.2.10.26

All external non-pressure welded attachments have their corners 32-SAMSS-011,

B17

rounded to a minimum radius of 50 mm and are fully seal welded. Para. 9.1.1.10

A sign: "Caution – Exchanger Has Been Postweld Heat Treated – Do

32-SAMSS-011,

B18 Not Weld", is painted on a postweld heat treated exchanger and

Para. 9.2.8

located such that it is clearly visible from grade.

All Walkways, Platforms, Ladders, Hoops, Handrails, Guards & Schedule "Q",

B19

Stairs, are as per drawings and free from mechanical damage. Att IV,

C Coating of External Surface

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Apllied coating is free of application deficiencies, mechanical damage

Schedule "Q",

C1 or pre-mature failure, ie: signs of corrosion and blistering.

Att IV,

(Refer to SAES-H-100)

Type Coating applied is suitable for the service condition of the of the SAES-E-007,

C2

equipment per SAES-H-101. Para. 11.3

D Insulation (if furnished by Vendor)

The extent and thickness of external insulation installed meets the

SAES-E-007,

D1 thickness requirement stated in the data sheet in accordance with

Para. 11.1

SAES-N-001.

Insulation installed is acceptable using Inspection Checklist, SAIC-N- Schedule "Q",

D2

2010 (for cold insulation) or SAIC-N-2016 (for hot insulation). Att IV,

E Fireproofing

The extent of fireproofing required on exchanger supports are in

SAES-E-007,

E1 accordance with the requirements of SAES-B-006 and specified on

Para. 12.1

the data sheet.

F Nozzles

SAES-E-007,

NPS 2½, 3½, and 5 nozzles are not used.

F1 Para. 8.1.3 & Design

All main flow nozzles are flanged.

8.1.4

Threaded or socket-welded connections are not used in hydrogen,

lethal, wet sour and caustic services. However, for other services,

threaded or socket-welded connections with 6000-lb rating

SAES-E-007,

F2 conforming to ASME B16.11 may be used for NPS 1-1/2 and smaller

Para. 8.1.5

vents, drains and instrument connections. Commentary note: This

requirement is intended for vents, drains and instruments

connections that may be attached to header or nozzles.

In total condensing services, a minimum of NPS 1½ connection is SAES-E-007,

F3

provided as a vent and located at the condensate outlet header. Para. 8.1.6

SAES-E-007,

F4 Pressure ratings of flanges are in accordance with ASME B16.5.

Para. 8.2.3

Flange facings are raised face or ring-type joint .

NOTE: Flat face flanges may be used in utility services. ASME

SAES-E-007,

pressure classes & facings shall be as specified on data sheet.

F5 Para. 8.2.1 &

Equipment specifies

8.2.4

flange facings to be compatible with ASME B31.3 Code Piping -

Identify associated piping specs

G Gaskets

The design of spiral wound gaskets are as follows:

1) For all services and design temperatures, spiral wound gaskets

are with solid outer centering rings. 2)

For design temps above 450°C, spiral wound gaskets are with solid SAES-E-007,

G1

outer centering rings & inner confining rings. Para. 8.4.2

3) For exchangers in continuous vacuum service, irrespective of

design temperature or design pressure, spiral wound gaskets are

solid outer centering rings & inner confining rings.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Gaskets for nozzle connections in utility services may be specified as

SAES-E-007,

G2 non-asbestos conforming to ASME B16.21, & must be chemically

Para. 8.4.4

resistant and mechanically suitable for the service conditions.

H Storage, Handling & Preservation

The Contractor's Handling, Storage & preservation procedure is Schedule "Q",

H1

available and approved. Att IV, Para. 5,6

1) The internals of exchangers are protected from corrosion by

use of a non-toxic vapor phase corrosion inhibitor such as

CORTEC VCI-309 or 307 or equivalent, applied at a rate of 0.3

kg/m³ fogged into the space. 32-SAMSS-011,

H2 2) Para. 11.4

Alternatively, nitrogen blanketing at a pressure of 5 psig may be used

or temporary coatings as per MIL-C-16173-D Grade IV (eg. Tectyl

846) was used.

Corrosion inhibitors for use on exchangers with stainless steel and

32-SAMSS-011,

H3 monel tubes are chloride free, suitable for intended use, and do not

Para. 11.4

result in crevice corrosion.

Flanged connections and other machined surfaces have been

protected/ covered by a suitable coating and fitted with a 3 mm thick 32-SAMSS-011,

H4

steel /wood cover, and neoprene gaskets with 4 bolts Equ spaced. Para. 11.5

For ocean shipment, flanged connections are covered with heavy 32-SAMSS-011,

H5

duty plastic bags securely taped to the nozzles. Para. 11.5

Lube-oil and seal-oil exchangers are demonstrated to meet the

H6 cleanliness requirements of API STD 614. SAEP-1028

See Attachment 2 & API 614 Inspector's Checklist.

Exchangers are completely dried and cleaned from all loose scales, 32-SAMSS-011,

H7

weld slags, dirt and debris. Para. 11.6

L LESSONS LEARNED (RECEIVING INSP & HANDLING TIPS TO PREVENT MAJOR PROJECT REWORK - ADD VALUE)

In-Situ Pressure Tests of New Fin Fan Coolers (Air-Cooled heat

Exchangers) are mandatory at Saudi Aramco. This is in addition to

SAES-A-004,

the manufacturer's pressure test. SEE ATTACHMENT 3.

L1 Para.

MAKE CERTAIN FIN FANS ARE CAREFULLY

6.4.5

HANDLED!!! BE CERTAIN THAT THESE

IN-SITU TESTS WILL PASS!!!

REMARKS:

ATTACHMENTS:

1. 32-SAMSS-011 Tables 1 & 2 (Exchanger Material & Impact Test Reqmts) & API 661 Table-1 Thickness of

Header 2 - API 614 (Lubrication, Shaft-Sealing, & Control-Oil

Systems & Auxiliaries, Appendix C (Inspector's Checklist) 3 - IN-SITU TESTING &

CARE OF FIN FAN COOLERS (MUST READ)

REFERENCE DOCUMENTS:

1. SAES-E-007, Design Critiera of Air-Cooled Heat Exchangers, (09 April 2015)

2. 32-SAMSS-011, Manufacture of Air-Cooled Heat Exchangers, (23 June 2010)

3. Schedule "Q", Quality Requirements

4. SAES-H-001, Painting Requirements for Industrial Facilities, (10 April 2011)

5. API 614, Lubrication, Shaft-Sealing and Control-Oil Systems, (5th Edition, APRIL 2008)

6. SAEP-1028, Chemical Cleaning and Flushing of Lube/Seal Oil and Fluid Power Systems, (12 January 2009)

7. API 661, Air Cooled Heat Exchangers For General Refrinery service, (February 2006)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 30-Apr-17 MECH-

ATTACHMENT 1 - 32-SAMSS-011 Tables 1 & 2 (Exchanger Material & Impact Test Reqmts)

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 30-Apr-17 MECH-

ATTACHMENT 2 - API 614 (Lubrication, Shaft-Sealing, & Control-Oil Systems & Auxiliaries for Petroleum,

Chemical & Gas Industry Services, Appendix C (Inspector's Checklist)

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 30-Apr-17 MECH-

Attachment 3 - IN-SITU TESTING & CARE OF FIN FAN COOLERS

1. Follow these simple guidelines to assure good test results.

2. Make certain Fin Fans (on arrival) were treated very carefully.

3. Inspect the load on arrival for proper preservation & damage

The internals of exchangers shall be protected from corrosion by use of a non-toxic vapor phase corrosion inhibitor such as CORTEC VCI-309

or 307 or equivalent, applied at a rate of 0.1 kg/m³ fogged into the space. The inhibitor selected must be appropriate for the metallurgy of the

exchanger. Exchangers must be sealed vapor tight for the inhibitor to be effective. Alternatively, nitrogen blanketing or temporary coatings in

accordance with MIL-C-16173-D Grade IV (example Tectyl 846) may be used. Corrosion inhibitors for use on exchangers with stainless steel

& monel tubes must be chloride free, suitable for its intended use & not result in crevice corrosion. 32-SAMSS-011, Sect. 11

Stainless steel exchangers shall be protected from salt water and salt water spray during shipment. 32-SAMSS-011, Sect. 11

4. Fin Fan Coolers can "twist" if improperly lifted. BEWARE!!!

Properly equipped cranes with "spreader" bars are used for unloading. NEVER ALLOW FORK TRUCK UNLOADING. Follow detailed

manufacturer handling and preservation requirements ... OR YOU CAN COUNT ON ADDED COST DUE TO TUBE/TUBESHEET LEAKS!!!

5. First thing, before it leaves the truck it arrives on! Inspection (camera)

a) Look at the top row of tubes. They should be VERY, VERY STRAIGHT!

b) If they aren't straight, i.e., bowed ... MAJOR PROBLEM!

c) Don't even let it be unloaded BEFORE YOU TAKE PICTURES.

d) Look at underside of the tubes, specifically the tube supports.

e) Severe shipping damage will result in "dislodged" support members.

6. Transit & erection clips & fasteners are checked closely for damage.

MAKE YOUR CLAIM RIGHT AWAY! TAKE EXTRA* PRECAUTIONS!

* The first one arrived damaged ... YOU CAN COUNT ON ALL OF THEM COMING THIS WAY "UNLESS YOU ACT QUICKLY".

* All the good Quality intentions in the world won't fix a badly mishandled Fin Fan Cooler.

*PLAN Proactive supervision at handling points to assure they arrive ok.

7. UNLOAD & STORE ON HARD & EXTREMELY LEVEL SITES ALWAYS.

a) Use good blocks (no nails). Make sure extra support is there & level.

b) NEVER exceed more a few meters between blocks.

8. Plan staging areas close to Units to minimize handling

OK, THIS HAS NOT HAPPENED ... ORDER EXTRA PLUGS & PRAY!

OK, YOU MADE IT THIS FAR OK ... NOW, PRESERVATION EFFORT

9. Corrosion Inhibitors can solidify, beware of opening these up.

10. Limit opening for "fit up" & piping work to good dry weather.

11. Keep system closed except when absolutely necessary.

12. Plan Test at test pressure on Manufacturer's Stamp.

If Chemical Cleaning (usually around 90 psi) is req'd, utilize this opportunity to meet the reqmt. (it's usually close enough)

Perform testing in accordance with good lay-up practices. Be Prepared to pull plugs and allow Proponent a visual exam.

Water removal after testing at low points can be assured by spool dropouts. Test as close to start-up as practical.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 30-Apr-17 MECH-

ALWAYS HAVE EXTRA PLUGS ON HAND (OR OVERNIGHT ACCESS AVAILABLE) IN THE EVENT OF TUBE/TUBESHEET LEAKS.

Saudi Aramco: Company General Use

S-ar putea să vă placă și

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 paginiSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominÎncă nu există evaluări

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 paginiSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 paginiSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWÎncă nu există evaluări

- Crosby ReliefValve JOS JBS JLT Cat D495Document64 paginiCrosby ReliefValve JOS JBS JLT Cat D495JudyÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 paginiSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14Document10 paginiSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14pravinÎncă nu există evaluări

- SAIC-W-2043 Rev 0Document3 paginiSAIC-W-2043 Rev 0philipyapÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocument4 paginiSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinÎncă nu există evaluări

- Saic RT 2007Document9 paginiSaic RT 2007munnaÎncă nu există evaluări

- SAIC-X-3104 Rev 3Document4 paginiSAIC-X-3104 Rev 3Imran khanÎncă nu există evaluări

- Saudi Aramco Inspection ChecklistDocument13 paginiSaudi Aramco Inspection ChecklistAli AhmedÎncă nu există evaluări

- 32 Samss 011Document27 pagini32 Samss 011naruto256Încă nu există evaluări

- 00 Saip 72Document6 pagini00 Saip 72Erin JohnsonÎncă nu există evaluări

- S Viii, D 3 - A R C H - P V: Ection Ivision Lternative Ules For Onstruction OF IGH Ressure EsselsDocument24 paginiS Viii, D 3 - A R C H - P V: Ection Ivision Lternative Ules For Onstruction OF IGH Ressure EsselsLuis VargasÎncă nu există evaluări

- SAIC-D-2005 Rev 2Document4 paginiSAIC-D-2005 Rev 2ரமேஷ் பாலக்காடுÎncă nu există evaluări

- Fat Procedure XMT Assembly Gas Test & Hydrostatical Test: SubseaDocument17 paginiFat Procedure XMT Assembly Gas Test & Hydrostatical Test: Subseadzamir203Încă nu există evaluări

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDocument3 paginiSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadÎncă nu există evaluări

- Investigation and Repair of H (1) - E.R Flange LeakDocument19 paginiInvestigation and Repair of H (1) - E.R Flange LeakriysallÎncă nu există evaluări

- 01 Saip 38Document14 pagini01 Saip 38Arjun RawatÎncă nu există evaluări

- SAIC-H-2010 Rev 7Document1 paginăSAIC-H-2010 Rev 7Satheesh Rama SamyÎncă nu există evaluări

- Saic MPT 2004 Rev 0Document6 paginiSaic MPT 2004 Rev 0philipyapÎncă nu există evaluări

- Optimization of Piping Expansion Loop in Process Plant: January 2015Document6 paginiOptimization of Piping Expansion Loop in Process Plant: January 2015Roberto Montano RuizÎncă nu există evaluări

- SATR-L-2001 Rev. 5Document10 paginiSATR-L-2001 Rev. 5Neelam AhmadÎncă nu există evaluări

- EXXON EPpressurevesselsDocument14 paginiEXXON EPpressurevesselsharrinsonfÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 paginiSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanÎncă nu există evaluări

- Saic RT 2001Document24 paginiSaic RT 2001munnaÎncă nu există evaluări

- 32 SAMSS 011 - 02 18 2018 - Final PDFDocument53 pagini32 SAMSS 011 - 02 18 2018 - Final PDFkartik_harwani4387Încă nu există evaluări

- ASME B 31.3 Process Piping - 1 PDFDocument9 paginiASME B 31.3 Process Piping - 1 PDFRamesh BaluÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingDocument5 paginiSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingpravinÎncă nu există evaluări

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 paginiInspection & Testing Requirements Scope:: Test and Inspection PeraneeshjokayÎncă nu există evaluări

- Saic D 2024Document9 paginiSaic D 2024Md ShariqueÎncă nu există evaluări

- MSFC Spec 3679 PDFDocument102 paginiMSFC Spec 3679 PDFDragan Sorin100% (1)

- 32 Samss 007Document38 pagini32 Samss 007naruto256Încă nu există evaluări

- N2 - Rev ADocument13 paginiN2 - Rev AChirag ShahÎncă nu există evaluări

- 32 Saip 11Document9 pagini32 Saip 11Jam100% (2)

- 32 Samss 031 PDFDocument9 pagini32 Samss 031 PDFFlorin Daniel AnghelÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 paginiSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalÎncă nu există evaluări

- Saic W 2011rev 0Document4 paginiSaic W 2011rev 0fariboy123Încă nu există evaluări

- Calculating Heat InputDocument5 paginiCalculating Heat InputAnonymous AlhzFE9EVNÎncă nu există evaluări

- Saep 306Document15 paginiSaep 306nadeem shaikh100% (1)

- SAIC-L-2014 Flange Joint Insp PDFDocument7 paginiSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyÎncă nu există evaluări

- SAIC-D-2022 Rev 2Document5 paginiSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுÎncă nu există evaluări

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 paginiInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Insl-Review Qualifications For Insulation Installers SAIC-N-2002 25-May-05Document1 paginăSaudi Aramco Inspection Checklist: Insl-Review Qualifications For Insulation Installers SAIC-N-2002 25-May-05philipyapÎncă nu există evaluări

- Evaluation of Smartphone Feature Preference by A Modified AHP ApproachDocument5 paginiEvaluation of Smartphone Feature Preference by A Modified AHP ApproachSeu Ze NinguemÎncă nu există evaluări

- Saudi Aramco Test ReportDocument2 paginiSaudi Aramco Test ReportEswari AnandÎncă nu există evaluări

- To Rerate or Not To RerateDocument6 paginiTo Rerate or Not To ReratekblaxtonÎncă nu există evaluări

- Saep 325Document43 paginiSaep 325AbdullahÎncă nu există evaluări

- Insulation Inspection ReportDocument2 paginiInsulation Inspection ReportKarthik100% (1)

- TF1 - 2Q92 - 100002 - 0 - Welder Welding Operator Qualification Test ProcedureDocument16 paginiTF1 - 2Q92 - 100002 - 0 - Welder Welding Operator Qualification Test ProcedureTuan LuuÎncă nu există evaluări

- Saudi Aramco Inspection ChecklistDocument13 paginiSaudi Aramco Inspection ChecklistRijwan MohammadÎncă nu există evaluări

- AIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01Document20 paginiAIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01faraz_muslimÎncă nu există evaluări

- Procedure Manual: Cast Valve ProductionDocument10 paginiProcedure Manual: Cast Valve ProductionParveen Kohli0% (1)

- SAIC-A-2023 Rev 6 Prssure Test Air GasDocument5 paginiSAIC-A-2023 Rev 6 Prssure Test Air Gaspookkoya thangalÎncă nu există evaluări

- SAIC-L-2002 Rev 6Document13 paginiSAIC-L-2002 Rev 6biplabpal2009Încă nu există evaluări

- SP 2154Document26 paginiSP 2154Anoop gokhaleÎncă nu există evaluări

- CML Optimization FinalDocument31 paginiCML Optimization FinalFatemeh SaadatmandÎncă nu există evaluări

- Materials System SpecificationDocument17 paginiMaterials System Specificationnadeem shaikhÎncă nu există evaluări

- SAIC-E-2005 Recvg Insp of AirCooled Heat ExchDocument5 paginiSAIC-E-2005 Recvg Insp of AirCooled Heat ExchAnonymous S9qBDVkyÎncă nu există evaluări

- Saic e 2002Document10 paginiSaic e 2002jerinÎncă nu există evaluări

- Saic A 1017Document1 paginăSaic A 1017jerinÎncă nu există evaluări

- Saic Gi 2102Document3 paginiSaic Gi 2102jerin100% (3)

- Saic J 6903Document9 paginiSaic J 6903jerinÎncă nu există evaluări

- Saic G 2011Document15 paginiSaic G 2011jerinÎncă nu există evaluări

- Saic G 2002Document32 paginiSaic G 2002jerinÎncă nu există evaluări

- Saic H 2060Document11 paginiSaic H 2060jerinÎncă nu există evaluări

- Saic e 2003Document7 paginiSaic e 2003jerinÎncă nu există evaluări

- Saic LPT 2003Document11 paginiSaic LPT 2003jerinÎncă nu există evaluări

- Saic LPT 2006Document12 paginiSaic LPT 2006jerinÎncă nu există evaluări

- Saic LPT 2001Document22 paginiSaic LPT 2001jerinÎncă nu există evaluări

- Saic A 1017Document1 paginăSaic A 1017jerinÎncă nu există evaluări

- Saic A 2013Document6 paginiSaic A 2013jerinÎncă nu există evaluări

- Saic LPT 2004Document13 paginiSaic LPT 2004jerinÎncă nu există evaluări

- Saic e 2004Document8 paginiSaic e 2004jerinÎncă nu există evaluări

- Saic B 1004Document2 paginiSaic B 1004jerinÎncă nu există evaluări

- Saic e 2001Document7 paginiSaic e 2001jerinÎncă nu există evaluări

- Saic e 2002Document10 paginiSaic e 2002jerinÎncă nu există evaluări

- Saic B 1002Document3 paginiSaic B 1002jerinÎncă nu există evaluări

- Saic A 1017Document1 paginăSaic A 1017jerinÎncă nu există evaluări

- Saic M 1002Document4 paginiSaic M 1002jerinÎncă nu există evaluări

- Saic F 2022Document4 paginiSaic F 2022jerinÎncă nu există evaluări

- Saic F 2021Document11 paginiSaic F 2021jerinÎncă nu există evaluări

- Saic A 1017Document1 paginăSaic A 1017jerinÎncă nu există evaluări

- Saic M 1004Document2 paginiSaic M 1004jerinÎncă nu există evaluări

- Saic A 2011Document8 paginiSaic A 2011jerinÎncă nu există evaluări

- Saic A 1016Document2 paginiSaic A 1016jerinÎncă nu există evaluări

- Saic A 1017Document1 paginăSaic A 1017jerinÎncă nu există evaluări

- Saic N 2031Document3 paginiSaic N 2031jerinÎncă nu există evaluări

- Saic A 2004Document4 paginiSaic A 2004jerinÎncă nu există evaluări

- Gas Dynamic Resonance Ignition For Repetitive StartsDocument8 paginiGas Dynamic Resonance Ignition For Repetitive StartsBrunno VasquesÎncă nu există evaluări

- Dynamic Depressurisation Calculations LNG Regasification UnitDocument15 paginiDynamic Depressurisation Calculations LNG Regasification Unitilmu2Încă nu există evaluări

- List Equipment Pltu Pangkalan Susu 2x200mwDocument7 paginiList Equipment Pltu Pangkalan Susu 2x200mwDanny SurbaktiÎncă nu există evaluări

- Mmscience - 2019 12 - Design of CNC Milling Machine As A Base of Industry 4 0 EnterpriseDocument6 paginiMmscience - 2019 12 - Design of CNC Milling Machine As A Base of Industry 4 0 EnterpriseKadir ŞUATAMANÎncă nu există evaluări

- CPD Review 2015 Chapter6 ErrataDocument22 paginiCPD Review 2015 Chapter6 ErrataMadhankumarÎncă nu există evaluări

- ASPE PSD - Fire Pump InstallationDocument4 paginiASPE PSD - Fire Pump InstallationNiong DavidÎncă nu există evaluări

- Gear Adendum Modification CoefficientDocument8 paginiGear Adendum Modification CoefficientRobert StuartÎncă nu există evaluări

- Conveyor DesignDocument73 paginiConveyor DesignAl Hisadin95% (22)

- BAE Airfoil Fans Catalogue M370 Metric PDFDocument78 paginiBAE Airfoil Fans Catalogue M370 Metric PDFHon NguyenÎncă nu există evaluări

- Manual Motores Audi A3Document74 paginiManual Motores Audi A3Carlos Garcia GodoyÎncă nu există evaluări

- Thermodynamics (5 Hours) : PhysicsDocument56 paginiThermodynamics (5 Hours) : PhysicsSaiful Nizam0% (1)

- Cooling Thesis PDFDocument60 paginiCooling Thesis PDFAudel Albarrán CÎncă nu există evaluări

- KC FLT 8809008 enDocument24 paginiKC FLT 8809008 enAnonymous l05hkK4yUV50% (4)

- MATERIALS AND CONSTRUCTION ArunachalamDocument6 paginiMATERIALS AND CONSTRUCTION Arunachalamdharanya sivabalanÎncă nu există evaluări

- CPP Report 2020-1Document20 paginiCPP Report 2020-1UnmayÎncă nu există evaluări

- Psychrometric Chart EditedDocument1 paginăPsychrometric Chart EditedMelord RoneÎncă nu există evaluări

- Robushi Robox BlowerDocument2 paginiRobushi Robox Bloweranguyen22153319Încă nu există evaluări

- Shaft GroundingDocument7 paginiShaft GroundingDan Alin MirceaÎncă nu există evaluări

- Cibse Variable Flow DPCV CPDDocument44 paginiCibse Variable Flow DPCV CPDmannu11Încă nu există evaluări

- Perkins 45 KVADocument4 paginiPerkins 45 KVASadiman SadimanÎncă nu există evaluări

- STP1210 Eb.1415051 1 PDFDocument298 paginiSTP1210 Eb.1415051 1 PDFpaolaÎncă nu există evaluări

- Operating and Maintenance Manual 6" To 8" Rewound Submersible MotorsDocument24 paginiOperating and Maintenance Manual 6" To 8" Rewound Submersible MotorsgeiyaulÎncă nu există evaluări

- Fixture Design: Introduction To Jigs and FixturesDocument10 paginiFixture Design: Introduction To Jigs and Fixturespankajpn100% (1)

- BerlinerLuft. Brochure HygCond 2017-2021 Eng. WebDocument24 paginiBerlinerLuft. Brochure HygCond 2017-2021 Eng. WebFabian FelsÎncă nu există evaluări

- J H Hooper Confectionery Packaging EquipmentDocument283 paginiJ H Hooper Confectionery Packaging Equipmentphucborso1Încă nu există evaluări

- B SafeunitDocument2 paginiB SafeunitvealealÎncă nu există evaluări

- HTO AssignmentDocument5 paginiHTO AssignmentMadhumita KumarÎncă nu există evaluări

- Reaffirmed 2001: For Current Committee PersonnelDocument24 paginiReaffirmed 2001: For Current Committee PersonnelJoel CieltoÎncă nu există evaluări

- Aircraft General Knowledge: Hydraulics and Landing GearDocument53 paginiAircraft General Knowledge: Hydraulics and Landing GearRizkinsya IlhamÎncă nu există evaluări

- Seleccion Chiller AguaDocument60 paginiSeleccion Chiller AguaÓscar Alfonso Gómez SepúlvedaÎncă nu există evaluări