Documente Academic

Documente Profesional

Documente Cultură

Methodsof Enzyme Immobilization

Încărcat de

Sãhïl KhãñDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Methodsof Enzyme Immobilization

Încărcat de

Sãhïl KhãñDrepturi de autor:

Formate disponibile

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/313366444

Methods of Enzyme Immobilization

Article in International Journal of Current Pharmaceutical Review and Research · December 2016

CITATIONS READS

6 22,472

3 authors:

Tamer M Tamer Ahmed Mohamed Omer

City Of Scientific Research And Technological Applications City Of Scientific Research And Technological Applications

91 PUBLICATIONS 559 CITATIONS 74 PUBLICATIONS 481 CITATIONS

SEE PROFILE SEE PROFILE

Mohamed Hassan

National Research Center, Egypt

41 PUBLICATIONS 246 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Development of smart superabsorbent hydrogels as conditioners for sandy soil View project

Post.doc.fellowship View project

All content following this page was uploaded by Mohamed Hassan on 08 August 2019.

The user has requested enhancement of the downloaded file.

Available online on www.ijcpr.com

International Journal of Current Pharmaceutical Review and Research; 7(6); 385-392

ISSN: 0976 822X

Review Article

Methods of Enzyme Immobilization

Hassan Mohamed E1,2*, Tamer Tamer M3, Omer Ahmed M3

1

Chemistry of Natural and Microbial Products Department, National Research Center, El Behouth Street, Cairo 12622,

Egypt.

2

Center of Excellence, Encapsulation & Nanobiotechnology Group, National Research Center, El-Behouth Street, Cairo

12622, Egypt.

3

Polymer Materials Research Department Advanced Technologies and New Materials Research Institute (ATNMRI),

City of Scientific Research and Technological Applications (SRTA-City), New Borg El-Arab City, P.O. Box: 21934

Alexandria, Egypt.

Available Online: 25th December, 2016

ABSTRACT

Enzyme immobilization is a technique specifically designed to restrict the freedom of movement of an enzyme.

Immobilization of enzymes is a common practice, mainly in order to minimize enzyme costs on the process economics by

making it possible to reuse the enzyme many times and also minimize the operation cost as the immobilization technique

may be modify the enzyme behavior, thus reducing the enzyme and product costs significantly. Many techniques have

been used previously for enzyme immobilization, as entrapment, adsorption, covalent binding, encapsulation, and cross

linking. Here we compare and contrast the basic properties of all immobilization methods.

Keywords: Immobilization, Entrapment, Adsorption, Covalent, Encapsulation, Crosslinking.

INTRODUCTION Choice of Support and Principal Method

Immobilization of Enzymes Over the previous decade, some synthetic routes for

The overall utilization of enzymes in industries (with the immobilized enzyme have been developed. To compare

exception of in medicines) is about € 1.5 billion. In enzyme immobilization nowadays with the past, we

Nutrition and medicine industries, as enzymes cannot be searched database for studies reporting enzyme

easily isolated from the product, and they are lost after the immobilization. Our search includes peer-reviewed

first use, so it is not better to be utilized in a free liquid English-language publications tending to at least one

state, also, some of them are very expensive (Figure 1). enzyme immobilization, and publication year between

The immobilization method would empower the 1990 and 2015. Fig. 2 shows the outcomes of publication

reusability of enzymes (Fig. 1b) for many of times, by year. As in figure, around 1426, 1628 and 1568 articles

therefor, the cost of enzymes and product will be reduced were published in 2013, 2014 and 2015 respectively;

significantly1. So, Immobilized enzyme form is more though in 1990 the corresponding figure was just 336,

favorable than free enzyme one since it offers the demonstrating expanding interest in enzyme

possibility of continuous flow processing and easy immobilization over the late years.

recovery of the immobilized enzyme and low cost In solution, soluble enzymes can disperse in the solution

operation can be done in industrial processing2. and also free in movement5. Enzyme immobilization is a

The immobilization of enzymes is a common practice, technique particularly designed to limit the enzyme

mainly in order to minimize the share of the enzyme costs movement. Immobilization provides support for enzymes.

on the process economics by making it possible to reuse For immobilization you have to decide the support material

the enzyme many times. This means that the enzyme is first, and then the immobilization method, taking into

physically confined, often in a polymer matrix in the form account the intended use and application. Some points

of beads or membranes, in such a manner that it cannot loss required to be considered are listed in table 1.

into solution3. The use of an immobilized enzyme also Numerous methods have been utilized previously for

generally facilitates the downstream processing because it immobilization of enzymes, for example: adsorption,

can simply be removed by sieving, whereas a considerable covalent binding, entrapment, encapsulation, and cross

effort and money would have to be invested in removing a linking6.

soluble enzyme from a reactor stream. In addition, Principal methods for immobilization of enzyme.

immobilized enzymes also tend to be more stable than the Adsorption

dissolved enzyme. Unfortunately, there are also Using adsorption as immobilization method (Figure 3) is

disadvantages, e.g. a (partial) loss of activity, changed the easiest technique and includes reversible surface

kinetics, and diffusion or mass transfer limitations4. interaction between carrier and enzyme7. The forces

*Author for Correspondence: mohassan81@gmail.com

Hassan et al. / Methods of Enzyme…

formed are weak force, mostly electrostatic, for example Other popular supports for immobilization of enzymes are

Van der Waals forces, ionic bond and hydrogen bonding porous silica and porous glass. Porous silica contains small

interactions, although hydrophobic bonding can be spherical particles of silica fused together having micro

significant, but although these forces are very weak, but cavities and small channels. The carrier is normally sold in

sufficiently large in number to enable reasonable binding. bead form, and is very strong and durable. Sintered

This method done by mixing the enzyme(s) and a support borosilicate glass has a system of uniform channels.

material with each other in adsorption properties, at Porous glass is also durable and resistant to microbial

optimum pH, ionic strength, etc., for a time, after that disintegration or solvent distortion. However, these two

collect immobilized enzyme and wash it to remove supports are procedures for coupling an enzyme and a

unbound enzymes. carrier is a covalent bond15. Most reactions may be one of

Advantages of this method are: the following categories:

Little or no damage to enzyme /cells. Isourea linkage Formation.

Easy, cheap, and fast. Diazo linkage Formation.

No changes happened to carrier or enzyme/ cells. Peptide bond Formation.

Reversible. An alkylation reaction.

Disadvantages are: It is very important to choose a technique that no effect on

Leakage of enzyme/cells from the support the enzyme as it may be inactivate it by reacting with

Separation of product is not easy. enzyme active site. Covalent binding consists of two steps.

Nonspecific binding. First one, activation of functional groups found on carrier

The most signification disadvantage is the separation of surface by a specific reagent, and the second, adding

enzyme from the support material, desorption may be enzyme to form covalent bond with activated surface of

happen under changes in pH, temperature, and also ionic carrier. Normally the activation reaction is designed to

strength. make strong electrophilic (electron deficient) functional

Desorption may be happen as a result of physical factors, groups on the carrier. In the coupling reaction, these

for example, flow rate, agitation, particle-particle activated groups will react with strong electron donating

Collisions. nucleophiles, such as the amino group (NH2), functional

Nonspecific binding may be lead to diffusion limitation groups of certain amino acids on the surface of most

and reaction kinetic problem, with consequent alteration in enzymes, to form strong covalent bond16.

parameter Vmax and Km8. Further, binding of protons to Cyanogen bromide (CNBr) is usually used to activate the

the support with consequent shift in pH optimum (1-2 pH), hydroxyl groups in polysaccharide materials. This method

which may be important enzymes with precise pH contains isourea linkage between enzyme and carrier. In

optimum requirement9. Unless carefully controlled, the case of carbodiimide activation, the support materials

overloading the support can lead to low catalytic activity, should contain carboxyl group (CO2 H) then enzyme and

and the presence of a suitable spacer between the enzyme support are combined by peptide bond. If the support

molecule and the support can produce problems related to material contains an aromatic amino group, it can be

steric hindrance. diazotized utilizing nitrous acid, addition of enzyme leads

Covalent binding to the formation of diazo linkage between the activated

Covalent binding immobilization method (Figure 4) diazo group on the support and the ring structure of an

consists of formation of a covalent bond, strong bond, aromatic amino acid, for example tyrosine. No technique

between the enzyme/cell and a carrier10,11. This covalent of immobilization is confined to a specific type of carrier,

bond formed between the functional groups present on the and large numbers of Probabilities are possible between

surface of carrier and the surface functional groups of the immobilization technique and support material. This is

enzyme. possible by chemical modifications on the support material

These functional groups on the surface of the enzyme such to produce different functional groups. For example, the

as amino groups (NH2) of arginine or lysine, carboxylic normal function group in cellulose is the hydroxyl group,

group (COOH) of glutamic acid or aspartic acid, hydroxyl and the chemical modification of this has produced a range

group (OH) of threonine or serine, and sulfhydryl group of cellulose derivative, such as AE-cellulose (amino ethyl),

(SH) of cysteine12. carboxymethyl cellulose, and DEAE-cellulose. Thus,

Many factors affect the choice of specific carrier, and chemical modification increases the number of

research work has demonstrated that hydrophilicity is one immobilization methods that can be utilized for each

of the most important factors for keeping up enzyme support material.

activity13. Thus, hydrophilic carriers such as Entrapment

polysaccharide polymers are popular materials for enzyme One of the easiest techniques of immobilization is

immobilization. For example, cellulose, starch, dextran entrapment. In recent years, calcium alginate has attraction

(sephadex), and agarose (sepharose). The sugar residues in as an immobilization support material. It has been utilized

these polymers contain ideal functional groups, hydroxyl for immobilization of variety of cell types, sub-cellular

groups, for covalent bond formation14. Also, hydroxyl organelles, multi-component systems, and enzymes. The

groups can form hydrogen bonds with water and create an physicochemical characteristics of this matrix in gel form

aqueous (hydrophilic) environment in the support. The have an important effect on the reactions of entrapped

supports are usually used in bead form3. biologically active material in the gel. Critical parameter

IJCPR, Volume 7, Issue 6, November- December 2016 Page 386

Hassan et al. / Methods of Enzyme…

in selecting a matrix is pore size17. The difference between entrapped in the lattice of the different natural or synthetic

entrapment technique and adsorption and covalent binding polymers. Alginate which is naturally occurring

is that however the enzyme is restricted in movement by polysaccharide that has the ability to form gels by

the structure of a gel lattice but it is free in solution18. The ionotropic gelation, is the most popular one23. Another

pore size of a gel lattice is controlled to ensure that the type, microcapsule, involves entrapment to porous

structure become tight enough to prevent loose of enzyme polymer. The preparation of micro capsules containing

or cells, it also allow free movement of the substrate and enzyme requires highly controlled conditions. Taqieddin

product. The support acts as a barrier to mass transfer, and and Amiji24 developed a new method for encapsulation in

although this have serious reaction kinetics implications, which the alginate-chitosan core-shell microcapsules were

but it can prevent interaction between harmful cell, prepared to immobilize β-galactosidase. The enzyme was

proteins, and enzymes and immobilized biocatalyst19,20. confined and protected in the inner core, alginate, while the

There are several major methods of entrapment: outer shell, chitosan, manages the transport properties.

Ionotropic gelation of macromolecules with multivalent Utilizing Ca2+ ions for alginate crosslinking,

cations (e.g. alginate). microcapsules with liquid core were developed with 60%

Temperature-induced gelation (e.g. agarose, gelatin). loading efficiency. And using Ba2+ ions, microcapsules

Organic polymerization reaction by with solid core were produced and 100% loading

chemical/photochemical (e.g.Polyacrylamide). efficiency was obtained25. The entrapment in liposome is

Precipitation from an immiscible solvent (e.g. increasingly recognized as a technique of protecting

polystyrene). biocatalysts from inactivation by proteolytic enzymes.

Entrapment can be accomplished by cross linking the Also, this enzyme, liposome, offers a noticeable increment

polyionic polymer material with multivalent cations in an in thermal protection. In the third type, reversed micelle,

ion-exchange reaction after mixing with enzyme to form a entrapping within the reversed micelles, it is formed by

structure that traps the enzymes/cells (ionotropic gelation) adding a surfactant with an organic solvent, such as aerosol

(Figure 5). Change in temperature is a simple way of OT/isooctane reverse micelles26 and used to entrap β-

gelation by phase transition utilizing 1-4% solutions of galactosidase. While in the membrane type, the enzyme is

gelation. κ-carrageen a polymers that can easy form gels isolated from the reaction solution microfiltration

by ionotropic gelation and by temperature-induced phase membrane or a hollow fiber27.

transition, which has form a greater degree of flexibility in Encapsulation

gelation frameworks for immobilization20. Encapsulation (Figure 6) of enzymes as well as cells can

On the other hand, it is possible to mix the enzyme with be accomplished by wrapping the biological components

material that is then polymerized to frame a crosslinked inside different forms of semi permeable membranes28,29.

polymeric system, trapping the enzyme in the internal It is as entrapment in that the enzymes/cells are free in

spaces of the lattice. The last method is more widely movements, however limited in space. Vast proteins or

utilized, and various acrylic materials are available for the enzymes cannot out or inter capsule, however small

formation of hydrophilic copolymers. For example, substrates and products can go freely across the semi

acrylamide monomer is polymerized to form permeable membrane. Numerous materials have been

polyacrylamide and methylacrylate is polymerized to form utilized to form microcapsules are in range of 10-100 µm

polymethacrylate. In addition to the monomer, a in diameter; such as, nylon and cellulose nitrate. Rupture

crosslinking agent is added during polymerization to form of the membrane is a problem associated with diffusion

cross linkage between the polymer chains and help to may be result if products from a reaction accumulate

create a three-dimensional network lattice. The formed rapidly.

polymer may be broken up into particles of a desired size, Biological cells also may be used as capsules, and a

or polymerization can be arranged to form beads of defined famous example of this is the use of erythrocytes (red

size. Precipitation occurs by phase separation rather than blood cells). The membrane of the erythrocytes is normally

by chemical reaction, but does bring the enzymes/cells into just permeable to small molecules. However, when

contact with a water-miscible organic solvent, and most erythrocytes are placed in hypotonic solution, they swell,

enzymes/cells are not tolerant of such solvents. Thus, this expanding the cell membrane and substantially expanding

method is limited to highly stable/previously stabilized the penetrability. In this condition, erythrocytes proteins

enzymes or nonliving cells21. go out of the cell and enzymes can inter into the cell.

This method is depending on localization of an enzyme Returning these erythrocytes, swollen, to the isotonic

inside polymer network or membrane lattice. Entrapment solution enables the cell membrane to return to the normal

has been advanced and broadly utilized for the state, and the enzymes inside the cell can't leak out. A

immobilization of cells more than for enzymes. It is distinct advantage of this technique is co immobilization.

limited for enzymes immobilization as it may be lost Cells and/or enzymes may be immobilized in any type of

during repeatedly using because of the small molecular combination to be suitable for particular application30.

size of enzyme compared to the cells. Diffusion limitations Cross linking

are also disadvantages for this method. This method may This method of immobilization (Figure 7) depend only on

be classified into five categories: lattice, microcapsule, enzyme and it is support- free as it done by joining the

liposome, membrane, and reverse micelle22. The most enzyme (or the cells) to each other to prepare a large, three-

widely one is the lattice method, in this type enzyme is dimensional complex structure, and it can be done

IJCPR, Volume 7, Issue 6, November- December 2016 Page 387

Hassan et al. / Methods of Enzyme…

Figure 1: a&b Schematic diagram of free and immobilized enzyme reactions.

(a), Reaction of free enzyme with substrate and formation of product, which has to be separated via dialysis;(b),

Reaction of immobilized enzyme with substrate and formation of product, which can be separated via filtration.

Figure 2: Annual number of articles on enzyme immobilization indexed in Scopus over the 1990–2015 period

chemically or physically31. Chemical type of crosslinking Hence, in the previous cases, conformational change of the

normally includes formation of covalent linkage between enzyme structure and partial destruction of the active site

the cells by means of a bi- or multifunctional reagent, for may occur. Accordingly, unless covalent binding method

example glutaraldehyde and toluene diisocyanate. is done under well controlled conditions, immobilized

However, limiting factors can be used in this method for enzyme having high activity cannot be obtained. Also, the

living cells and many enzymes because of harmful enzyme cannot easily be lost from carriers because of the

materials. To minimize the close problems that can be strong binding forces between the enzyme and carrier.

found because of crosslinking of single enzyme, both

albumin and gelatin have been used. CONCLUSION

This technique uses a bi- or multifunctional compounds, Enzymes can catalyze reactions in different forms: as

which serve as the reagent for intermolecular cross-linking individual free enzyme in solution, in aggregates with

of the biocatalyst22. others, and as attached to carrier surfaces. The attached or

Covalent binding or crosslinking methods are done under “immobilized” form has been of particular interest32.

relatively severe conditions in comparison with those of Enzymes can be immobilized by using many methods.

physical adsorption or encapsulation. And every method has its advantages and disadvantages as

shown in table 2.

IJCPR, Volume 7, Issue 6, November- December 2016 Page 388

Hassan et al. / Methods of Enzyme…

Figure 3: Immobilization by adsorption

Figure 4: Immobilization by covalent

Figure 5: Immobilization by Entrapment

Figure 6: Immobilization by Encapsulation

IJCPR, Volume 7, Issue 6, November- December 2016 Page 389

Hassan et al. / Methods of Enzyme…

Figure 7: Immobilization by crosslinking

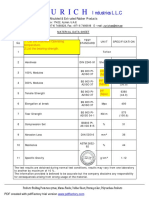

Table 1: Fundamental considerations in selecting a support and methods of immobilization

Property Points of Consideration

Physical Strength, non-compression of particles, available surface area, Share/form (beads/sheets/fibers),

degree of porosity, pore volume, permeability, Density, space for increased biomass, flow rate, and

pressure drop.

Chemical Hydrophilicity (water binding by the support), inertness toward enzyme/cell, available functional

groups for modification, and regeneration/ reuse of support

Stability Storage, residual enzyme activity, cell productivity, regeneration of enzyme activity, maintenance of

cell availability, and mechanical stabilityof support material

Bacterial/fungal attack, disruption by chemicals, pH, temperature, organic solvent, proteases, and

Resistance cell defence mechanism (proteins/cells), Biocompatibility (invokes an immune response), toxicity of

component

Safety reagents, proteases, health and safety for process workers and end-product users, specification of

immobilized preparation (GRAS list requirements for FDA approval) for food, pharmaceutical, and

medical applications Availability and cost of support, mechanicals, special equipment, reagents,

technical skill required, environmental impact, Industrial-scale chemical preparation, feasibility for

Economic scale-up, continuous processing, effective working life, reusable support, and CRL or zero

contamination (enzyme/cell-free product) Flow rate, enzyme/cell loading and catalytic productivity,

reaction kinetics, side reactions, multiple enzyme and/or cell systems, batch, CSTR, PBR, FBR,

Reaction ALR, and so on: diffusion limitations on mass transfer of cofactors, substrates, and products

Table 2: Preparation and Characteristics of Immobilized Enzyme

Carrier-binding method

Characteristic Physical Encapsulation Covalent Cross-linking Entrapping method

adsorption binding method

Preparation Easy Easy Difficult Difficult Difficult

Enzyme activity Low High High Moderate High

Substrate specificity Unchangeable Unchangeable Changeable Changeable Unchangeable

Binding force Weak Moderate Strong Strong Strong

Regeneration Possible Possible Impossible Impossible Impossible

General applicability Low Moderate Moderate Low High

Cost of Low Low High Moderate Low

immobilization

On the other hand, enzymes immobilized by encapsulation Unlike encapsulation, covalent-binding, and cross linking

technique can be achieved simply under mild conditions methods, in the entrapping method, no bond formed

but the binding forces between enzyme and support are between enzyme and carrier should occur in theory.

very weak in comparison with those found in the covalent- Therefore, in many cases, preparations having high

binding methods. So, losing the enzyme from the carrier activity are acquired. However, in this strategy, recovery

may happen after changes condition like ionic strength, pH of activity losses is impossible, in comparison with

of the substrate, or product solution. covalent-binding method.

IJCPR, Volume 7, Issue 6, November- December 2016 Page 390

Hassan et al. / Methods of Enzyme…

Table 3: Properties of immobilized enzymes

Technological properties of immobilized Enzyme

system:

Advantages Disadvantages

Catalyst reuses Loss or reduction in

Easier reactor operation activity Where νimm. and νfree are the rates of the reaction catalyzed

Easier product separation Diffusional limitation by immobilized and free enzyme at the same condition of

Wider choice of reactor Additional cost the active enzyme38. The kinetic behavior of immobilized-

enzyme systems depends principally on the carrier pore

Table 4: products of immobilized enzymes. size and also its size, likewise on enzyme density, but it is

Major products obtained using immobilized enzymes: independent on whether carrier-bound or carrier-free

Enzyme Product biocatalyst is used (table 4).

β- Galactosidase Hydrolyzed lactose

Glucose isomerase (whey) REFERENCES

Amino acid acylase High- fructose corn syrup 1. Elnashar, Magdy MM, and Mohamed E. Hassan.

Penicillin acylase Amino acid production "Novel epoxy activated hydrogels for solving lactose

Nitrile hydratase Semi-synthetic penicillins intolerance." BioMed research international 2014;

Acrylamide 2014 Article ID 817985, 9 pages.

2. http://dx.doi.org/10.1155/2014/817985

But the significant disadvantage of immobilization by 3. Magdy M. Elnashar, Ghada E. Awad, Mohamed E.

entrapping method is that it is limited to small molecular Hassan, Mohamed S. Mohy Eldin, Bakry M. Haroun,

substrate and product; the entrapped enzyme has little or and Ahmed I. El-Diwany. Optimal Immobilization of

no activity toward macromolecular substrates. β-Galactosidase onto κ-Carrageenan Gel Beads Using

Despite the fact that a number of immobilization Response Surface Methodology and Its Applications.

techniques have been studied, there is no ideal general The Scientific World Journal Volume 2014, Article ID

technique suitable for many enzymes have yet been 571682, 7 pages

developed. Every technique has specific advantages and 4. Mohy Eldin, M. S., El Enshasy, H. A., Hassan, M. E.,

disadvantages. Thus, in practice, it is important to find an Haroun, B., & Hassan, E. A. Covalent Immobilization

appropriate method and optimum conditions for the of Penicillin G Acylase onto Chemically Activated

immobilization of each enzyme in the light of planned Surface of Poly(vinyl chloride) Membranes for 6-

application. Penicillic Acid Production from Penicillin Hydrolysis

While immobilization procedures often decrease the Process I. Optimization of Surface Modification and Its

enzyme activity and selectivity, it keeps the enzyme in Characterization. Journal of Applied Polymer Science

their native state, and also can be easily separated from the 2012; 125: 3820–3828.

products by a semi-permeable membrane. Micro filtration- 5. Ghada E. A. Awad, Abeer A. Abd El Aty, Abeer N.

and hollow-fiber- membrane utilizing is described in Shehata,

“Ullmann’s Encyclopedia of Industrial Chemistry” (1989). Mohamed E. Hassan, Magdy M. Elnashar. Covalent

Enzymes can be also cross-linked by using different bi- immobilization of microbial naringinase using novel

functional agents (e.g. glutardialdehyde) and thus thermally stable biopolymer for hydrolysis of naringin.

converted to insoluble form33,34,35. Some of the discussed 3 Biotech 2016; 6-14

immobilization strategies are represented schematically in 6. Bickerstaf G.F. Impact of genetic technology on

Figure 2. enzyme technology. Genet Engineer Biotechnologist

In the recent years the dilemma concerning the choice 1995; 15: 13-30.

between “carrier-bound or carrier-free enzyme” was 7. Wahba, M.I. and Hassan, M.E. Novel grafted agar

subject of some researches. Kasche and Tischer36 disks for the covalent immobilization of β-D-

discussed possible advantages and disadvantages of galactosidase. Biopolymers 2015; 103(12): 675−684

enzyme in Free State compared to the immobilized one 8. Woodward J. Immobilized enzymes: Adsorption and

onto support materials. Table 3 demonstrates a few covalent coupling. In: Immobilized Cells and

disadvantages of the carrier used in enzyme EnzymesA Practical Approach. (Woodward, j., ed.)

immobilization: decreased mobility of the biocatalyst; IRL, Oxford: 3-1, 1985.

possible steric hindrances; diffusional limitations (depends 9. Goldstein L., Methods in Enzymology vol. XLIV

on the material size and its pore size); development of pH (mosbach, K.,ed.), academic, New York 1979; 397-

gradients (can be noticed also by enzyme-crystals); fouling 443,.

of the carrier-pores with substrate and/or product; extra 10. Toher J., Kelly A. M., Bickerstaff G.F. Stability

costs for carrier activation. properties of two supports for immobilization of

The mathematical description of the diffusional and mass enzymes. Biochem. SOC. Trans. 1990; 18: 313-314.

transfer effects of the enzyme kinetics is done by Kasche 11. Porath J., Axen R. Immobilization techniques,

et al.37. The degree of mass transfer control is frequantly Immobilization of Enzymes to Agar, Agarose, and

expressed by the stationary effectiveness factor η: Sephadex Supports. Academic, New York 1976; 3: 19-

45.

IJCPR, Volume 7, Issue 6, November- December 2016 Page 391

Hassan et al. / Methods of Enzyme…

12. Cabral J.M.S., Kennedy J.F. Covalent and coordination 26. Kirby C.J., Gregoriadis G. Dehydration-rehydration

immobilization of proteins, in Protein vesicles: a simple method for high yield drug

Immobilization—Fundamentals and Applications - entrapment in liposomes. BioTechnology 1984; 2:

(Taylor, R. F., ed.) Marcel Dekker, New York 1991; 979–984.

73-138 27. Chen W., Ou-Yang Ch.Ch. Bounded water kinetic

13. Srere P. A., Uyeda K. Immobilization techniques, model of β-galactosidase in reverse micelles.

Functional Groups on Enzymes Suitable for Binding to Bioprocess and Biosystems Engineering 2004; 26:

Matrices. Academic, New York 1976; 2: 11-19. 307–313.

14. Gemeiner P. Materials for enzyme engineering. In 28. Zuzana G., Michal R. and Martin R. Perspectives and

Gemeiner P (ed) enzyme engineering. Ellis Horwood, Applications of Immobilised β-Galactosidase in Food

New York 1992; 13-119. Industry – a Review. Czech J. Food Sci. 2008; 26 (1):

15. Hashem, Amal M., Amira A. Gamal, Mohamed E. 1–14.

Hassan, Naziha M. Hassanein, and Mona A. Esawy. 29. Osamu A., Mitsuhiro K., Tetsuya S., Yukio. Yoshiki S.

"Covalent immobilization of Enterococcus faecalis Mechanical and kinetic properties of PVA hydrogen

Esawy dextransucrase and dextran synthesis." immobilizing β-galactosidase. J. of Fermentation and

International journal of biological macromolecules Bioengineering. 1993; 76 (3): 203-206,

2016; 82: 905-912. 30. Kierstan M. P. J., Coughlan M. P. principles and

16. Scouten W. H. Immobilization techniques, A Survey of applications in Protein Immobilization (Taylor, R. F.,

Enzyme Coupling Techniques. Academic, New York ed.), Marcel Dekker, New York 1991; 13-71,

1987; 2: 30-65. 31. Ahmed MS Hussein, Shereen N Lotfy, Mohie M Kamil

17. Zaborsky O.R. Immobilized Enzymes-Miscellaneous and Mohamed E Hassan. Effect of microencapsulation

Methods and General Classification. Chemical Rubber on chemical composition and antioxidant activity of

Co. Press, Ohio 1973; 2: 4317-4332. cumin and fennel essential oils. Research Journal of

18. Mohy Eldin M. S., Hassan E. A. and Elaassar M. R. β- Pharmaceutical, Biological and Chemical Sciences

Galactosidase covalent immobilization on the surface 2016; 7 (3): 1565-1574.

of alginate beads and its application in lactose 32. Grobillot A., Boadi D. K., Poncelot D. Crit.

hydrolysis. Deutsche Lebensmittel-Rundschau 101. Govardhan. Crosslinking of enzymes for improved

Jahrgang, Heft 2005; 6: 255-259. stability and performance. Rev. Biotechnol. 1994; 14:

19. Driscoll K. F. Methods in Enzymology, Techniques of 75-107.

Enzyme Entrapment in Gels. Academic, New York 33. Guisan, Jose, M. Methods in Biotechnology:

1979; 12: 169-183. Immobilization of Enzymes and Cells, (Second

20. Brodeliu P. In Enzymes and Immobilized Cells in Edition) 2006.

Biotechnology (Laskin, A. I., ed.) Benjamin 34. Cao L., van Rantwijk, F., Sheldon, R.A. Cross-linked

Cummings, London 1985; 109-148, enzyme aggregates: a simple and effective method for

21. Bucke C. Immobilized cells Phil. Trans.R.Soc.B 1983; the immobilization of penicillin acylase. Organic

300: 369-389. Letters 2000; 2 (10): 1361-1364.

22. 21- Elnashar, Magdy MM, Mohamed E. Hassan, and 35. Cao LQ, Van Langen L, Sheldon RA. Immobilised

Ghada EA Awad. "Grafted carrageenan gel disks and enzymes: carrier-bound or carrier-free? Curr. Opin.

beads with polyethylenimine and glutaraldehyde for Biotechnol. 2003; 14 (4): 387-394.

covalent immobilization of penicillin G acylase." 36. Kennedy JF, Cabral JM, Kosseva MR, Paterson M.

Journal of Colloid Science and Biotechnology 2013; 2 Bickerstaff GF, ed. Methods in Biotechnology. Vol 1.

(1): 27-33. Immobilization of Enzymes and Cells. New Jersey:

23. Tanaka A., Kawamoto T. Cell and Enzyme Humana Press Inc., 1997; 345–359.

Immobilization. American Society for Microbiology, 37. Kasche V. and Tischer W. Immobilized enzymes:

Washington 1999; 94 crystals or carriers? Trends Biotechnol. 1999; 17(8):

24. Mammarella E.J., Rubiolo A.C. Study of the 326-35.

deactivation of β-galactosidase entrapped in 38. Kasche, V. Buchholz, K. Biokatalysatoren und

alginatecarrageenan gels. Journal of Molecular Enzymtechnologie, Verlagsgesellschaft mbH

Catalysis B: Enzymatic 2005; 34: 7–13. Weinheim 1997.

25. Taqieddin E., Amiji M. Enzyme immobilization in 39. Kasche, V. Correlation of theoretical and experimental

novel alginate-chitosan core-shell microcapsules. data for immobilized biocatalysts Enzyme. Microbiol.

Biomaterials 2004; 25: 1937–1945. Technol. 1983; 5: 2-13.

IJCPR, Volume 7, Issue 6, November- December 2016 Page 392

View publication stats

S-ar putea să vă placă și

- Polymeric Supports for Enzyme Immobilization: Opportunities and ApplicationsDe la EverandPolymeric Supports for Enzyme Immobilization: Opportunities and ApplicationsÎncă nu există evaluări

- Ramani Pradhan - Enzyme ImmobilizationDocument16 paginiRamani Pradhan - Enzyme ImmobilizationramaniÎncă nu există evaluări

- A Review On Methods Application and Properties of Immobilized EnzymeDocument9 paginiA Review On Methods Application and Properties of Immobilized EnzymeSimon LexsÎncă nu există evaluări

- Theory and Practice in Microbial Enhanced Oil RecoveryDe la EverandTheory and Practice in Microbial Enhanced Oil RecoveryÎncă nu există evaluări

- An Overview of Techniques in Enzyme ImmobilizationDocument7 paginiAn Overview of Techniques in Enzyme ImmobilizationKNTÎncă nu există evaluări

- Liquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentDe la EverandLiquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentÎncă nu există evaluări

- Enzymatic Desizing For Effective Processing: April 2020Document11 paginiEnzymatic Desizing For Effective Processing: April 2020umamkhairulÎncă nu există evaluări

- Content 5 (Immobilized Enzymes and Cells)Document10 paginiContent 5 (Immobilized Enzymes and Cells)Chala KelbessaÎncă nu există evaluări

- Assignment SeparationDocument28 paginiAssignment Separationeffak750iÎncă nu există evaluări

- ImmobilizationDocument16 paginiImmobilizationDavid Muñoz HuachuhuillcaÎncă nu există evaluări

- Enzym ImmobilizationDocument19 paginiEnzym ImmobilizationYash PatelÎncă nu există evaluări

- Enzyme ImmobilizationDocument15 paginiEnzyme ImmobilizationramaniÎncă nu există evaluări

- Ankita Gupta: M.Pharm (1 Year) Psit - KanpurDocument25 paginiAnkita Gupta: M.Pharm (1 Year) Psit - Kanpurmonamoname2Încă nu există evaluări

- MB36172P - AssignmentDocument5 paginiMB36172P - AssignmentSounak DasÎncă nu există evaluări

- 634904411345780000Document24 pagini634904411345780000chintan kapadiaÎncă nu există evaluări

- Practice 5 VerdeDocument17 paginiPractice 5 Verdeantonio salasÎncă nu există evaluări

- Methods & Applications of Enzyme & Whole Cell ImmobilizationDocument14 paginiMethods & Applications of Enzyme & Whole Cell ImmobilizationSandhya SharmaÎncă nu există evaluări

- Food and Industrial MicrobiologyDocument29 paginiFood and Industrial MicrobiologyAishwarya KashyapÎncă nu există evaluări

- Biochemical SensorsDocument10 paginiBiochemical SensorsAntonio Juárez AlonsoÎncă nu există evaluări

- Bio Lab 4Document6 paginiBio Lab 4candy andersonÎncă nu există evaluări

- Fermentation 20190426132559Document22 paginiFermentation 20190426132559JivashiniBalasupurManiamÎncă nu există evaluări

- Vidhi A. Modh Assistant Professor at SSSCP, ZundalDocument30 paginiVidhi A. Modh Assistant Professor at SSSCP, ZundalVidhi ModiÎncă nu există evaluări

- Catalytic, Kinetic and Thermodynamic Properties of Free and ImmobilizedDocument13 paginiCatalytic, Kinetic and Thermodynamic Properties of Free and ImmobilizedJoão Pedro MiguezÎncă nu există evaluări

- Biochem PPT FinalDocument42 paginiBiochem PPT Finalkivumbi AchileoÎncă nu există evaluări

- Application Prospects and Opportunities of Inorganic SilicaDocument8 paginiApplication Prospects and Opportunities of Inorganic SilicaPriyanshu JainÎncă nu există evaluări

- Enzymes and BiocatalysisDocument6 paginiEnzymes and BiocatalysisTatiana Souza PortoÎncă nu există evaluări

- Presented To:: Dr. Manisha Bhardwaj Presented By: Prerna (M.SC Biochemistry)Document15 paginiPresented To:: Dr. Manisha Bhardwaj Presented By: Prerna (M.SC Biochemistry)Anubhuti JhaÎncă nu există evaluări

- The Preparation and Kinetics of Immobilised EnzymesDocument60 paginiThe Preparation and Kinetics of Immobilised EnzymesRajashekhar BogarajulaÎncă nu există evaluări

- Biochem Molecular Bio Educ - 2011 - Valls - Characterization of The Protease Activity of Detergents Laboratory PracticalsDocument11 paginiBiochem Molecular Bio Educ - 2011 - Valls - Characterization of The Protease Activity of Detergents Laboratory PracticalsGeorge KoukouvesÎncă nu există evaluări

- 3 Biochemical Engineering CH 3Document36 pagini3 Biochemical Engineering CH 3yordanos gulilatÎncă nu există evaluări

- Immobilised Enzymes Science ArtDocument10 paginiImmobilised Enzymes Science ArtSebastian Andres Ramos GodoyÎncă nu există evaluări

- 71 PDFDocument4 pagini71 PDFRitu SinghÎncă nu există evaluări

- Enzyme TechnologyDocument47 paginiEnzyme TechnologyCharulata BhattacharyaÎncă nu există evaluări

- Ultra Filteration ReportDocument8 paginiUltra Filteration ReportNehaÎncă nu există evaluări

- Enzyme Immobilized EnzymeDocument3 paginiEnzyme Immobilized EnzymeDivya TripathyÎncă nu există evaluări

- Microencapsulation by Complex Coacervation Methods Techniques Benefits and Applications A RevieDocument6 paginiMicroencapsulation by Complex Coacervation Methods Techniques Benefits and Applications A RevieNguyễn Trần Hòa HợpÎncă nu există evaluări

- Module IiiDocument31 paginiModule IiiAathira SÎncă nu există evaluări

- (MCBT 404E) - On Line 1 - 3Document17 pagini(MCBT 404E) - On Line 1 - 3Ahmed LozzÎncă nu există evaluări

- EnzymesDocument15 paginiEnzymesShruti TiwariÎncă nu există evaluări

- Application of Enzyme Immobilization in The Food Industry: M. B. Mandake, Urvashi Das, Laxman Phad, Sakshi BusamwarDocument5 paginiApplication of Enzyme Immobilization in The Food Industry: M. B. Mandake, Urvashi Das, Laxman Phad, Sakshi BusamwarKRISHNA SINGHÎncă nu există evaluări

- A Review On Downstream Processing of Monoclonal Antibodies (MAbs)Document13 paginiA Review On Downstream Processing of Monoclonal Antibodies (MAbs)IJRASETPublicationsÎncă nu există evaluări

- BiochemicalDocument17 paginiBiochemicalYonas TarekegnÎncă nu există evaluări

- 225 286 JMTR Oct2016 PDFDocument66 pagini225 286 JMTR Oct2016 PDFKevinÎncă nu există evaluări

- Technical Report 1Document41 paginiTechnical Report 1Nur Illahi'Încă nu există evaluări

- Temperature-Triggered Enzyme Immobilization and ReDocument10 paginiTemperature-Triggered Enzyme Immobilization and RekevinÎncă nu există evaluări

- Downstream ProcessingDocument21 paginiDownstream ProcessingNasir Ahmed YusufÎncă nu există evaluări

- Figure 1: Molecular Transport Through A MembraneDocument5 paginiFigure 1: Molecular Transport Through A MembraneSanika TalathiÎncă nu există evaluări

- Industrial Biocatalysts NatureDocument11 paginiIndustrial Biocatalysts NatureManda AndreeaÎncă nu există evaluări

- 1986 EMT Disruption of Microbial Cells For Intracellular ProductsDocument11 pagini1986 EMT Disruption of Microbial Cells For Intracellular ProductsLezid CortesÎncă nu există evaluări

- Enzyme Immobilisation in BiocatalysisDocument13 paginiEnzyme Immobilisation in BiocatalysisVale VegaÎncă nu există evaluări

- Tetrahedron Report Number 489Document92 paginiTetrahedron Report Number 489SachidanandanÎncă nu există evaluări

- Acid Activated Montmorillonite An Efficient ImmobilizationDocument9 paginiAcid Activated Montmorillonite An Efficient ImmobilizationJoão Pedro MiguezÎncă nu există evaluări

- Acs Jafc 9b04385Document66 paginiAcs Jafc 9b04385Nguyễn QuangÎncă nu există evaluări

- 1 s2.0 S2213343720306151 MainDocument23 pagini1 s2.0 S2213343720306151 Mainbrisj34Încă nu există evaluări

- BTH 401 AssignmentDocument15 paginiBTH 401 AssignmentMelissa lhingnunhoi SimteÎncă nu există evaluări

- Immobilized EnzymesDocument9 paginiImmobilized EnzymesNITIN100% (1)

- Arun IEMDocument7 paginiArun IEMAmit RohillaÎncă nu există evaluări

- Chap 1Document24 paginiChap 1Yonas FekaduÎncă nu există evaluări

- Enzymes in DetergentsDocument21 paginiEnzymes in Detergentsmayankj31100% (39)

- Pre-Reformer Catalyst in A Hydrogen PlantDocument4 paginiPre-Reformer Catalyst in A Hydrogen Plantbikas_saha100% (1)

- Self Assessment Questions OneDocument3 paginiSelf Assessment Questions OneTendus StephanÎncă nu există evaluări

- 4ch1 1c Pef 20220825Document37 pagini4ch1 1c Pef 20220825sherÎncă nu există evaluări

- Bacterial Corrosion Brochure - tcm4-416324Document6 paginiBacterial Corrosion Brochure - tcm4-416324Joaquin LanderosÎncă nu există evaluări

- Nuclear ChemistryDocument14 paginiNuclear ChemistryGoldèn DawnÎncă nu există evaluări

- Chapter 1 Sem 20192020 Updated 24.9.2019Document134 paginiChapter 1 Sem 20192020 Updated 24.9.2019Nur HazwaniÎncă nu există evaluări

- OL Lab 9 Organic ChemistryDocument17 paginiOL Lab 9 Organic ChemistryHezekiah AtindaÎncă nu există evaluări

- PH-2102 SR L-1 Furan Chemistry 13Document3 paginiPH-2102 SR L-1 Furan Chemistry 13Mahendra PandaÎncă nu există evaluări

- Chapter 6 - PolymersDocument123 paginiChapter 6 - Polymerscory kurdapyaÎncă nu există evaluări

- ASSIST - Burning Magnesium Ribbon - 2019-02-22Document3 paginiASSIST - Burning Magnesium Ribbon - 2019-02-22Fatimah MÎncă nu există evaluări

- TERM 2 Chapter 7 Topical Revision Bio STPMDocument59 paginiTERM 2 Chapter 7 Topical Revision Bio STPMKeertana SubramaniamÎncă nu există evaluări

- Learning Issues: 1. What Characteristic of Free Drugs? (Iftitah) AnswerDocument8 paginiLearning Issues: 1. What Characteristic of Free Drugs? (Iftitah) AnswerIftitah N. RÎncă nu există evaluări

- CHE 029 - Exercise No 1Document3 paginiCHE 029 - Exercise No 1ronduexÎncă nu există evaluări

- Artigo Macauba PCADocument14 paginiArtigo Macauba PCAjuventude JuventudePIBFÎncă nu există evaluări

- Cheat Sheet - Exam 3Document20 paginiCheat Sheet - Exam 3textbookwhoreÎncă nu există evaluări

- Biological Roles of Water - Why Is Water Necessary For Life - Science in The NewsDocument17 paginiBiological Roles of Water - Why Is Water Necessary For Life - Science in The NewsJoel SteveÎncă nu există evaluări

- GI 2.709 Gas Testing PDFDocument12 paginiGI 2.709 Gas Testing PDFMANI DEEP67% (3)

- Class 12 Chemistry Ch-4.the D - and F-Block ElementsDocument37 paginiClass 12 Chemistry Ch-4.the D - and F-Block Elementskarnan karupiahÎncă nu există evaluări

- Presentasi IKOM Handover Gas Metering Services PHE Jambi Merang (20jan2022)Document47 paginiPresentasi IKOM Handover Gas Metering Services PHE Jambi Merang (20jan2022)irwanypcÎncă nu există evaluări

- New Improved PPA Akabori SyntheseDocument5 paginiNew Improved PPA Akabori SyntheseRobert Bonka100% (4)

- Chemistry - Nuclear - Physics - WebquestDocument6 paginiChemistry - Nuclear - Physics - Webquesto18.makiÎncă nu există evaluări

- Msds Sigma Vikote 15 (Sigmavinyl Primer)Document8 paginiMsds Sigma Vikote 15 (Sigmavinyl Primer)kumarÎncă nu există evaluări

- Tetraamminecopper (II) Sulfate Monohydrate: Discover New Opportunities at Ultra High PurityDocument1 paginăTetraamminecopper (II) Sulfate Monohydrate: Discover New Opportunities at Ultra High Purityjorge fravegaÎncă nu există evaluări

- Duoline 20 - Reasons WhyDocument4 paginiDuoline 20 - Reasons Whycasda73Încă nu există evaluări

- Simple Syrup IP 66 Https://youtu - Be/6oiy - AdjLJkDocument23 paginiSimple Syrup IP 66 Https://youtu - Be/6oiy - AdjLJkSunanda Chaudhari100% (1)

- Advanced Separation ProcessesDocument33 paginiAdvanced Separation Processesعمار ياسر50% (2)

- Installation Instruction For Conventional Castables PDFDocument2 paginiInstallation Instruction For Conventional Castables PDFakv_bhelÎncă nu există evaluări

- Ácido FumaricoDocument12 paginiÁcido FumaricoGeorginaMartinezÎncă nu există evaluări

- Teflon MDSDocument1 paginăTeflon MDSSajir ThiyamÎncă nu există evaluări

- 5.1 Defects AllDocument40 pagini5.1 Defects AllOmar Giovanny Ballén RodríguezÎncă nu există evaluări

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincDe la EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincEvaluare: 3.5 din 5 stele3.5/5 (137)

- It's Elemental: The Hidden Chemistry in EverythingDe la EverandIt's Elemental: The Hidden Chemistry in EverythingEvaluare: 4 din 5 stele4/5 (10)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactDe la EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactEvaluare: 5 din 5 stele5/5 (5)

- ICH Quality Guidelines: An Implementation GuideDe la EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleÎncă nu există evaluări

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsDe la EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsEvaluare: 5 din 5 stele5/5 (3)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDe la EverandChemistry for Breakfast: The Amazing Science of Everyday LifeEvaluare: 4.5 din 5 stele4.5/5 (14)

- Chemistry: a QuickStudy Laminated Reference GuideDe la EverandChemistry: a QuickStudy Laminated Reference GuideEvaluare: 5 din 5 stele5/5 (1)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactDe la EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactEvaluare: 5 din 5 stele5/5 (1)

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideDe la EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideÎncă nu există evaluări

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeDe la EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeEvaluare: 4 din 5 stele4/5 (1)

- The Production of Volatile Oils and Perfumery Plants in the United StatesDe la EverandThe Production of Volatile Oils and Perfumery Plants in the United StatesÎncă nu există evaluări

- Practical High-Performance Liquid ChromatographyDe la EverandPractical High-Performance Liquid ChromatographyÎncă nu există evaluări

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeDe la EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeEvaluare: 5 din 5 stele5/5 (4)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeDe la EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeÎncă nu există evaluări

- The Nature of Drugs Vol. 2: History, Pharmacology, and Social ImpactDe la EverandThe Nature of Drugs Vol. 2: History, Pharmacology, and Social ImpactÎncă nu există evaluări

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDe la EverandChemistry for Breakfast: The Amazing Science of Everyday LifeEvaluare: 4.5 din 5 stele4.5/5 (90)