Documente Academic

Documente Profesional

Documente Cultură

Case Study Kraljics' Matrix

Încărcat de

MEHDIDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Case Study Kraljics' Matrix

Încărcat de

MEHDIDrepturi de autor:

Formate disponibile

CASE STUDY – Suppliers’ strategy: the case of TIMBER HOMES.

Adapted from Bildsten, L., Rehme, J., & Brege, S. (2010). Applying the kraljic model to the construction sector: The case of a

prefab housing factory. Proceedings of the 26th Association of Researchers in Construction Management (ARCOM), 1029-

1037.

The case company studied is a manufacturer of timber houses (TIMBER HOMES Ltd.). They produce

vacation houses, villas and multi-storey residential buildings. The company is situated in northern

Sweden and has an annual turnover of 4.8 million Euros. The factory produces timber panels that are

assembled as a complete structure at the construction site. The company is only responsible for the

production of the house shell components, and not, for example, for the foundations, water, gas and

electricity supplies or interior decoration. The CEO of the house manufacturer was interviewed by

telephone about the company's purchasing strategies. The CEO then verified the answers to

guarantee validity. The values of the purchased materials were taken directly from the company’s

bookkeeping accounts.

The questions asked to the CEO were:

What construction materials do you purchase?

What is the annual purchasing cost of each component?

What is the total purchasing value for a year?

Who are the suppliers for each of the components?

Why have you chosen these particular suppliers?

How satisfied are you with your suppliers? (scale 1-3, 1=dissatisfied, 3=very

satisfied) Why are you satisfied / dissatisfied with them?

Is it easy to shift supplier for the different materials (scale 1-3, 1=easy,

3=hard)?

Do you have few or many alternative suppliers?

The answers are summarised in table1. The total purchasing value of the materials is 50%, including

transports of the total turnover. Many suppliers are local distributors and the CEO says that this is

the only way to handle the factory’s low sales volumes. Excessive warehouse stock is otherwise

eventually destroyed. The local distributors were chosen because of their total offer regarding

logistics rather than price.

Questions:

1. Segment TIMBER HOMES suppliers against Kraljic’s matrix.

2. Looking into the levels of satisfaction (provided in table 2), and the results of the Kraljic’s

matrix…Would you do any strategic change in relation to existing suppliers?

3. Do you think a new suppliers’ strategy could increase TIMBER HOMES competitive

advantage? How?

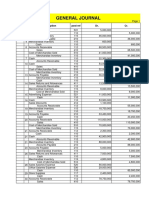

Table 1. Suppliers table

Type of Percentage Source Level of Switching Alternative

product of total satisfaction costs suppliers

purchasing

Insulation 20% Local Medium Low Few

distributor

Windows 12% Local Low Low Few

distributor

Timber 15% National Medium Medium Many

distributor

Inner floors 8% Local Low Low Many

and walls distributor

Doors 5% Local High Low Many

distributor

Rafters 6% Local High Medium Few

distributor

Scaffoldings 5% Local Low Low Few

distributor

Outer roofs 4% National Medium Medium Many

distributor

Timber 5% National Low High Few

machinery distributor

Nails, 2% National Medium Medium Many

hammers distributor

Drillers 2% National Medium Low Many

distributor

Project and 5% Local Low Medium Few

compliance distributor

management

services

Computers & 3% National Medium High Many

printers distributor

(HW)

CAD 2% National Low High Few

software distributor

Office 1% Local Medium Low Many

supplies distributor

S-ar putea să vă placă și

- HRM-470-S1-Group-K (Union)Document29 paginiHRM-470-S1-Group-K (Union)I.M.H. Hemal Chowdhury 1611692630100% (1)

- The Impact of Extended Warehouse Management System Implementation On Warehouse Operational PerformanceDocument31 paginiThe Impact of Extended Warehouse Management System Implementation On Warehouse Operational PerformanceNhi LêÎncă nu există evaluări

- Flare July Aug 07Document92 paginiFlare July Aug 07rizwanflare100% (1)

- PDF 6Document50 paginiPDF 6فرزاد ”Angra“ mavaraniÎncă nu există evaluări

- HRM CaseDocument20 paginiHRM CasePriyam ChakrabortyÎncă nu există evaluări

- Final Project UmtDocument38 paginiFinal Project UmtwinkycheemaÎncă nu există evaluări

- Information Systems in The Enterprise - Prentice Hall 2002Document37 paginiInformation Systems in The Enterprise - Prentice Hall 2002Calvin TungkiÎncă nu există evaluări

- Overview of Sonargaon Textiles LTD 3Document12 paginiOverview of Sonargaon Textiles LTD 3Akib Javed FahimÎncă nu există evaluări

- ERP Chapter 5Document32 paginiERP Chapter 5Jootoo NitishÎncă nu există evaluări

- BGA's, LGA's, QFN/DFN's - Oh My, Can Traditional DFM SurviveDocument54 paginiBGA's, LGA's, QFN/DFN's - Oh My, Can Traditional DFM SurvivemrbustaÎncă nu există evaluări

- Bca Cbcs Sylllabus Mku 2016 17Document50 paginiBca Cbcs Sylllabus Mku 2016 17SUKUMAR MÎncă nu există evaluări

- Discussion Board Module 6 - Woodmere Case - Aman SyedDocument4 paginiDiscussion Board Module 6 - Woodmere Case - Aman SyedAman Syed100% (1)

- WesternLife Blended Case StudyDocument6 paginiWesternLife Blended Case StudyHoàng HưngÎncă nu există evaluări

- DELL OperationDocument15 paginiDELL OperationDian Inda Sari100% (10)

- PDF 9Document70 paginiPDF 9فرزاد ”Angra“ mavaraniÎncă nu există evaluări

- Experiential Learning Group 29 JSW SteelDocument71 paginiExperiential Learning Group 29 JSW Steelkarunakar vÎncă nu există evaluări

- WPS Parking: Competitor AnalysisDocument44 paginiWPS Parking: Competitor AnalysisGiu MartinsÎncă nu există evaluări

- Chap 2 Steel WorksDocument2 paginiChap 2 Steel WorksVAISHNAVI KÎncă nu există evaluări

- Tetra Laval Report 2019 - 2020Document31 paginiTetra Laval Report 2019 - 2020Karim NasriÎncă nu există evaluări

- Lead Group7 Haier Case StudyDocument16 paginiLead Group7 Haier Case StudyashiÎncă nu există evaluări

- Ascm 2020 School Round Data Exhibit VF NsDocument37 paginiAscm 2020 School Round Data Exhibit VF NsRajat Shrinet0% (1)

- Groupe-Renault Ev-Strategy Ubs 3 April 2019Document11 paginiGroupe-Renault Ev-Strategy Ubs 3 April 2019arshadÎncă nu există evaluări

- KiWi Power Overview 19072017Document33 paginiKiWi Power Overview 19072017santiagoÎncă nu există evaluări

- TATM1 - Week 6Document4 paginiTATM1 - Week 6Phuong Trinh MaiÎncă nu există evaluări

- Introduction To Project Management II: TopicsDocument18 paginiIntroduction To Project Management II: TopicsRaluca BolbaÎncă nu există evaluări

- Report of ROBIDocument21 paginiReport of ROBIShironamhin Light100% (1)

- Individual ReportDocument12 paginiIndividual ReportVinay AttriÎncă nu există evaluări

- Advance PM Initialization 2021 VFDocument17 paginiAdvance PM Initialization 2021 VFkhanhÎncă nu există evaluări

- Agile UP Intro-LarmanDocument25 paginiAgile UP Intro-LarmanFenil Desai100% (1)

- HR-JIO LTD NewDocument1 paginăHR-JIO LTD Newsaikishore.dÎncă nu există evaluări

- SBL Notes (1) - Hassan DossaniDocument195 paginiSBL Notes (1) - Hassan DossaniKevinÎncă nu există evaluări

- Project Associate Case StudyDocument5 paginiProject Associate Case StudyBharani KrishnaÎncă nu există evaluări

- Fed ExDocument16 paginiFed ExrahulÎncă nu există evaluări

- SPACE Matrix: Internal Analysis: External AnalysisDocument3 paginiSPACE Matrix: Internal Analysis: External AnalysisMuhammad Faiez HazlyÎncă nu există evaluări

- 1-Tn - ss005 - E1 - 1 ZXWN MSC Server Dimensioning (New Edit) - 73Document64 pagini1-Tn - ss005 - E1 - 1 ZXWN MSC Server Dimensioning (New Edit) - 73AsaadAdeepÎncă nu există evaluări

- 7 1 CarrefourDocument4 pagini7 1 CarrefourRoxana RobuÎncă nu există evaluări

- Project Management: Chapter 2: Project Stakeholder ManagmentDocument26 paginiProject Management: Chapter 2: Project Stakeholder ManagmentTâm ĐặngÎncă nu există evaluări

- 2023 First Team Assignment M1Document3 pagini2023 First Team Assignment M1Wanjiru R0% (1)

- ITI LTDDocument20 paginiITI LTDgiridhar bv100% (2)

- A Generic Case Study On Microtalk Communications PVT LTD and Its ProductsDocument32 paginiA Generic Case Study On Microtalk Communications PVT LTD and Its ProductsSayantan DasÎncă nu există evaluări

- Business DHLDocument3 paginiBusiness DHLAshwin RacerÎncă nu există evaluări

- Invitation To Bid: General GuidelinesDocument25 paginiInvitation To Bid: General GuidelinesGregoria ReyesÎncă nu există evaluări

- Assignment DFA6127Document3 paginiAssignment DFA6127parwez_0505Încă nu există evaluări

- Case Study: NmimsDocument5 paginiCase Study: NmimsJAYESH VAYAÎncă nu există evaluări

- Create A Database Schema and Table Relationships For A Logistic Company's DataDocument7 paginiCreate A Database Schema and Table Relationships For A Logistic Company's DatavishnuvkÎncă nu există evaluări

- Addcom Product Line CardDocument4 paginiAddcom Product Line CardSuttisak SuriyachanhomÎncă nu există evaluări

- Training Report of Iti MankapurDocument48 paginiTraining Report of Iti Mankapurbaladivya550% (2)

- Interloop LimitedDocument7 paginiInterloop LimitedHamza SiddiquiÎncă nu există evaluări

- Exercise Chapter 5 MADocument5 paginiExercise Chapter 5 MASOK JING ROUÎncă nu există evaluări

- D23 Mock 2 Corjets PLUS Marking Scheme and Suggested Solutions WhereDocument33 paginiD23 Mock 2 Corjets PLUS Marking Scheme and Suggested Solutions Wherebizuayehu.fassil65Încă nu există evaluări

- Mckinsey - Transforming Advanced Manufacturing Through Industry 4 Point 0 - 2022Document7 paginiMckinsey - Transforming Advanced Manufacturing Through Industry 4 Point 0 - 2022Victor Cervantes AÎncă nu există evaluări

- CV Akram EngDocument2 paginiCV Akram EngAkram DridiÎncă nu există evaluări

- LC Concept Profile 1Document7 paginiLC Concept Profile 1Bạch NguyễnÎncă nu există evaluări

- Title: To Develop Marketing Strategy For The Infrastructure Storage and Security System in Effective MannerDocument16 paginiTitle: To Develop Marketing Strategy For The Infrastructure Storage and Security System in Effective MannerTamil VelanÎncă nu există evaluări

- CBS Case Competition 2007Document20 paginiCBS Case Competition 2007thanhÎncă nu există evaluări

- Integer Linear Programming: ILP Milp BilpDocument22 paginiInteger Linear Programming: ILP Milp BilpYến Oanh Nguyễn LêÎncă nu există evaluări

- Lecture 2 - Business Application of FintechDocument19 paginiLecture 2 - Business Application of Fintechanon_888020909Încă nu există evaluări

- Marketing Mix at JerseyDocument86 paginiMarketing Mix at JerseynaveenÎncă nu există evaluări

- Funtime Inc Manufactures Video Game Machines Market SaturatiDocument2 paginiFuntime Inc Manufactures Video Game Machines Market SaturatiAmit PandeyÎncă nu există evaluări

- Atta Food Traders and Rice Mill P.V.T (LTD) : Pakistan's Contribution in Rice IndustryDocument10 paginiAtta Food Traders and Rice Mill P.V.T (LTD) : Pakistan's Contribution in Rice IndustryTalha RiazÎncă nu există evaluări

- Prelims Finals InvestmentDocument45 paginiPrelims Finals InvestmentGelo AgcaoiliÎncă nu există evaluări

- Lijjat PapadDocument14 paginiLijjat PapadKeyur Popat100% (1)

- Soa 0020230429297Document1 paginăSoa 0020230429297Redilyn Corsino Agub0% (1)

- Jensen-1991-Corporate Control and The Politics of FinanceDocument23 paginiJensen-1991-Corporate Control and The Politics of Financeebrahimnejad64Încă nu există evaluări

- IKEA CaseDocument2 paginiIKEA CaseHoneyÎncă nu există evaluări

- Ipsos SEA Ahead - Shift + Sentiments - 20211209Document35 paginiIpsos SEA Ahead - Shift + Sentiments - 20211209Dhiyaa' Ayu Widaad CitraÎncă nu există evaluări

- Employees' State Insurance General Regulations 1950Document102 paginiEmployees' State Insurance General Regulations 1950P VenkatesanÎncă nu există evaluări

- Truearth Healthy Foods: Market Research For A New Product IntroductionDocument5 paginiTruearth Healthy Foods: Market Research For A New Product IntroductionFree Guy100% (1)

- SolutionManual (Project Managment)Document9 paginiSolutionManual (Project Managment)Ayan Ahmed0% (1)

- Summer Internship Report at Future Generali Insurance LTDDocument44 paginiSummer Internship Report at Future Generali Insurance LTDpratiksha2467% (3)

- Ican SyllabusDocument94 paginiIcan Syllabusolawax5100% (4)

- External Analysis: Customer AnalysisDocument18 paginiExternal Analysis: Customer AnalysisSaron GebreÎncă nu există evaluări

- Labor Law Chapter-2Document9 paginiLabor Law Chapter-2Toriqul IslamÎncă nu există evaluări

- Causes of Industrial Backward NessDocument2 paginiCauses of Industrial Backward NessFawad Abbasi100% (1)

- Overview Record To ReportDocument21 paginiOverview Record To Reportsharmavarun01Încă nu există evaluări

- Schumpeter's Theory of Economic Development - EconomicsDocument24 paginiSchumpeter's Theory of Economic Development - EconomicsreggydevvyÎncă nu există evaluări

- TTF AuditingDocument19 paginiTTF AuditingThiện NhânÎncă nu există evaluări

- LVB Moratorium To End As Cabinet Okays Dbs Deal Unacademy Raises Fresh Funds at $2 BN Valuation Up1Document18 paginiLVB Moratorium To End As Cabinet Okays Dbs Deal Unacademy Raises Fresh Funds at $2 BN Valuation Up1makiÎncă nu există evaluări

- Cash Flow StatementDocument11 paginiCash Flow StatementHemanshu MehtaÎncă nu există evaluări

- Fsac 230Document11 paginiFsac 230mahssounys.mÎncă nu există evaluări

- Final AssignmentDocument20 paginiFinal AssignmentTabish KhanÎncă nu există evaluări

- General Journal: Description Post Ref Dr. Cr. DateDocument14 paginiGeneral Journal: Description Post Ref Dr. Cr. DateRizki MuhammadÎncă nu există evaluări

- BANKING ALLIED LAWS 10 November 2019Document19 paginiBANKING ALLIED LAWS 10 November 2019David YapÎncă nu există evaluări

- Coal India Limited ProjectDocument61 paginiCoal India Limited ProjectShubham KhuranaÎncă nu există evaluări

- Lic Final ProjectDocument80 paginiLic Final Projectshaibaaz_ibm797354100% (3)

- Strategy Session 3Document3 paginiStrategy Session 3Maria Alejandra RamirezÎncă nu există evaluări

- Week 1 LabDocument3 paginiWeek 1 LabSara ThompsonÎncă nu există evaluări

- H C D C: OLY Ross OF Avao OllegeDocument8 paginiH C D C: OLY Ross OF Avao OllegeFretchiel Mae SusanÎncă nu există evaluări

- Build Your StaxDocument1 paginăBuild Your StaxdesignexampreparationÎncă nu există evaluări

- Cambridge O Level: Accounting 7707/22 October/November 2022Document16 paginiCambridge O Level: Accounting 7707/22 October/November 2022Marlene BandaÎncă nu există evaluări