Documente Academic

Documente Profesional

Documente Cultură

OPGW Bolted Dead End Instructions

Încărcat de

Andika HandyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

OPGW Bolted Dead End Instructions

Încărcat de

Andika HandyDrepturi de autor:

Formate disponibile

Installation Instructions

INS-ACA015

Installation Instructions for

OPGW Bolted Dead End

Procedure

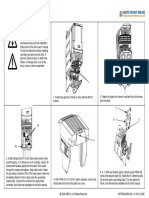

1. Disassemble dead end. Remove one bolt from the same side of each keeper. Loosen other bolts to permit conductor to be placed in the conductor

groove. If keepers and bolts are removed completely, care must be taken to return the keeper closest to the span end of the dead end to its original

position (chamfered edge towards span). Remove clevis hardware.

2. Straighten conductor removing set caused by reel.

3. Place conductor into groove and install dead end keepers with washers break-away bolts.

4. Care should be taken during installation to maintain the keepers squarely on the conductor with equal clearance on both sides of conductor.

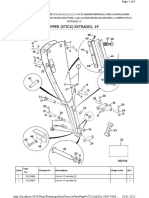

5. Starting at the span end of the dead end, follow the tightening sequence shown below, tighten all bolts to approximately 5 ft.-lbs. (7 Nm for metric).

Repeat to approximately 25 ft.-lbs. (33 Nm for metric). Then final pass until break-away head breaks off. The sequential pattern is set up to equalize

the load in each bolt and to prevent the deadend keepers from cocking to one side during installation.

2 3 6 7 10 11 13

Keepers

Tightening

Must Start at

Span End of

Deadend

1 4 5 8 9 12 14

Break-away Bolt

Chamfered Edge

6. If cable guide is not supplied, proceed to step 8. Cable guide, if used, is provided to insure that minimum bending radius of OPGW is not violated. Care

should be exercised to avoid undue stress on cable guide. Note: cable guide is not a structural member and adds nothing to the holding strength of the

clamp. Train conductor to make it bottom along the cable guide groove. This is important to assure clearance for the link plate/connecting hardware.

7. After placing OPGW into cable guide groove, install cable guide keeper with lockwashers and green break-away bolts alternately tightening bolts

by 2 ft.-lbs. Repeat until break-away head breaks off. Care should be taken during installation to maintain the keeper squarely on the conductor

with equal clearance on both sides of conductor.

8. Install connecting hardware with dead end clevis bolt. Check for clearance with OPGW.

9. If re-installation is necessary, bolts should be torqued according to the chart below. Installation with a torque wrench must be performed when break-away

bolt is not present.

BOLT SIZE BOLT BREAK-AWAY Link Plate 5/8” Break-away Bolt (M14-Metric)

(IN.) COLOR TORQUE (FT-LBS.) (Ordered Separately)

1/2 Black 27-32 Keeper

5/8 Red 35-40

5/8 Blue 40-45

3”

(76.2 mm)

continued

www.AFLglobal.com or 800-866-7385 © 2008, AFL, all rights reserved. Revision 3, 4.12.19

Specifications are subject to change without notice.

1

Installation Instructions

INS-ACA015

Installation Instructions for

OPGW Bolted Dead End

10. Attach grounding lug to grounding pad on side of dead end body (using 1/2”-13) if

grounding is required. Ground wire assembly must be long enough such that 12” of free

slack wire extends directly down from the suspension grounding pad before looping back up

to the adjacent structure attachment point.

Reduce 12” of Slack

bending stress

www.AFLglobal.com or 800-866-7385 © 2008, AFL, all rights reserved. Revision 3, 4.12.19

Specifications are subject to change without notice.

2

S-ar putea să vă placă și

- Same Laser 110-130-150 Workshop ManualDocument439 paginiSame Laser 110-130-150 Workshop ManualAgro Zamora100% (7)

- HFC1035K (D8171) Workshop ManualDocument445 paginiHFC1035K (D8171) Workshop Manualsamuel ortega100% (4)

- Volvo Service Manual Fault Tracing Repairs Maintenance TP30518-10Document168 paginiVolvo Service Manual Fault Tracing Repairs Maintenance TP30518-102bjorn92% (12)

- Kawasaki ZX9R 98-99Document307 paginiKawasaki ZX9R 98-99motomech100% (3)

- Mikado LOGO 600SE ManualDocument13 paginiMikado LOGO 600SE Manualr521999Încă nu există evaluări

- AT520CT Users ManualDocument14 paginiAT520CT Users ManualAlbert SomendraÎncă nu există evaluări

- SAT IS enDocument5 paginiSAT IS enedgardo valdiviaÎncă nu există evaluări

- Jackscrew Backshell Installation Instructions: 190-00313-11 October, 2017 Revision EDocument24 paginiJackscrew Backshell Installation Instructions: 190-00313-11 October, 2017 Revision EAlex AnishchykÎncă nu există evaluări

- Engine ASZDocument52 paginiEngine ASZkalleanka00100% (1)

- WA380-6 S/N H60051 - UpDocument1.489 paginiWA380-6 S/N H60051 - UpRAMON TEIXIDOR100% (1)

- Engine M35a2 PDFDocument260 paginiEngine M35a2 PDFhilalmelhem100% (1)

- 657-13 - 657-21 Snow Plow Hdi - FrontierDocument7 pagini657-13 - 657-21 Snow Plow Hdi - Frontiercristi_stoiciucÎncă nu există evaluări

- Installation PracticeDocument16 paginiInstallation PracticeramsesiÎncă nu există evaluări

- Pandrol DFC - Operation & Maintenance ManualDocument20 paginiPandrol DFC - Operation & Maintenance ManualOon Chee Koon100% (1)

- Make-Up Procedure Mu-Cplg-004Document7 paginiMake-Up Procedure Mu-Cplg-004huyenhvtc252Încă nu există evaluări

- Manual ConectoresDocument19 paginiManual ConectoresLuis EduardoÎncă nu există evaluări

- Inst OAC Steel Tube-GB-05Document7 paginiInst OAC Steel Tube-GB-05kobus8180Încă nu există evaluări

- FT1390-2-9-500 Crimp MachineDocument8 paginiFT1390-2-9-500 Crimp MachineJulián Ricardo RodriguezÎncă nu există evaluări

- Fanuc R30iA LR Mate 200 IC J3 Motor and Reducer ReplacementDocument5 paginiFanuc R30iA LR Mate 200 IC J3 Motor and Reducer ReplacementAndrés M. ReyesÎncă nu există evaluări

- AG SL: Installation, Operation and Maintenance Manual Stop Gate Stop LogDocument15 paginiAG SL: Installation, Operation and Maintenance Manual Stop Gate Stop LogMohamed Ismail ShehabÎncă nu există evaluări

- AG SL: Installation, Operation and Maintenance Manual Stop Gate Stop LogDocument15 paginiAG SL: Installation, Operation and Maintenance Manual Stop Gate Stop Logkim haroldÎncă nu există evaluări

- OPGWInstallation InstructionsDocument15 paginiOPGWInstallation InstructionsjorgemachigueÎncă nu există evaluări

- BX1150 1Document13 paginiBX1150 1Виталий ЦаринныйÎncă nu există evaluări

- Cc-Link IoDocument181 paginiCc-Link IoJinKi LeeÎncă nu există evaluări

- Halat KlemensDocument2 paginiHalat Klemensakın ersözÎncă nu există evaluări

- OPGW Installation Manual v2 6 12Document15 paginiOPGW Installation Manual v2 6 12gaurang1111Încă nu există evaluări

- Mini Skalper W EZ Torque Rev9 152Document10 paginiMini Skalper W EZ Torque Rev9 152Dug1as GreyÎncă nu există evaluări

- MUL1-R1 Installation Instructions: ACS150, ACS310, ACS320, ACS350 and ACS355Document4 paginiMUL1-R1 Installation Instructions: ACS150, ACS310, ACS320, ACS350 and ACS355Mani RichardÎncă nu există evaluări

- JC2013 JAW CRUSHER 200 X 130 All Voltages (Rev3)Document15 paginiJC2013 JAW CRUSHER 200 X 130 All Voltages (Rev3)sharedfilepcÎncă nu există evaluări

- Optional Parts: 4-3. External Electronic Expansion Valve Kit For Indoor Unit CZ-P56SVK2, CZ-P160SVK2 (For R410A)Document3 paginiOptional Parts: 4-3. External Electronic Expansion Valve Kit For Indoor Unit CZ-P56SVK2, CZ-P160SVK2 (For R410A)Priesilia PresleyÎncă nu există evaluări

- Cam Follower Suggested Installation Procedure: Power Transmission SolutionsDocument2 paginiCam Follower Suggested Installation Procedure: Power Transmission SolutionsHamdi AslanÎncă nu există evaluări

- Installation and Operation: General MountingDocument9 paginiInstallation and Operation: General MountingLarry JorgensonÎncă nu există evaluări

- Pro-Ject Essential/Phono USB: Instructions For UseDocument8 paginiPro-Ject Essential/Phono USB: Instructions For UseAleksandar KeracÎncă nu există evaluări

- MGF 305 UC Brace Tech File 2019 PDFDocument12 paginiMGF 305 UC Brace Tech File 2019 PDFLingesh SivaÎncă nu există evaluări

- P130 VAR 00-Manual-EnDocument6 paginiP130 VAR 00-Manual-Enalaynnastaabx786Încă nu există evaluări

- ABB Drives ACS150 ACS350 Installation GuideDocument4 paginiABB Drives ACS150 ACS350 Installation GuideZakaria DjellabÎncă nu există evaluări

- Clesta 511, 512, 515, 517N, 518, 530X Light Inst & Operation Manual E120105Document32 paginiClesta 511, 512, 515, 517N, 518, 530X Light Inst & Operation Manual E120105Taha ImamiÎncă nu există evaluări

- Technical Info 02 2008b AD Hub ReplacementDocument11 paginiTechnical Info 02 2008b AD Hub ReplacementRafa DiazÎncă nu există evaluări

- Ford Installation InstructionDocument14 paginiFord Installation Instructiontxr qcÎncă nu există evaluări

- Cable Care Best ParcticeDocument4 paginiCable Care Best ParcticeHariomÎncă nu există evaluări

- Mikado LOGO 550SE ManualDocument13 paginiMikado LOGO 550SE Manualr521999Încă nu există evaluări

- TH 3jrs ManualDocument11 paginiTH 3jrs ManualOscar NavaÎncă nu există evaluări

- Et500plus Install ManualDocument26 paginiEt500plus Install ManualDirk HennÎncă nu există evaluări

- 625-43 - 825-42K Supertrack Kit (Rev. 04-2015)Document6 pagini625-43 - 825-42K Supertrack Kit (Rev. 04-2015)George finkleÎncă nu există evaluări

- Track Shop Manual 2011 Lynx XU - ACE 600 - 1200 4-TEC enDocument2 paginiTrack Shop Manual 2011 Lynx XU - ACE 600 - 1200 4-TEC enSkorost SkorostÎncă nu există evaluări

- Opticom Rack Mount Fiber Enclosures: Assembly ViewDocument8 paginiOpticom Rack Mount Fiber Enclosures: Assembly ViewmrdcshoesÎncă nu există evaluări

- 120A2A Distribution PDFDocument49 pagini120A2A Distribution PDFnachoÎncă nu există evaluări

- 005 038Document11 pagini005 038shaicoÎncă nu există evaluări

- Recommended Field Running Procedure For EUE-PA ConnectionsDocument3 paginiRecommended Field Running Procedure For EUE-PA ConnectionsHanyÎncă nu există evaluări

- Digitilt Horizontal Probe Manual 2006Document17 paginiDigitilt Horizontal Probe Manual 2006Mahesh JalluÎncă nu există evaluări

- Omega Elastomeric Couplings - Installation ManualDocument2 paginiOmega Elastomeric Couplings - Installation ManualmmkattaÎncă nu există evaluări

- Challenger Vs10 IOMDocument16 paginiChallenger Vs10 IOMLeo ForteyÎncă nu există evaluări

- Anexo 03 Instructivo Instalación Herraje de Suspensión OPGW - ADSSDocument4 paginiAnexo 03 Instructivo Instalación Herraje de Suspensión OPGW - ADSSDidier solanoÎncă nu există evaluări

- Open PDFDocument2 paginiOpen PDFmahendrandsÎncă nu există evaluări

- BOPP - Type - GK-Ops-Maint Procedure RevisedDocument16 paginiBOPP - Type - GK-Ops-Maint Procedure RevisedTarasÎncă nu există evaluări

- R8iMaintinstr 00262693Document11 paginiR8iMaintinstr 00262693Anonymous 9WNqHZÎncă nu există evaluări

- 1521 PS 0008 GS4 GS6 Manual Issue 3Document25 pagini1521 PS 0008 GS4 GS6 Manual Issue 3olumideÎncă nu există evaluări

- CrutchfieldMasterSheet 0000530033Document10 paginiCrutchfieldMasterSheet 0000530033martinÎncă nu există evaluări

- MIN - 549410 - Poseidon Pegasus Seals (Aft) Installation & Maintenance ...Document9 paginiMIN - 549410 - Poseidon Pegasus Seals (Aft) Installation & Maintenance ...Marlon Alejandro Arboleda TapiaÎncă nu există evaluări

- F550 User Manual v1.9 en PDFDocument7 paginiF550 User Manual v1.9 en PDFAnonymous MGQjG1Încă nu există evaluări

- TELESCOPIC ShortCuts-1Document15 paginiTELESCOPIC ShortCuts-1Vailson AraújoÎncă nu există evaluări

- Dismantling Information Foruse by Professionalrecyclers: Original Manual Issue Date: 2021.05Document37 paginiDismantling Information Foruse by Professionalrecyclers: Original Manual Issue Date: 2021.05DecebalÎncă nu există evaluări

- Instruction Manual Professional Cord Reel: WarningDocument24 paginiInstruction Manual Professional Cord Reel: WarningEstrella CarcamoÎncă nu există evaluări

- EC - OI-II, EC-01 Electronics Internatonal IncDocument47 paginiEC - OI-II, EC-01 Electronics Internatonal IncRenato ParetaÎncă nu există evaluări

- Terminales Termocontractiles PDFDocument18 paginiTerminales Termocontractiles PDFcbeltranochoaÎncă nu există evaluări

- REPORTDocument8 paginiREPORTSaksham MalhotraÎncă nu există evaluări

- FSB 5406bDocument20 paginiFSB 5406balfonsoÎncă nu există evaluări

- Carraro 26.22Document9 paginiCarraro 26.22Mindaugas MonkevičiusÎncă nu există evaluări

- Cambio Alisson15482 - MergedDocument22 paginiCambio Alisson15482 - MergedJoao Victor Vargas RosaÎncă nu există evaluări

- Iveco Daily Euro 4Document112 paginiIveco Daily Euro 4FeitozaÎncă nu există evaluări

- Fag Split SRB PDFDocument30 paginiFag Split SRB PDFAlain Gonzalo Larama CastroÎncă nu există evaluări

- Detroit - 60 Series Service Tech ManualDocument4 paginiDetroit - 60 Series Service Tech Manualdot341100% (1)

- E20100617739 - 1 Removal Tool For F.inj - ValveDocument13 paginiE20100617739 - 1 Removal Tool For F.inj - ValveIvanciu Ionut-FabianÎncă nu există evaluări

- Asber Easy-H500Document26 paginiAsber Easy-H500Juan GtzÎncă nu există evaluări

- Kotači Od Poliamida Velike NosivostiDocument8 paginiKotači Od Poliamida Velike NosivostidinvalÎncă nu există evaluări

- Compresor TuFlo 750-RepDocument40 paginiCompresor TuFlo 750-RepRimbert100% (1)

- 9812/0010 B4-6-1 Dipper (Stick) Extradig, 14'Document4 pagini9812/0010 B4-6-1 Dipper (Stick) Extradig, 14'Виталий РогожинскийÎncă nu există evaluări

- Ap 03 101Document36 paginiAp 03 101TariqÎncă nu există evaluări

- Gelen Malzeme Li̇stesi̇Document5 paginiGelen Malzeme Li̇stesi̇Uğur ZoroğluÎncă nu există evaluări

- ZKL MRP Pricelist 2011Document55 paginiZKL MRP Pricelist 2011Mahesh Daxini Thakker100% (4)

- Shimano Stella SW Stl5000swbxgDocument1 paginăShimano Stella SW Stl5000swbxgWk NgÎncă nu există evaluări

- Super ChargersDocument12 paginiSuper ChargersSealtiel1020Încă nu există evaluări

- 21-Ryan Lutz Engine DiagramDocument1 pagină21-Ryan Lutz Engine DiagramyogapostÎncă nu există evaluări

- Chapter 03 Electronic Fuel InjectionDocument44 paginiChapter 03 Electronic Fuel Injectioncarlos galdamezÎncă nu există evaluări

- Pto Hydraulic CatalogDocument48 paginiPto Hydraulic Catalogjesus silvaÎncă nu există evaluări

- Chain Coupling 243Document1 paginăChain Coupling 243NHÂN LÊ HOÀNGÎncă nu există evaluări

- WORKSHOP MANUAL MAXX FORCE 4.8-7.2 Parte 2Document119 paginiWORKSHOP MANUAL MAXX FORCE 4.8-7.2 Parte 2Daniel Graterol0% (1)

- Chrysler/Dodge StratusDocument98 paginiChrysler/Dodge StratusDamir Nišić100% (1)

- Twin Slash Duals Installation Instructions Part# 16853Document5 paginiTwin Slash Duals Installation Instructions Part# 16853Giovani DiasÎncă nu există evaluări