Documente Academic

Documente Profesional

Documente Cultură

TDS Nitoflor SL3000 UT Saudi Arabia

Încărcat de

ShaikhRizwanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TDS Nitoflor SL3000 UT Saudi Arabia

Încărcat de

ShaikhRizwanDrepturi de autor:

Formate disponibile

Fosroc® Nitoflor SL3000 UT constructive solutions

Flow applied medium to heavy duty

polyurethane floor topping

Description

Typical Properties

Nitoflor SL3000 UT is a medium-heavy duty, flow applied

polyurethane floor topping system designed with the highest BS 8204-6 (3 mm) Type 5 Floor (medium duty)

order of durability to resist abrasion, chemical attack and BS 8204-6 (4-6mm) Type 7 Floor (heavy duty)

other physical aggression. Compressive Strength,

ASTM C109, 28 days, MPa 50.8

Typical application areas include: BS6319-2, 28 days, MPa 54

Tensile Strength,

Food and beverage production

BS6319-7, MPa 6.8

Dairy processing Flexural Strength,

Pharmaceutical BS6319-3, MPa 17.9

Density

Engineering process areas (ASTM D792), kg/ m3 1968

Dynamic elastic modulus

Appearance (ASTM C597), MPa 6266

Flexural Modulus

Smooth matt finish. (ASTM C580), MPa 3295

Taber abrasion resistance

Colours (ASTM D4060)

CS17 wheels, mg/1000 cycles 125

Available in the following standard colours: Dark Grey, Mid Water absorption

Grey, Blue, Dark Brown, Buff, Yellow, Red and Green. (ASTM C413) % 0.06

Thermal Expansion Coefficient

Advantages (BS EN1770), /ºC 5.6 x 10-5

Impact Resistance

Hard wearing: provides a durable, high resistance to (ASTM D2794), Joules

traffic abrasion and low maintenance cost option 3mm thickness 8.1

6mm thickness 10.8

Easily laid: designed for quick and easy laying Thermal conductivity

(Thermtest TPS method), W/m. K 1.1

Non-slip: good gripping surface to both vehicular and Slip Resistance (ASTM E303)

pedestrian traffic Dry, S96 32 (moderate slip risk)

Reaction To Fire (BS476-7)

Moisture insensitive: can withstand high residual Flame Spread Classification Class 2

moisture in concrete Cleanability Pass

Non-taint property

Hygienic: provides a dense, taint-free and impervious (IS-8639, 24 hours) Pass

flooring which is easily to clean Ideal application temperature

range 15ºC - 30ºC

Seamless: no joints, providing a complete protection

Note: The typical physical properties given above are

Attractive: available in wide range of colours to improve derived from testing in a controlled laboratory environment.

the working environment and identity Results derived from testing field-applied samples may

vary, dependent on actual site conditions.

Thickness

The slip resistance figures given above are affected by

3 – 6 mm application techniques and prevailing site conditions. Slip

resistance can reduce over time due to poor maintenance,

Substrates general wear or surface contaminants. Nitoflor SL3000 UT

has a smooth finish so can be expected to become slippery

Concrete, polymer modified screeds, grano concrete and when wet. Good housekeeping practices must be observed.

other construction substrates (for more details on other

substrates, please consult local Fosroc office).

constructive solutions Page 1

Fosroc® Nitoflor SL3000 UT constructive solutions

Chemical Resistance

Nitoflor SL3000 UT is resistant to a wide range of commonly 24hr Exposure 72hr Exposure

used chemicals in the food, dairy and pharmaceutical Chemical Result Temp Result Temp

industries, and engineering workshops. Good housekeeping Lard R 50°C R 50°C

practices should be employed. Please consult Fosroc for Lactic acid R 50°C R 50°C

further advice. (25%)

Lard R 50°C R 50°C

Some staining or discolouration may occur with some Lime juice R 50°C R 50°C

chemicals, depending on dwell time, temperature, type of Linseed oil R 50°C R 50°C

chemical and degree of housekeeping employed. This does Milk R 50°C R 50°C

not necessarily affect the product service integrity or Mineral oil R 50°C R 50°C

durability. Motor oil R 50°C R 50°C

Nitric acid R-DIS 25°C NR 25°C

Chemical Resistance Chart (30%)

N-Methyl R-DIS 50°C R-C 50°C

ASTM D 1308-Spot Test pyrollidone

Phosphoric acid R 50°C R 50°C

24hr Exposure 72hr Exposure

(50%)

Chemical Result Temp Result Temp

Pine oil R 50°C R 50°C

Acetic acid (30%) R-DIS 50°C R-DIS 50°C

Pottasium R 50°C R 50°C

Acetic acid (10%) R-DIS 50°C R-DIS 50°C

Hydroxide

Hydrochloric acid R 50°C R-DIS 50°C (50%)

(10%) Skydrol R-DIS 50°C R-DIS 50°C

Hydrochloric acid R 50°C R-DIS 50°C Sodium R 50°C R 50°C

(4%) bicarbonate

Sulphuric acid R 50°C R-DIS 50°C solution

(20%) (saturated)

Sulphuric acid R 50°C R-DIS 50°C Sodium R 50°C R 50°C

(50%) hydroxide (50%)

Ethylene glycol R 50°C R 50°C Sodium R 50°C R 50°C

Acetone R 50°C R 50°C hypochlorite

Brake fluid R 50°C R-DIS 50°C (15%)

Braine (satured) R 50°C R 50°C Sugar solution R 50°C R 50°C

Castor oil R 50°C R 50°C (30%)

citric acid (60%) R 50°C R 50°C Sunflower seed R 50°C R 50°C

coconut oil R 50°C R 50°C oil

cod liver oil R 50°C R 50°C Trichloro R 50°C R 50°C

ethylene

Copper sulphate R 50°C R 50°C

solution (30%) Vegetable oil R 50°C R 50°C

Deionised water R 50°C R 50°C White spirit R 50°C R 50°C

Grape juice R 50°C R 50°C Xylene R 50°C R 50°C

Groundnut oil R 50°C R 50°C

Legend:

Diesel oil R 50°C R 50°C

Ethanol R 50°C R 50°C

R : Resistant

Iso-Proponal R 50°C R 50°C R-DIS : Resistant – Discolouration only

Kerosene R 50°C R 50°C R-C : Resistant – Conditional; discolouration and/or

Methanol R 50°C R 50°C slight softening or swelling

Methyl isobutyl R 50°C R 50°C NR : Not Resistant

ketone

Methylene chloride R 50°C R 50°C

Petrol R 50°C R 50°C

(unleaded)

Hydrogen peroxide 50°C R-DIS 50°C

(30%)

Olive oil R 50°C R 50°C

Lactic acid (85%) 50°C R-DIS 50°C

Lactic acid (25%) R 50°C R 50°C

constructive solutions Page 2

Fosroc® Nitoflor SL3000 UT constructive solutions

Design criteria The product can be applied outside this ideal temperature

range (subject to a minimum of 10ºC and maximum of

Nitoflor SL3000UT is designed for application at a nominal 34ºC). Surface finish may be subject to spike roller marks;

thickness between 3 mm to 6 mm. thickness design criteria however, in such cases physical properties and durability of

would depend on service temperature and chemical the floor are not affected.

exposures.

Surface Preparation

Thickness selection

Inadequate preparation may lead to loss of adhesion and

Service Temperature -5ºC to +60ºC : 3-4 mm failure. With flow-applied systems, there is a tendency for

Service Temperature -25ºC to +90ºC : 6 mm the finish to mirror imperfections in the substrate. Grinding

or light vacuum-contained shot-blasting is therefore

Important Notes: preferred over planing for these systems. Percussive

scabbling or acid etching is not recommended.

Despite Nitoflor SL3000UT is suitable for use @ service

temperature range from -25ºC to +90ºC @ 6 mm, it’s not Anchorage grooves should be cut to a minimum depth and

recommended for thermal shock conditions. width of 2x the flooring thickness to be laid, at the edges,

day joints, up-stands, drains, doorways and at regular

For application intended in areas continuously subjected to points across the floor, and all debris removed.

cold or hot conditions, please ensure strict adherence to

application procedure for cold and hot conditions. New concrete floors

Cure Schedule The base should be a minimum of Grade RC30 of BS 8500-

2: 2002 and should not contain a water repellent admixture.

Note: usable working life of material following mixing and The surface strength when assessed using a rebound

immediate spreading as per the application instructions hammer should be above 25 or the surface tensile strength

should exceed 1.5 MPa.

Finished floor:

The laitance and any surface sealer or curing membrane

should be removed by mechanical means such as shot-

Cure time to light pedestrian traffic 12 hours

blasting or grinding to expose the coarse aggregate.

Cure time to light wheeled traffic 24 hours

Cure time to medium duty traffic 48 hours After surface preparation, all loose debris and dirt should be

Cure time to heavy duty traffic 7 days removed by vacuum equipment.

Full chemical resistance 7 days For concrete bases in contact with the ground, a damp-

proof membrane should have been incorporated into the

Note: The above cure times are approximate and given as a slab design, in accordance with the requirements of CP102

guide only. These times can vary due to prevailing site (Code Of Practice For The Protection Of Buildings Against

conditions. Water From The Ground).

Finished floor: Old concrete floors

Nitoflor SL3000 UT 15 – 20 minutes All laitance and surface contamination should be removed

by mechanical means such as shot-blasting or diamond

Instructions for preparation and use grinding to expose the coarse aggregate.

Fosroc Nitoflor SL3000 UT should be installed by specialist After surface preparation, all loose debris and dirt should be

applicators, whom must follow the procedures, laid down in removed by vacuum. Heavy oil or grease deposits should

guideline documents such as BS 8204 Part 6:2008 Code of be removed either mechanically, or by steam cleaning, or

practice – Synthetic Resin Floorings, and the Fosroc Method by biological treatment, then by high pressure water blasting

Statement - PU Cementitious Flooring. followed by the application of a penetrating primer.

Application Conditions Where oil or grease contamination has been severe or of

long duration, these methods may prove unsatisfactory and

Ideal ambient, material and substrate temperature range is in these cases removal of the affected base is necessary.

15 - 30ºC to achieve best results. The product components

should be stored in a cool area (or warm area in the case of In existing buildings without a functioning damp-proof

low ambient temperature), using localised forced cooling or membrane, the application of a surface-applied membrane

heating equipment as appropriate, in order to bring product should be considered. Hydrostatic pressure may, under

temperature within the ideal range. certain circumstances, cause adhesive failure between the

flooring and the substrate.

constructive solutions Page 3

Fosroc® Nitoflor SL3000 UT constructive solutions

Where this is likely to occur, such as in areas where the The finished floor should be protected from other trades

ground water table is higher than the substrate, and where using Kraft paper or similar breathable material. Polythene

external tanking has not been applied, pressure relief must should not be used. Protect the installed floor from damp,

be provided, e.g. by direct drainage. condensation and water for at least 4 days.

A close visual examination should be made to verify Applications in Areas Intended for Hot or Cold

cleanliness and soundness. Any weak or suspect areas Conditions

should be repaired.

For these areas Fosroc must be consulted before

Application Instructions proceeding.

Priming/ Scratch coating Estimating

Nitoflor SL3000 UT should be applied as a primer/scratch Supply

coat at a coverage rate of up to a nominal 1 mm thickness;

actual coverage rate will depend on concrete surface texture Fosroc Nitoflor SL3000 UT 20.25 kg packs

and porosity. This scratch coat is designed to prime and seal Fosroc Nitoflor Coving UT 14 kg packs

the floor. Mix (see Application below) and spread evenly by

trowel. Fosroc Nitoflor HB200 UT 4 kg packs

The scratch coat should be allowed to cure for 12 - 48 hours Coverage

at 20ºC before applying the Nitoflor SL3000 UT. If the scratch

coat has been allowed to cure for >48 hours, then the coat Coverage appropriate to

must be thoroughly abraded and a fresh layer of scratch coat Nitoflor SL3000 UT

texture and porosity of floor

applied. (primer/scratch coat)

Nominal 10 m²/pack

If severe pin-holing is evident in the cured scratch coat, 3.5 m²/pack at 3 mm

Nitoflor SL3000 UT

indicating that air is rising from the substrate, then remedial 2.5 m²/pack at 4 mm

(floor topping)

action should be taken. Contact your local Fosroc office for 1.7 m²/pack at 6 mm

advice. Failure to do so may result in increased risk of pin- 1.8 – 2.0 kg/m²/mm

holing of the surface topping. Nitoflor Coving UT

thickness

15m²/ pack/coat

Coving*

Nitoflor HB 200 UT (DFT per coat~140

microns)

Nitoflor Coving UT : Coving Mortar

Nitoflor HB 200 UT : Roller applied high build coving coating

Note: Coverage figures given are theoretical. Actual site

*Refer to individual technical datasheets for the application practical coverage figures may vary, due to wastage factors

and the type and condition of the substrate.

instructions.

Cleaning

Application of Nitoflor SL3000 UT topping

Regular cleaning is essential to maintain and enhance the

Fosroc Nitoflor SL3000 UT is a three-component product. life expectancy, slip resistance and appearance of the floor.

Fosroc Nitoflor SL3000 UT can be easily cleaned using

A forced-action rotary paddle mixer is recommended for industry standard cleaning chemicals and techniques.

mixing the product. Drain the contents of the liquid base and Consult your cleaning chemical and equipment supplier for

liquid hardener components into a large plastic container and more information.

mix briefly. Load the coloured aggregate component whist

mixing, and continue mixing for at least 1 minute, until a Health and Safety

lump-free mix is obtained, including a scrape down if

necessary. Fosroc Nitoflor SL3000 UT should not come into contact

with the skin and eyes, or be swallowed. Ensure adequate

Immediately discharge and spread the mix over the ventilation and avoid inhalation of vapours.

application area, using a notched trowel to achieve the

required coverage rate. De-aerate using a spiked roller. Wear suitable protective clothing, gloves and eye

Spike rolling should be carried out within 10 minutes of protection. If working in confined areas, suitable respiratory

application in order to avoid interfering with flow and surface protective equipment must be used. The use of barrier

finish. Ensure that anchorage grooves are fully wetted out creams provides additional skin protection. In case of

with material. Do not return to spike roll older applied areas contact with skin, rinse with plenty of clean water, then

as the product is fast-setting and this action will leave spoiling cleanse with soap and water. Do not use solvent.

marks on the applied floor.

constructive solutions Page 4

Fosroc®Nitoflor SL3000 UT

In case of contact with eyes, rinse immediately with plenty

of clean water and seek medical advice. If swallowed seek

medical attention immediately - do not induce vomiting.

Refer to Product Safety Data Sheet for further information.

Storage, Mixing & Application

Fosroc Nitoflor SL3000 UT has a shelf life of 6 months for

the Aggregate components and 12 months for the Resin

components if stored off the ground in unopened packs in a

covered dry store at 10 -30ºC. Storage outside this

temperature range or repeated fluctuations in storage

temperature can reduce the storage life. Protect from frost.

Fire

Fosroc Nitoflor SL3000 UT is non-flammable.

Limitations

Do not proceed with application if atmospheric relative

humidity is, or is anticipated to be within the tack-free

period, >90% or if the surface temperature is <3ºC above

the dew point. Application should not commence when the

substrate temperature or the ambient temperature is, or is

anticipated to be, <10ºC during the application or within the

tack-free period.

The manufacture of Fosroc Nitoflor SL3000 UT is a batch

process and despite close manufacturing tolerances, colour

variation may occur between batches.

Slip resistance can reduce over time due to poor

maintenance, general wear or surface contaminants.

Nitoflor SL3000 UT has a smooth finish so can be expected

to become slippery when wet. Good housekeeping practices

must be observed.

Application can take place outside the ideal temperature

range of 15 - 30ºC, subject to a minimum of 10ºC and a

maximum of 34ºC, however the surface finish may be

subject to e.g. trowel and/or spike roller marks.

Fosroc Nitoflor SL3000 UT is not colour fast and may yellow

over time. The rate of change will depend on UV light and

heat levels and cannot be predicted.

Fosroc and Nitoflor are trademarks of Fosroc International

Limited.

Important note:

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions

for the Supply of Goods and Services, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that

any advice, recommendation, specification of information it may give is accurate and correct, it cannot, because it has no di rect

or continuous control over where or how its products are applied, accept any liability either directly or indirectly arising from the

use of its products, whether or not in accordance with any advice, specification, recommendation of information given by it.

Fosam Company Limited

Head Office Telephone: +966 12 637 5345 Fax: +966 12 637 5891 email: fosam@fosroc.com

Post Box 11081 Regional Offices

Jeddah – 21453 Jeddah Sales Office Tel: (012) 608 0999 Fax: (012) 638 0693 Yanbu Tel: (014) 322 4280 Fax: (014) 391 2980

Jeddah Showroom Tel: (012) 665 0187 Fax: (012) 667 4844 Makkah Tel: (012) 542 0869 Fax: (012) 542 0869

Saudi Arabia Riyadh Tel: (011) 482 9303 Fax: (011) 482 7562 Medinah Tel: (014) 855 0091 Fax: (014) 855 0047

Dammam Tel: (013) 814 1282 Fax: (013) 814 1581 Jubail Tel: (013) 362 3904 Fax: (013) 362 3875

www.fosroc.com Khamis Mushayt Tel: (017) 250 0469 Fax: (017) 250 0469 CSD Tel: (012) 608 0999 Fax: (012) 638 0693

Registered Office: Industrial Area, Phase 4, Road No. 102 Street No. 82

Page 5 SA FO/ NITOFLOR SL3000 UT/1403/19

S-ar putea să vă placă și

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965De la EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Încă nu există evaluări

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingDe la EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingÎncă nu există evaluări

- TDS Nitoflor SL3000 UT IndiaDocument4 paginiTDS Nitoflor SL3000 UT IndiaqmsudhirÎncă nu există evaluări

- Ucrete Ud200 AseanDocument2 paginiUcrete Ud200 AseanDoby YuniardiÎncă nu există evaluări

- Urethane Coating 165 PWDocument3 paginiUrethane Coating 165 PWANIBALLOPEZVEGAÎncă nu există evaluări

- Ucrete MF AsDocument2 paginiUcrete MF AsDoby YuniardiÎncă nu există evaluări

- Flowcrete Asia Flowshield CR May2020 TdsDocument2 paginiFlowcrete Asia Flowshield CR May2020 TdsQuoc AnÎncă nu există evaluări

- Nitoproof 600: Constructive SolutionsDocument22 paginiNitoproof 600: Constructive SolutionsMazen AlRefaaiÎncă nu există evaluări

- Nitoflor SL2050: Constructive SolutionsDocument4 paginiNitoflor SL2050: Constructive SolutionsNishant VasuÎncă nu există evaluări

- 253 PDS AiDocument4 pagini253 PDS AiHrvoje RuzicÎncă nu există evaluări

- Product Specification - Apcoshield Py905sg Grey Ral 7016 20kgDocument1 paginăProduct Specification - Apcoshield Py905sg Grey Ral 7016 20kgVenkatraman SubramaniamÎncă nu există evaluări

- Protective & Marine Coatings: Polysiloxane 1KDocument4 paginiProtective & Marine Coatings: Polysiloxane 1KAna CabreraÎncă nu există evaluări

- Sikaflex Pro 3 I CureDocument5 paginiSikaflex Pro 3 I Curemuhammad aliÎncă nu există evaluări

- Nitoflor SL1000: Flow Applied, 0.5 - 1.5mm Thick Epoxy Resin Based Floor Topping UsesDocument4 paginiNitoflor SL1000: Flow Applied, 0.5 - 1.5mm Thick Epoxy Resin Based Floor Topping UsestalatzahoorÎncă nu există evaluări

- Sikaflex®-2c SL: Two-Component, Self-Levelling, Polyurethane Elastomeric SealantDocument3 paginiSikaflex®-2c SL: Two-Component, Self-Levelling, Polyurethane Elastomeric SealantRay GongÎncă nu există evaluări

- WBEpoxyCoating Data SheetDocument2 paginiWBEpoxyCoating Data SheetkaleshÎncă nu există evaluări

- Fosroc Nitoflor SL1000: Uses PropertiesDocument4 paginiFosroc Nitoflor SL1000: Uses PropertiesTheo TodingÎncă nu există evaluări

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 paginiDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraÎncă nu există evaluări

- Flowfresh RT TDSDocument2 paginiFlowfresh RT TDSiqmalexcruzÎncă nu există evaluări

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 paginiDTM Bonding Primer: Protective & Marine CoatingsAna CabreraÎncă nu există evaluări

- 3M Scotchkote Epoxy Primer GP220 - Rev2Document2 pagini3M Scotchkote Epoxy Primer GP220 - Rev2satya ranjanÎncă nu există evaluări

- Fosroc Nitoflor TF5000: Constructive SolutionsDocument4 paginiFosroc Nitoflor TF5000: Constructive SolutionsVincent JavateÎncă nu există evaluări

- Fosroc Nukote BLDocument4 paginiFosroc Nukote BLm.elsanee.cubicÎncă nu există evaluări

- Nitoflor RT6000 UTDocument4 paginiNitoflor RT6000 UTAndrew KasanaÎncă nu există evaluări

- Csaf305 000490aDocument6 paginiCsaf305 000490aJorge Manuel Guedes SilvaÎncă nu există evaluări

- Nukote STDocument4 paginiNukote STMarco Dos Santos NevesÎncă nu există evaluări

- Fosroc Polyurea FLMDocument4 paginiFosroc Polyurea FLMtalatzahoorÎncă nu există evaluări

- Csaf30ultima 000050aDocument2 paginiCsaf30ultima 000050aJorge Manuel Guedes SilvaÎncă nu există evaluări

- 3M Scotchkote Epoxy Primer GP 120+Document2 pagini3M Scotchkote Epoxy Primer GP 120+satya ranjanÎncă nu există evaluări

- Polylon 1900 (3853091)Document4 paginiPolylon 1900 (3853091)JOCELYN MEDINAÎncă nu există evaluări

- 718 Stangard Egf (NV)Document5 pagini718 Stangard Egf (NV)Sandeep gangulyÎncă nu există evaluări

- TDS - Premix Marine ThixotropeDocument3 paginiTDS - Premix Marine ThixotropegmÎncă nu există evaluări

- Sikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatDocument6 paginiSikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatmilanbrasinaÎncă nu există evaluări

- Strongcoat HB400Document4 paginiStrongcoat HB400osama mohÎncă nu există evaluări

- Strongcoat HB400Document53 paginiStrongcoat HB400irfan shafiqueÎncă nu există evaluări

- Hi Solid PolyurethaneDocument4 paginiHi Solid PolyurethaneafvasquezÎncă nu există evaluări

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 paginiTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranÎncă nu există evaluări

- Chersterton Arc 982 PDFDocument2 paginiChersterton Arc 982 PDFMohamed Nouzer100% (1)

- Fluteck P7500 CA v01.19Document2 paginiFluteck P7500 CA v01.19fprovitaliÎncă nu există evaluări

- Plastic Steel Putty A v3Document2 paginiPlastic Steel Putty A v3feri.ferdianto02Încă nu există evaluări

- Basf-Ucrete Ud 200 - TdsDocument3 paginiBasf-Ucrete Ud 200 - TdsAbdul ZailaniÎncă nu există evaluări

- Nukote Har: DescriptionDocument4 paginiNukote Har: DescriptionMarco Dos Santos NevesÎncă nu există evaluări

- Datasheet CG60Document3 paginiDatasheet CG60ouss oussÎncă nu există evaluări

- Maincote™ Hg-31: Waterborne Acrylic Resin For Water and Corrosion-Resistant Industrial CoatingsDocument7 paginiMaincote™ Hg-31: Waterborne Acrylic Resin For Water and Corrosion-Resistant Industrial CoatingsLong An DoÎncă nu există evaluări

- FosrocDocument4 paginiFosrocDamodharanÎncă nu există evaluări

- Pro Mastic Ste 87Document4 paginiPro Mastic Ste 87ahmedyahea181Încă nu există evaluări

- Flowcrete Asia Mondéco Crystal May2020 TdsDocument2 paginiFlowcrete Asia Mondéco Crystal May2020 TdsQuoc AnÎncă nu există evaluări

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 paginiIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraÎncă nu există evaluări

- Product Datasheet: Interpon 610 - NW300M/25KG ANTRACITE FERRO IP610Document2 paginiProduct Datasheet: Interpon 610 - NW300M/25KG ANTRACITE FERRO IP610Ina - EdenGarden UmbrellasÎncă nu există evaluări

- COLORBONDUltra ACTIVATETDS200706Document4 paginiCOLORBONDUltra ACTIVATETDS200706Ramiro RivasÎncă nu există evaluări

- Maincote™ EC-11: Waterborne Elastomeric Acrylic Resin For Industrial Maintenance CoatingsDocument10 paginiMaincote™ EC-11: Waterborne Elastomeric Acrylic Resin For Industrial Maintenance CoatingsLong An ĐỗÎncă nu există evaluări

- Ube Nylon 5034bDocument1 paginăUbe Nylon 5034bDiegoTierradentroÎncă nu există evaluări

- Universal 1-Component Polyurethane Joint Sealant: DescriptionDocument2 paginiUniversal 1-Component Polyurethane Joint Sealant: DescriptionAkram ShaikhÎncă nu există evaluări

- HT 521 82055 170 ENDocument5 paginiHT 521 82055 170 ENEdward AguillónÎncă nu există evaluări

- Fosroc Nitoflor FC550: Constructive SolutionsDocument4 paginiFosroc Nitoflor FC550: Constructive SolutionsVincent JavateÎncă nu există evaluări

- Sabic M80064SDocument2 paginiSabic M80064STungdinh NguyenÎncă nu există evaluări

- MOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01Document2 paginiMOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01MAHESH BELEÎncă nu există evaluări

- Especificaciones Pintura Macropoxi NavalDocument4 paginiEspecificaciones Pintura Macropoxi NavalVicenteRojasLeonÎncă nu există evaluări

- Tds of Interpon RDX Plus-Al180cs-EnDocument4 paginiTds of Interpon RDX Plus-Al180cs-EnjmcastellviÎncă nu există evaluări

- Sikafloor - 264 EngDocument5 paginiSikafloor - 264 Engbassem kooliÎncă nu există evaluări

- PGMP Lessons Learnt - 09-16-2019Document7 paginiPGMP Lessons Learnt - 09-16-2019ShaikhRizwanÎncă nu există evaluări

- Quiz For Decimals Grade 8Document1 paginăQuiz For Decimals Grade 8ShaikhRizwanÎncă nu există evaluări

- Pages From Q & As - Good To StudyDocument9 paginiPages From Q & As - Good To StudyShaikhRizwanÎncă nu există evaluări

- Product: Fiberflect™ Blanket: Material Safety Data SheetDocument4 paginiProduct: Fiberflect™ Blanket: Material Safety Data SheetShaikhRizwanÎncă nu există evaluări

- Material Safety Data SheetDocument4 paginiMaterial Safety Data SheetShaikhRizwanÎncă nu există evaluări

- Fire Blanker MSDSDocument3 paginiFire Blanker MSDSShaikhRizwanÎncă nu există evaluări

- Safety Data Sheet: SDS Acc. Hazard Communication StandardDocument5 paginiSafety Data Sheet: SDS Acc. Hazard Communication StandardShaikhRizwanÎncă nu există evaluări

- HL-428 MSDSDocument7 paginiHL-428 MSDSShaikhRizwanÎncă nu există evaluări

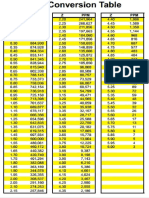

- PPM Conversion TableDocument1 paginăPPM Conversion TableShaikhRizwanÎncă nu există evaluări

- IASSC Exam Packet: Version: 1.2.0M Publish Date: 12.12.2010Document21 paginiIASSC Exam Packet: Version: 1.2.0M Publish Date: 12.12.2010ShaikhRizwanÎncă nu există evaluări

- Bfi 345-196 LdpeDocument1 paginăBfi 345-196 LdpeShaikhRizwanÎncă nu există evaluări

- 4170 PP Impact Copolymer MSDSDocument6 pagini4170 PP Impact Copolymer MSDSShaikhRizwanÎncă nu există evaluări

- Quarterly Test in g9 Science 2nd GradingDocument4 paginiQuarterly Test in g9 Science 2nd GradingPedro GenosasÎncă nu există evaluări

- A New Nitration Product, 3-Nitro-4-Acetamidophenol, Obtained From Acetaminophen With Nitrous AcidDocument2 paginiA New Nitration Product, 3-Nitro-4-Acetamidophenol, Obtained From Acetaminophen With Nitrous AcidxcvÎncă nu există evaluări

- Heterocyclic Nomenclature: Heterocyclic Chemistry at A Glance, Second Edition. John A. Joule and Keith MillsDocument3 paginiHeterocyclic Nomenclature: Heterocyclic Chemistry at A Glance, Second Edition. John A. Joule and Keith MillsMàrwå Rägb ZäkyÎncă nu există evaluări

- H2S VogelDocument2 paginiH2S VogelBrilian RAÎncă nu există evaluări

- Two Types of Hydrocarbons: Open in Desktop App. Aromatic Compounds (Arene)Document11 paginiTwo Types of Hydrocarbons: Open in Desktop App. Aromatic Compounds (Arene)Freya SawÎncă nu există evaluări

- API 5L - 43rd and 44th Ed - Comparison r1Document68 paginiAPI 5L - 43rd and 44th Ed - Comparison r1gopidhan100% (1)

- Experiment 7 - Gravimetric Determination of Aluminum As OxinateDocument2 paginiExperiment 7 - Gravimetric Determination of Aluminum As OxinateSavita ChemistryÎncă nu există evaluări

- Chapter 3 - Fluid StaticsDocument6 paginiChapter 3 - Fluid StaticsKristine Joy BagaporoÎncă nu există evaluări

- Komposit UHMWPE Sebagai Alternatif Bantalan Rel Kereta Api: Abel Evan, Alia Kristika, Farid Mulia LatiefDocument11 paginiKomposit UHMWPE Sebagai Alternatif Bantalan Rel Kereta Api: Abel Evan, Alia Kristika, Farid Mulia LatiefAlia KristikaÎncă nu există evaluări

- Ciba - Irgastab PURDocument2 paginiCiba - Irgastab PURThatinant Prompijarn (Boy)Încă nu există evaluări

- Chemistery NotesDocument3 paginiChemistery NotesseeratytÎncă nu există evaluări

- Assignment Lesson 5 UNIT 01 and UNIT 02Document5 paginiAssignment Lesson 5 UNIT 01 and UNIT 02CRUZ, Rochelle Joy V.Încă nu există evaluări

- PinAAcle 900 Family Preparing Your LabDocument12 paginiPinAAcle 900 Family Preparing Your LabUswatul HasanahÎncă nu există evaluări

- Lecture Planner - ChemistryDocument7 paginiLecture Planner - ChemistryRajat BhartiÎncă nu există evaluări

- CH 7 Statistical Data Treatment and EvaluationDocument30 paginiCH 7 Statistical Data Treatment and Evaluationjhzlbarrera09Încă nu există evaluări

- Mean Median Mode RangeDocument2 paginiMean Median Mode RangeShin WonHoÎncă nu există evaluări

- HELMER DH8 User ManualDocument30 paginiHELMER DH8 User ManualSamson AyalewÎncă nu există evaluări

- Chemical, Synonym, and Trade Name IndexDocument4 paginiChemical, Synonym, and Trade Name IndexLuis CastroÎncă nu există evaluări

- 11 - Group 2Document37 pagini11 - Group 2enderothÎncă nu există evaluări

- En 14758-1Document35 paginiEn 14758-1Attef BedaweÎncă nu există evaluări

- Wbi11 01 Que 20240109Document28 paginiWbi11 01 Que 20240109tongshuo066Încă nu există evaluări

- Effects of Preparation Parameters On Paraffin Wax MicroemulsionDocument5 paginiEffects of Preparation Parameters On Paraffin Wax MicroemulsionCarlotta C.Încă nu există evaluări

- Determination of Total Ion Concentration Using Ion Exchange Chromatography - Ace de La SernaDocument6 paginiDetermination of Total Ion Concentration Using Ion Exchange Chromatography - Ace de La Sernaaodelaserna100% (1)

- Sigmazinc 158Document7 paginiSigmazinc 158JORGEALEXERÎncă nu există evaluări

- Ver.2014 1 MagCore SUPER PLUS Service ManualDocument72 paginiVer.2014 1 MagCore SUPER PLUS Service Manualمحمد سامىÎncă nu există evaluări

- Exp 2Document13 paginiExp 2Jasmine NguÎncă nu există evaluări

- Biochemical Energy ProductionDocument15 paginiBiochemical Energy ProductionBeatrice ChenÎncă nu există evaluări

- Christopher James, The Book of Alternative Photographic Processes - Cap 6 - The-Cyanotype-ProcessDocument22 paginiChristopher James, The Book of Alternative Photographic Processes - Cap 6 - The-Cyanotype-ProcessFernanda Eda PazÎncă nu există evaluări

- 838552-Bom.h 2022620115332 830876 3Document22 pagini838552-Bom.h 2022620115332 830876 3Alejo CastroÎncă nu există evaluări

- Electrochemistry, Board Paper Question - CBSE Class 12-Science CHEMISTRY, Chemistry Part I Ncert Solutions - MeritnationDocument34 paginiElectrochemistry, Board Paper Question - CBSE Class 12-Science CHEMISTRY, Chemistry Part I Ncert Solutions - MeritnationKamal Kaum Deep SinghÎncă nu există evaluări