Documente Academic

Documente Profesional

Documente Cultură

Pipe Material Selection PDF

Încărcat de

Moh'd KhadTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pipe Material Selection PDF

Încărcat de

Moh'd KhadDrepturi de autor:

Formate disponibile

© BCAS FACT SHEET NO.

750

Pipe material selection

Piping for compressed air system comes in a range of materials. With the emphasis on energy

efficiency, the correct choice of piping materials brings positive benefits to the cost of running a well

designed and maintained compressed air system. The previous cost advantage that steel maintained is

no longer a consideration which then focuses the choice on technical specifications.

Advantages and disadvantages of available compressed air pipe materials

Pipe material Advantages Disadvantages

Heavy, prone to rusting, threaded joints require

Galvanised steel Known technology, widely available careful preparation, inner surfaces are not smooth

and as a result promotes energy loss (pressure drop)

Lightweight, easy to install, does not Not suitable for applications where there is a fire

Aluminium

rust. risk, e.g. mines, offshore and hospitals.

Use only piping specified as suitable for compressed

High performance

air.

plastic Lightweight, non-corrodible, non-

Pressure rating reduces as temperatures increase

e.g. ABS, toxic

check suppliers data for suitablity

polyethylene

Subject to ultra-violet degradation

Applications tend to be limited to high specification,

High rigidity, corrosion and rust

Stainless steel critical processes (e.g. food processing) due to the

resistant.

higher initial cost

High purity copper inhibits microbial

Copper growth useful for medical Maximum diameter is 40mm

applications

Relevant standards - examples

BS EN 10255 – steel pipe for general use (formerly BS 4825 - Stainless steel tubes and fittings for the

BS1387) food industry (in 5 parts)

BS EN 10296-2 – Stainless steel BS EN 12449:1999 Copper and copper alloys.

Seamless, round tubes for general purposes

BS 6362 – Stainless steel pipe for threading BS 3974 – Supporting of piping

BS 5391-1:2006 ABS pressure pipe. Specification BS1710 – Identification of pipelines

Pipe corrosion

Rusting (a specific form of corrosion) on steel or galvanised steel leads to the following:

• Contamination of product

• Reduces the effective cross-sectional area of the pipe thus restricting flow and increasing

pressure drop

• Premature blocking of pneumatic components and filters

Corrosion of aluminium results in a layer of aluminium oxide which is very stable and has in addition a

very good adhesion to the metal surface and thus protects aluminium from corrosion or further

oxidation. Once the oxide layer is formed provided that it is not disturbed it will not react further in the

manner of the rusting of steel. Therefore any restriction to flow will be limited unlike that for steel.

The importance of system design

Remember that whatever materials are selected, the efficiency of the system depends on the correct

design and application of the joints and connections. More details appear in the Installation Guide (5th

edition) and Pressure & Leak Testing Code of Practice.

If you have a specific issue related to distribution systems, send an email to: technical@bcas.org.uk

www.bcas.org.uk Tel. 020 7935 2464 April 2007

S-ar putea să vă placă și

- Astm A513 PDFDocument20 paginiAstm A513 PDFpradelles89% (9)

- Cable Tray Selection - : Material & FinishDocument6 paginiCable Tray Selection - : Material & FinishBenRoseÎncă nu există evaluări

- Application of Stainless SteelDocument13 paginiApplication of Stainless Steelsweety1188Încă nu există evaluări

- CETEST Notes FinalsDocument33 paginiCETEST Notes FinalsKrischanSayloGelasanÎncă nu există evaluări

- StainlessSteel TechnicalDocument48 paginiStainlessSteel Technicalwajoy42773Încă nu există evaluări

- Stainless Steel Material PropertiesDocument4 paginiStainless Steel Material PropertiesMohammed RiyazÎncă nu există evaluări

- Materials ProjectDocument4 paginiMaterials Projectxtopherus124Încă nu există evaluări

- A512-06 (2012) Standard Specification For Cold-Drawn Buttweld Carbon Steel Mechanical TubingDocument20 paginiA512-06 (2012) Standard Specification For Cold-Drawn Buttweld Carbon Steel Mechanical TubingChuthaÎncă nu există evaluări

- TQIWPJS0ON 9 Aluminium ExtrusionDocument3 paginiTQIWPJS0ON 9 Aluminium Extrusionlamia97Încă nu există evaluări

- Electric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingDocument21 paginiElectric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingIsaac ZTÎncă nu există evaluări

- Corrosione - Abstract From SchneiderDocument5 paginiCorrosione - Abstract From SchneiderMaxÎncă nu există evaluări

- ABS For HVAC, Advantages and BenifitsDocument10 paginiABS For HVAC, Advantages and BenifitsonspsnonsÎncă nu există evaluări

- Astm. A-513Document20 paginiAstm. A-513Jivi' Gernot DunckelÎncă nu există evaluări

- Calbrite CatalogDocument24 paginiCalbrite Catalogkevin smithÎncă nu există evaluări

- Introduction To The Design of Structural SteelDocument18 paginiIntroduction To The Design of Structural SteelRoan SaldivarÎncă nu există evaluări

- Astm B633-19Document3 paginiAstm B633-19Cj Elamparo100% (1)

- Ahana's Ortho Seminar - Ortho WiresDocument31 paginiAhana's Ortho Seminar - Ortho WiresAnoop AnilÎncă nu există evaluări

- Astm B633-19Document8 paginiAstm B633-19sharma.sumeet2290Încă nu există evaluări

- Dimensioning The Pipes FinalDocument35 paginiDimensioning The Pipes FinalJose Lapera Jr.Încă nu există evaluări

- Thep Khong GiDocument9 paginiThep Khong GiQuân BùiÎncă nu există evaluări

- Stainless Steel ReinforcementDocument8 paginiStainless Steel Reinforcementsattar12345Încă nu există evaluări

- And Steel Framing: Pressure Treated WoodDocument2 paginiAnd Steel Framing: Pressure Treated WoodGopi KrishnanÎncă nu există evaluări

- Specifications of Ductile Iron Pipes and Carbon Steel Pipes - en - 01Document3 paginiSpecifications of Ductile Iron Pipes and Carbon Steel Pipes - en - 01djrote4Încă nu există evaluări

- Specifications of Ductile Iron Pipes and Carbon Steel Pipes - en - 01Document3 paginiSpecifications of Ductile Iron Pipes and Carbon Steel Pipes - en - 01djrote4Încă nu există evaluări

- Materials Stud Bolts: ASTM A197 B7Document5 paginiMaterials Stud Bolts: ASTM A197 B7scribddisantoÎncă nu există evaluări

- Cold-Formed Welded and Seamless High-Strength, Low-Alloy Structural Tubing With Improved Atmospheric Corrosion ResistanceDocument5 paginiCold-Formed Welded and Seamless High-Strength, Low-Alloy Structural Tubing With Improved Atmospheric Corrosion Resistancewatt_hrÎncă nu există evaluări

- Powder Metallurgy Stainless Steels - Processing Microstructures, and PropertiesDocument227 paginiPowder Metallurgy Stainless Steels - Processing Microstructures, and PropertiesSamuel TesfayeÎncă nu există evaluări

- Difference Between SEAMless and ERW PipesDocument3 paginiDifference Between SEAMless and ERW PipesnewspaÎncă nu există evaluări

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocument2 paginiStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdÎncă nu există evaluări

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Document2 paginiAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloÎncă nu există evaluări

- F1545 15a PDFDocument8 paginiF1545 15a PDFMarius Onofrei100% (2)

- Rolf Rolf: Engg. Solutions IncDocument6 paginiRolf Rolf: Engg. Solutions IncPham Huu Loc HoÎncă nu există evaluări

- IJETR021817Document3 paginiIJETR021817erpublicationÎncă nu există evaluări

- Structural Stainless Steel PDFDocument5 paginiStructural Stainless Steel PDFGiri DharanÎncă nu există evaluări

- Valve Material Chemical Compatibility Lookup - Flowstar (UK) Limited PDFDocument5 paginiValve Material Chemical Compatibility Lookup - Flowstar (UK) Limited PDFHARSHAÎncă nu există evaluări

- Compared Austenitic Stainless Steel With Duplex Stainless Steel Strengths and VulnerableDocument2 paginiCompared Austenitic Stainless Steel With Duplex Stainless Steel Strengths and VulnerableSampath GaneshÎncă nu există evaluări

- Carbon Steel Pipe - An Overview - ScienceDirect Topics PDFDocument21 paginiCarbon Steel Pipe - An Overview - ScienceDirect Topics PDFsaif asqalanyÎncă nu există evaluări

- Datasheet For Carbon Steel A333 Grade 6Document10 paginiDatasheet For Carbon Steel A333 Grade 6Aneesh JoseÎncă nu există evaluări

- TB26 - Weathering Steels Sept 02Document2 paginiTB26 - Weathering Steels Sept 02Ravinesh SinghÎncă nu există evaluări

- Reject DowDocument2 paginiReject Dowcoolguy12345Încă nu există evaluări

- Corrosion Prevention in Railway Coaches PDFDocument7 paginiCorrosion Prevention in Railway Coaches PDFnaveenjoy84Încă nu există evaluări

- AM Hot Rolled Product Range For Construction 201503Document43 paginiAM Hot Rolled Product Range For Construction 201503duduqueÎncă nu există evaluări

- Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel PipesDocument12 paginiSeamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel PipeschandrasekarÎncă nu există evaluări

- Report Stainless SteelDocument6 paginiReport Stainless SteelAhmed ShokryÎncă nu există evaluări

- New Generation Stainless Steel Reinforcing Bars For Concrete StructuresDocument28 paginiNew Generation Stainless Steel Reinforcing Bars For Concrete StructuresAshfaq SaudagarÎncă nu există evaluări

- 02 Mike Lewus - BSSADocument32 pagini02 Mike Lewus - BSSAjeetÎncă nu există evaluări

- What Is Stainless SteelDocument3 paginiWhat Is Stainless SteelmadzieuuuuÎncă nu există evaluări

- Flange Insulating Brochure Rev12 2022Document11 paginiFlange Insulating Brochure Rev12 2022Michael PhamÎncă nu există evaluări

- Stainless Steel 6Document10 paginiStainless Steel 6YKAGARWALÎncă nu există evaluări

- Nsba White Paper - A Primer On Weathering SteelDocument6 paginiNsba White Paper - A Primer On Weathering SteelMario Guevara Ubidia- IngenieroCivilÎncă nu există evaluări

- Belzona 1321 (Ceramic S-Metal) : Key BenefitsDocument22 paginiBelzona 1321 (Ceramic S-Metal) : Key BenefitsIrvansyah RazadinÎncă nu există evaluări

- Metallographic Properties: 1. Mild SteelsDocument4 paginiMetallographic Properties: 1. Mild SteelsmuralidharanÎncă nu există evaluări

- Steel Pipe Manufacturing ProcessDocument22 paginiSteel Pipe Manufacturing ProcessNatthasartÎncă nu există evaluări

- What Are Astm A286 and ASTM A193 B7 BoltsDocument2 paginiWhat Are Astm A286 and ASTM A193 B7 BoltsJignesh SteelÎncă nu există evaluări

- Astm A312 PDFDocument12 paginiAstm A312 PDFStephen TilleyÎncă nu există evaluări

- Air BalancingDocument4 paginiAir BalancingMoh'd KhadÎncă nu există evaluări

- Commissioning Best Practices For Building PerformanceDocument3 paginiCommissioning Best Practices For Building PerformanceMoh'd KhadÎncă nu există evaluări

- Airflow DiscrepanciesDocument2 paginiAirflow DiscrepanciesMoh'd KhadÎncă nu există evaluări

- Drains Below and Near To BuildingsDocument1 paginăDrains Below and Near To BuildingsMoh'd KhadÎncă nu există evaluări

- Drainage Design - Surface AreasDocument1 paginăDrainage Design - Surface AreasMoh'd KhadÎncă nu există evaluări

- Drainage Design - Velocities and Hydraulic Mean DepthDocument5 paginiDrainage Design - Velocities and Hydraulic Mean DepthMoh'd KhadÎncă nu există evaluări

- Drainage Design - Foul WaterDocument7 paginiDrainage Design - Foul WaterMoh'd KhadÎncă nu există evaluări

- Hydraulic Design of Storm Sewers Using EXCELDocument39 paginiHydraulic Design of Storm Sewers Using EXCELMark Cargo PereyraÎncă nu există evaluări

- Compressed Air7 PDFDocument2 paginiCompressed Air7 PDFMoh'd KhadÎncă nu există evaluări

- Air CurtainDocument1 paginăAir CurtainMoh'd KhadÎncă nu există evaluări

- Ac-404 - Carpark Ventilation Schematic DiagramDocument1 paginăAc-404 - Carpark Ventilation Schematic DiagramMoh'd KhadÎncă nu există evaluări

- Presentation On Lifesafety System Readiness For The Tournamet 3Document29 paginiPresentation On Lifesafety System Readiness For The Tournamet 3Moh'd KhadÎncă nu există evaluări

- FF - B1 - R0 Comments ComplianceDocument1 paginăFF - B1 - R0 Comments ComplianceMoh'd KhadÎncă nu există evaluări

- Intro To Wastewater Collection and PumpingDocument84 paginiIntro To Wastewater Collection and PumpingMoh'd KhadÎncă nu există evaluări

- Analysis and Design of Heating, Ventilating, and Air-Conditioning Systems'' PDFDocument477 paginiAnalysis and Design of Heating, Ventilating, and Air-Conditioning Systems'' PDFMoh'd Khad100% (3)

- Geometry FormulasDocument1 paginăGeometry FormulasMoh'd KhadÎncă nu există evaluări

- Energy Tips: MOTOR SYSTEMSDocument2 paginiEnergy Tips: MOTOR SYSTEMSJoséÎncă nu există evaluări

- Us DoeDocument2 paginiUs DoeFelipe CarvalhoÎncă nu există evaluări

- CalculationDocument1 paginăCalculationMoh'd KhadÎncă nu există evaluări

- Air Compressor - Solved ProblemDocument1 paginăAir Compressor - Solved ProblemMoh'd KhadÎncă nu există evaluări

- Air TreatmentDocument27 paginiAir TreatmentMoh'd KhadÎncă nu există evaluări

- Pressure Leak Testing GuideDocument20 paginiPressure Leak Testing Guidefezzeh kabiri kenari100% (1)

- 2015 PDFDocument551 pagini2015 PDFMoh'd KhadÎncă nu există evaluări

- Buildings For Extreme Environments - AridDocument119 paginiBuildings For Extreme Environments - AridMoh'd KhadÎncă nu există evaluări

- Major Head Minor Head Detailed Head: ShimlaDocument11 paginiMajor Head Minor Head Detailed Head: ShimlaRajat SharmaÎncă nu există evaluări

- Eni Dicrea SX 68Document2 paginiEni Dicrea SX 68AMAZING AGÎncă nu există evaluări

- Sintesis Dan Karakterisasi Nanopartikel Aluminium Oxide (Al O) Dari Limbah Aluminium Untuk NanofluidaDocument5 paginiSintesis Dan Karakterisasi Nanopartikel Aluminium Oxide (Al O) Dari Limbah Aluminium Untuk NanofluidaYulia Puspa DewiÎncă nu există evaluări

- Us20110117142a1 PVP Peg PDFDocument13 paginiUs20110117142a1 PVP Peg PDFethylenepluschlorineÎncă nu există evaluări

- Ultra-High-Performance Geopolymer Concrete A ReviewDocument25 paginiUltra-High-Performance Geopolymer Concrete A ReviewShaker QaidiÎncă nu există evaluări

- Vdocuments - MX - Ampacet Bopp Standard Masterbatch SynopticDocument1 paginăVdocuments - MX - Ampacet Bopp Standard Masterbatch Synopticfakiv83032Încă nu există evaluări

- FLOWTITE - Installation Guide For Buried Pipes - AWWA - Abbr. Version - enDocument31 paginiFLOWTITE - Installation Guide For Buried Pipes - AWWA - Abbr. Version - envuqar0979Încă nu există evaluări

- Casting Material Gray Iron in ASTM A48Document5 paginiCasting Material Gray Iron in ASTM A48Novaldi Andryoga 1707122616Încă nu există evaluări

- Vapor-Phase Synthesis of Nanoparticles - Swihart PDFDocument7 paginiVapor-Phase Synthesis of Nanoparticles - Swihart PDFJoel E ValenciaÎncă nu există evaluări

- Astm - A234/a234mDocument5 paginiAstm - A234/a234mVõ Duy ĐăngÎncă nu există evaluări

- Mcguire 2007 List Price Sheet 15-Jan-07Document56 paginiMcguire 2007 List Price Sheet 15-Jan-07Maria StewartÎncă nu există evaluări

- Safrole From Sassafras OilDocument8 paginiSafrole From Sassafras OilDerrick HensonÎncă nu există evaluări

- A Review Paper On Fire Resistance PropertiesDocument7 paginiA Review Paper On Fire Resistance PropertiesInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- How Plastics WorkDocument20 paginiHow Plastics WorkdidacbrÎncă nu există evaluări

- List of Groundwater Contaminated Sites CPCBDocument4 paginiList of Groundwater Contaminated Sites CPCBParas Singh RajpurohitÎncă nu există evaluări

- Catalogo GatesDocument255 paginiCatalogo GatesBenjamin HedoneweÎncă nu există evaluări

- 2009 Vittoria Bicycle Tire CatalogDocument46 pagini2009 Vittoria Bicycle Tire CatalogtspinnerÎncă nu există evaluări

- Specification:: Details Plumbing DrawingDocument1 paginăSpecification:: Details Plumbing DrawingCarl Lou BaclayonÎncă nu există evaluări

- LUBCON Lubricants Textile Complete ENDocument5 paginiLUBCON Lubricants Textile Complete ENMajed DawaÎncă nu există evaluări

- Wire Arc Additive Manufacturing of Functionally Graded Material For Marine RisersDocument13 paginiWire Arc Additive Manufacturing of Functionally Graded Material For Marine RisersElina AkbarzadeÎncă nu există evaluări

- Scotch-Brite Hand Pads: Surface Conditioning AbrasivesDocument2 paginiScotch-Brite Hand Pads: Surface Conditioning AbrasivesdoiskÎncă nu există evaluări

- TDS Fixoflex H PDFDocument4 paginiTDS Fixoflex H PDFLulzim BeqirajÎncă nu există evaluări

- Attachment 32 - Amend To Shell DEPsDocument34 paginiAttachment 32 - Amend To Shell DEPsBasker BaluÎncă nu există evaluări

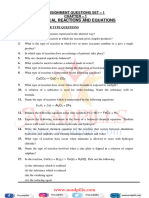

- Chemical Reactions and Equations Assignment Questions Set - 1Document6 paginiChemical Reactions and Equations Assignment Questions Set - 1kayace8055Încă nu există evaluări

- Ireps Tender 3Document22 paginiIreps Tender 3Project DS EnterpriseÎncă nu există evaluări

- International Journal of TechnologyDocument12 paginiInternational Journal of TechnologyDwinaRahmayaniÎncă nu există evaluări

- B.6.23 - STD SPECS - For Plum Concrete & Plum MasonaryDocument3 paginiB.6.23 - STD SPECS - For Plum Concrete & Plum MasonaryBijay Krishna Das100% (3)

- Measurement Edavannapara Elamaram 2020Document4 paginiMeasurement Edavannapara Elamaram 2020insafaÎncă nu există evaluări

- AERI-09-16-5 Matadeen Ramchandra Agrawal - Cement PhysicalDocument2 paginiAERI-09-16-5 Matadeen Ramchandra Agrawal - Cement PhysicalAhmedabad Engineering Research InstituteÎncă nu există evaluări

- Pipe Sizing and Cost 071216Document18 paginiPipe Sizing and Cost 071216gilbert PTSCEÎncă nu există evaluări