Documente Academic

Documente Profesional

Documente Cultură

Backup Rod

Încărcat de

jitendraDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Backup Rod

Încărcat de

jitendraDrepturi de autor:

Formate disponibile

4

1

2 0

HBR

®

ER

Closed-Cell Backer Rod

MB

Round, flexible, continuous lengths of extruded, closed-cell

E

polyethylene foam backer rod for use as a backing material

C

for elastomeric and other cold applied sealants.

D E

Features Physical Properties

• Easy to apply Property Value ASTM Test

• Non-exuding Methods

• Chemically inert

Density lb/ft3 (kg/m3), avg. > 1.5 (24) D 1622

• Virtually dust-free

Outgassing (No. of Bubbles) >1 C 1253

• Meets all of the requirements of the 1990

Clean Air Act Compression Recovery, %, min > 96 D 5249

• Is a “Domestic End Product” as defined in Compression Deflection psi (kPa) 5.5 (38.2) D 5249

the Buy American Act, Title 41 USC 10

Tensile Strength psi (kPa) > 29 (200) D 1623

Description Water Absorption (g/cc) < .03 C 1016 - Procedure B

TYPE: C - Per ASTM C 1330. Cylindrical, flexible sealant backings composed

predominantly of closed cell material per ASTM C 1330 for use with cold applied

sealants.

TYPE: 3 -Per ASTM D 5249. Round rods of various diameters for use with cold applied

joint sealants.

FORM: Round Foam Rod.

TEMPERATURE LIMITS: -45˚F to +160˚F.

Benefits

HBR limits the depth of the sealant and prevents excessive sealant use. It also

helps sealant assume optimum shape factor to prolong sealant service life and

acts as a barrier to the flow of sealant through the joint.

Applications

Common applications include, but are not limited to, expansion and contraction joints,

curtain walls, construction partitions, parking decks and bridge construction.

Storage

Store in a well ventilated area. Do not store products in direct sunlight. Keep away from heat sources and open flames.

3006 Anaconda Road, Tarboro, NC 27886

Phone: 1.877.291.1157 • Fax: 919.269.7936 • www.nomacoefs.com

HBR

®

Closed-Cell Backer Rod

Product Packaging Information and Recommended Diameter Use for Joint Width

Product Unit Roll Length Unit Weight Unit Dimension Joint Dimension

1/4” (6 mm) Spool 6400’ (1951 m) 12 lbs (5.4 kg) 18” x 18” x 31” 3/16” or less (5 mm or less)

1/4” (6 mm) Handy Pack 2500’ (762 m) 7 lbs (3 kg) 15” x 15” x 18” 3/16” or less (5 mm or less)

3/8” (10 mm) Spool 3600’ (1097 m) 12 lbs (5.4 kg) 18” x 18” x 31” 1/4” (6 mm)

3/8” (10 mm) Handy Pack 1400’ (427 m) 7 lbs (3 kg) 15” x 15” x 18” 1/4” (6 mm)

1/2” (13 mm) Spool 2500’ (762 m) 12 lbs (5.4 kg) 18” x 18” x 31” 3/8” (10 mm)

1/2” (13 mm) Handy Pack 800’ (244 m) 7 lbs (3 kg) 15” x 15” x 18” 3/8” (10 mm)

5/8” (16 mm) Spool 1550’ (472 m) 12 lbs (5.4 kg) 18” x 18” x 31” 1/2” (13 mm)

5/8” (16 mm) Handy Pack 550’ (168 m) 7 lbs (3 kg) 15” x 15” x 18” 1/2” (13 mm)

3/4” (19 mm) Spool 1100’ (335 m) 12 lbs (5.4 kg) 18” x 18” x 31” 5/8” (16 mm)

3/4” (19 mm) Handy Pack 400’ (122 m) 7 lbs (3 kg) 15” x 15” x 18” 5/8” (16 mm)

7/8” (22 mm) Spool 850’ (259 m) 12 lbs (5.4 kg) 18” x 18” x 31” 11/16” (18 mm)

1” (25 mm) Spool 550’ (168 m) 12 lbs (5.4 kg) 18” x 18” x 31” 3/4” (19 mm)

1-1/4” (32 mm) Spool 400’ (122 m) 12 lbs (5.4 kg) 18” x 18” x 31” 7/8” (22 mm)

1-1/2” (38 mm) Cut Length 550’ (168 m) 18 lbs (8 kg) 23” x 13” x 75” 1-1/8” (29 mm)

2” (51 mm) Cut Length 360’ (110 m) 18 lbs (8 kg) 23” x 13” x 75” 1-5/8” (41 mm)

2-1/2” (63 mm) Cut Length 240’ (73 m) 18 lbs (8 kg) 23” x 13” x 75” 2” (51 mm)

3” (76 mm) Cut Length 144’ (44 m) 18 lbs (8 kg) 23” x 13” x 75” 2-1/2” (64 mm)

4” (102 mm) Cut Length 90’ (27 m) 18 lbs (8 kg) 23” x 13” x 75” 3” (76 mm)

6” (152 mm) Cut Length 72’ (22 m) 40 lbs (18 kg) 25” x 12” x 112” 4-1/2” (114 mm)

Joint Preparation and Installation

Just prior to installing HBR, clean all joints per the sealant manufacturer’s recommendations. Thoroughly remove any concrete form-release agents,

curing compound residue, laitance, or any foreign materials. To ensure a good sealant bond, joints must be clean and dry when the new sealant is

installed. Air compressors used for this purpose must be equipped with traps for removal of oil and moisture. Install HBR at the depth recommended

by the sealant manufacturer with a blunt tool.

Size Selection

Proper size selection is important as it controls the depth of the sealant bead. It must be oversized (25-50%) to fit tightly into the joint and function

as a bondbreaker to prevent back-side adhesion of the sealant.

Compatibility

Closed-cell polyethylene foam is an inert material; and therefore, it is compatible, both physically and chemically, with virtually all known cold

applied sealants including self-leveling types.

Precautions

Do not puncture, over compress or stretch HBR during insertion. Do not use with hot applied sealants. Tests for outgassing of cold applied sealants

shall be made in accordance with ASTM Test Method C 1253. Sealant compatibility should be confirmed by the sealant manufacturer. Compatibility

characteristics of sealants in contact with sealant backings can be determined by ASTM Test Method C 1087.

Distributed by:

EFS0005HBR

Although every effort has been made to assure the accuracy of this information and the safety and suitability of its products, Nomaco accepts no responsibility for results obtained by the application of this information or for the safety and suitability of its products, either

alone or in combination with other products. Users are advised to make their own tests to determine the safety and suitability of each such product or product combination for their own purposes. In view of the various conditions under which this information and our

products or the products of other manufacturers in combination with our products may be used, Nomaco sells its products without warranty, and buyers and users assume all responsibility and liability for loss or damage from handling and use of these products, whether

used alone or in combination with other products.

S-ar putea să vă placă și

- Rolas Pasa Cable de Fibra de VidrioDocument1 paginăRolas Pasa Cable de Fibra de Vidriogian marcoÎncă nu există evaluări

- Copper Pan Cake Coil Weight Chart (3 Range)Document1 paginăCopper Pan Cake Coil Weight Chart (3 Range)Gaurav Panditrao Udanshiv50% (2)

- Jacketed Wire RopeDocument2 paginiJacketed Wire RopeAnandÎncă nu există evaluări

- Kwikzip Info Sheets GTDocument2 paginiKwikzip Info Sheets GTcristiano68071Încă nu există evaluări

- Spec Sheet 17 - Cs Combo 86ff9fe0Document2 paginiSpec Sheet 17 - Cs Combo 86ff9fe0Eduardo QuiñonesÎncă nu există evaluări

- Properties: Navigation 1/4" (6.55 MM) Monoconductor Corrosion ResistantDocument1 paginăProperties: Navigation 1/4" (6.55 MM) Monoconductor Corrosion ResistantRaed fouadÎncă nu există evaluări

- Lav Common BedroomDocument2 paginiLav Common Bedroomhucyg63Încă nu există evaluări

- Hoja Tecnica QJ341Document2 paginiHoja Tecnica QJ341Guillermo PaisÎncă nu există evaluări

- Dasan - Company Introduction - 2018 - Black Version PDFDocument44 paginiDasan - Company Introduction - 2018 - Black Version PDFOoi Tze YuanÎncă nu există evaluări

- HexTow AS4C Carbon Fiber TDSDocument2 paginiHexTow AS4C Carbon Fiber TDSJHOSDOUGLASÎncă nu există evaluări

- Machine DimensionsDocument4 paginiMachine DimensionsLucas Matias BarretoÎncă nu există evaluări

- Catalogue PT - Surya Sarana Maxindo PDFDocument59 paginiCatalogue PT - Surya Sarana Maxindo PDFRidwanullah StoreÎncă nu există evaluări

- Pump Installation and Maintenance: Learning OutcomeDocument6 paginiPump Installation and Maintenance: Learning OutcomeMohammed Amin BenharkatÎncă nu există evaluări

- Mandev Weight Chart.Document1 paginăMandev Weight Chart.mohammed bilalÎncă nu există evaluări

- Backer Rod Prod DataDocument4 paginiBacker Rod Prod Datacricket storiesÎncă nu există evaluări

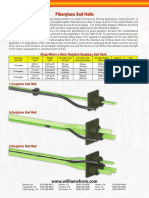

- Fiberglass Soil NailsDocument2 paginiFiberglass Soil NailsPrakashÎncă nu există evaluări

- Wenger - Tourmaster Risers - TSDocument1 paginăWenger - Tourmaster Risers - TSRichardRobbinsÎncă nu există evaluări

- Window MillDocument6 paginiWindow MillrahulÎncă nu există evaluări

- Properties: 7/32" (5.69 MM) Monoconductor NavigationDocument1 paginăProperties: 7/32" (5.69 MM) Monoconductor NavigationmarcioÎncă nu există evaluări

- 11 10K Double Cameron U BOPDocument2 pagini11 10K Double Cameron U BOPbalaji baluÎncă nu există evaluări

- Maritime Marine Supply Supplement 2023Document32 paginiMaritime Marine Supply Supplement 2023BM HướngÎncă nu există evaluări

- LoMasterDockLift BrochureDocument4 paginiLoMasterDockLift BrochureDaniel Sandoval FernándezÎncă nu există evaluări

- MTC Attach A Puller SpecsDocument4 paginiMTC Attach A Puller SpecsCarlos MurilloÎncă nu există evaluări

- Minispecsheet16 06 10 - 000 PDFDocument2 paginiMinispecsheet16 06 10 - 000 PDFLuis SousaÎncă nu există evaluări

- Delco RGA Product Line 2023 FinalDocument5 paginiDelco RGA Product Line 2023 FinalOnebigunicornÎncă nu există evaluări

- VR Lubricator ToolDocument2 paginiVR Lubricator ToolChrisÎncă nu există evaluări

- 4DG FibreDocument8 pagini4DG FibreSANGAVI TÎncă nu există evaluări

- 370 Dragon Series Dredge Web Form OptimizedDocument2 pagini370 Dragon Series Dredge Web Form OptimizedIkechukwu UzoÎncă nu există evaluări

- Techspec - QA330 - Fintec 542Document2 paginiTechspec - QA330 - Fintec 542Benjamin MurphyÎncă nu există evaluări

- Aluminum Bulk TIG PKG Sell SHTDocument1 paginăAluminum Bulk TIG PKG Sell SHTHuỳnh TrươngÎncă nu există evaluări

- AS4C Aerospace HexTow 231GPaDocument2 paginiAS4C Aerospace HexTow 231GPaShravani ZadeÎncă nu există evaluări

- Action Eng 2007Document24 paginiAction Eng 2007Nader GaafarÎncă nu există evaluări

- Slam Air ShocksDocument2 paginiSlam Air ShocksArkhamÎncă nu există evaluări

- Leaflet SMA Max LowDocument8 paginiLeaflet SMA Max LowCarlos Florencio UrbanoÎncă nu există evaluări

- Cotton Loader S 3216 CatalogDocument4 paginiCotton Loader S 3216 Catalogحمزة hamzaÎncă nu există evaluări

- Eco 2i Traction MRL enDocument17 paginiEco 2i Traction MRL enhabibullaÎncă nu există evaluări

- 670 Tech Data Sheet 112020Document2 pagini670 Tech Data Sheet 112020Anibal José Gómez ArrietaÎncă nu există evaluări

- Qe341 Scalping Screen Pioneering Solutions For You: Technical SpecificationDocument2 paginiQe341 Scalping Screen Pioneering Solutions For You: Technical SpecificationJesusFloresRodriguezÎncă nu există evaluări

- Automated Power Catwalk 1404Document6 paginiAutomated Power Catwalk 1404KACEMÎncă nu există evaluări

- 9×25mm Dillon: History Cartridge Dimensions Reloading Commercial Availability See Also References External LinksDocument4 pagini9×25mm Dillon: History Cartridge Dimensions Reloading Commercial Availability See Also References External Linkstyrant88Încă nu există evaluări

- DSI Underground Systems Cable Bolts US 01Document16 paginiDSI Underground Systems Cable Bolts US 01Tato Del AguilaÎncă nu există evaluări

- Accessories SALISBURYDocument12 paginiAccessories SALISBURYEdans LoaizaÎncă nu există evaluări

- AN04Document4 paginiAN04carlossu18Încă nu există evaluări

- Arkal Leader Twin 3Document2 paginiArkal Leader Twin 3Ame Mena SantosÎncă nu există evaluări

- Thermo Scientific Haemaflex 6 Swinging Bucket Rotor: Large Capacity RotorsDocument2 paginiThermo Scientific Haemaflex 6 Swinging Bucket Rotor: Large Capacity RotorsFrancisco EsparzaÎncă nu există evaluări

- Grippack CombinedDocument2 paginiGrippack CombinedHector NinajaÎncă nu există evaluări

- Anti Vibration PadsDocument5 paginiAnti Vibration PadsNikhil RajanÎncă nu există evaluări

- Cable Lashing Equipment: J2 Cable Lasher C2 Cable LasherDocument1 paginăCable Lashing Equipment: J2 Cable Lasher C2 Cable LasherSerafinÎncă nu există evaluări

- Commercial Specification Sheet Cordlash 105 & HDB 10 N - 6310000 6310900 7400300Document2 paginiCommercial Specification Sheet Cordlash 105 & HDB 10 N - 6310000 6310900 7400300Juanma SalamancaÎncă nu există evaluări

- 13.625 10K Single Cameron U BOPDocument2 pagini13.625 10K Single Cameron U BOPa.solvevÎncă nu există evaluări

- 670 Dragon Series Dredge Web Form OptimizedDocument2 pagini670 Dragon Series Dredge Web Form OptimizedIkechukwu UzoÎncă nu există evaluări

- Wirtgen W 2000 DatasheetDocument8 paginiWirtgen W 2000 DatasheetBeltazor HellboyÎncă nu există evaluări

- 13.625 10K Double Cameron U BOP PDFDocument2 pagini13.625 10K Double Cameron U BOP PDFAndung Suwarto100% (1)

- Rontier 5707: Compact Low-Speed Centrifuge With A Modern Touch-Wheel Interface Ideal For General Lab ApplicationsDocument2 paginiRontier 5707: Compact Low-Speed Centrifuge With A Modern Touch-Wheel Interface Ideal For General Lab ApplicationsumarÎncă nu există evaluări

- Calculate Size of Anchor Fastener For Water Pipe Support (19.1.20)Document4 paginiCalculate Size of Anchor Fastener For Water Pipe Support (19.1.20)jiguparmar1516Încă nu există evaluări

- T1B Specifications enDocument1 paginăT1B Specifications enjunyang liÎncă nu există evaluări

- Govind Steel QtyDocument1 paginăGovind Steel QtyEr Ezhilarasan MuthuÎncă nu există evaluări

- Delta / Delta DT: Roll-Bag ConvertingDocument2 paginiDelta / Delta DT: Roll-Bag Convertingmahfoud lazreugÎncă nu există evaluări

- Shore "X" 11-Kip Shoring SystemDocument4 paginiShore "X" 11-Kip Shoring SystematiÎncă nu există evaluări

- Construction MethodologyDocument102 paginiConstruction MethodologyjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendra100% (1)

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Bitumen SpecDocument1 paginăBitumen SpecvikasbadhanÎncă nu există evaluări

- TCS PDFDocument2 paginiTCS PDFjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendra100% (1)

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendra100% (1)

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendra100% (1)

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofjitendraÎncă nu există evaluări

- Tquins Resources Training Template For MT Work Programme SCS RevisedDocument12 paginiTquins Resources Training Template For MT Work Programme SCS RevisedLileth LagasimÎncă nu există evaluări

- New Text DocumentDocument246 paginiNew Text DocumentMustafa Al-RawiÎncă nu există evaluări

- "Truthland": Chesapeake S Rebuttal To GaslandDocument14 pagini"Truthland": Chesapeake S Rebuttal To GaslandJames "Chip" NorthrupÎncă nu există evaluări

- Managing Risk: Chapter SevenDocument39 paginiManaging Risk: Chapter SevenGrinaldo VasquezÎncă nu există evaluări

- Chapter 7 - Design FocusDocument2 paginiChapter 7 - Design FocusMegan Camaya100% (1)

- A Exercises SolutionsDocument13 paginiA Exercises SolutionsuxÎncă nu există evaluări

- Heat Rate EpriDocument48 paginiHeat Rate EpritbfakhrimÎncă nu există evaluări

- Challenges in Providing Leisure and RecreationDocument6 paginiChallenges in Providing Leisure and RecreationAnalyn CabilloÎncă nu există evaluări

- Evoque Owners Club Manual PDFDocument258 paginiEvoque Owners Club Manual PDFmihai12moveÎncă nu există evaluări

- Fluid MechDocument2 paginiFluid MechJade Kristine CaleÎncă nu există evaluări

- Be Katalog-Grabenfr 2013 Engl RZ KleinDocument36 paginiBe Katalog-Grabenfr 2013 Engl RZ Kleincherif100% (1)

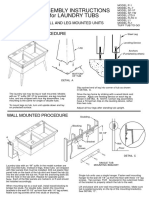

- American Standard fl7tg Installation SheetDocument2 paginiAmerican Standard fl7tg Installation SheetJonn Denver NuggetsÎncă nu există evaluări

- McGraw-Hill (Level 1) PDFDocument41 paginiMcGraw-Hill (Level 1) PDFDarpan GajjarÎncă nu există evaluări

- Prince CPVC Pipes and Fittings Pricelist1Document1 paginăPrince CPVC Pipes and Fittings Pricelist1Dee Raja38% (8)

- Abuyog 2018 PDFDocument503 paginiAbuyog 2018 PDFJackelyn Fortaliza RosquettesÎncă nu există evaluări

- EE020-Electrical Installation 1-Th-Inst PDFDocument69 paginiEE020-Electrical Installation 1-Th-Inst PDFSameera KodikaraÎncă nu există evaluări

- 11 443734731Document71 pagini11 443734731Prio ApÎncă nu există evaluări

- Commodity Market (A Project Report)Document6 paginiCommodity Market (A Project Report)Manish GargÎncă nu există evaluări

- Syllabus For Management 120A Intermediate Accounting - Spring 2009Document6 paginiSyllabus For Management 120A Intermediate Accounting - Spring 2009John KimÎncă nu există evaluări

- McbcomDocument72 paginiMcbcomopenjavier5208Încă nu există evaluări

- Tabla 1-1 (W Shapes)Document17 paginiTabla 1-1 (W Shapes)Leonardo ZambranoÎncă nu există evaluări

- Welding Machine Project Report FinalDocument44 paginiWelding Machine Project Report FinalJAYAPRABHAKARAN N NÎncă nu există evaluări

- BE Enus DP3441DP3441e DP3661e Series Portable Radios Quick Reference GuideDocument6 paginiBE Enus DP3441DP3441e DP3661e Series Portable Radios Quick Reference GuideEduardoÎncă nu există evaluări

- Relocation SurveyDocument2 paginiRelocation SurveyMarco ConopioÎncă nu există evaluări

- Cycle CountDocument58 paginiCycle CountPJ190275% (4)

- OxyGEN Router User's GuideDocument83 paginiOxyGEN Router User's Guidemakro100% (1)

- Marketing Information Systems & Market ResearchDocument20 paginiMarketing Information Systems & Market ResearchJalaj Mathur100% (1)

- Management Information System KFCDocument29 paginiManagement Information System KFCTamilSelvan0% (1)

- Wind LoadDocument1 paginăWind Loadvikramjain66Încă nu există evaluări

- 6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionDocument2 pagini6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionNita SebastianÎncă nu există evaluări