Documente Academic

Documente Profesional

Documente Cultură

Lifting lug-U-FA 121 - R0

Încărcat de

manish318Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lifting lug-U-FA 121 - R0

Încărcat de

manish318Drepturi de autor:

Formate disponibile

Input Echo, Leg & Lug Item 1, Description: New Leg/Lug

Design Internal Pressure 0.00 MPa

Design Temperature for Attachment TEMP 40.00 C

Vessel Outside Diameter OD 1210.000 mm

Vessel Wall Thickness Ts 5.0000 mm

Vessel Corrosion Allowance Cas 0.0000 mm

Vessel Material SA-240 304L

Vessel Material UNS Number S30403

Vessel Allowable Stress at Design S 115.23 MPa

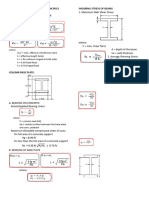

Analysis Type: Lifting Lug

Empty Weight of Vessel Wemp 10000.00 N

Operating Weight of Vessel (vertical load ) W 0.00 N

Lifting Lug Material SA-240 304

Lifting Lug Material UNS Number S30400

Lifting Lug Yield Stress YIELD 205.18 MPa

Lifting Lug Orientation to Vessel Perpendicular

Total Height of Lifting Lug w 160.0000 mm

Thickness of Lifting Lug t 12.0000 mm

Diameter of Hole in Lifting Lug dh 60.0000 mm

Radius of Semi-Circular Arc of Lifting Lug r 60.0000 mm

Height of Lug from bottom to Center of Hole h 100.0000 mm

Offset from Vessel OD to Center of Hole off 100.0000 mm

Minimum thickness of Fillet Weld around Lug tw 5.0000 mm

Length of weld along side of Lifting Lug wl 12.0000 mm

Length of Weld along Bottom of Lifting Lug wb 160.0000 mm

Lift Orientation Vertical

Force Along Vessel Axis Fax 5000.00 N

Force Normal to Vessel Fn 0.00 N

Force Tangential to Vessel Ft 0.00 N

Impact Factor Impfac 1.50

Occasional Load Factor (AISC A5.2) Occfac 1.00

Results for lifting lugs, Description : New Leg/Lug

Weld Group Inertia about the Circumferential Axis ILC 120373.227 mm^4

Weld Group Centroid distance in the Long. Direction YLL 11.000 mm

Dist. of Weld Group Centroid from Lug bottom YLL_B 6.000 mm

Weld Group Inertia about the Longitudinal Axis ILL 3422249.750 mm^4

Weld Group Centroid Distance in the Circ. Direction YLC 11.000 mm

Applying the Impact factor to the loads:

Fax = 5000.00 * 1.50 = 7500.00 N

Primary Shear Stress in the Welds due to Shear Loads [Ssll]:

= Sqrt( Fax^2+Ft^2+Fn^2 ) / ( (2*wl+wb) * tw )

= Sqrt(7500^2+0^2+0^2) / ( (2*12.0 +160.0 ) * 5.0000 )

= 8.16 MPa

Shear Stress in the Welds due to Bending Loads [Sblf]:

= (Fn*(h-YLL_B)) *YLL/ILC + (Fax*off *YLL/ILC) + (Ft*off *YLC/ILL)

= (0 *(100.000 -6.000 )) * 11.000 /120373.227 +

(7500 *100.000 * 11.000 /120373.227) +

(0 *100.000 * 11.000 /3422249 )

= 68.59 MPa

Total Shear Stress for Combined Loads [St]:

= Ssll + Sblf

= 8.159 + 68.592

= 76.75 MPa

Allowable Shear Stress for Combined Loads [Sta]:

= 0.4 * Yield * Occfac (AISC Shear All.)

= 0.4 * 205 * 1.00

= 82.07 MPa

Shear Stress in Lug above Hole [Shs]:

= Sqrt( Fax^2 + Fn^2 + Ft^2 ) / Sha

= Sqrt( 7500^2 + 0^2 + 0^2 ) / 720.000

= 10.43 MPa

Allowable Shear Stress in Lug above Hole [Sas]:

= 0.4 * Yield * Occfac

= 0.4 * 205 * 1.00

= 82.07 MPa

Pin Hole Bearing Stress [Pbs]:

= Sqrt( Fax^2 + Fn^2 ) / ( t * dh )

= Sqrt( 7500^2 + 0^2 ) / ( 12.000 * 60.000 )

= 10.43 MPa

Allowable Bearing Stress [Pba]:

= Min( 0.75 * Yield * Occfac, 0.9*Yield ) AISC Bearing All.

= Min( 0.75 * 205 * 1.00 , 184.7 )

= 153.89 MPa

Bending stress at the base of the lug [Fbs]:

= Ft*off / (w*t^(2) / 6) + Fax*off / (w^(2)*t / 6)

= 0 * 100.000 / (160.000 * 12.000^(2) / 6) +

7500 * 100.000 / (160.000^(2) * 12.000 / 6)

= 14.66 MPa

Tensile stress at the base of the lug [Fa]:

= Fn / (w * t) = 0 / (160.000 * 12.000 )

= 0.00 MPa

Total Combined Stress at the base of the lug:

= Fbs + Fa = 14.7 MPa

Lug Allowable Stress for Bending and Tension:

= Min( 0.66 * Yield * Occfac, 0.75*Yield )

= Min( 0.66 * 205 * 1.00 , 153.9 ) = 135.4 MPa

Note: Check the Shell Stresses using method such as WRC-107.

Summary of Results

Stress (MPa

------------------------------------------------------------------------------

Primary Shear Stress of Weld : 76.75 82.07 Ok |

Shear Stress above Hole : 10.43 82.07 Ok |

Pin Hole Bearing Stress : 10.43 153.89 Ok |

Total Combined Stress at the lug base : 14.66 135.42 Ok |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2016

S-ar putea să vă placă și

- Spreadsheet For Single Span Cast in Place Concrete Bridge DesignDocument16 paginiSpreadsheet For Single Span Cast in Place Concrete Bridge DesignAli Akbar100% (1)

- PV Elite 2014 Licensee Filename: Rectangular Vessel Rectves Analysis: New Rectangular Item: 1 8:09P Aug 25,2015Document7 paginiPV Elite 2014 Licensee Filename: Rectangular Vessel Rectves Analysis: New Rectangular Item: 1 8:09P Aug 25,2015Pressure VesselÎncă nu există evaluări

- Anchor Bolt DesignDocument2 paginiAnchor Bolt DesignsamvendanÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Astm B987-2020Document6 paginiAstm B987-2020Hammad Rashid100% (2)

- Problems # 4-Solution: TopicsDocument11 paginiProblems # 4-Solution: TopicsJerry AlejosÎncă nu există evaluări

- Lifting LugDocument2 paginiLifting LugSACHIN PATELÎncă nu există evaluări

- Input Echo, Leg & Lug Item 1, Description: New Leg/LugDocument2 paginiInput Echo, Leg & Lug Item 1, Description: New Leg/LugEngr Khurram Jaan RamayÎncă nu există evaluări

- Crane Lifting Lug DesignDocument3 paginiCrane Lifting Lug DesignsajadbeÎncă nu există evaluări

- Lifting Lug CalculationDocument2 paginiLifting Lug Calculationmih1Încă nu există evaluări

- Lifting Lug CalcDocument4 paginiLifting Lug CalcdharwinÎncă nu există evaluări

- Lifting Lug & PartitionsDocument4 paginiLifting Lug & PartitionsbytestefÎncă nu există evaluări

- 11 TrunnionDocument21 pagini11 TrunnionMitul PatelÎncă nu există evaluări

- Tailing LugDocument3 paginiTailing LugSajad AbdulÎncă nu există evaluări

- 11.2 Lifting Lug Cal Rev 1Document17 pagini11.2 Lifting Lug Cal Rev 1Astle DsouzaÎncă nu există evaluări

- Trunnion CalculationDocument3 paginiTrunnion Calculationpradeep4545Încă nu există evaluări

- Lifting Lug CalculationsDocument6 paginiLifting Lug CalculationsYash RamiÎncă nu există evaluări

- PV Design Calc3Document6 paginiPV Design Calc3evrim77Încă nu există evaluări

- 27Document3 pagini27Fazri CMEÎncă nu există evaluări

- PV Elite: Input Echo, Leg & Lug Item 1, Description: Trunnion 1-2Document15 paginiPV Elite: Input Echo, Leg & Lug Item 1, Description: Trunnion 1-2SYedZYnAleÎncă nu există evaluări

- Retaining Wall 5MDocument6 paginiRetaining Wall 5MImran37AfiqÎncă nu există evaluări

- Support Lug CalculationsDocument26 paginiSupport Lug CalculationsDinesh ChouguleÎncă nu există evaluări

- (1. Earthquake Analysis Results Per ASCE 7Document20 pagini(1. Earthquake Analysis Results Per ASCE 7ankitÎncă nu există evaluări

- Trunnion 6 TonDocument3 paginiTrunnion 6 TonEngr Khurram Jaan RamayÎncă nu există evaluări

- Retaining Wall Design: Ver W2.5.03 - 09 Feb 2011 Title: Cantilever Retainiing Wall Input DataDocument6 paginiRetaining Wall Design: Ver W2.5.03 - 09 Feb 2011 Title: Cantilever Retainiing Wall Input DataAnantrupa Gauranga DasÎncă nu există evaluări

- Lug Calculation 1Document2 paginiLug Calculation 1Sachin5586Încă nu există evaluări

- Note de Calcul Ancrage Rev3Document3 paginiNote de Calcul Ancrage Rev3Bilel MahjoubÎncă nu există evaluări

- Saddle Reaction Summary - For Empty CaseDocument12 paginiSaddle Reaction Summary - For Empty CasesridharÎncă nu există evaluări

- Davit CalculationDocument13 paginiDavit CalculationNiraj PandyaÎncă nu există evaluări

- Results For LegsDocument9 paginiResults For LegsOscar MarinÎncă nu există evaluări

- Deep Beam TypicalDocument6 paginiDeep Beam TypicalArpit SinghÎncă nu există evaluări

- Proposed Two Storey Aparment Building Struct AnalysisDocument26 paginiProposed Two Storey Aparment Building Struct AnalysisIver Ace BihisÎncă nu există evaluări

- Appendix A - Tank Calculations - A4L0L6Document19 paginiAppendix A - Tank Calculations - A4L0L6Ignacio OñateÎncă nu există evaluări

- TankDocument7 paginiTankBolarinwaÎncă nu există evaluări

- Lifting LugDocument8 paginiLifting LugAzwan ShahÎncă nu există evaluări

- Torispherical HeadDocument5 paginiTorispherical HeadLiaquat AliÎncă nu există evaluări

- Geometry of MS Pipe Staging For PSC GirderDocument5 paginiGeometry of MS Pipe Staging For PSC Girderqs.saidurrahmanÎncă nu există evaluări

- Dry / Empty Case: Section ADocument6 paginiDry / Empty Case: Section Aevrim77100% (1)

- Tinh Dam San 2C25024 Co GiangDocument5 paginiTinh Dam San 2C25024 Co Giangtrung1983Încă nu există evaluări

- Prokon - Muro Apuntalado en El La Parte SuperiorDocument7 paginiProkon - Muro Apuntalado en El La Parte SuperiorValiente ImperatorÎncă nu există evaluări

- Mechanical Stopper - Structure CAlculationDocument9 paginiMechanical Stopper - Structure CAlculationik43207Încă nu există evaluări

- Spile Bar DeflectionDocument9 paginiSpile Bar DeflectionIsaac KendallÎncă nu există evaluări

- ASME Horizontal Vessel Analysis - Friction 0.025 PDFDocument10 paginiASME Horizontal Vessel Analysis - Friction 0.025 PDFSyed Zain AliÎncă nu există evaluări

- StaadFoundation DesignDocument97 paginiStaadFoundation DesignaquibzafarÎncă nu există evaluări

- Spreader Beam (Planning)Document28 paginiSpreader Beam (Planning)AKSHAY BHATKARÎncă nu există evaluări

- Refractory Support Ring & SeatingDocument12 paginiRefractory Support Ring & SeatingAstle DsouzaÎncă nu există evaluări

- TRUNNION CHECK CN-0xxDocument2 paginiTRUNNION CHECK CN-0xxAkashÎncă nu există evaluări

- Skirt Support Analysis TransportDocument5 paginiSkirt Support Analysis TransportHunnymijie NorÎncă nu există evaluări

- Sample Heat Exchanger U-TUBE ReportDocument66 paginiSample Heat Exchanger U-TUBE Report9913489806Încă nu există evaluări

- Sample CalculationDocument35 paginiSample CalculationYoesbar Sofyan100% (1)

- AnchorageDocument5 paginiAnchoragemanish318Încă nu există evaluări

- Vertical Reporte DetalladoDocument28 paginiVertical Reporte DetalladoGabriel RomeroÎncă nu există evaluări

- HDD Installation CalculationsDocument4 paginiHDD Installation CalculationsN FantinÎncă nu există evaluări

- Bp8-Tension: User Defined Applied Forces at Interface Basic DimensionsDocument4 paginiBp8-Tension: User Defined Applied Forces at Interface Basic DimensionsMallesh NenkatÎncă nu există evaluări

- Intercambiadores Reporte DetalladoDocument16 paginiIntercambiadores Reporte DetalladoGabriel RomeroÎncă nu există evaluări

- AnchorDocument4 paginiAnchormanish318Încă nu există evaluări

- Code Calcs Rev1Document11 paginiCode Calcs Rev1Tauqeer AhmedÎncă nu există evaluări

- Proposed-Two-Storey-Resort-Structural-Analysis (1) DDocument26 paginiProposed-Two-Storey-Resort-Structural-Analysis (1) DIver Ace BihisÎncă nu există evaluări

- Characteristics of Viscous Wall Damper of Intense Oscillation Test Against Large EarthquakesDocument9 paginiCharacteristics of Viscous Wall Damper of Intense Oscillation Test Against Large EarthquakesAli M. MohammedÎncă nu există evaluări

- Pressure Vessel and Stacks Field Repair ManualDe la EverandPressure Vessel and Stacks Field Repair ManualEvaluare: 4 din 5 stele4/5 (4)

- M-056 - Data SheetR1Document1 paginăM-056 - Data SheetR1manish318Încă nu există evaluări

- Nozzle Load Calculation - U-FA 201Document32 paginiNozzle Load Calculation - U-FA 201manish318Încă nu există evaluări

- WoodTech Wood Stains Exterior PDFDocument2 paginiWoodTech Wood Stains Exterior PDFsanjay guhaÎncă nu există evaluări

- TicketDocument3 paginiTicketsandeep uttaralaÎncă nu există evaluări

- A Guide To Storage Tank Repair Based On API 653 StandardDocument7 paginiA Guide To Storage Tank Repair Based On API 653 Standardmanish318Încă nu există evaluări

- M-056 - Data SheetR1Document1 paginăM-056 - Data SheetR1manish318Încă nu există evaluări

- AnchorageDocument5 paginiAnchoragemanish318Încă nu există evaluări

- Heating Coil Design CalculationDocument3 paginiHeating Coil Design Calculationmanish318Încă nu există evaluări

- WindDocument5 paginiWindmanish318Încă nu există evaluări

- Print of Xi - An Hyatt RegencyDocument1 paginăPrint of Xi - An Hyatt Regencymanish318Încă nu există evaluări

- Design of Storage Tanks For Internal PressureDocument7 paginiDesign of Storage Tanks For Internal Pressuremanish318Încă nu există evaluări

- Capcity CalcuDocument1 paginăCapcity Calcumanish318Încă nu există evaluări

- SizingDocument1 paginăSizingmanish318Încă nu există evaluări

- IndexDocument1 paginăIndexmanish318Încă nu există evaluări

- Foundation LoadingsDocument1 paginăFoundation Loadingsmanish318Încă nu există evaluări

- AnchorDocument4 paginiAnchormanish318Încă nu există evaluări

- WeightDocument3 paginiWeightmanish318Încă nu există evaluări

- Int PressDocument8 paginiInt Pressmanish318Încă nu există evaluări

- Max Rafter SpacingDocument1 paginăMax Rafter Spacingmanish318Încă nu există evaluări

- Age Calculator Etc (1) .Document2 paginiAge Calculator Etc (1) .manish318Încă nu există evaluări

- Dealing With Organisational Change Can Emotional Intelligence Enhance Organisational LearningDocument16 paginiDealing With Organisational Change Can Emotional Intelligence Enhance Organisational LearningSabiqNadzimÎncă nu există evaluări

- IndexDocument1 paginăIndexmanish318Încă nu există evaluări

- Main Door Canopy PlanDocument1 paginăMain Door Canopy Planmanish318Încă nu există evaluări

- Main Door Canopy Section-DDocument1 paginăMain Door Canopy Section-Dmanish318Încă nu există evaluări

- Main Door Canopy ElevationDocument1 paginăMain Door Canopy Elevationmanish318Încă nu există evaluări

- Main Door Canopy Section-CDocument1 paginăMain Door Canopy Section-Cmanish318Încă nu există evaluări

- EngDocument13 paginiEngmanish318Încă nu există evaluări

- Crude Oil Stroage Tanks SpecsDocument48 paginiCrude Oil Stroage Tanks Specsmanish318Încă nu există evaluări

- Eng 2015Document103 paginiEng 2015manish318Încă nu există evaluări

- A Glimpse of Our Life TodayDocument3 paginiA Glimpse of Our Life Todaymanish318Încă nu există evaluări

- Cycles of Time An Extraordinary New View of The Universe by Roger Penrose B004dephtiDocument5 paginiCycles of Time An Extraordinary New View of The Universe by Roger Penrose B004dephtijohnÎncă nu există evaluări

- Lecture-10 SensorsDocument84 paginiLecture-10 SensorsАмир КулиевÎncă nu există evaluări

- Steel Design Formulas and Principles - CompressDocument6 paginiSteel Design Formulas and Principles - CompressClint SusarnoÎncă nu există evaluări

- Computational and Data Sciences: FacultyDocument2 paginiComputational and Data Sciences: FacultyAmarjeet KrishhnanÎncă nu există evaluări

- Free WAEC Time Table For Science, Commercial, Arts Student 2023Document11 paginiFree WAEC Time Table For Science, Commercial, Arts Student 2023Charles ObaleagbonÎncă nu există evaluări

- 3 A) PDS - E - JER - v4.1Document4 pagini3 A) PDS - E - JER - v4.1Anish KarthikeyanÎncă nu există evaluări

- Design Hi eFF Centri BlowerDocument123 paginiDesign Hi eFF Centri BlowerJo PastorÎncă nu există evaluări

- Speed and VelocityDocument2 paginiSpeed and VelocityJeya Plays YTÎncă nu există evaluări

- KS4 Waves: Refraction: © Boardworks LTD 2002Document47 paginiKS4 Waves: Refraction: © Boardworks LTD 2002Shalini KulshresthaÎncă nu există evaluări

- 01.M.E. Structural PDFDocument51 pagini01.M.E. Structural PDFSubasharavind KaruppasamyÎncă nu există evaluări

- Pages From 0-Fan Coil Unit (Zamil) - 2Document1 paginăPages From 0-Fan Coil Unit (Zamil) - 2Vic BayotÎncă nu există evaluări

- Lecture 3Document18 paginiLecture 3ssaalleehh340Încă nu există evaluări

- De Thi Chon Hoc Sinh Gioi Mon Tieng Anh Lop 9 TP Ho Chi Minh Nam Hoc 2012 2013Document10 paginiDe Thi Chon Hoc Sinh Gioi Mon Tieng Anh Lop 9 TP Ho Chi Minh Nam Hoc 2012 2013Qian JinÎncă nu există evaluări

- Locking Ring Calculator OD2700Document10 paginiLocking Ring Calculator OD2700muscleglassesÎncă nu există evaluări

- Spring 2020 Gems Gemology v2 PDFDocument195 paginiSpring 2020 Gems Gemology v2 PDFJORGE LUIS HERNANDEZ DUARTE100% (1)

- Astm D 2208-00Document2 paginiAstm D 2208-00yok patchnakanÎncă nu există evaluări

- Jee Main Leader SyllabusDocument1 paginăJee Main Leader SyllabusMampÎncă nu există evaluări

- PR-9000-D - Adjustment Manual (E) (Training Document Vol.1) 2017.12.18Document53 paginiPR-9000-D - Adjustment Manual (E) (Training Document Vol.1) 2017.12.18Jose VivarÎncă nu există evaluări

- Indux R4, Indux R5 and Indux R7: Industrial X-Ray FilmsDocument2 paginiIndux R4, Indux R5 and Indux R7: Industrial X-Ray FilmsMian Ahmer AliÎncă nu există evaluări

- Born's Conditions On The Wave FunctionDocument4 paginiBorn's Conditions On The Wave FunctionSaswati BanerjeeÎncă nu există evaluări

- Aristo Science Workbook 1A (Answer) PDF Solubility EvaporationDocument1 paginăAristo Science Workbook 1A (Answer) PDF Solubility Evaporationntlroblox870% (1)

- Bolted Flanged Joint Creep/Relaxation Results at High TemperaturesDocument7 paginiBolted Flanged Joint Creep/Relaxation Results at High TemperaturesjlbarretoaÎncă nu există evaluări

- IB Mathematics AA HL Questionbank - Integral CalculusDocument53 paginiIB Mathematics AA HL Questionbank - Integral CalculusMatias LandiÎncă nu există evaluări

- (Chapter) Neonatal Infrared Thermography MonitoringDocument43 pagini(Chapter) Neonatal Infrared Thermography MonitoringErwin SmithÎncă nu există evaluări

- Motor CatalogueDocument9 paginiMotor CatalogueMahalingam Nanjappan0% (1)

- Dissertation CGDocument147 paginiDissertation CGChiheb BaÎncă nu există evaluări

- MEC331-Chapter-03 - Rivets & BearingsDocument52 paginiMEC331-Chapter-03 - Rivets & BearingsMuhammad Muadz Amirul AzamÎncă nu există evaluări

- A Mathematical Model For Predicting The Relaxation of Creep Strains in MaterialsDocument18 paginiA Mathematical Model For Predicting The Relaxation of Creep Strains in MaterialsAmina DinariÎncă nu există evaluări