Documente Academic

Documente Profesional

Documente Cultură

BF00881125 PDF

Încărcat de

Igor SampaioTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

BF00881125 PDF

Încărcat de

Igor SampaioDrepturi de autor:

Formate disponibile

International Journal of Mining and Geological Engineering, 1990, 8, 13-34

A three dimensional model of muckpile

formation and grade boundary movement in

open pit blasting

R . L . Y A N G and A. K A V E T S K Y

Julius KruttschnittMineralResearch Centre,Isles Road, Indooroopilly, Queensland,4068,Australia

Received 30 October 1989

Summary

Formulation and case studies of a three dimensional kinematic model are presented. The in situ

overburden geometry can be simulated accurately and various initiation patterns of blasts can be

modelled. The overburden geometry, hole patterns and explosive distribution are all explicit model

inputs. Because the effect of explosive properties, rock mass condition and inter-row delay are very

difficult to measure in terms of blast performance, these are represented in the model by control

parameters which are left for calibration using field data. The output of the model is a three dimensional

muckpile shape of any cross section and a contour map of grade distribution within the muckpile. Two

case studies are presented which have shown that the model is a valuable tool for optimizing production

blasting as well as for controlling grade dilution during blasting.

Keywords: Blasting; three dimensional model; muckpile shape; grade control; explosive performance

Introduction

Modelling of blasting has tended to be concentrated on the fragmentation process and

modelling of muckpile formation has received relatively scant attention in the literature. At

present, there are few documented case studies of successful applications of modelling to

predict muckpile shapes and there are no three dimensional models of muckpile formation.

Yet this aspect of the blasting process is particularly important in open pit mining.

Muckpile shape and productivity

Measures of blast effectiveness in surface mining operations are different from those used in

underground operations. In the underground situation, particle size has a great influence on

productivity. In surface mining operation, however, the ease with which a muckpile may be

dug is within broad limits largely independent of fragment size distribution, since the

equipment used to move the broken rock is generally much larger than in underground

mines. In such cases, muckpile shape strongly influences mine productivity. In open pit

mining situations, a suitable muckpile shape after blasting is required for a selected piece of

0269-0136/90 $03.00+.12 © 1990Chapman & Hall Ltd.

14 Yang and Kavetsky

digging equipment. A front-end loader is best suited to low, flat-lying, loose muckpiles, as

most front-end loaders only generate a fairly small break-out force with the bucket and can

work very efficiently over a large area. In contrast, a rope shovel lacks mobility, generates a

much larger bucket break-out force and the bucket is filled in a vertical filling motion. This

makes the rope shovel ideally suited to well fragmented, steep faces (Bulow, 1988). In some

strip mining situations, throw blasting is designed to cast as much as possible of the spoil

across the pit with explosives. Evaluation of the technical and economic aspects of the

method has indicated that considerable benefits can be achieved, provided that the

environmental impact is acceptable. It is necessary to optimize the design of the throw blast

in terms of maximizing the throw percentage under the necessary constraints. For dragline

operations in some strip mining situations, the muckpile shape is of more interest than the

percentage of throw across the pit. If the dragline operation uses a conventional bridge, the

preferred working level of the dragline is at the top of the new highwall. This dig working level

must be maintained, so that the dragline may sit over the key cut and little preparation of the

dragline pad should be required.

Grade control during blasting

In many open cut operations, in particular gold, nickel and iron ore mines, the delineation of

regions of differing grade and the ability to mine those regions separately from within the

same blast pattern is critical. Delineation of grade regions prior to blasting is usually known

to an accuracy of within a few metres (at least in plan) since blastholes are assayed routinely.

After the blast has occurred, grade boundaries very rarely follow the pre-blast regions since

significant displacements occur. Unless there are marked colour differences between regions,

large errors can be incurred in the laying out of post-blast digging regions. Thus prediction of

grade region boundary movement and subsequent dilution is of interest to many open cut

mines. Such a predictive tool would enable blast design changes to be made to reduce mixing

of certain boundaries.

Current modelling approaches and their difficulties

Most existing models of blasting are dynamic, namely, the model calculations are based on

the fundamental physics to analyse the detailed interactions between explosive and rock

overburden (Cherry, 1967 and Schamaun, 1983). In fact, details of the complex dynamic

mechanisms of rock blasting are still far from clear at present because of the difficulties in

measuring the behaviour of the explosive and the response of the rock mass during blasting.

In using the dynamic method to model the blasting process many uncertain parameters will

be involved. This method is normally complex to implement and takes a large amount of

computer time. This forms a major impediment to the simulations of real production blasts.

Modelling approach selected

The model presented in this paper is based on a simpler 'kinematic' approach to modelling

muckpile formation. It is an extension of the two-dimensional kinematic model reported by

Yang and Kavetsky (1989). The method does not calculate the velocitiy from the acceleration

process of the fragmented rock block. The model is simplified by determining major trends

and macro-phenomenon and includes both fundamental and empirical aspects. This

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- SÔ 1 de Thi HSG Tieng Anh Tinh Phu Tho 20162017Document8 paginiSÔ 1 de Thi HSG Tieng Anh Tinh Phu Tho 20162017Huỳnh Minh ĐứcÎncă nu există evaluări

- Scientific Notation Unit TestDocument3 paginiScientific Notation Unit TestMohamed AbdisamedÎncă nu există evaluări

- Brand Book Elena Jovanka DenisaDocument32 paginiBrand Book Elena Jovanka DenisaelenajovankadÎncă nu există evaluări

- Product Information: 2C-B (Hydrochloride)Document1 paginăProduct Information: 2C-B (Hydrochloride)Captain KaswanÎncă nu există evaluări

- Mobile Phones and RadiationDocument6 paginiMobile Phones and RadiationGehanShabanÎncă nu există evaluări

- Stochastic Oscillator Sto - Chas.tic (Sto Kas'tik) Adj. 2. Math. Designating A Process Having An Infinite ProgressionDocument3 paginiStochastic Oscillator Sto - Chas.tic (Sto Kas'tik) Adj. 2. Math. Designating A Process Having An Infinite ProgressiongmsbhatÎncă nu există evaluări

- Lecture ST1201Document34 paginiLecture ST1201SheinzenÎncă nu există evaluări

- Lo1 Obtain and Convey Workplace InformationDocument15 paginiLo1 Obtain and Convey Workplace InformationRamramramManmanmanÎncă nu există evaluări

- Real Analysis: Jos e Mar Ia CuetoDocument14 paginiReal Analysis: Jos e Mar Ia CuetoFor ThingsÎncă nu există evaluări

- Analysis of Fishing Ports To Support The DevelopmentDocument10 paginiAnalysis of Fishing Ports To Support The DevelopmentValentino SaputraÎncă nu există evaluări

- 178 Capstone: - DigitalDocument1 pagină178 Capstone: - DigitalAbdul Nafi SarwariÎncă nu există evaluări

- Q4 Week 3 Lesson 4-GenyoDocument55 paginiQ4 Week 3 Lesson 4-GenyoNORIELIE RODRIGUEZÎncă nu există evaluări

- Civil Engineering Laws and Ethics in The PhilippinesDocument16 paginiCivil Engineering Laws and Ethics in The PhilippinesMonde Nuylan90% (48)

- Sefirot - The GuidebookDocument28 paginiSefirot - The GuidebookOscarC2Încă nu există evaluări

- Outcomes Advanced TB Review Test 2 PDFDocument3 paginiOutcomes Advanced TB Review Test 2 PDFВиктория ЛысенкоÎncă nu există evaluări

- RC MENQOL-I AU1.0 1week-Recall eng-CAoriDocument6 paginiRC MENQOL-I AU1.0 1week-Recall eng-CAoriRoviqi Bozgank AzemÎncă nu există evaluări

- Structural Analysis of Steel Structures Under Fire Loading: Acta Polytechnica Hungarica January 2009Document9 paginiStructural Analysis of Steel Structures Under Fire Loading: Acta Polytechnica Hungarica January 2009Nenad GajicÎncă nu există evaluări

- LogDocument18 paginiLogPrawiro indro BhaktiÎncă nu există evaluări

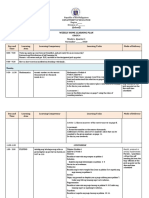

- CAPILLAN, SHAIRA - Semi-Detailed-Lesson-PlanDocument7 paginiCAPILLAN, SHAIRA - Semi-Detailed-Lesson-PlanShai Ra CapillanÎncă nu există evaluări

- Sara Teasdale PoemsDocument2 paginiSara Teasdale PoemsChris NobleÎncă nu există evaluări

- Hydrosphere Class 7 NotesDocument5 paginiHydrosphere Class 7 NotesDEOHE BOTOKO GAMER100% (1)

- 新托福百日百句百篇(第一册)Document274 pagini新托福百日百句百篇(第一册)张子楚Încă nu există evaluări

- Morph Elegant Powerpoint TemplateDocument6 paginiMorph Elegant Powerpoint TemplateAl FaritsiÎncă nu există evaluări

- Electrical Method PDFDocument65 paginiElectrical Method PDFVioleta Reyes OrozcoÎncă nu există evaluări

- Chaos Theory 2020Document31 paginiChaos Theory 2020seth feanorÎncă nu există evaluări

- The National Academies Press: Space Nuclear Propulsion For Human Mars Exploration (2021)Document93 paginiThe National Academies Press: Space Nuclear Propulsion For Human Mars Exploration (2021)Cable KurwitzÎncă nu există evaluări

- QI-WEEK 4-ADM BasedDocument10 paginiQI-WEEK 4-ADM BasedMarloCris ToqueroÎncă nu există evaluări

- Using Hexagonal Thinking' To Deepen Classroom ConversationsDocument5 paginiUsing Hexagonal Thinking' To Deepen Classroom ConversationsKathryn LupsonÎncă nu există evaluări

- Bending TM 1806Document4 paginiBending TM 1806Richa RohillaÎncă nu există evaluări

- Cholinoceptor AntagonistDocument21 paginiCholinoceptor Antagonistraafat mohammedÎncă nu există evaluări