Documente Academic

Documente Profesional

Documente Cultură

THERMALANALYSISINLARGEDIAMETERBOREDPILES1

Încărcat de

Miguel Balunsat Sabban Jr.Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

THERMALANALYSISINLARGEDIAMETERBOREDPILES1

Încărcat de

Miguel Balunsat Sabban Jr.Drepturi de autor:

Formate disponibile

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/301340964

THERMAL ANALYSIS IN LARGE DIAMETER BORED PILES

Conference Paper · October 2002

CITATIONS READS

0 467

2 authors:

Ahmed Al-Obaidi Mosa J. Al-Mosawe

Tikrit University 15 PUBLICATIONS 5 CITATIONS

31 PUBLICATIONS 13 CITATIONS

SEE PROFILE

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Soil improvement View project

Piles foundation View project

All content following this page was uploaded by Ahmed Al-Obaidi on 16 April 2016.

The user has requested enhancement of the downloaded file.

3

PROCEEDINGS OF THE 6th INTERNATIONAL CONFERENCE ON

CONCRETE TECHNOLOGY FOR DEVELOPING COUNTRIES

THERMAL ANALYSIS IN LARGE DIAMETER

BORED PILES

Dr. Mosa J. Al-Mosawe Dr. Ahmed A. H. Al-Obaidi

Professor Lecturer

University of Baghdad University of Tikrit

ABSTRACT

In recent years, one of the important developments in foundation engineering has been

the rapidly growing popularity of large diameter bored piles. The bored pile can be

installed in sands and clays, above or below the water table, with a diameter up to 3.5

m.

A concrete member of such size is usually subjected to secondary stresses such as

thermal stresses due to the dissipation of the heat of hydration and from periodic cycles

of ambient.

In this paper, thermal analyzes of a concrete pile subjected to a heat of hydration release

and heat transfer were considered. The heat flow through the pile shaft and the thermal

stresses are analyzed and discussed.

The result of the analysis indicated that the dissipation of the heat is relatively high at

the concrete shaft especially within the 60 hours after placing of the concrete. The

dissipation of the heat of hydration generates tensile stresses in the pile shaft. Additional

reinforcement should be provided to the pile shaft to resist such stresses. The full-length

reinforcement was prompt to obtain an adequate crack distribution and a reasonable

limit on crack width.

INTRODUCTION

There are a number of factors, which should be considered in the design of the bored

piles beyond the routine computation procedures. A review of these factors reveals

serious defects, such as the loss of continuity along the pile length, and the shaft may

contain cracks, voids, inclusion, etc. These defects may not affect the pile performance

in the short term. However, the long-term behaviour may be important, particularly

when a pile is subjected to bending stresses.

In concrete structures, deformations and volume changes should be considered even

through the external loading is small. Volume changes are caused by changes in

moisture content of the concrete, changes in temperature, and chemical reactions, (ACI

Committee 207, 1970). Excessive volume change is detrimental to concrete and leads

to form cracks.

Volume III 763

PROCEEDINGS OF THE 6th INTERNATIONAL CONFERENCE ON

CONCRETE TECHNOLOGY FOR DEVELOPING COUNTRIES

Cracking is a weakening factor that may affect the ability of the concrete to withstand

its designed load and may also detract from durability and appearance, (ACI Committee

224, 1984).

The thermal stresses in concrete are developed in two ways, from the dissipation of the

heat of hydration and from periodic cycles of ambient. In ordinary structure, most of

the heat generated by the hydration of cement is dissipate almost quickly and there is

little temperature difference from the inside to the outside of the body. A structural

element with large dimensions differs in its behaviour with that of ordinary structure.

The thermal properties allow only slow movements of heat, which means that heat

trapped within a mass concrete structure can hardly be escaped. This will cause a

difference in temperature between the internal mass and the surface. As concrete gains

both strength and stiffness, the restraint of the free contraction will result and generate

the tensile stresses, (ACI Committee 224, 1984).

Salih (2001) found in his experimental study that the maximum temperature recorded

in the internal part of mass concrete was 76°C and remains for a long period of time,

(about three weeks). The cracks were noticed in a concrete pedestal with dimensions

(33*6*5) m when the difference in temperature between the internal part and surface

was 41°C.

Neville, (1981) found that cracking is developed when the difference in temperature

between the interior body and the exterior surface is large. This may occur during hot

weather period, in which cause the cracks will develop in the interior mass as shown in

Fig. (1). Also, cracks can occur during the course of cooling and appear on the surface

as shown in Fig. (2). These figures also indicate that the development of cracks become

important when the temperature difference exceeds 20ºC.

Large diameter bored piles which may be considered in behaviour as a massive concrete

structural element can be affected by the hydration of cement during construction and

curing, which may lead to series of tension cracks in the pile body before loading.

In this study, a non-linear, two-dimensional finite element model is described for the

analysis of concrete pile subjected to a heat of hydration release and heat transfer.

THEORETICAL CONSIDERATIONS

In order to study the thermo-mechanical behaviour of structures, two stages of analysis

are needed, thermal and stress analysis. The thermal analysis of concrete structures

depends on their thermal properties (i.e. conductivity, density and specific heat). It is

widely known that these properties can vary with temperature. These variations (if

considered) will result in a considerable nonlinearity in the covering equation for heat

flow.

The general covering differential equation for heat diffusion analysis is:

∂ ∂T ∂ ∂T ∂ ∂T ∂T

kx + ky + kz + q = ρ ⋅c (1)

∂x ∂x ∂y ∂y ∂z ∂z ∂t

where, kx, ky, kz are thermal conductivity in x, y, and z-direction respectively,

ρ: density,

c: specific heat,

T: temperature, and

Volume III 764

PROCEEDINGS OF THE 6th INTERNATIONAL CONFERENCE ON

CONCRETE TECHNOLOGY FOR DEVELOPING COUNTRIES

q: the rate of heat generated in the body.

The rate of increase of the internal heat c(∂Tof∂tthe

ρ ⋅sum

is the ) rate of heat

generates q and the rate of heating entering by conduction. The derivation of this

equation may be found in any related reference.

The thermal conductivity of ordinary concrete depends on its composition, and it ranges

from 1.4 to 3.6 J/m2s°C/m. The specific heat depends on moisture content for the

concrete, it increases with an increase in temperature and with a decrease in the density

of the concrete. The common range values for ordinary concrete is between 840 and

1170 J/kg/°C.

The rate and the magnitude of the heat generated of concrete depend on the amount per

unit volume of cement and pozzolans (if any), the component composition and fineness

of cement, and upon the temperature during hydration of the cement. The hydration

temperature is affected in turn by the amount of heat lost or gained as governed by the

size and exposure conditions of the member. Thus, the exact temperature of the

concrete at any given time depends on many variables.

Byfors, (1980) assumed a relationship between heat developed and degree of hydration:

[

H e (t ) = ki exp − ai (ln(t ))

− bi

] (2)

where ki, ai, bi: constants depending on cement type and (t) time in hours.

ACI Committee 207, (1973) presents curves where simple mathematical relations were

used to conduct the heat of hydration. In this method, the peak temperature was

assumed to be equal to ambient air temperature. In hot weather, the placing temperature

of concrete might exceed the mean daily ambient air temperature from 2 to 5.5°C. This

peak temperature in concrete may occur anytime during the first week depending on

member size, type of cement and concrete placing temperature as shown in Fig. (3).

The peak temperature can be estimated by using Fig. (4) which correlate the volume to

surface ratio for different placing temperature for Type (I) cement containing 223 kg/m3

of cement. A correction for the difference in air temperature and placing temperature

can be made using Fig. (5) by estimating the time of peak temperature from Fig. (3).

The correction for actual cement content used can be calculated from:

(T)cec = (T)223kg x (cement content in the concrete mix. Kg/m3))/223 (3)

The correction also can be made to the cement type and fineness of cement.

The results of the finite difference method presented by Thurston, et al, (1980) and the

results of the experimental tests carried by Salih, (2001) of the maximum temperature

were close to the ACI Committee, 207, (1973) method.

PARAMETERS STUDIED

The aim of the study in the following articles is to find the distribution of the

temperature due to the release of the heat of hydration and then to find the stresses

Volume III 765

PROCEEDINGS OF THE 6th INTERNATIONAL CONFERENCE ON

CONCRETE TECHNOLOGY FOR DEVELOPING COUNTRIES

connected with this phenomenon. Thus, the method presented by the ACI Committee

207, (1973) was used to estimate the maximum heat of hydration.

In order to confirm the above method, the placing temperature was chosen as 40°C in

summer and 18°C in winter. The cement type was sulphate-resisting Portland cement

(Type V), and the cement content was 400 kg/m3.

Following the procedure is given by the ACI Committee 207, (1973), the peak

temperature obtained were 68°C after 18 hrs of placing in the summer and 35°C after

one day in winter for a concrete pile with one meter in diameter. The soil temperature

was considered to be equal to 25°C, both in summer and in winter, (Al-Obaidi 1999).

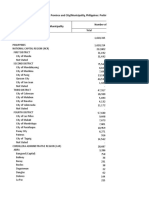

The assumed values of thermal conductivity and specific heat for the concrete pile shaft

and the soil around are shown in Table (1).

Table (1) Thermal properties of the concrete pile shaft and the soil used in the

analysis

Thermal properties The pile shaft The soil

Thermal conductivity J/m2s°C/m 3 1.73

Specific heat J/kg/°C 950 1150

THE FINITE ELEMENT METHOD

A general finite element program “ANSYS, 5.4” (1997) was selected to generate the

solution for the thermal and the stress analysis.

Since the pile length to diameter ratio is high, thus it is assumed that the heat will

transfer in the radial direction only and the problem can be considered as plane

axisymmetric. A small angle θ = 10° is used for approximating the circular boundary

with a straight-sided element as shown in Fig. (6).

In thermal analysis, plane elements with two-dimensional thermal conduction

capabilities were used to represent the pile and the soil. Each element has four nodes

with a single degree of freedom and temperature at each node. The boundary condition

will locate at a horizontal distance of three times the diameter of the pile measured from

the pile centre.

In stress analysis also, the problem was considered as plane axisymmetric. Plane solid

elements were used with four nodes having two degrees of freedom at each node. Only

the pile was representative in the analysis of the finite element. The section initially

considered being free from axial, lateral and flexural restrained in all directions. The

loading introduced as a nodal temperature at each node. In both analyzes (thermal and

stress analysis), automatic time stepping was used.

The magnitude of the stress in the concrete depends on the modulus of elasticity, which

varies rapidly with time over the first 28 days after concrete placing. It is generally

′

fc

accepted that the concrete modulus of elasticity is proportional to . Thus, relating to

28-day values:

Volume III 766

PROCEEDINGS OF THE 6th INTERNATIONAL CONFERENCE ON

CONCRETE TECHNOLOGY FOR DEVELOPING COUNTRIES

Ect f ct ′ (4)

=

Ec 28 f c 28 ′

where Ect is the modulus of elasticity at any time,

Ec28 is the modulus of elasticity at 28 days,

fct is the strength of the concrete at any time, and

fct28 is the strength of concrete at 28 days.

The relationship between the strength of concrete at 28 days and at any age t is

′ t ′

f ct = f c 28 (5)

4.0 + 0.85t

Thus, from Equation. (4) and (5),

1/ 2

t (6)

Ect = Ec 28

4.0 + 0.85t

The values of Ect were calculated for each temperature and introduced to the input file

of the program. The coefficient of thermal expansion of concrete was considered to be

constantly equal to 12*10-6 per °C.

TEMPERATURE DISTRIBUTION AFTER HYDRATION

The temperature distribution within the pile shaft and the soil around the pile due to the

dissipation of heat of hydration were drowned and shown in Fig. (7). The curves in this

figure represent the distribution of temperature after 24 hrs, 48 hrs, 60 hrs, 5 days and

10 days after concrete placing.

As shown in the figure, the dissipation of the heat is relatively properly high at the

concrete shaft, especially within the 60 hours after placing of the concrete, where the

difference in temperature between the pile centre and the surface reach 20°C after 24

hrs of concrete placing. This difference will reduce to 13°C after 60 hrs of concrete

placing. The rate of dissipation after 10 days seems to be little, where the difference

between the piles centre temperature and the surface equal to 2°C.

The soil around the pile also plays a certain role in the heat dissipation regime. The

figure shows that this effect is in the zone confined by the 1-1.5 m of the soil around

the pile.

The changes of the temperature at points starting from the pile centre and continued to

0.25 m and 0.5 m, were shown in Fig. (8). The curves in this figure show that a high

rate of heat dissipation takes place during through the first two days after placing. This

high rate leads to produce the difference in temperature between the inner and outer

points within the pile shaft. This change in temperature lead to volume change and

therefore generate stresses within the pile shaft. The values of these stresses are shown

in Fig. (9) in a relationship with the time after placing for the same points represented

in Fig. (7).

Volume III 767

PROCEEDINGS OF THE 6th INTERNATIONAL CONFERENCE ON

CONCRETE TECHNOLOGY FOR DEVELOPING COUNTRIES

Figure (9) shows a tensile stress of about 1.77 MPa generated at the inner point and 1.0

MPa the near the surface. These stresses drop to as low as 0.1 MPa after 10 days of

concrete placing.

The results of this analysis indicated that a solution should provide to eliminate the bad

effect of the tensile stresses produced. This solution might be revealed that the pile

should be provided a minimum reinforcement.

CONCLUSIONS

The results of analysis on large diameter bored pile indicate the following conclusions:

1. The finite element technique is a useful tool in predicting the stresses

generated due to thermal effect.

2. The dissipation of heat is relatively high during the first 60 hrs after casting

the concrete of the pile shaft.

3. The stresses generated due to heat dissipation should not be ignored. These

tensile stresses might reduce the capacity of concrete to loading

4. Additional reinforcement to take the effect of the tension occurred due to

thermal stresses might be very beneficial.

REFERENCES

1. ACI Committee 207: “Effect of Restraint, Volume Change, and

Reinforcement on Cracking of Massive Concrete”, ACI Journal, vol. 70 No.

7 July 1973, pp. 445-470.

2. ACI Committee 207 “Mass Concrete for Dams and other Massive

Structures”, ACI Journal, vol. 67 No. 4 April 1970, pp. 273-309.

3. ACI Committee 224 “Causes, Evaluation, and Repair of Cracks in Concrete

Structures”, ACI Journal, vol. 81 No. 3 May-June 1984, pp. 211-230.

4. Al-Obaidi, A. A. H. “Performance of unreinforced concrete bored piles

under different loading conditions”, Ph.D. Thesis, University of Baghdad,

2001, 171pp.

5. Al-Obaidi, A. A. H. “Temperature Variations and its Effect on some

Engineering Properties Of Tikrit Soils”, Scientific Journal of Tikrit

University/ Eng. Sic., vol. 6, No. 5, 1999, pp. 13-28.

6. ANSYS Inc. “ANSYS user’s manual”, Release 5.4, 1997.

7. Byfors, J., “Plain Concrete at Early-ages,” Swedish Cement Concrete

Research Institute, 1980.

8. Neville, A. M. “Properties of Concrete”, 3d edition, Pittman, Marshfield,

Massachusetts, 1981, 779 pp.

9. Salih, S. M., “Shrinkage and Thermal Cracking of Internally Restrained

Reinforced Concrete Members” M. Sc. Thesis, University of Baghdad,

2001, 116pp.

10. Thurston, S. J. et al, “Thermal analysis of Thick Concrete Sections” ACI

Journal, vol. 73 No. 38 Sept-Oct. 1980, pp. 347-357.

Volume III 768

PROCEEDINGS OF THE 6th INTERNATIONAL CONFERENCE ON

CONCRETE TECHNOLOGY FOR DEVELOPING COUNTRIES

Fig. (1) The pattern of temperature Fig. (2) The pattern of temperature change

change which causes internal which causes external cracking of

cracking of large concrete mass, large concrete mass, (after

(after Neville, 1981). Neville, 1981).

Fig. (3) Effect of placing temperature and exposure on the age of peak temperature.

Type (I) cement. Air temperature equals placing temperature, (after ACI

Committee 207, 1973).

Volume III 769

PROCEEDINGS OF THE 6th INTERNATIONAL CONFERENCE ON

CONCRETE TECHNOLOGY FOR DEVELOPING COUNTRIES

Fig. (4) A temperature rise of concrete members containing 223 kg/m3 of cement,

(after ACI Committee 207, 1973).

Fig. (5) Heat flow between air and concrete for different in placing and ambient air

temperature, (after ACI Committee 207, 1973).

Volume III 770

PROCEEDINGS OF THE 6th INTERNATIONAL CONFERENCE ON

CONCRETE TECHNOLOGY FOR DEVELOPING COUNTRIES

Fig. (6) Problem sketches for thermal analysis.

Fig. (7) Dissipation of heat of hydration from the pile in summer

Volume III 771

PROCEEDINGS OF THE 6th INTERNATIONAL CONFERENCE ON

CONCRETE TECHNOLOGY FOR DEVELOPING COUNTRIES

Fig. (8) Hydration temperature time – history for pile

Fig. (9) Stress-induced due to the dissipation of hydration.

Volume III 772

View publication stats

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Sitrep 11 Ncov 1Document8 paginiSitrep 11 Ncov 1Omar SalehÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Approved Revised Transaction Dispute Form 062618 PDFDocument2 paginiApproved Revised Transaction Dispute Form 062618 PDFGersonCallejaÎncă nu există evaluări

- PCCP Minimum StandardDocument3 paginiPCCP Minimum StandardJanssen Gerardo Valbuena100% (4)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- EhDocument123 paginiEhRed TanÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- 9 Traffic Jams in Metro Manila CreatingDocument2 pagini9 Traffic Jams in Metro Manila CreatingMiguel Balunsat Sabban Jr.Încă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Booklist ProjectDocument13 paginiThe Booklist ProjectMiguel Balunsat Sabban Jr.Încă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Correct Answer Liquid LimitDocument46 paginiCorrect Answer Liquid LimitMiguel Balunsat Sabban Jr.100% (3)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Mns SystemDocument16 paginiThe Mns SystemMiguel Balunsat Sabban Jr.100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- CultureDocument2 paginiCultureMiguel Balunsat Sabban Jr.Încă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- CultureDocument2 paginiCultureMiguel Balunsat Sabban Jr.Încă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- As A Man Thinketh - James AllenDocument28 paginiAs A Man Thinketh - James AllenMiguel Balunsat Sabban Jr.Încă nu există evaluări

- As A Man Thinketh - James AllenDocument28 paginiAs A Man Thinketh - James AllenMiguel Balunsat Sabban Jr.Încă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)