Documente Academic

Documente Profesional

Documente Cultură

Nut Bolt Table

Încărcat de

bunta007Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Nut Bolt Table

Încărcat de

bunta007Drepturi de autor:

Formate disponibile

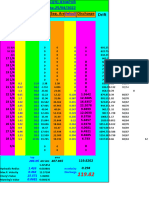

American Standard (UNC/UNF) Thread Geometry American Standard (UNC/UNF) Bolt Geometry American (UNC/UNF) Generic Torque Settings

American Standard (UNC/UNF) Bolt Geometry American (UNC/UNF) Generic Torque Settings (ft-lbs)

Size Threads Pitch Major Diameter Tap Drill (75%) Minor Diam. Nut ID Str. Area Typ. Thread Lgth Hex Head Socket Head Button Hd Flat Hd Set Screw Shoulder Screw SH Torx Aircraft SHCS Gr. 8 Gr. 5 Gr. 2 Set Sc

# or in. per in. in/rot. in. mm Drill § Size in. in. mm in. in.^2 Bolt<6" SHCS Size Wrench Hd Ht Key Size Hd Dia Hd Hght Key Size (82 deg) Key Size Key Size Shld Dia Key Size Size Dry, Cad Dry Oil Dry Oil Dry Oil Dry Oil

#0 80 .0125 .0600 1.52 1/16 3/64 .0469 .0447 1.14 .0465 .0018 .500 #0-80 5/32 0.050 .096 .060 0.035 0.035 0.028 #0-80

64 .0156 53 .0595 .0538 1.37 .0561 .0026 #1-64 #1-64

#1 .0730 1.85 49 .625 5/32 1/16 .118 .073 0.050 0.050 0.035

72 .0139 53 .0595 .0560 1.42 .0580 .0028 #1-72 #1-72

56 .0179 50 .0700 .0641 1.63 .0667 .0037 #2-56 #2-56

#2 .0860 2.18 44 .625 3/16 5/64 .140 .086 0.050 0.050 0.035

64 .0156 50 .0700 .0668 1.70 .0691 .0039 #2-64 #2-64

48 .0208 47 .0785 .0734 1.86 .0764 .0049 #3-48 #3-48

#3 .0990 2.51 39 .625 3/16 5/64 .161 .099 1/16 1/16 0.050

56 .0179 45 .0820 .0771 1.96 .0797 .0052 #3-56 #3-56

40 .0250 43 .0890 .0813 2.07 .0849 .0060 #4-40 #4-40

#4 .1120 2.84 33 .750 1/4 3/32 .183 .112 1/16 1/16 0.050 T10

48 .0208 42 .0935 .0864 2.19 .0894 .0066 #4-48 #4-48

40 .0250 38 .1015 .0943 2.40 .0979 .0080 #5-40 #5-40

#5 .1250 3.18 1/8 .750 5/16 3/32 .205 .125 5/64 5/64 1/16 T10

44 .0227 37 .1040 .0971 2.47 .1004 .0083 #5-44 #5-44

32 .0313 36 .1065 .0997 2.53 .1040 .0091 #6-32 #6-32 2 10 in# 10 in#

#6 .1380 3.51 28 .750 5/16 7/64 .226 .138 5/64 5/64 1/16 T15

40 .0250 33 .1130 .1073 2.73 .1110 .0102 #6-40 #6-40

32 .0313 29 .1360 .1257 3.19 .1300 .0140 #8-32 #8-32 4 24 in# 24 in#

#8 .1640 4.17 19 .875 11/32 9/64 .270 .164 3/32 3/32 5/64 T25

36 .0278 29 .1360 .1299 3.30 .1340 .0147 #8-36 #8-36

24 .0417 25 .1495 .1389 3.53 .1450 .0175 #10-24 1/8 1/4 #10-24 20-25 in# 5 36 in# 36 in#

#10 .1900 4.83 11 .875 3/8 5/32 .312 .190 1/8 1/8 3/32 T27

32 .0313 21 .1590 .1517 3.85 .1560 .0200 #10-32 #10-32 12-15 in#

24 .0417 16 .1770 .1649 4.19 .1710 .0242 #12-24 #12-24

#12 .2160 5.49 7/32 .682 7/16

28 .0357 14 .1820 .1722 4.37 .1770 .0258 #12-28 #12-28

20 .0500 7 .2010 .1887 4.79 .1960 .0318 1/4 - 20 5/32 5/16 1/4 - 20 3-4 14 11 12 9 8 6 4 3 7

1/4 .2500 6.35 1/4 .750 1.000 7/16 5/32 3/16 .375 .250 5/32 5/32 1/8 T30

28 .0357 3 .2130 .2062 5.24 .2110 .0364 1/4 - 28 1/4 - 28 4-6 16 13 14 10 10 7 6 4

18 .0556 F .2570 .2443 6.21 .2520 .0524 5/16-18 3/16 3/8 5/16-18 8 - 12 29 23 25 18 17 13 9 7 14

5/16 .3125 7.94 5/16 .875 1.125 1/2 13/64 1/4 .469 .313 3/16 3/16 5/32 T45

24 .0417 I .2720 .2614 6.64 .2670 .0580 5/16-24 5/16-24 7-8 33 26 29 20 19 14 12 9

16 .0625 5/16 .3125 .2983 7.58 .3070 .0775 3/8- 16 1/4 1/2 3/8- 16 13 - 16 49 39 45 35 30 23 16 12 24

3/8 .3750 9.53 3/8 1.000 1.250 9/16 15/64 5/16 .562 .375 7/32 7/32 3/16 T50

24 .0417 Q .3320 .3239 8.23 .3300 .0878 3/8- 24 3/8- 24 13 - 15 54 44 50 40 35 25 22 16

14 .0714 U .3680 .3499 8.89 .3600 .1063 7/16-14 5/8 & 7/16-14 20 - 21 76 61 70 55 50 35 24 17 35

7/16 .4375 11.11 7/16 1.125 1.375 9/32 3/8 .656 .438 1/4 7/32 T55

20 .0500 25/64 .3906 .3762 9.56 .3830 .1187 7/16-20 11/32 7/16-20 38 - 42 85 68 80 60 55 40 34 26

13 .0769 27/64 .4219 .4056 10.30 .4170 .1419 1/2 - 13 5/16 5/8 1/2 - 13 33 - 40 113 90 110 80 75 55 38 31 51

1/2 .5000 12.70 1/2 1.250 1.500 3/4 5/16 3/8 .750 .500 5/16 1/4 T55

20 .0500 29/64 .4531 .4387 11.14 .4460 .1599 1/2 - 20 1/2 - 20 40 - 58 126 100 120 90 90 65 52 42

12 .0833 31/64 .4844 .4603 11.69 .4720 .1820 9/16-12 9/16-12 42 - 58 163 130 150 110 110 80 52 42

9/16 .5625 14.29 9/16 1.375 1.625 13/16 23/64 7/16 T60

18 .0556 33/64 .5156 .4943 12.56 .5020 .2030 9/16-18 9/16-18 67 - 83 181 144 170 130 120 90 71 57

11 .0909 17/32 .5312 .5135 13.04 .5270 .2260 5/8 - 11 3/8 3/4 5/8 - 11 58 - 75 230 184 220 170 150 110 98 78

5/8 .6250 15.88 5/8 1.500 1.750 15/16 25/64 1/2 .938 .625 3/8 5/16 T70

18 .0556 37/64 .5781 .5568 14.14 .5650 .2560 5/8 - 18 5/8 - 18 92-108 255 204 240 180 180 130 115 93

§ Body drill size above equals major diameter. Increase drill size by 10% (close fit) to 20% (normal fit) using a mill. Ft-lbs times 1.356 gives Nm (1 ft-lb= 12 in-lb= 1.356 Nm). Nm times 0.7375 gives ft-lbs (1 Nm= 0.7375 ft-lb= 8.851 in-lb) SAE Torques are in ft-lbs or in-lbs; Metric torques are in Nm!

Inches times 25.36 gives mm (1 in = 25.36 mm). mm times 0.03943 gives in (1 mm = 0.03943 in). ex: 5/16" = 7.925 mm Ex: 60 ft-lb. = 720 in-lb. = 60 *1.356 = 81.36 Nm. Ex: 34 Nm = 34 * 0.7375 = 25.08 ft-lb. = 300.1 in-lb. For clean, rolled threads; turning (not static) friction; rigid steel parts and steel nuts

Metric Thread Geometry Metric Bolt Geometry Metric Generic Torque Settings (Nm)

Size Pitch Major Diameter Tap Drill (81.5%) Minor Diam Nut ID Str. Area Typ. Thread Lgth Hex Head Socket Head Button Hd Flat Hd Set Screw Shoulder Screw SH Torx All Torques in Newton-Meters

mm mm/rot mm in. Metric Equiv. Eq. (in.) Eq. (mm) mm in. mm mm^2 HHCS SHCS Size Wrench Hd Ht Key Size Hd Dia Hd Hght Key Size (90 deg) Key Size Key Size Shld Dia Key Size Size 12.9 & SHCS 10.9 8.8 5.8 Set Sc

M3 0.50* 3.0 .1181 2.5 #39 .100 2.5 2.39 .094 2.46 5.0 12 18 M3 5.5 2 2.5 5.5 3.0 2 2 1.5 T10 M3-0.50* 2-4

M4 0.70* 4.0 .1575 3.3 #30 .129 3.3 3.14 .124 3.24 8.8 14 20 M4 7 2.8 3 7.0 4.0 2.5 2.5 2 T25 M4-0.70* 4-4 3-4 2-3 1-2

M5 0.80* 5.0 .1969 4.2 #19 .166 4.2 4.02 .158 4.13 14.2 16 22 M5 8 3.5 4 8.5 5.0 3 3 2.5 3 6 T27 M5-0.80* 7-9 6-8 4-5 3-3

M6 1.00* 6.0 .2362 5.0 #9 .196 5.0 4.77 .188 4.92 20.1 18 24 M6 10 4 5 10.0 6.0 4 4 3 4 8 T30 M6-1.00* 12 - 15 10 - 13 7-9 5-6 7

1.25* 6.8 17/64 .266 6.7 6.47 .255 6.65 37

M8 8.0 .3150 22 28 M8 13 5.3 6 13.0 8.0 5 5 4 5 10 T45 M8-1.25* 30 - 38 25 - 31 18 - 22 11 - 14 17

1.00 7.0 J .277 7.0 6.77 .267 6.92 39

1.5* 8.5 R .339 8.6 8.16 .321 8.38 58

M10 1.25 10.0 .3937 8.8 11/32 .344 8.7 8.47 .333 8.65 61 26 32 M10 17 6.4 8 16.0 10.0 6 6 5 6 12 T50 M10-1.50* 60 - 75 50 - 63 36 - 45 22 - 28 35

1.00 9.0 T .354 9.0 8.77 .345 8.92 65

1.75* 10.2 13/32 .406 10.3 9.85 .388 10.11 84

M12 1.50 12.0 .4724 10.5 13/32 .406 10.3 10.16 .400 10.38 88 30 36 M12 19 7.5 10 18.0 12.0 8 8 6 8 16 T55 M12-1.75* 105 - 132 88 - 110 62 - 78 39 - 49 60

1.25 11.0 7/16 .438 11.1 10.47 .412 10.65 92

2.00* 12.0 15/32 .469 11.9 115

M14 14.0 .5512 34 40 M14 22 8.8 12 10 6 T60 M14-2.00* 168 - 211 140 - 176 100 - 125 62 - 78

1.25 12.8 1/2 .500 12.7

2* 14.0 35/64 .547 13.9 13.55 .533 13.84 157

M16 16.0 .6299 38 44 M16 24 10 14 24.0 16.0 10 10 8 T70 M16-2.00* 264 - 333 220 - 277 156 - 197 98 - 123 125

1.5 14.5 37/64 .578 14.7 14.16 .557 14.38 167

* An asterisk (*) indicates Metric Coarse (DIN standard) threads -- the ones you usually meet. Metric tap drill size is major diameter minus pitch, truncated to first decimal. Ex: M8-1.25 = 6.75 = 6.7mm (17/64") Use low end of range for cad plated or machined surfaces;

Rule of thumb: A set screw is tight enough when long end of the hex key bends the distance of about one hour. Use high end for dry, zinc-plated, or ground surfaces.

Decimal, Screw, and Metric Equivalents Pipe Screw Extractors Mechanical Properties of English Fasteners

Size in. mm Size in. mm Size in. mm Pipe Tapered Straight Screw Diameter Length SAE Screws Metric Screws Pipe Use Drill SAE Diam., Min. Tensile 0.2% Yield Rockwell Hard. Min % Min %

1/32" .0313 0.79 3/16" .1875 4.76 13 mm .5118 13 Size Tap Drill Tap Dr. Extr'r Sm.End Big End From To From To Size Grade in Str, Mpa Point, Mpa min. max. Elongt'n Area Redct'n

1 mm .0394 1 # 10 .1900 4.83 14 mm .5512 14 1/16 - 27 D 1/4 1 .054 5/32 2 3/16 1/4 4.8 6.4 5/64 2 .25-.75 510 393 B80 B100 18 35

#0 .0600 1.52 5 mm .1969 5 9/16" .5625 14.29 1/8 - 27 R 11/32 2 .080 3/16 2 3/8 1/4 5/16 6.4 8.0 7/64 5 .25-1.0 828 634 C25 C34 14 35

1/16" .0625 1.59 # 12 .2160 5.49 15 mm .5906 15 1/4 - 18 7/16 7/16 3 1/8 1/4 2 11/16 5/16 7/16 8.0 11.2 5/32 8 .25-1.5 1034 897 C33 C39 12 35

#1 .0730 1.85 7/32" .2188 5.56 5/8" .6250 15.88 3/8 - 18 37/64 37/64 4 3/16 21/64 2 7/8 7/16 9/16 11.2 14.4 1/4 SHCS 1103 C39 C45

5/64" .0781 1.98 6 mm .2362 6 16 mm .6299 16 1/2 - 14 45/64 23/32 5 1/4 7/16 3 3/8 9/16 3/4 14.4 19.2 1/8,1/4 17/64 Aircraft 862 517

2 mm .0787 2 1/4" .2500 6.35 17 mm .6693 17 3/4 - 14 59/64 59/64 6 3/8 19/32 3 3/4 3/4 1 19.2 25.6 3/8" 13/32 18-8 SS 517 379 B100

#2 .0860 2.18 7 mm .2756 7 11/16" .6875 17.46 1 - 11.5 1 5/32 1 5/32 7 1/2 3/4 4 1/8 1 1 3/8 25.6 35.3 1/2" 17/32 18-8 comes in 302, 303, & 304 (usually 303). Consider 303 & 316 to have same strength

3/32" .0938 2.38 9/32 " .2813 7.14 18 mm .7087 18 1¼-11.5 1 1/2 1 1/2 8 3/4 1 4 3/8 1 3/8 1 3/4 35.3 44.9 3/4" 13/16 Mechanical Properties of Metric Fasteners

#3 .0990 2.51 5/16" .3125 7.94 19 mm .7480 19 1½-11.5 1 47/64 1 3/4 9 1 1 9/32 4 5/8 1 3/4 2 1/8 44.9 54.5 1" 1 1/16 Prop Diam., Min. Tensile 0.2% Yield Rockwell Hard. Min % Min %

#4 .1120 2.84 8 mm .3150 8 3/4 " .7500 19.05 2 - 11.5 2 7/32 2 7/32 10 1 1/4 1 9/16 5 2 1/8 2 1/2 54.5 64.1 1 1/4" 1 5/16 Class mm Str, Mpa Point, Mpa min. max. Elongt'n Area Redct'n

3 mm .1181 3 11/32" .3438 8.73 20 mm .7874 20 2½ - 8 2 5/8 2 21/32 11 1 1/2 1 7/8 5 5/8 2 1/2 3 64.1 76.9 1 1/2" 1 9/16 5.8 5.0-24 520 400 B82 B95

1/8" .1250 3.18 9 mm .3543 9 13/16" .8125 20.64 3-8 3 1/4 12 1 7/8 2 5/16 6 1/4 3 3 1/2 76.9 89.7 2" 1 15/16 8.8 17-36 800 640 C23 C34 12 35

#5 .1250 3.18 3/8" .3750 9.53 22 mm .8661 22 9.8 1.6-16 900 717 C27 C36

MrFlip's All-Inclusive Omnibus of Fastener Data

#6 .1380 3.51 10 mm .3937 10 7/8 " .8750 22.23 10.9 6.0-36 1040 900 C33 C39 9 35

9/64" .1406 3.57 11 mm .4331 11 15/16" .9375 23.81 12.9 1.6-36 1220 1080 C38 C44 8 35

5/32" .1563 3.97 7/16" .4375 11.11 24 mm .9449 24 1 Mpa = 1 N / mm2 = 0.145 ksi = 145 psi

4 mm .1575 4 12 mm .4724 12 25 mm .9843 25

Containing a Myriad of Useful & Fascinating Data, Including the Metric Sizes popular in Prussia and Europe Mpa times 145 gives ksi:

ksi times 6.897 gives Mpa: 1 ksi = 1000 psi = 6.897 Mpa

#8 .1640 4.17 1/2" .5000 12.70 1" 1 25.40 Double Checked and Compiled against Multiple Sources by our Meticulous Staff. If it's in this chart, it's on here! A2-70 is 18-8 SS, class 70 (higher class gives higher strength)

S-ar putea să vă placă și

- RFQ Crane (MHE - DEMAG)Document6 paginiRFQ Crane (MHE - DEMAG)Agung Pandega PutraÎncă nu există evaluări

- 02 Standard Compression CatalogDocument146 pagini02 Standard Compression Catalogtanto_deep_15Încă nu există evaluări

- Cu Xlpe PVC 0.6 1 KV (N2xa)Document1 paginăCu Xlpe PVC 0.6 1 KV (N2xa)Fani Dwi PutraÎncă nu există evaluări

- INA CatalogueDocument110 paginiINA CatalogueStroia Constantin MariusÎncă nu există evaluări

- Bushing PDFDocument92 paginiBushing PDFYigit SarıkayaÎncă nu există evaluări

- TongHeer Brouchure)Document10 paginiTongHeer Brouchure)bkprodhÎncă nu există evaluări

- Jewelry Laser Spot Welding MachineDocument20 paginiJewelry Laser Spot Welding MachineSantosh BabarÎncă nu există evaluări

- PDS Nytro Libra EN PDFDocument2 paginiPDS Nytro Libra EN PDFmk116dÎncă nu există evaluări

- Variable Speed DrivesDocument68 paginiVariable Speed DriveschikoopandaÎncă nu există evaluări

- MC600 Modular Conveyor: Revision 12 January 2014 Document Number: PCM-03-02-02Document60 paginiMC600 Modular Conveyor: Revision 12 January 2014 Document Number: PCM-03-02-02Carl RichterÎncă nu există evaluări

- CPS5200 5000 Non Asbestos and Asbestos SheetsDocument2 paginiCPS5200 5000 Non Asbestos and Asbestos SheetsBagus AdiriantoÎncă nu există evaluări

- ABB Limited: LV Motors FRSM-57C Effective From 01.10.2012 Price ListDocument5 paginiABB Limited: LV Motors FRSM-57C Effective From 01.10.2012 Price ListSudipto MajumderÎncă nu există evaluări

- JS500 Mixer ManualDocument18 paginiJS500 Mixer ManualHector OsorioÎncă nu există evaluări

- Clra 1970Document37 paginiClra 1970Rituparna MallickÎncă nu există evaluări

- Erection of Transformer and ReactorDocument90 paginiErection of Transformer and Reactorumamaheshwarrao100% (1)

- Unbrako Fasteners Price List 2Document70 paginiUnbrako Fasteners Price List 2TarunPatraÎncă nu există evaluări

- System Features: Floor StandingDocument1 paginăSystem Features: Floor StandingKevin Lau100% (1)

- Pipa Tembaga - Streamline MuellerDocument8 paginiPipa Tembaga - Streamline MuellerAhmad Syaifudin ZÎncă nu există evaluări

- Draft-Instruction Manual No 1838 Wa6800522-523 Rev0 Siemens TransformerDocument114 paginiDraft-Instruction Manual No 1838 Wa6800522-523 Rev0 Siemens TransformerDan Cosac100% (1)

- Luckyindia CGL Power Transformer CatalogueDocument14 paginiLuckyindia CGL Power Transformer CatalogueSharafat AliÎncă nu există evaluări

- Cembre Lugs Crimps TerminalsDocument168 paginiCembre Lugs Crimps TerminalsJeffrey ArandiaÎncă nu există evaluări

- VeridriDocument0 paginiVeridriiviji81Încă nu există evaluări

- Cable Tray New Price List 23 May 2013Document1 paginăCable Tray New Price List 23 May 2013RITESH D.MEHTAÎncă nu există evaluări

- Rotomac Progressive Cavity Pumps: Installation, Operation and Maintenance Manual 'LDocument14 paginiRotomac Progressive Cavity Pumps: Installation, Operation and Maintenance Manual 'Lkallappa naikÎncă nu există evaluări

- Thru StakesDocument3 paginiThru StakeschakmrinalÎncă nu există evaluări

- NA2 XFGB YDocument4 paginiNA2 XFGB YRinda_RaynaÎncă nu există evaluări

- Spec Plummer Block BearingDocument2 paginiSpec Plummer Block BearingSithipol PoprayoonÎncă nu există evaluări

- Entice CatalogueDocument12 paginiEntice Cataloguebharath sÎncă nu există evaluări

- Jotamastic 80: Technical Data SheetDocument14 paginiJotamastic 80: Technical Data SheetCv RONATAMA GUSLHANÎncă nu există evaluări

- Standarisasi KabelDocument44 paginiStandarisasi Kabeladzan isaacÎncă nu există evaluări

- General Catalogue InglesDocument18 paginiGeneral Catalogue InglesSaravanan BÎncă nu există evaluări

- Stainless Steel Upn Channels SectionsDocument4 paginiStainless Steel Upn Channels SectionsKriengsak RuangdechÎncă nu există evaluări

- EELL Price List 28.11.2022Document13 paginiEELL Price List 28.11.2022md ShadikurÎncă nu există evaluări

- Tonase Dan Kebutuhan Material CV04A Dan RF45Document2 paginiTonase Dan Kebutuhan Material CV04A Dan RF45Bagas Lesta CoratiesÎncă nu există evaluări

- Sensor de FlujoDocument2 paginiSensor de FlujoDany Chl100% (1)

- Festo CPX PDFDocument346 paginiFesto CPX PDFCarlos Badilla PeñaÎncă nu există evaluări

- General ReferenceDocument28 paginiGeneral ReferenceJeya VasanthÎncă nu există evaluări

- Tabel Berat 1Document22 paginiTabel Berat 1Mamat SubekanÎncă nu există evaluări

- Fenner GearsDocument28 paginiFenner Gearsmanoj983@gmail.comÎncă nu există evaluări

- Smi Cable Gland - Better by DesignDocument2 paginiSmi Cable Gland - Better by DesignamiteshÎncă nu există evaluări

- Design of Conveyor in Metric UnitsDocument10 paginiDesign of Conveyor in Metric Unitsmuhd.qasimÎncă nu există evaluări

- Onshore Combined Mto Updated 9-04-20Document97 paginiOnshore Combined Mto Updated 9-04-20Ahmed Al-MenshadÎncă nu există evaluări

- EMCO Electro - Hydraulic Drum BrakeDocument7 paginiEMCO Electro - Hydraulic Drum Brakehardik033Încă nu există evaluări

- Medium Voltage Power CableDocument3 paginiMedium Voltage Power CableGuruh Panji SukardiÎncă nu există evaluări

- Price List Wasser Pump (2016.07.01)Document1 paginăPrice List Wasser Pump (2016.07.01)kosasih aji somantri100% (1)

- Instrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard RatingDocument5 paginiInstrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard Ratinggohjh80Încă nu există evaluări

- F4a 2020 LEEA Assessments - Information For Members Students Nov 2019Document4 paginiF4a 2020 LEEA Assessments - Information For Members Students Nov 2019VishnuÎncă nu există evaluări

- GeneralDocument39 paginiGeneralDeerendra KaranthÎncă nu există evaluări

- Drive Chains EwartDocument3 paginiDrive Chains Ewarttrevorwoest100% (1)

- Spare Part Turbin PLTA Bengkok PDFDocument1 paginăSpare Part Turbin PLTA Bengkok PDFAditya PrajasÎncă nu există evaluări

- High Carbon Wire RodDocument9 paginiHigh Carbon Wire Rodninganray6316100% (1)

- Panasonic Conduits PDFDocument1 paginăPanasonic Conduits PDFCharilyn EcheverreÎncă nu există evaluări

- Automatic Power Factor Controller Relay: Operating InstructionsDocument7 paginiAutomatic Power Factor Controller Relay: Operating InstructionsKatty MenaÎncă nu există evaluări

- Agrawal Agencies: Wholesellers in Building MaterialDocument9 paginiAgrawal Agencies: Wholesellers in Building MaterialShrinivas HansanpalliÎncă nu există evaluări

- Mueller WeigertDocument76 paginiMueller WeigertTibor DanielÎncă nu există evaluări

- CNC Machinist Reference Guide-LargeDocument43 paginiCNC Machinist Reference Guide-LargeOmar GutierrezÎncă nu există evaluări

- MU07 Rosca Americana Fina Unf Tecem PDFDocument1 paginăMU07 Rosca Americana Fina Unf Tecem PDFmarcosÎncă nu există evaluări

- Rosca Americana Fina Unf TecemDocument1 paginăRosca Americana Fina Unf TecemPauloPaixãoÎncă nu există evaluări

- Wa0000Document5 paginiWa0000BIPLAB KUMARÎncă nu există evaluări

- Ounsellor: Drills, Taps, Reamers, DiesDocument49 paginiOunsellor: Drills, Taps, Reamers, DiesMareks LezevskisÎncă nu există evaluări

- Case Study: BajajDocument2 paginiCase Study: Bajajbunta007Încă nu există evaluări

- Case Study: Monopoly - Mumbai TaxiDocument2 paginiCase Study: Monopoly - Mumbai Taxibunta00767% (3)

- Human Resource Management (HRM) - PearsonDocument21 paginiHuman Resource Management (HRM) - Pearsonbunta007Încă nu există evaluări

- Ecommerce in India Accelerating GrowthDocument20 paginiEcommerce in India Accelerating GrowthkavyaÎncă nu există evaluări

- Lean and Agile Manufacturing: ToyotaDocument9 paginiLean and Agile Manufacturing: Toyotabunta007Încă nu există evaluări

- Elite 08Document96 paginiElite 08Razza WilliÎncă nu există evaluări

- S No Name of The Company Regional OfficeDocument39 paginiS No Name of The Company Regional OfficeNo nameÎncă nu există evaluări

- Nomura, SBI Caps, IDFC, Wellington Are in Talks To Buy 10% Stake For Rs 1000 CR in Kerala-Based ManappuramDocument2 paginiNomura, SBI Caps, IDFC, Wellington Are in Talks To Buy 10% Stake For Rs 1000 CR in Kerala-Based ManappuramRaghu.GÎncă nu există evaluări

- Communication To Offer-ContractsDocument20 paginiCommunication To Offer-ContractsAarif Mohammad BilgramiÎncă nu există evaluări

- ISM JRF BrochureDocument37 paginiISM JRF BrochureVikas Patel100% (1)

- BSM - Company ProfileDocument15 paginiBSM - Company ProfileLarasanto Cipta AgungÎncă nu există evaluări

- 3 Filtration Lecture NotesDocument16 pagini3 Filtration Lecture NotesRuben SIbayanÎncă nu există evaluări

- Guillang Vs Bedania and SilvaDocument2 paginiGuillang Vs Bedania and Silvajdg jdgÎncă nu există evaluări

- Euroleague Basketball: Change Pays Off ForDocument36 paginiEuroleague Basketball: Change Pays Off ForNikos TagalnikÎncă nu există evaluări

- User Mode I. System Support Processes: de Leon - Dolliente - Gayeta - Rondilla It201 - Platform Technology - TPDocument6 paginiUser Mode I. System Support Processes: de Leon - Dolliente - Gayeta - Rondilla It201 - Platform Technology - TPCariza DollienteÎncă nu există evaluări

- Power GREPDocument392 paginiPower GREPCeles NubesÎncă nu există evaluări

- DSU ManualDocument204 paginiDSU ManualCarlos Alberto Rueda100% (1)

- 1.0 Design Andheri Khola Bridge, 1x25m 8.4m 3 GirderDocument18 pagini1.0 Design Andheri Khola Bridge, 1x25m 8.4m 3 GirderManoj ChaudharyÎncă nu există evaluări

- Shell Answer Book 07 The Driving Emergency BookDocument8 paginiShell Answer Book 07 The Driving Emergency BookKenneth100% (2)

- Text-Book P3Document147 paginiText-Book P3Nat SuphattrachaiphisitÎncă nu există evaluări

- ''Adhibeo'' in LatinDocument5 pagini''Adhibeo'' in LatinThriw100% (1)

- TIAPortalOpennessenUS en-USDocument656 paginiTIAPortalOpennessenUS en-USskyttt135Încă nu există evaluări

- El Condor1 Reporte ECP 070506Document2 paginiEl Condor1 Reporte ECP 070506pechan07Încă nu există evaluări

- Icd-10 CM Step by Step Guide SheetDocument12 paginiIcd-10 CM Step by Step Guide SheetEdel DurdallerÎncă nu există evaluări

- CV - Oscar ChampionDocument3 paginiCV - Oscar ChampionKarina Gamarra NinaÎncă nu există evaluări

- 201805graphene PDFDocument204 pagini201805graphene PDFMohammad RezkyÎncă nu există evaluări

- Solar Smart Irrigation SystemDocument22 paginiSolar Smart Irrigation SystemSubhranshu Mohapatra100% (1)

- Forging 2Document17 paginiForging 2Amin ShafanezhadÎncă nu există evaluări

- Operating Instruction PMD55Document218 paginiOperating Instruction PMD55Dilip ARÎncă nu există evaluări

- December + Yearly ReviewDocument2 paginiDecember + Yearly ReviewNick FabrioÎncă nu există evaluări

- Akta-332 Copyright Act 1987Document50 paginiAkta-332 Copyright Act 1987Kartigesan999Încă nu există evaluări

- NDT Technician TrainingDocument6 paginiNDT Technician TraininglarsonndeservicesÎncă nu există evaluări

- 12 C AdminstrationDocument2 pagini12 C AdminstrationMuditÎncă nu există evaluări

- Domestic Accidents Among Under-5 Year Children: A Study On The Modern Day EpidemicDocument7 paginiDomestic Accidents Among Under-5 Year Children: A Study On The Modern Day EpidemicPriyanjali SainiÎncă nu există evaluări

- Asap 2020Document21 paginiAsap 2020KarenÎncă nu există evaluări