Documente Academic

Documente Profesional

Documente Cultură

Iodine Value AOAC Official Method 993.20

Încărcat de

Guillaume merlaud100%(1)100% au considerat acest document util (1 vot)

2K vizualizări2 paginiDrepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

2K vizualizări2 paginiIodine Value AOAC Official Method 993.20

Încărcat de

Guillaume merlaudDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

41.1.15 (e) Analytical balance.—Accurate to ±0.0001 g.

AOAC Official Method 993.20 (f) Filters.—Ashless, coarse grade (Whatman No. 541 is suit-

Iodine Value of Fats and Oils able).

Wijs (Cyclohexane–Acetic Acid Solvent) Method (g) Hot air oven.—Capable of maintaining 100°C within ±1.5°C.

First Action 1993

Final Action 1996 C. Reagents

IUPAC–AOCS–AOAC Method (a) Potassium iodide (KI) solution.—15%. Dissolve 15 g KI in

100 mL H2O.

(Applicable to determination of iodine value for fats and oils which (b) Wijs iodine solution.—(1) Dissolve 13 g resublimed I in 1 L

do not contain conjugated double bonds.) acetic acid, and pass in dried (through H2SO4) Cl until original

Na2S2O3 titration of solution is not quite doubled. (Characteristic

Caution: Wijs solution causes severe burns; vapors can cause color change at end point indicates proper amount of Cl. Convenient

lung and eye damage. Use of fume hood is recom- method is to reserve some of original I solution, add slight excess of

mended. See Appendix B, Laboratory Safety for proce- Cl to bulk of solution, and bring to desired titer by readditions of re-

dures on safe handling of acids and organic solvents served portion.) Or: (2) Dissolve 16.5 g ICl in 1 L acetic acid.

(cyclohexane). Determine I/Cl ratio as follows:

(1) Iodine content.—Pipet 5 mL Wijs solution into 500 mL

See Table 993.20A for the results of the interlaboratory study sup-

Erlenmeyer flask containing 150 mL saturated Cl–H2O and some

porting acceptance of the method.

glass beads. Shake, heat to boiling, and boil briskly 10 min. Cool,

A. Principle add 30 mL H2SO4 solution (1 + 49) and 15 mL 15% KI solution, and

Fat or oil is mixed with iodine monochloride solution to titrate immediately with 0.1M Na2S2O3.

halogenate double bonds in fat or oil. Excess iodine monochloride is (2) Total halogen content.—Pipet 20 mL Wijs solution into

reduced to free iodine in presence of potassium iodide, and free io- 500 mL Erlenmeyer flask containing 150 mL recently boiled and

dine is measured by titration with sodium thiosulfate using starch as cooled H2O and 15 mL 15% KI solution. Titrate immediately with

indicator. 0.1M Na2S2O3.

Iodine value (IV), calculated as cg iodine absorbed per g of sam-

ple (% iodine absorbed), is a measure of unsaturation of fats and oils. 2X

I/Cl =

B. Apparatus 3B − 2X

(a) Glass-stoppered iodine flasks.—500 mL.

(b) Glass-stoppered volumetric flasks.—1000 mL, for preparing

standard solutions. where X = mL 0.1 M Na2S2O3 required for I content and B = mL re-

(c) Volumetric dispensers.—(1) 25 mL, for Wijs and 15% potas- quired for total halogen content. If I/Cl ratio is not 1.10 ± 0.1, add I or

sium iodide (KI) solutions. (2) 2 mL, for starch solution. (3) 50 mL, Cl to correct ratio.

for H2O. Standardized Wijs solution may be obtained from commercial

(d) Repeater pipet.—20 mL, with filling flask, for cyclohexane. suppliers (specify without carbon tetrachloride).

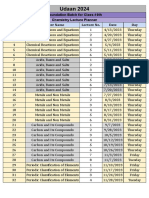

Table 993.20A Interlaboratory study results for determination of iodine value by Wijs method using carbon tetrachloride solvent

or cyclohexane–acetic acid (1 + 1) solvent

Mean Value sr sR RSDr, % RSDR, %

Sample CTCa CHXb CTC CHX CTC CHX CTC CHX CTC CHX

Sunflower 133.6 132.9 1.4 1.7 3.4 2.3 1.1 1.3 2.6 1.7

Refined palm 53.1 53.0 0.1 0.2 0.3 0.4 0.2 0.3 0.5 0.7

Crude fish 109.1 108.5 0.7 0.5 1.7 1.1 0.6 0.5 1.6 1.0

Tung 164.5 163.1 2.0 1.4 3.1 2.5 1.2 0.9 1.9 1.5

Tallow (beef) 47.2 46.9 0.2 0.2 0.5 0.4 0.5 0.5 1.0 0.8

Crude palm 52.5 52.6 0.3 0.4 0.4 0.5 0.5 0.8 0.8 1.0

Used frying 37.7 37.7 0.1 0.2 0.2 0.3 0.4 0.5 0.4 0.9

Palm kernel 18.2 18.3 0.01 0.01 0.03 0.04 0.1 0.1 0.2 0.2

Olive 82.3 82.2 0.2 0.5 0.6 0.8 0.3 0.6 0.7 0.9

HSBOc-1 102.6 102.3 0.5 0.8 1.8 1.9 0.5 0.8 1.7 1.8

HSBO-2 74.7 74.8 0.5 0.4 1.0 0.6 0.6 0.5 1.3 0.8

HFOd 73.0 72.8 0.4 0.4 0.7 0.6 0.6 0.6 0.9 0.8

a

Carbon tetrachloride.

b

Cyclohexane–acetic acid (1 + 1).

c

Hydrogenated soybean oil.

d

Hydrogenated fish oil.

© 2000 AOAC INTERNATIONAL

Table 993.20B Test sample weights and continue adding thiosulfate solution slowly until blue color just

disappears.

Value Test sample, g Accuracy, mg

3 10.58–8.46 0.5 20.394 × wt K 2 Cr2 O 7

Na2S2O3 solution molarity, M =

10 3.17–2.54 0.2 mL sodium thiosulfate

20 1.59–1.27 0.2

E. Determination

40 0.79–0.63 0.2

Melt test sample, if not already liquid (do not exceed sample melt-

80 0.40–0.32 0.2

ing point by >10°C). Pass test sample through double layer of filter

120 0.26–0.21 0.2

paper to remove any solid impurities and traces of H2O (filtration

160 0.20–0.16 0.2 may be performed in air oven, ca 100°C, but should be completed

200 0.16–0.13 0.2 within 5 min ± 30 s). Test sample must be absolutely dry. (Note: All

glassware must be absolutely clean and completely dry.)

Let filtered test sample cool to 68–71°C. Immediately weigh

Store in amber bottle sealed with paraffin until ready for use. Wijs amount of test sample indicated in Table 993.20B into clean, dry

solutions are sensitive to temperature, moisture, and light. Store in 500 mL flask, B(a).

dark at <30°C. Prepare at least 2 blank determinations to run with each sample

(c) Soluble starch solution.—Mix paste of 1 g starch with small group.

amount cold H2O. While stirring, add 200 mL boiling H2O. Test for Add 15 mL cyclohexane–acetic acid solvent, C(h), to each test

sensitivity: place 5 mL starch solution in 100 mL H2O and add sample and swirl to ensure that it is completely dissolved.

0.05 mL 0.1M iodine solution; deep blue color produced must be Dispense 25 mL Wijs solution into flask containing test sample,

discharged by 0.05 mL 0.1M sodium thiosulfate solution. (Note: stopper flask, and swirl to mix. Immediately set timer for 1.0 or 2.0 h,

1% starch solution, commercially available, is suitable.) depending on iodine value of sample (IV <150, 1.0 h; IV ≥150, 2.0 h)

(d) Potassium dichromate (K2Cr2O7).—Finely grind and dry to and store flasks in dark at 25° ± 5°C for duration of reaction.

constant weight (ca 110°C) before using in D. Remove flasks from dark, add 20 mL KI solution, C(b), and mix.

(e) Sodium thiosulfate (Na2S2O3×5H2O) solution.—0.1M. Stan- Add 150 mL H2O and gradually titrate with 0.1M standard Na2S2O3

dardize as in D. solution, D, with constant and vigorous shaking or mechanical stir-

(f) Acids.—(1) Hydrochloric acid (HCl).—Concentrated, sp gr ring. Continue titrating until yellow color has almost disappeared.

1.19. (2) Acetic acid (C2 H 4 O 2 ).—Glacial. (3) Sulfuric acid Add 1–2 mL starch indicator solution to flasks and continue titrating

(H2SO4).—Concentrated. until blue color has just disappeared. (Note: If reaction is not termi-

(g) Cyclohexane.—[Note: Erratic results may result if cyclohex- nated by addition of KI and H2O within 3 min past 1.0 or 2.0 h reac-

ane is old, i.e., contains oxidizable matter; see (h).] tion time, sample must be discarded. The sample must be titrated

(h) Cyclohexane–acetic acid solvent.—Mix cyclohexane, (g), within 30 min of reaction termination; if not, the analysis is invalid.)

and acetic acid, (f)(2), 1 + 1 (v/v). Verify absence of oxidizable mat- F. Calculation

ter in solvent by shaking 10 mL solvent with 1 mL saturated aqueous

K2Cr2O7 solution and 1 mL H2SO4, (f)(3). No green color should ap- ( B − S ) × M × 12.69

Iodine value (IV) =

pear. wt of fat or oil

D. Standardization of Sodium Thiosulfate Solution

Accurately weigh 0.16–0.22 g dried, finely ground K2Cr2O7, where B = titration of blank (mL); S = titration of test sample (mL);

C(d), to nearest 0.0001 g into 500 mL flask, dissolve in 25 mL H2O, M = molarity of Na2S2O3 solution.

add 5 mL HCl, C(f)(1), and 20 mL KI solution, C(b), and rotate to

References: Pure & Appl. Chem. 62, 2339(1990).

mix. Let stand 5 min. Add 100 mL H2O. Titrate with sodium

J. AOAC Int. 77, 674(1994).

thiosulfate solution, C(e), shaking continuously until yellow color

has almost disappeared. Add 1–2 mL starch indicator solution, C(c), Revised: March 1997

© 2000 AOAC INTERNATIONAL

S-ar putea să vă placă și

- CapacitorsDocument25 paginiCapacitorsAlbert Rosete0% (1)

- Cyliani's Hermes UnveiledDocument31 paginiCyliani's Hermes UnveiledAndre Bambu100% (2)

- ACI 207.1R-05 Guide To Mass ConcreteDocument31 paginiACI 207.1R-05 Guide To Mass ConcreteLukusa Badimuena100% (3)

- 93-1315 Deoiling ManualDocument269 pagini93-1315 Deoiling ManualManash Mudoi100% (2)

- Peroxide Value DeterminationDocument5 paginiPeroxide Value DeterminationJohn Paul Pasicaran75% (20)

- Oil AnalysisDocument11 paginiOil AnalysisTowfiq Hossain Tasku100% (1)

- AOAC 994.10 - GC - Cholesterol in Foods PDFDocument2 paginiAOAC 994.10 - GC - Cholesterol in Foods PDFdennisaberliani100% (1)

- AOAC 965.33 Peroxide ValueDocument1 paginăAOAC 965.33 Peroxide ValueRessa Aja100% (1)

- AOCS Te 1a-64 - Acid Value (2017) PDFDocument2 paginiAOCS Te 1a-64 - Acid Value (2017) PDFWilson50% (2)

- Aoac 962.02 P2o5Document1 paginăAoac 962.02 P2o5akloioÎncă nu există evaluări

- USP-NF 857 UV Spectros PDFDocument10 paginiUSP-NF 857 UV Spectros PDFGuillaume merlaud100% (1)

- USP-NF 857 UV Spectros PDFDocument10 paginiUSP-NF 857 UV Spectros PDFGuillaume merlaud100% (1)

- Faqc Lab: Determination of Acid Value and Sap. Value of OilDocument17 paginiFaqc Lab: Determination of Acid Value and Sap. Value of OilJoyita khanÎncă nu există evaluări

- AOCS Official Method CD 29a-13Document1 paginăAOCS Official Method CD 29a-13M Yusuf Hermawan50% (2)

- Establishing Scientifically Justified Acceptance Criteria For The Cleaning Validation of Apis (Active Pharmaceutical Ingredients) (Le Blanc)Document6 paginiEstablishing Scientifically Justified Acceptance Criteria For The Cleaning Validation of Apis (Active Pharmaceutical Ingredients) (Le Blanc)jorgeÎncă nu există evaluări

- 41.1.18 AOAC Official Method 920.160 Saponification Number (Koettstorfer Number) of Oils and FatsDocument1 pagină41.1.18 AOAC Official Method 920.160 Saponification Number (Koettstorfer Number) of Oils and FatsEmiliano García50% (2)

- AOAC Methods for Analyzing Oils and FatsDocument74 paginiAOAC Methods for Analyzing Oils and FatsWynona Basilio100% (1)

- Iodine Value of Fats and Oils Cyclohexane-Acetic Acid MethodDocument3 paginiIodine Value of Fats and Oils Cyclohexane-Acetic Acid MethodNovianto Nugroho100% (2)

- Determination of FFA - Standard Test MethodDocument2 paginiDetermination of FFA - Standard Test MethodPaula Pablo100% (2)

- AOCs CD 1d-92Document3 paginiAOCs CD 1d-92dwi anggraeni100% (1)

- Moisture and volatile matter analysisDocument3 paginiMoisture and volatile matter analysisZeref SaintÎncă nu există evaluări

- Color of Fats and Oil, Lovibond (ISO Method) : Through GlassDocument4 paginiColor of Fats and Oil, Lovibond (ISO Method) : Through Glasswil100% (2)

- AOCS CD 1-25 Iodine Value of Fats and Oils - Wijs MethodDocument4 paginiAOCS CD 1-25 Iodine Value of Fats and Oils - Wijs Methodedshe67% (3)

- AOCS CA 12-55 PhosphorusDocument2 paginiAOCS CA 12-55 PhosphorusLuki Wahyuning Tiyas100% (6)

- Alkaline Titration Method for Hydrocyanic Acid in BeansDocument1 paginăAlkaline Titration Method for Hydrocyanic Acid in BeansAngie Cerinza Acosta0% (1)

- Lane and Eynon's MethodDocument3 paginiLane and Eynon's MethodAllan Batista75% (12)

- AOCS Acid ValueDocument1 paginăAOCS Acid ValueAnonymous BcT42WLnÎncă nu există evaluări

- Sheet-Piling Walls PDFDocument55 paginiSheet-Piling Walls PDFAnonymous zvC1xS100% (1)

- Aoac 995.11 PDFDocument2 paginiAoac 995.11 PDFAnisa RahmawatiÎncă nu există evaluări

- AOAC 922.06 Grasa en HarinasDocument1 paginăAOAC 922.06 Grasa en HarinasCompras Fisicoquimico100% (1)

- AOCS CD 1b 87 IV PDFDocument4 paginiAOCS CD 1b 87 IV PDFzarlyÎncă nu există evaluări

- Commercial Fats and Oils Cloud Point TestDocument1 paginăCommercial Fats and Oils Cloud Point Testdwi anggraeniÎncă nu există evaluări

- AOCS Official Method Ce 2-66Document2 paginiAOCS Official Method Ce 2-66Salvador Gomez100% (1)

- FTIR Analysis of Polymer MaterialsDocument11 paginiFTIR Analysis of Polymer MaterialsfatinzalilaÎncă nu există evaluări

- Scope: AOCS Official Method Ba 3-38Document3 paginiScope: AOCS Official Method Ba 3-38Ammar MarzukiÎncă nu există evaluări

- Estimation of Free Fatty Acids (Acid Values) in Oilsfats by Direct Titration MethodDocument1 paginăEstimation of Free Fatty Acids (Acid Values) in Oilsfats by Direct Titration MethodMuhammad Aslam100% (2)

- AOCS CD 1b-87Document3 paginiAOCS CD 1b-87Luigi Avicenna100% (3)

- AOAC Official Method for Determining Ash in Sugars and SyrupsDocument1 paginăAOAC Official Method for Determining Ash in Sugars and SyrupsCamilita Mishelle MierÎncă nu există evaluări

- AOCS-Method Free Fatty AcidDocument2 paginiAOCS-Method Free Fatty AcidAnonymous BcT42WLn100% (7)

- Iodine ValueDocument4 paginiIodine ValueRobert Gilmore100% (4)

- Sampling and analysis of commercial fats and oilsDocument1 paginăSampling and analysis of commercial fats and oilsAntoni Pepe100% (1)

- Peroxide ValueDocument6 paginiPeroxide ValueKrishna KalsekarÎncă nu există evaluări

- Iodine Value Aocs CD 1d-92Document3 paginiIodine Value Aocs CD 1d-92Wynona Basilio75% (4)

- AOCS Official Method Ba 5a-49 PDFDocument1 paginăAOCS Official Method Ba 5a-49 PDFAmmar Marzuki0% (1)

- AOAC Official Methods 19 TH Ed PDFDocument3 paginiAOAC Official Methods 19 TH Ed PDFfabianadb33% (3)

- AOCS Official Method Ca 2c-25, Moisture and Volatile Matter, Air Oven Method, Reappoved 1997Document1 paginăAOCS Official Method Ca 2c-25, Moisture and Volatile Matter, Air Oven Method, Reappoved 1997laboratorium pc08100% (2)

- Microchemical determination of nitrogenDocument1 paginăMicrochemical determination of nitrogenIsmael Morales PuenteÎncă nu există evaluări

- Analytical methods for moisture, protein, ash and fat contentDocument4 paginiAnalytical methods for moisture, protein, ash and fat contentRam Kumar100% (3)

- AOCS Ca 5a-40Document2 paginiAOCS Ca 5a-40Bimmo Dwi Hartono100% (15)

- 991.20 Nitrogeno en LecheDocument2 pagini991.20 Nitrogeno en LechedcardonasterÎncă nu există evaluări

- Iodine Value of OilDocument3 paginiIodine Value of OilUsman Ghani100% (2)

- Listado de Normas AocsDocument10 paginiListado de Normas AocsJosé Nemo Di Natale0% (1)

- AOCS Method Ce 1c-89Document4 paginiAOCS Method Ce 1c-89Lam Lai YanÎncă nu există evaluări

- AOCS CD 8 53 Peroxido Con CL PDFDocument2 paginiAOCS CD 8 53 Peroxido Con CL PDFIvone Sulistya92% (13)

- 45.4.10 AOAC Official Method 994.10 Cholesterol in Foods: C) D) E) F) G) H)Document11 pagini45.4.10 AOAC Official Method 994.10 Cholesterol in Foods: C) D) E) F) G) H)Angélica VargasÎncă nu există evaluări

- Ca 5a 40 FfaDocument3 paginiCa 5a 40 FfaLamya SlassiÎncă nu există evaluări

- AOAC Official Method 940.28 Fatty Acids (Free) in Crude and Refined Oils PDFDocument1 paginăAOAC Official Method 940.28 Fatty Acids (Free) in Crude and Refined Oils PDFprasAjaÎncă nu există evaluări

- AOCS - Da4a-48 Free Acid or Free Alkali in Soda SoapDocument4 paginiAOCS - Da4a-48 Free Acid or Free Alkali in Soda Soapwil100% (1)

- AOCS CC 3-25-2009 Melting PointDocument2 paginiAOCS CC 3-25-2009 Melting Pointdwi anggraeniÎncă nu există evaluări

- AOCS Recommended Practice Ca 12-55 Phosphorus PDFDocument2 paginiAOCS Recommended Practice Ca 12-55 Phosphorus PDFWynona Basilio100% (1)

- Saponification of OilDocument3 paginiSaponification of OilMahnoor AkbarÎncă nu există evaluări

- Acid ValueDocument3 paginiAcid ValueAli Jazie100% (1)

- Aoac 906.03 PDFDocument2 paginiAoac 906.03 PDFAngie Cerinza AcostaÎncă nu există evaluări

- AOCS Recommended Practice Ca 12-55 Phosphorus PDFDocument2 paginiAOCS Recommended Practice Ca 12-55 Phosphorus PDFMaximino Alvarez100% (1)

- Astm d5768 PDFDocument3 paginiAstm d5768 PDFAmir HamzahÎncă nu există evaluări

- Analysis of Oils and Fats Lab ReportDocument7 paginiAnalysis of Oils and Fats Lab ReportdrugdrugÎncă nu există evaluări

- Iodine Value SOPDocument3 paginiIodine Value SOPsuresh kumarÎncă nu există evaluări

- 6.1 Estimation of Total PhenolicsDocument8 pagini6.1 Estimation of Total PhenolicsYogesh BagadÎncă nu există evaluări

- CPI Virtual Lab: Estimating Saponification and Iodine Values of OilsDocument36 paginiCPI Virtual Lab: Estimating Saponification and Iodine Values of OilsSamriddha Das GuptaÎncă nu există evaluări

- Omcl Annex 3 Qualification of Uv Visible SpectrophotometersDocument9 paginiOmcl Annex 3 Qualification of Uv Visible SpectrophotometersGuillaume merlaudÎncă nu există evaluări

- General European OMCL Network (GEON) Quality Management DocumentDocument8 paginiGeneral European OMCL Network (GEON) Quality Management DocumentGuillaume merlaudÎncă nu există evaluări

- General European OMCL Network (GEON) Quality Management DocumentDocument7 paginiGeneral European OMCL Network (GEON) Quality Management DocumentGuillaume merlaudÎncă nu există evaluări

- Stabilite Des Huiles Alimentaires Au Cours de Leur Stockage PDFDocument8 paginiStabilite Des Huiles Alimentaires Au Cours de Leur Stockage PDFImane ARÎncă nu există evaluări

- Heavy MetalsDocument5 paginiHeavy Metalsiqbalpec8721Încă nu există evaluări

- 2 Fundamentals of Stability TestingDocument32 pagini2 Fundamentals of Stability TestingHitarth SolankiÎncă nu există evaluări

- 2 Fundamentals of Stability TestingDocument32 pagini2 Fundamentals of Stability TestingHitarth SolankiÎncă nu există evaluări

- D3376-14 Standard Test Methods of Sampling and Testing Pulps To Be Used in The Manufacture of Electrical InsulationDocument10 paginiD3376-14 Standard Test Methods of Sampling and Testing Pulps To Be Used in The Manufacture of Electrical Insulationastewayb_964354182Încă nu există evaluări

- Glassware Cleaning ProcedureDocument3 paginiGlassware Cleaning ProcedureMukta TalukderÎncă nu există evaluări

- EOR Screening-TaberDocument14 paginiEOR Screening-TaberAjeng AyuÎncă nu există evaluări

- 17-Oil Centrifuge PDFDocument89 pagini17-Oil Centrifuge PDFUmangtarangÎncă nu există evaluări

- Flexible PavementsDocument13 paginiFlexible PavementsAhmad NajiÎncă nu există evaluări

- Sulfur and Nirogen IndustriesDocument58 paginiSulfur and Nirogen IndustriesSarah SanchezÎncă nu există evaluări

- Drying Technology: An International JournalDocument53 paginiDrying Technology: An International JournalNishant Kumar GuptaÎncă nu există evaluări

- Chemistry 9 Chap 1 Long QADocument17 paginiChemistry 9 Chap 1 Long QAAkbar Ali AhmedÎncă nu există evaluări

- Lecture Planner - Chemistry PDF OnlyDocument1 paginăLecture Planner - Chemistry PDF OnlyJai ChandÎncă nu există evaluări

- Complementary Commutation by AshakoorDocument16 paginiComplementary Commutation by AshakoorSobi100% (2)

- Vertical forces-WPS OfficeDocument2 paginiVertical forces-WPS OfficeJesusa EstradaÎncă nu există evaluări

- Test II. Multiple Choice. Encircle The Letter of The Correct AnswerDocument1 paginăTest II. Multiple Choice. Encircle The Letter of The Correct AnswerjoylynÎncă nu există evaluări

- Astm 2Document5 paginiAstm 2carlos salinasÎncă nu există evaluări

- DX 2010 0625 EngDocument12 paginiDX 2010 0625 EngguillermorettoÎncă nu există evaluări

- Analisis Karbohidrat MetodeDocument28 paginiAnalisis Karbohidrat MetodearikuraÎncă nu există evaluări

- Maximum Equivalent Stress Safety ToolDocument2 paginiMaximum Equivalent Stress Safety ToolDonfack BertrandÎncă nu există evaluări

- Handout BottleneckDocument7 paginiHandout BottleneckVenkatesh NenavathÎncă nu există evaluări

- UTM Arau Prepares 4-BromobenzophenoneDocument7 paginiUTM Arau Prepares 4-BromobenzophenoneMay Lee100% (1)

- Amines PDFDocument1 paginăAmines PDF최승원Încă nu există evaluări

- Bio Molecules 9Document3 paginiBio Molecules 9SilVI MARDELÎncă nu există evaluări

- Patrick Biller, Brajendra K. Sharma, Bidhya Kunwar, Andrew B. RossDocument9 paginiPatrick Biller, Brajendra K. Sharma, Bidhya Kunwar, Andrew B. RossBrahian Alexander RinconÎncă nu există evaluări

- MASTERY PHYSICS SPM EXPERIMENTSDocument12 paginiMASTERY PHYSICS SPM EXPERIMENTSSuhami IbrahimÎncă nu există evaluări

- LL0220AA Linear Low Density Polyethylene Film PropertiesDocument1 paginăLL0220AA Linear Low Density Polyethylene Film PropertiesXuân Giang NguyễnÎncă nu există evaluări