Documente Academic

Documente Profesional

Documente Cultură

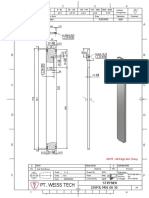

G-01 Model K-9 Rigid Coupling Rev-L

Încărcat de

Mohammed NiqrisTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

G-01 Model K-9 Rigid Coupling Rev-L

Încărcat de

Mohammed NiqrisDrepturi de autor:

Formate disponibile

K-9 G-01

MODEL K-9 RIGID COUPLING

- T&G Design -

The Shurjoint Model K-9 is a T&G (tongue & groove) design coupling for

moderate pressure applications where rigidity is required including valve

connections, mechanical rooms, fire mains and long straight runs. The built-in

teeth and T&G mechanism firmly grasp the pipe ends to eliminate undesired flex.

Support and hanging requirements correspond to ANSI B31.1, B31.9 and NFPA

13.

The Model K-9 couplings are comprised of two identical housing segments, EPDM

rubber gasket and plated track bolts and nuts. Housing segments are supplied

with our standard painted finishes, i.e. orange or RAL3000 red. Optional finishes

such as hot dipped zinc galvanized and custom epoxy coatings are available.

K-9 couplings should always be installed so that

the coupling bolt pads make metal to metal

For Fire Protection pressure rating, listing,

contact.

and approval information, refer to Data

Sheet B-42 or visit SHURJOINT website,

No need to worry about bold pad interference as the Model www.shurjoint.com for details or contact

K-9 works well with both regular and short radius elbows your SHURJOINT Representative.

and tees.

Full warranty terms

can be found on

www.shurjoint.com

Model K-9 Rigid Coupling

Max. Max

Working End Dimension

Nominal Pipe Pressure Load Axial

Size O.D. (CWP)* (CWP) Displacement A B C Bolt Size Weight

in in PSI Lbs in in in in in Lbs

mm mm Bar kN mm mm mm mm mm Kgs

1¼ 1.660 500 1080 0~0.06 2.56 4.33 1.73 ⅜ x 1¾ 1.3

32 42.2 35 4.82 0~1.6 65 110 44 M10 x 45 0.6

1½ 1.900 500 1410 0~0.06 2.80 4.45 1.73 ⅜ x 2⅛ 1.3

40 48.3 35 6.32 0~1.6 71 113 44 M10 x 55 0.6

2 2.375 500 2210 0~0.06 3.27 4.88 1.73 ⅜ x 2⅛ 1.5

50 60.3 35 9.85 0~1.6 83 124 44 M10 x 55 0.7

2½ 2.875 500 3240 0~0.06 3.86 5.39 1.73 ⅜ x 2⅛ 1.8

65 73.0 35 14.43 0~1.6 98 137 44 M10 x 55 0.8

76.1 mm 3.000 500 3530 0~0.06 4.00 5.51 1.73 ⅜ x 2⅛ 1.8

76.1 35 15.68 0~1.6 102 140 44 M10 x 55 0.8

3 3.500 500 4800 0~0.06 4.50 5.94 1.73 ⅜ x 2¾ 2.6

80 88.9 35 21.40 0~1.6 114 151 44 M10 x 70 1.2

4 4.500 350 5560 0~0.13 5.63 7.48 1.97 ⅜ x 2¾ 3.6

100 114.3 24 24.72 0~3.2 143 190 50 M10 x 70 1.7

139.7 mm 5.500 350 8310 0~0.13 6.77 9.21 2.00 ½x3 4.6

139.7 24 36.92 0~3.2 172 234 51 M12 x 75 2.1

5 5.563 350 8500 0~0.13 6.89 8.98 1.97 ½x3 4.6

125 141.3 24 37.77 0~3.2 175 228 50 M12 x 75 2.1

165.1 mm 6.500 350 11600 0~0.13 7.75 9.92 2.09 ½x3 5.3

165.1 24 51.57 0~3.2 197 252 53 M12 x 75 2.4

6 6.625 350 12050 0~0.13 7.87 10.04 2.09 ½x3 5.9

150 168.3 24 53.59 0~3.2 200 255 53 M12 x 75 2.7

8 8.625 350 20430 0~0.13 10.16 13.15 2.44 ⅝ x 3½ 9.7

200 219.1 24 90.82 0~3.2 258 334 62 M16 x 90 4.4

* Working Pressure is based on roll grooved standard wall carbon steel pipe.

G-01-1/3 Rev.L 20180903

20141114

K-9 G-01

MODEL K-9H RIGID COUPLING

Model K-9H Rigid Coupling

Max. Max

Working End Dimension

Nominal Pipe Pressure Load Axial

Size O.D. (CWP)* (CWP) Displacement A B C Bolt Size Weight

in in PSI Lbs in in in in in Lbs

mm mm Bar kN mm mm mm mm mm Kgs

8 8.625 350 20430 0~0.13 10.29 13.08 2.44 ¾ x 4¾ 15.8

200 219.1 24 90.82 0~3.2 261 332 62 M20 x 120 7.2

* Working Pressure is based on roll grooved standard wall carbon steel pipe.

Performance Data

The following tables show the maximum working pressures (CWP) of Shurjoint Model K-9/K-9H Rigid Coupling used on both carbon steel

and stainless steel pipes. Shurjoint ductile iron couplings can be used in conjunction with stainless steel pipe in non-corrosive environment

as the flow media does not come in direct contact with the coupling housings but rather only the gasket.

Model K-9 on Carbon Steel Pipe Model K-9 on Stainless Steel Pipe

Nom. Size Cut-Grooved Roll-Grooved Nom. Size Cut-Grooved Roll-Grooved

XS STD STD Sch. 10 Sch. 7 Sch. 80S Sch. 40S Sch. 40S Sch. 10S Sch. 5S

in / mm in / mm

PSI / Bar PSI / Bar PSI / Bar PSI / Bar PSI / Bar PSI / Bar PSI / Bar PSI / Bar PSI / Bar PSI / Bar

1¼ 600 600 500 400 300 1¼ 600 600 450 300 250

32 42 42 35 28 20 32 42 42 31 20 17

1½ 600 600 500 400 300 1½ 600 600 450 300 250

40 42 42 35 28 20 40 42 42 31 20 17

2 600 600 500 400 300 2 600 600 450 300 250

50 42 42 35 28 20 50 42 42 31 20 17

2½ 600 600 500 400 300 2½ 600 600 450 300 250

65 42 42 35 28 20 65 42 42 31 20 17

3 600 600 500 400 300 3 600 600 450 300 250

80 42 42 35 28 20 80 42 42 31 20 17

4 600 600 500 400 300 4 600 600 450 300 200

100 42 42 35 28 20 100 42 42 31 20 14

5 450 450 450 350 250 5 450 450 300 200

NR

125 31 31 31 24 17 125 31 31 20 14

6 450 450 450 350 250 6 450 450 300 125

NR

150 31 31 31 24 17 150 31 31 20 9

8 450 450 300 250 200 8 450 450 300 100

NR

200 31 31 20 17 14 200 31 31 20 7

8 (K-9H) 450 450 300 250 200 8 (K-9H) 450 450 300 100

NR

200 31 31 20 17 14 200 31 31 20 7

G-01-2/3 Rev.L 20180903

20141114

K-9 G-01

MATERIAL SPECIFICATIONS

• Housing:

Ductile Iron to ASTM A536, Gr. 65-45-12 and or ASTM A395, (Option) Grade “T” Nitrile (Color code: Orange stripe)

Gr. 65-45-15, min. tensile strength 65,000 psi (448 MPa). Recommended for petroleum products, air with oil vapors,

vegetable and mineral oils within the specified temperature

range. Also good for water services under +150 oF

• Surface Finish: (+66oC).

Standard painted finishes in orange or RAL3000 red. Temperature range: -20 oF to +180 oF (-29 oC to +82 oC).

Hot dip zinc galvanized (Option). Do not use for HOT WATER above +150 oF (+66 oC) or

Epoxy Coatings in RAL3000 red or other colors (Option) HOT DRY AIR above +140 oF (+60 oC)

Other options: Grade “O” Fluoroelastomer.

• Rubber Gasket: Grade “L” Silicone.

Grade “E” EPDM (Color code: Green stripe) Good for cold & hot For additional details contact Shurjoint.

water up to +230oF (+110oC). Also good for services for water

with acid, water with chlorine, deionized water, seawater and

waste water, dilute acids, oil-free air and many chemicals. • Bolts & Nuts:

Not recommended for petroleum oils, minerals oils, solvents and Heat treated carbon manganese steel track bolts to ASTM

aromatic hydrocarbons. A449-83a (or A183 Gr. 2), minimum tensile strength 110,000 psi

Maximum Temperature Range: -30oF (-34oC) to +230oF (758 MPa), Zinc electroplated, with heavy-duty hexagonal nuts to

(+110oC)*. ASTM A563.

*EPDM gaskets for water services are not recommended for

steam services unless couplings or components are accessible

for frequent gasket replacement.

General Notes:

Maximum Working Pressure (CWP) listed is the maximum cold water pressure for general piping services tested to ASTM F1476 and or AWWA C606

methods. Figures listed are based on roll- or cut-grooved standard wall carbon steel pipe. For other pipe schedules or pipe materials, contact

Shurjoint for additional information.

Max. End Load is calculated based on the maximum working pressure (CWP).

Listed and or Approved Pressures are pressure ratings for fire protection systems, tested and approved by various approval bodies. Please always

refer to the latest approval data posted on the Shurjoint website.

Field Joint Test: For one time only the system may be tested hydrostatically at 1½ times the maximum working pressure listed (AWWA C606 5.2.3).

Warning: Piping systems must always be depressurized and drained before attempting disassembly and or removal of any components.

The 10 Year Limited Warranty applies to manufacturing defects only and does not cover severe service/temperature applications or wear parts.

Shurjoint reserves the right to change specifications, designs and or standard without notice and without incurring any obligations.

Shurjoint product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise

measurements, please contact Shurjoint Technical Service. Shurjoint reserves the right to change or modify product design, construction,

specifications, or materials without prior notice and without incurring any obligations to make such changes and modifications on Shurjoint

products previously subsequently sold.

G-01-3/3 Rev.L 20180903

20141114

S-ar putea să vă placă și

- Grooved Fittings - ShurjointDocument7 paginiGrooved Fittings - ShurjointitskittylimÎncă nu există evaluări

- C-01 Model 7705 Standard Flexible CouplingDocument4 paginiC-01 Model 7705 Standard Flexible CouplingDaniel SanÎncă nu există evaluări

- G-03 Model Z05 Rigid Coupling - Rev N PDFDocument3 paginiG-03 Model Z05 Rigid Coupling - Rev N PDFDaniel SanÎncă nu există evaluări

- C-02 Model 7707 Heavy Duty Flexible Coupling - Rev-UDocument3 paginiC-02 Model 7707 Heavy Duty Flexible Coupling - Rev-UDaniel SanÎncă nu există evaluări

- MODEL 7705 Flexible CouplingDocument2 paginiMODEL 7705 Flexible CouplingKalagan YadaÎncă nu există evaluări

- Retaining Rings MetricDocument5 paginiRetaining Rings MetricNur SugiartoÎncă nu există evaluări

- Metric Bolt Torque TableDocument1 paginăMetric Bolt Torque Tablemihai90100% (2)

- K-01 MODEL SS-7 STAINLESS STEEL RIGID COUPLING - Rev.tDocument3 paginiK-01 MODEL SS-7 STAINLESS STEEL RIGID COUPLING - Rev.tSANOOJ NASARUDEENÎncă nu există evaluări

- K-01 Model SS-7 Stainless Steel Rigid Coupling With GasketDocument5 paginiK-01 Model SS-7 Stainless Steel Rigid Coupling With GasketSANOOJ NASARUDEENÎncă nu există evaluări

- Momen Kekencangan BautDocument1 paginăMomen Kekencangan BautRandy Merwansyah12Încă nu există evaluări

- Momen Kekencangan BautDocument1 paginăMomen Kekencangan BautEdy Setyawan100% (4)

- Pipe Schedules Chart Imperial and Metric HFT50-WEB-P PDFDocument2 paginiPipe Schedules Chart Imperial and Metric HFT50-WEB-P PDFAnonymous ITKbMGWMÎncă nu există evaluări

- Master CatalogDocument114 paginiMaster CatalogFINNING CATÎncă nu există evaluări

- VictaulicDocument5 paginiVictaulicTayo TayoÎncă nu există evaluări

- ROOFSEAL C-PURLIN SPECSDocument4 paginiROOFSEAL C-PURLIN SPECSLer Kai HuiÎncă nu există evaluări

- MetricBoltTorqueNm AspxDocument1 paginăMetricBoltTorqueNm AspxjbsÎncă nu există evaluări

- Applications: N N N N N NDocument4 paginiApplications: N N N N N NYana Jarang OlÎncă nu există evaluări

- Metric Bolt Torque Table NmDocument1 paginăMetric Bolt Torque Table NmninatenaÎncă nu există evaluări

- Metric Bolt Torque Table NM - CNCexpoDocument1 paginăMetric Bolt Torque Table NM - CNCexponate anantathat100% (1)

- Nutsert 9468 MMDocument1 paginăNutsert 9468 MMAJITHÎncă nu există evaluări

- Metric Bolt Torque Table - CNCexpoDocument1 paginăMetric Bolt Torque Table - CNCexpoMohsen Keramati100% (1)

- SAE J518 Split FlangesDocument1 paginăSAE J518 Split Flangesmanh hung leÎncă nu există evaluări

- Job 10 Torsion Test by Muhammad KhawarDocument12 paginiJob 10 Torsion Test by Muhammad KhawarMake Every Thing LiveÎncă nu există evaluări

- Metric Bolt Torque Table NM - CNCexpoDocument1 paginăMetric Bolt Torque Table NM - CNCexpoNepoleon KaruppiahÎncă nu există evaluări

- Product Specifications: Hole-Cut SystemDocument1 paginăProduct Specifications: Hole-Cut SystemErickÎncă nu există evaluări

- FRP Tank Price PackageDocument8 paginiFRP Tank Price PackageWira Brata SamodraÎncă nu există evaluări

- Wall ChartDocument1 paginăWall Chartduhast123Încă nu există evaluări

- Eye Bolt 1Document1 paginăEye Bolt 1Adi SutardiÎncă nu există evaluări

- Sutrado Kabel Catalogue - Product Catalogue for Low Voltage Power CablesDocument12 paginiSutrado Kabel Catalogue - Product Catalogue for Low Voltage Power CablesFahmi IdrsÎncă nu există evaluări

- Vigas Wide Flange WF ASTM A-572/992 Gr.50: Perfil Americano de Alas AnchasDocument4 paginiVigas Wide Flange WF ASTM A-572/992 Gr.50: Perfil Americano de Alas AnchasCLAUDIA TAPIA SANCHEZÎncă nu există evaluări

- Grosime PereteDocument1 paginăGrosime Peretebogd32000Încă nu există evaluări

- Tabular Presentation of Basic Technical Data RMC ConductorsDocument2 paginiTabular Presentation of Basic Technical Data RMC ConductorsBuyme1 CNC BIZÎncă nu există evaluări

- SOCKET HEAD CAP SCREW TIGHTENING TORQUE GUIDEDocument1 paginăSOCKET HEAD CAP SCREW TIGHTENING TORQUE GUIDEChandru VelÎncă nu există evaluări

- List Material: Strengthen Column Site CheposDocument3 paginiList Material: Strengthen Column Site Cheposiyan supriadiÎncă nu există evaluări

- E1 Perfiles CDocument1 paginăE1 Perfiles CCesar Augusto Castillo RoqueÎncă nu există evaluări

- PVDF Socket Fusion Concentric Reducer DRG.-008Document1 paginăPVDF Socket Fusion Concentric Reducer DRG.-008rasukathirÎncă nu există evaluări

- Parallel Flanges Channels - Steel DimensionsDocument1 paginăParallel Flanges Channels - Steel DimensionsAxiv The GreatÎncă nu există evaluări

- Fastener Weight & Count ChartDocument12 paginiFastener Weight & Count Chartsudarshan pugaliaÎncă nu există evaluări

- Schedule ChartDocument1 paginăSchedule ChartSubash Gold KingÎncă nu există evaluări

- Nominal Wall Thickness For Schedule Sizes.: 5 10 20 30 40 60 STD 80 XS 100 120 140 160 XXSDocument2 paginiNominal Wall Thickness For Schedule Sizes.: 5 10 20 30 40 60 STD 80 XS 100 120 140 160 XXSChano HanokÎncă nu există evaluări

- Balls BallsDocument2 paginiBalls BallsOm PurandareÎncă nu există evaluări

- Forged Machinery Eye Bolts: See Application and Warning InformationDocument1 paginăForged Machinery Eye Bolts: See Application and Warning InformationHasrul SunÎncă nu există evaluări

- TABLE 4 Nut Proof Load Values, KN: OTE OTEDocument1 paginăTABLE 4 Nut Proof Load Values, KN: OTE OTEanishÎncă nu există evaluări

- GERDAU: Wide Flange Beams For Solar PostsDocument1 paginăGERDAU: Wide Flange Beams For Solar PostsersinÎncă nu există evaluări

- Technical GuideDocument31 paginiTechnical GuideRolando Palma LatorreÎncă nu există evaluări

- Pipe Schedule and Thickness PDFDocument2 paginiPipe Schedule and Thickness PDFskychurch100% (1)

- Project Material ListDocument5 paginiProject Material ListSBS CONSULTANT BATAMÎncă nu există evaluări

- Dextra: System DescriptionDocument10 paginiDextra: System DescriptionHiba SolimanÎncă nu există evaluări

- HayDocument8 paginiHayMinh Tâm TrầnÎncă nu există evaluări

- Tas Lockingassemblie Eng r03-3012Document2 paginiTas Lockingassemblie Eng r03-3012प्रवीण देशारÎncă nu există evaluări

- CHAINDocument4 paginiCHAINJhon Jairo Arango MarquezÎncă nu există evaluări

- Systems of Unts and MeasurementsDocument17 paginiSystems of Unts and MeasurementsRegina Grace OficiarÎncă nu există evaluări

- Tap Drill Sizes Chart for Forming TapsDocument1 paginăTap Drill Sizes Chart for Forming Tapsamir.suljic23-1Încă nu există evaluări

- Group 2 Tightening TorqueDocument3 paginiGroup 2 Tightening Torquedeniden2013Încă nu există evaluări

- PT. SWADAYA GRAHA Engineering TablesDocument9 paginiPT. SWADAYA GRAHA Engineering TablesAndri EkoÎncă nu există evaluări

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesDe la EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesEvaluare: 5 din 5 stele5/5 (3)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingDe la EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingEvaluare: 4.5 din 5 stele4.5/5 (9)

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosDe la EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosÎncă nu există evaluări

- 447 - en - CAAV - DAAV (CAAV0620S)Document1 pagină447 - en - CAAV - DAAV (CAAV0620S)Mohammed NiqrisÎncă nu există evaluări

- 22VP3L M01 00 30 StiffnerDocument1 pagină22VP3L M01 00 30 StiffnerMohammed NiqrisÎncă nu există evaluări

- E-02 7112 22 o ELBOWDocument3 paginiE-02 7112 22 o ELBOWMohammed NiqrisÎncă nu există evaluări

- E-07 Models 7151 Eccentric ReducerDocument4 paginiE-07 Models 7151 Eccentric ReducerMohammed NiqrisÎncă nu există evaluări

- MotorsDocument4 paginiMotorsMohammed NiqrisÎncă nu există evaluări

- Y Strainer VictaulicDocument4 paginiY Strainer VictaulicMohammed NiqrisÎncă nu există evaluări

- Drum Level ControlDocument10 paginiDrum Level Controlgotosky12345678Încă nu există evaluări

- 1konsep Dasar TermodinamikaDocument39 pagini1konsep Dasar TermodinamikaYunsa LenggoÎncă nu există evaluări

- Lightweight UAV LauncherDocument149 paginiLightweight UAV Launcherchaidir rahman susanto100% (1)

- Orbital ForgingDocument4 paginiOrbital ForgingMrLanternÎncă nu există evaluări

- Computer-Aided Analysis of Mechanical Systems PDFDocument388 paginiComputer-Aided Analysis of Mechanical Systems PDFnbritomarÎncă nu există evaluări

- Modelling and Control of Diesel Engine Modelling and Control of Diesel EngineDocument296 paginiModelling and Control of Diesel Engine Modelling and Control of Diesel EngineTerryÎncă nu există evaluări

- Lecture Notes in Cve163 Design of Steel and Timber StructuresDocument71 paginiLecture Notes in Cve163 Design of Steel and Timber StructuresMerwin Andrew UyÎncă nu există evaluări

- Grade 12 LM General Physics 1 Module6Document18 paginiGrade 12 LM General Physics 1 Module6Marco DadoÎncă nu există evaluări

- Triple Wire Machine Exampl KiwiDocument39 paginiTriple Wire Machine Exampl KiwiVenkatÎncă nu există evaluări

- 33-Impact of CFD On Aircraft Design PDFDocument42 pagini33-Impact of CFD On Aircraft Design PDFJohn MaclinsÎncă nu există evaluări

- Powder Technology: Apoorva Karamchandani, Hojae Yi, Virendra M. PuriDocument9 paginiPowder Technology: Apoorva Karamchandani, Hojae Yi, Virendra M. Puriitalo mayuber mendoza velezÎncă nu există evaluări

- ZK 61 A PDFDocument5 paginiZK 61 A PDF孙俊磊Încă nu există evaluări

- iBend-Catalog (WEB - ENG) 201904Document21 paginiiBend-Catalog (WEB - ENG) 201904MOISESÎncă nu există evaluări

- B25D ADT Parts ManualDocument680 paginiB25D ADT Parts ManualBiswajit DasÎncă nu există evaluări

- BSW, BS,,AF, BA and Metric Tool SizeDocument4 paginiBSW, BS,,AF, BA and Metric Tool SizeUNES100% (1)

- STABURAGS NBU 12-300 KP 017062 PI GB enDocument2 paginiSTABURAGS NBU 12-300 KP 017062 PI GB enmuhammad saputraÎncă nu există evaluări

- Matter and Energy PDFDocument2 paginiMatter and Energy PDFJoanna GaribayÎncă nu există evaluări

- 223 Excavator After SN AD00453Document160 pagini223 Excavator After SN AD00453Fernando Sabino100% (3)

- Sop For Bag FilterDocument5 paginiSop For Bag FiltervinodsnÎncă nu există evaluări

- 2016 IB Physics - Motion and ForcessDocument5 pagini2016 IB Physics - Motion and ForcessGajendraÎncă nu există evaluări

- Filter With Metal BowlDocument3 paginiFilter With Metal BowlBiswanath LenkaÎncă nu există evaluări

- Design of TG Foundation BlockDocument26 paginiDesign of TG Foundation BlockSyed Zeeshan HusainÎncă nu există evaluări

- 1586 - Your Second SOLIDWORKS Flow Simulation Tips, Tricks, and Frequent FeaturesDocument7 pagini1586 - Your Second SOLIDWORKS Flow Simulation Tips, Tricks, and Frequent Featuresmlik borhenÎncă nu există evaluări

- Water for Injection Generation System RequirementsDocument14 paginiWater for Injection Generation System Requirementsyogendra100% (2)

- RVBD 10 - 520 P 030520 enDocument2 paginiRVBD 10 - 520 P 030520 enfeironmaidenÎncă nu există evaluări

- CNC Controller Tc55xx User Manual RuDocument28 paginiCNC Controller Tc55xx User Manual Ruanhthong3kÎncă nu există evaluări

- Thermal Expansion Loop - ML Loops ALLDocument6 paginiThermal Expansion Loop - ML Loops ALLPamela De Melo-LangfordÎncă nu există evaluări

- Sanitary Engineering Licensure Exam PrepDocument15 paginiSanitary Engineering Licensure Exam PrepDan UnabiaÎncă nu există evaluări

- Engine Parts Manual for SAA4D95LE-5D S/N 521394-UPDocument157 paginiEngine Parts Manual for SAA4D95LE-5D S/N 521394-UPGustavoOliveira100% (1)

- Plumbing Grade 9 LAS 1 4TH QuarterDocument10 paginiPlumbing Grade 9 LAS 1 4TH QuarterFranklin LirazanÎncă nu există evaluări

- Text Book of Automobile Engineering PDFDocument665 paginiText Book of Automobile Engineering PDFDavid GaddalaÎncă nu există evaluări

- Non-Hazardous Areas Adjustable Pressure Switch: 6900P - Piston SensorDocument2 paginiNon-Hazardous Areas Adjustable Pressure Switch: 6900P - Piston SensorDiana ArredondoÎncă nu există evaluări