Documente Academic

Documente Profesional

Documente Cultură

Mini-Sub Technical Data For Mines

Încărcat de

8612045483082Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mini-Sub Technical Data For Mines

Încărcat de

8612045483082Drepturi de autor:

Formate disponibile

DS 543005

Debswana Specification

Electrical:

Mini Sub-station for Underground

Reticulation

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 1 of 19

DS 543005

1 SCOPE 3

2 TECHNICAL REQUIREMENTS TO BE SPECIFIED BY THE ENGINEER 3

3 DEFINITIONS 3

4 REQUIREMENTS 3

4.1 GENERAL 3

4.2 CORROSION PROTECTION 5

4.3 HIGH VOLTAGE EQUIPMENT 5

4.4 LOW VOLTAGE EQUIPMENT 7

4.5 CONTROL AND INSTRUMENT WIRING 8

4.6 TRANSFORMER COMPARTMENT 8

4.7 NEUTRAL EARTHING RESISTOR 9

4.8 NEUTRAL EARTH RESISTANCE MONITOR 10

4.9 ADIT SENSITIVE EARTH FAULT RELAY 10

4.10 NOTICE BOARDS 10

5 QUALITY ASSURANCE PROVISIONS 11

APPENDIX A : RELATED DOCUMENTS 12

APPENDIX B : RECORD OF AMENDMENTS 12

APPENDIX C : DATA SHEET TO BE COMPLETED BY THE COMPANY 13

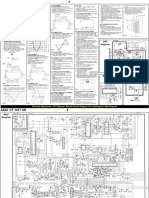

APPENDIX D: OUTLINE OF MOBILE MINISUB 18

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 2 of 19

DS 543005

1 SCOPE

This specification covers the manufacture, factory testing and delivery of mobile mini sub-

stations for underground reticulation.

2 TECHNICAL REQUIREMENTS TO BE SPECIFIED BY THE ENGINEER

• Title, reference and issue of this specification.

• Detail drawings of the following:

Chassis

Transformer core supports

Tap change switch

3 DEFINITIONS

For the purpose of this specification, the following definitions shall apply: -

APPROVED : Approved by the Engineer in writing

BS : British Standard

SABS : South African Bureau of Standards

SANS : South African National Standards

IEC : International Electro technical Commission

HIGH VOLTAGE (HV) : Between 6.6kV and 33kV

MEDIUM VOLTAGE (MV) : Between 650V and 6.6kV

LOW VOLTAGE (LV) : Below 650V

The following terms are defined in the General Conditions of Contract:

• Debswana, Company, Contractor, Engineer.

4 REQUIREMENTS

4.1 GENERAL

The basic design of the mobile mini sub-station shall be in accordance with outline drawing

No.Y2341 and shall consist of a welded steel unit of 5 mm gauge, except where specified,

on a robust fabricated chassis.

4.1.1 Construction: The unit shall be a totally enclosed vermin type, well ventilated and

designed so that easy access can be obtained to all equipment for installation,

maintenance and replacement purposes.

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 3 of 19

DS 543005

4.1.2 Compartments: The mobile mini sub-station shall be constructed in three separate

compartments:

a) High voltage

b) Transformer

c) Low voltage

All three sections shall be bolted or welded to a common undercarriage to form a compact

unit.

4.1.3 Roof covering: The unit shall be provided with a drip proof bolt on roof, (3,2 mm thick

steel to SANS 1431 grade 300WA) covering the entire sub-station.

4.1.4 Lifting brackets: Four box type non-removable lifting brackets or lugs shall be provided

for off-loading and general handling, suitably mounted on the unit to prevent:

a) The unit becoming top heavy when lifted.

b) Damage to the unit when rope slings are used during the lifting operation.

Additional lifting facilities shall be provided and approved before fabrication commences.

Slinging brackets shall be bolted on as shown on drawing Y2341.

4.1.5 Towing brackets: The unit shall be provided with two robust towing brackets designed to

allow for the fitting of standard cast steel type buffers. See the data sheet for height and

type of buffer.

A drawbar shall be fitted as shown on drawing Y2341.

4.1.6 Wheels: If wheels are to be fitted they shall be of the type specified on the data sheet.

The Contractor shall supply the wheel manufacturer with the total mass of the unit.

4.1.7 Overall dimensions: The maximum height of unit from crown of rail shall not exceed

1550 mm, width 1300 mm, and length 2400 mm buffer to buffer.

4.1.8 High voltage access: Access to the HV section shall be through a weatherproof hinged

door at the end of the compartment. The opening dimensions of which shall allow the

operator an unobstructed view of all switch operations, earth blade positions, live line

indicators etc.

The transparent earthing indicator bottles shall be clearly visible when the earth switch is in

the closed or open position by means of a reflective angle stainless steel plate behind and

above the bottles.

The switch shall be positioned to ensure that all switch operations can be carried out using

the standard operating handles provided by the switchgear manufacturer.

Bullet type hinges (12mm x 100mm) shall be fitted on the compartment door. There shall be

at least three hinges per door.

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 4 of 19

DS 543005

The fixings and fastenings of the side doors shall only be unlocked from inside the

compartment through the end door which shall be provided with a handle and a catch

suitable for padlocking from outside.

4.1.9 Cable access: Cable access to the HV section shall be:

i. directly below, or

ii. from the side, or

iii. at an angle below the cable termination of the HV switch.

The aperture necessary for the cable entry shall be closed with a removable split plate, the

split plate being cut on site to the diameter of the incoming feeder. Dry type HV cable

termination to be used.

4.1.10 Low voltage access: Access to the LV section shall be through weatherproof hinged

(bullet type, at least 3 hinges per door) double doors at the end of the compartment of

suitable dimensions and be provided with a handle and catch for padlocking from outside.

4.1.11 Cover plates: A removable inner split plate shall be provided for covering of all live LV

parts. Toggles of the MCBs shall protrude through the upper half of the plate and the

lower half to provide access to the lower portion of the MCB for connecting purposes.

Holes shall be left in any plates covering any earth leakage relays to enable the reset

button to the operable with the doors open.

4.1.12 LV cable glands: The bottom of the LV compartment shall be of steel plate set at an

angle of 45° ± 2°. Onto this plate shall be mounted removable gland plates suitable for the

reception of the cable glands specified in the data sheet.

4.1.13 Handling: The unit shall be designed to withstand robust handling and shall be supported

to permit transportation at a position of 90° to the horizontal.

4.1.14 Earthing: An earth bar of minimum dimensions 25mm x 3mm shall bond the housing - HV

switch - transformer and continue through to the HV compartment with terminal studs for

earthing of outgoing LV feeders and the transformer neutral via the earth fault limiting

resistors installed.

A separate section for protection relays shall be provided on the earth bar. (To prevent in

adherent disconnection of the protection circuit when cables are installed or disconnected).

4.2 CORROSION PROTECTION

Corrosion protection shall be in accordance with the requirements of Debswana DS164050

and DS000122. The finish coat shall be in accordance with Debswana color coding

specification DS164051.

4.3 HIGH VOLTAGE EQUIPMENT

4.3.1 Rating: All equipment in the MV compartment shall be rated for 20 kA at 6600V or 18 kA

at 11000V.

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 5 of 19

DS 543005

4.3.2 Switchgear: The insulation shall be SF6. The switchgear shall comply with the following:

a) Arrangement of the switchgear shall be suitable for mounting in the mobile mini sub-

station, considering the maximum dimensions in Clause 4.1.7.

The support bracket on the ring main unit shall be a 3-way angle iron type on both

sides of the ring main unit. Top support brackets shall be fitted to both sides of the

ring main unit, fixing it to the mini sub-station side walls.

The type of switchgear shall be as selected in the data sheet. It shall comprise fault

make load break switches, fused fault make load break switches or circuit breakers.

Neon indicators for "Cable Alive" indication with capacitive dividers shall be

provided.

Integral earthing shall be provided.

A visual inspection aperture shall be provided so that the following positions of

contacts of the isolating devices can be clearly seen:

i. ON position

ii. OFF position

iii. EARTH position.

A cable box shall be provided for paper (PILC) or cross linked polyethylene (XLPE)

insulated three core cable, as indicated in the data sheet. The cable shall be of

cross section 95 mm² (diameter ± 60 mm). Should clearance from the gland plate to

the top of rail be less than 900 mm, an angular cable box shall be provided. The

cable box shall be suitable for side entry or on the bottom by means of an angled

entry.

All cable gland plates shall be removable and left for drilling on site, unless specified

for drilling in the data sheets.

4.3.3 Fuses: Fuses shall be striker pin type for protecting the primary (MV) side of the

transformer.

Fuses shall be fault rated for 20 kA at 6600V or 18 kA at 11000V as necessary and sized as

in the data sheet. Three spare fuses mounted in clips in the HT compartment shall be

supplied with each mini sub-station.

4.3.4 Transformer MV connections: Suitable lengths of 11/6,35 or 6,6/3,8 kV single core

copper conductor PVC/PCV or PVC/XLPE insulated shall be used as "flexible"

connections between the outgoing terminals of the fuse switch or circuit breaker and the

MV terminals of the transformer. The terminations shall be shrouded and heat shrink

elbows are permissible.

4.3.5 MV cable glands: The type of cable glands provided on the cable connection shall be as

indicated in the data sheet.

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 6 of 19

DS 543005

4.4 LOW VOLTAGE EQUIPMENT

All equipment in the LV compartment shall be rated for a fault level of not less than that

specified in the data sheet:

4.4.1 Standard

3 x 600A - Copper busbars

1 x voltmeter 0-600V Elima 96 x 96 mm to indicate LV busbar voltage

3 x fuses 2 Amp HRC for voltmeter protection

1 x voltmeter selector switch

1 x auxiliary transformer 550V/110V, 500VA, 1 phase

2 x 10A HRC fuses for auxiliary transformer primary protection

3 x 600/5 Amp Class 1 CT Epiring wired to the red, yellow and blue phase and to indicate

the total LV load

3 x Ammeter Elima Type FB1A 0-600A 96 x 96 mm for operation from 600/5 C.T.s

(maximum demand type)

1 x EPC designed CT for Adit protection (for rating see data sheet)

1 x 5 amp EPC Type Adit earth fault relay fed from C.T.

4 x 27 ohm earth resistors each shall be continuously rated for 10 Amperes for the neutral

earthing connected in series paralled to give a 27 ohm resistance unless otherwise

specified.

1 x neutral earthing resistance monitor type Nerm 500, including indication

4.4.2 Outgoing feeders: The ratings and quantities of the following equipment shall be

specified in the data sheet:

i. Approved MCBs, complete with direct acting o/c protection and fitted with 500V

shunt trip coil.

ii. Earth leakage relay

iii. C T Epiring wired to the yellow phase

iv. Ammeter Elima type FB 1A 96 x 96 mm fed from the C.T.

v. Engraved labels shall be fitted above each outgoing circuit breaker.

Circuit breaker No1 - Outgoing feeder No 1

Circuit breaker No 2 - Outgoing feeder No 2

vi. The letters on the labels shall be at least 15mm high.

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 7 of 19

DS 543005

vii. The labels shall be fitted by means of steel rivets.

viii. All fuses, instruments, etc, shall be labeled in the same way.

4.5 CONTROL AND INSTRUMENT WIRING

All wiring shall be 7 strand 2,5 mm² grey or black, numbered at each end and adequately

supported by either cleats or tube. (See drawing Y2342)

4.6 TRANSFORMER COMPARTMENT

The transformer shall comply with the latest edition of Debswana DS514003 for oil filled

units or Debswana DS514005 for dry type units. The transformer shall be oil filled, sealed, or

alternatively, of the dry type.

The tank cover for oil filled sealed units shall be bolted to the tank.

4.6.1 Electrical specifications

Capacity kVA (see data sheet)

Ratio (see data sheet)

Frequency 50 Hz

Cooling ONAN

Number of phases 3

Vector group DYN 11

Off load tap change ± 10%, ± 5%, 0%

The tap change switch shall have padlock facilities. An engraved riveted label shall be fitted

next to the tap switch reading: “Only operate when the primary side of the transformer is

isolated”.

Impedance

• Up to 500 kVA 4,0- 5,0%

• Up to 630 kVA 4,5 - 5,5%

Temperature rise

• Windings (by resistance) 65°C (ambient 40°C)

• Top Oil (by resistance) 60°C (ambient 40°C)

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 8 of 19

DS 543005

Losses

No Load Load

kVA Rating Loss (W) Loss (W)

200 520 2 700

250 620 3 200

315 720 3 800

400 910 4 500

500 1 100 5 400

630 1 300 6 400

Total loss deviation 10% declared

Total component loss deviation 15% declared

The transformer shall be designed to withstand mechanical or electrical damage from a

short circuit connected directly to its secondary terminals and with nominal 3-phase volts

applied to the primary terminals for 1 second. Type test certificates of the transformer

tested shall be provided and all essential dimensions etc and equipment used in the

transformer shall be specified for use in subsequent units.

This test and the stripping of the transformer after testing shall be witnessed by the

Engineer.

4.6.2 Fittings: Rating and diagram plate (order number to be indicated on duty plate).

Oil level gauge.

Earth terminal.

Pressure release valve.

4.6.3 Transformer neutral: Transformer neutral shall be wired with 16 mm² PVC/PVC insulated

copper conductor 600/1000V grade through the EPC CT designed for Adit protection,

through the earth resistor to earth.

4.6.4 Busbar clearances: Busbar clearances shall be in accordance with BS 159 Standard

Class B. All busbar, transformer connections etc, shall be properly insulated.

4.7 NEUTRAL EARTHING RESISTOR

Four 27 ohm suitably designed and fabricated resistors shall be provided each being

continuously rated for 5000 watts to carry a current of 10 amperes continuously with a

temperature rise not exceeding 375o C.

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 9 of 19

DS 543005

The resistors shall be made from chrome, iron, aluminium alloy resistance wire wound

onto a grooved and fluted ceramic body and shall be housed, mounted and connected by

the movement of a set of retained links so that a maximum earth fault current of 10

amperes can be selected.

4.8 NEUTRAL EARTH RESISTANCE MONITOR

The neutral earth resistance monitor type NERM with indicator, shall have its main

connection between the transformer neutral terminal and the earth busbar in the LV

compartment and the trip circuit connected so that any increase or decrease in neutral

earth resistance will trip the MV circuit breaker controlling the transformer primary winding.

4.9 ADIT SENSITIVE EARTH FAULT RELAY

The earth fault sensing element of the relay shall consist of an encapsulated current

transformer (see data sheet for rating) connected between the transformer neutral

terminal to the "top" end of the neutral earthing resistance. The 5 ampere ADIT relay shall

have its current element set at 16% and its time element at 2,5 seconds.

4.10 NOTICE BOARDS

The following notice boards, shall be fitted to the sub-station on the outside of both of the

longer sides of the mini sub-station.

a) Danger sign (lightning bolt – SABS WW7) Extra High Voltage, secured to the

outside of the HV panel door.

b) Water extinguisher prohibition sign (SABS PV4).

c) Notice prohibiting unauthorised persons from handling or interfering with electrical

apparatus.

d) A notice containing the procedure in case of fire on either side of the mini sub-

station.

e) A notice giving directions for the resuscitation of persons suffering from the effects

of electrical shock on either side of the mini sub-station. (SABS EC14)

f) A notice prohibiting unauthorised entrance to the mini sub-station.

g) Electrical drawing fixed to inside of both HT and LT doors.

h) Fit an engraved brass label (riveted), mounted on the inside of the MV ring main unit

compartment reading:

Ensure that the feeder feeding this mini sub-station is isolated and withdrawn.

In the case where this mini sub-station is fed from a previous mini sub-station, this feeder

shall be isolated and earthed at the previous mini sub-station.

Check that the neon indication is off.

The earthing switch shall now be switched to the earth position – cable side.

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 10 of 19

DS 543005

Test with Approved MV phasing sticks that the supply to this mini sub-station is isolated -

dead.

Maintenance or repairs on this mini sub-station can now take place.

NOTE: The above brass label shall be engraved in 15mm high lettering.

5 QUALITY ASSURANCE PROVISIONS

Debswana QAP 100 shall apply.

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 11 of 19

DS 543005

APPENDIX A : RELATED DOCUMENTS

Botswana Mines, Quarries, Work and Machinery CAP 44:02

South African laws, regulations, recommendations and standards:

Mine Health and safety act 29 of 1996 (as amended)

Minerals Act 50 of 1991 (as amended)

AAC Drawing Y2342 : Connection diagram of mobile mini sub-station

AAC Drawing Y2341 : Outline of mobile mini sub-station

Debswana DS164050 : Corrosion protection of steelwork with coatings

Debswana DS514003 : Oil filled distribution transformers

Debswana DS514005 : Dry type distribution transformers

BS 159 : Specification for high-voltage busbars and busbar connections

Debswana DS000122 : MIO epoxy and acrylic finish

SANS 1091 : National colour standards for paint

APPENDIX B : RECORD OF AMENDMENTS

Issue 0 : First issue

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 12 of 19

DS 543005

APPENDIX C : DATA SHEET TO BE COMPLETED BY THE COMPANY

PUT (X) IN APPROPRIATE BLOCK

1.0 RATINGS

TRANSFORMER 11 000 6 600

PRIMARY VOLTAGE

(VOLT)

TRANSFORMER 550

SECONDARY

VOLTAGE (VOLT)

TRANSFORMER 630 500 400 315 250 300

RATING (KVA)

2.0 BUFFERS

TYPE MILD STEEL

CAST STEEL

SUPPLY BUFFERS YES NO

HEIGHT – CROWN OF RAIL 290 320 390

TO CENTRE OF BUFFER (MM)

3.0 WHEELS SEE SECTION 2.1.6

TYPE NO WHEELS ROXOR

TO BE CANNON

FITTED

WHEEL 230 305

DIAMETER

(MM)

RAIL GAUGE 610 762 914

(MM)

4.0 H.V. SWITCHGEAR

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 13 of 19

DS 543005

4.1 RING MAIN UNIT WITH CIRCUIT BREAKER ON TRANSFORMER

T – OFF FEEDER

USE VIP – 12 PROTECTION RELAY

MERLIN GERIN – TYPE RM6 – 2I X 1B – (IDI)

OTHER (SPECIFY)

OR

4.2 Ring main unit with fuse switch on transformer

T – off feeder

Merlin Gerin – type RM6 – 2I x 1Q (IQI)

Other (specify)

5.0 H.V. FUSE RATINGS

VOLTAGE TRANSFORMER DIN TYPE QTY GEC TYPE QTY

RATING

11 kV 200 kVA 25A 25A

250 kVA 25A 32A

315 kVA 40A 40A

400 kVA 40A 45A

500 kVA 40A 50A

630 kVA 63A 63A

6,6 kV 200 kVA 40A 40A

250 kVA 40A 50A

315 kVA 40A 63A

400 kVA 63A 80A

500 kVA 63A 100A

630 kVA 80A 100A

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 14 of 19

DS 543005

6.0 H.V.CABLE GLANDS

RAND MINES (PILC CABLES)

Compression gland (XLPE cables)

Clampblock (XLPE cables)

Captive cone gland (PILC cables)

7.0 LOW VOLTAGE EQUIPMENT (OUTGOING FEEDERS)

7.1 If Mitsubishi circuit breakers are to be used then arc barriers shall be used on the top and

bottom of the CB’s

7.2 FAULT LEVEL RATING

18kA 35kA

7.3 18kA BREAKER SELECTIONS

Qty Manufacturer Fame Rating Shunt Thermal Magnetic

Size A Trip s

Mitsubishi NF-100SPA 50 Yes Fixed Fixed

Mitsubishi NF-100SPA 100 Yes Fixed Fixed

Mitsubishi NF-250SPA 225 Yes Fixed Fixed

Mitsubishi NF-400SPA 225 Yes Fixed Fixed

7.4 35kA BREAKER SELECTIONS

Qty Manufacturer Fame Rating Shunt Thermal Magnetics

Size A Trip

Mitsubishi NF100SHA 50 Yes Fixed Fixed

Mitsubishi NF100SHA 100 Yes Fixed Fixed

Mitsubishi NF400SHA 400 Yes Adjustable Adjustable

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 15 of 19

DS 543005

7.5 EARTH LEAKAGE RELAYS

250A Instantaneous MS1 earth leakage relay

500 mA Instantaneous MS1 earth leakage relay

375 mA EPC curve 1 Elsec relay with Transcore

500 mA EPC curve 2 Elsec relay with Transcore

100/5 CT Epiring Class 3

250/5 CT Epiring Class 3

300/5 CT Epiring Class 3

400/5 CT Epiring Class 3

Max demand ammeter 100/5 Elima type FB IA 0-100A 96 x

96mm

Max demand ammeter 250/5 Elima type FB IA 0-250A 96 x

96mm

Max demand ammeter 300/5 Elima type FB IA 0-300A 96 x

96mm

Max demand ammeter 400/5 Elima type FB IA 0-400A 96 x

96mm

8.0 L.V. CABLE GLANDS

SM

COMPRESSION

EMES No. D3

EMES No. B4

Note: Gland plates shall be drilled to size as specified. If unspecified then they should not

be drilled.

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 16 of 19

DS 543005

9.0 ADIT EARTH FAULT RELAY

Current transformer ratio

10/5 50/5

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 17 of 19

DS 543005

APPENDIX D: OUTLINE OF MOBILE MINISUB

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 18 of 19

DS 543005

Document status Approved Copyright

ISSUE 0 6 December 2006 Page 19 of 19

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Curtis 1207B Manual PDFDocument46 paginiCurtis 1207B Manual PDFAlex CastilloÎncă nu există evaluări

- G7 8 CSS Explo Module 4Document27 paginiG7 8 CSS Explo Module 4Heart NicoleÎncă nu există evaluări

- 1 Akai CT 1417 Uk: CRT DiagramDocument2 pagini1 Akai CT 1417 Uk: CRT Diagramdivubi2004Încă nu există evaluări

- Tny274 280Document24 paginiTny274 280jucamobaÎncă nu există evaluări

- 2 N 7000Document6 pagini2 N 7000zhlikhonÎncă nu există evaluări

- 9006ct1101 EncodersDocument52 pagini9006ct1101 Encodersam198801Încă nu există evaluări

- Cycloconverters TopologiesDocument12 paginiCycloconverters Topologiesjuan_fimÎncă nu există evaluări

- OPX 105 Rev.q EngDocument10 paginiOPX 105 Rev.q EngLyht TVÎncă nu există evaluări

- Study of Fuses and Types of Fuses: Experiment No. 2Document13 paginiStudy of Fuses and Types of Fuses: Experiment No. 2Jude JohnÎncă nu există evaluări

- Testing of DC MachinesDocument5 paginiTesting of DC Machines2K20EE102 GauravÎncă nu există evaluări

- PTS-100 PTS-100F: PTS Series - DC High Voltage Test Set and MegohmmeterDocument1 paginăPTS-100 PTS-100F: PTS Series - DC High Voltage Test Set and MegohmmeterSelk CLÎncă nu există evaluări

- BJT analysis & biasingDocument51 paginiBJT analysis & biasingNour Yasser100% (1)

- Conductor Ampacity Based On The 2017 National Electrical Code®Document1 paginăConductor Ampacity Based On The 2017 National Electrical Code®Ira Jane LosañezÎncă nu există evaluări

- 2GDCCAP0700C0247 - 200kVAr-16599VDocument1 pagină2GDCCAP0700C0247 - 200kVAr-16599VLucio ArrazolaÎncă nu există evaluări

- TJC 6 - 01VLC000521 Rev.3, en 2016.10.06Document6 paginiTJC 6 - 01VLC000521 Rev.3, en 2016.10.06muraliÎncă nu există evaluări

- Osisense XC Xckn0118p20Document4 paginiOsisense XC Xckn0118p20Boby SaputraÎncă nu există evaluări

- Here are the conversions:1. #14 AWG = 1.628 mm2. #8 AWG = 4.177 mm 3. #12 AWG = 2.053 mm4. #6 AWG = 8.255 mm5. #10 AWG = 3.226 mm6. 0.088 mm = #22 AWGDocument17 paginiHere are the conversions:1. #14 AWG = 1.628 mm2. #8 AWG = 4.177 mm 3. #12 AWG = 2.053 mm4. #6 AWG = 8.255 mm5. #10 AWG = 3.226 mm6. 0.088 mm = #22 AWGstfup zeliaÎncă nu există evaluări

- Door Alarm: Circuit DiagramDocument2 paginiDoor Alarm: Circuit DiagramRohit GaikwadÎncă nu există evaluări

- Programmable Logic Controller (PLC) and AutomationDocument27 paginiProgrammable Logic Controller (PLC) and AutomationJeeva RajÎncă nu există evaluări

- 230 VOLTS, 3000 AT 3-PHASE, 65KAIC: First Private PoleDocument1 pagină230 VOLTS, 3000 AT 3-PHASE, 65KAIC: First Private PoleAngelo SergantesÎncă nu există evaluări

- PB Am1 en PDFDocument20 paginiPB Am1 en PDFcosmin1975Încă nu există evaluări

- CY TypeDocument4 paginiCY TypeprabumunishÎncă nu există evaluări

- MB Knit Fashion LTD - 2nd FUiN Electrical OA - 260917Document9 paginiMB Knit Fashion LTD - 2nd FUiN Electrical OA - 260917MasumÎncă nu există evaluări

- PCS50-630 User Manual 20220509Document37 paginiPCS50-630 User Manual 20220509hswaÎncă nu există evaluări

- Topic 1 - Electronics FundamentalsDocument12 paginiTopic 1 - Electronics FundamentalsKiro Da rareÎncă nu există evaluări

- CLARO COMBO Emergency Light With Exit Signs v1.3Document2 paginiCLARO COMBO Emergency Light With Exit Signs v1.3Charlie MendozaÎncă nu există evaluări

- Assembly and operating instructions for TERMINA TR 610/612 top2 time switchesDocument12 paginiAssembly and operating instructions for TERMINA TR 610/612 top2 time switchesKen VikstromÎncă nu există evaluări

- Philco G4710 Predicta Tandem Sams 441 2Document21 paginiPhilco G4710 Predicta Tandem Sams 441 2daviÎncă nu există evaluări

- Silicon PNP Power Transistors: Inchange Semiconductor Product SpecificationDocument3 paginiSilicon PNP Power Transistors: Inchange Semiconductor Product Specificationsigit raharjoÎncă nu există evaluări

- Nader-NDM1-miniature-circuitn-breaker 63A 125ADocument16 paginiNader-NDM1-miniature-circuitn-breaker 63A 125Alitech technicalÎncă nu există evaluări