Documente Academic

Documente Profesional

Documente Cultură

Kvara - System Monitor

Încărcat de

Mdj AdiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Kvara - System Monitor

Încărcat de

Mdj AdiDrepturi de autor:

Formate disponibile

HW Diagnostics

3 Diagnostics

3.1 LED

3.1.1 LEDs card power supply unit

Figure 3.1 -LEDs card power supply unit

• LED 1: CNC on signal led (RUN) (green led)

• LED 2: CNC off signal led (STOP) (red led)

• LED 3: Internal power supply signal led +5V (green led)

• LED 4: Internal power supply signal led +12V (green led)

• LED 5: Internal power supply signal led -12V (green led)

• LED 6: Internal power supply signal led +Ve (green led)

• LED 7: System state signal led (SYSTEM MONITOR)

Esa/Gv 00008.HW.0.GB 3.1

Diagnostics HW

LEDs power supply The 4 LEDs (LED 3, 4, 5 and 6) indicate the state of the voltages generated by the

power supply unit card and used by the equipment. The following conditions may arise.

• All of the LEDs are on: the card is working properly.

• All the LEDs are off: the card is not supplied with power correctly. The causes can

be:

− no power supply voltage 24V AC/DC;

− one or both of the fuses F = 6.3A T to the side of the power supply sockets are

blown;

− there is a fault in the equipment; please contact Esa/Gv Technical Assistance.

• LED 6 (+Ve) is off but all the others are on: the card is not working properly. The

causes can be:

− one of the sensors connected to the CNC (encoder, lines optics, etc.) causes a

short circuit on the encoder power supply; turn the power of the CNC off,

disconnect all the connectors of the encoder and turn the power of the CNC on;

if LED 6 lights, one of the sensors is faulty or the wiring is wrong, repeat the

operation connecting each encoder separately and then check the wiring and

the sensors. If LED 6 does not light, the card is faulty.

− the power supply unit card is faulty, replacing the card requires in-depth

knowledge of the CNC, therefore we recommend replacing the part;

− there is a fault in the equipment, please contact Esa/Gv Technical Assistance.

• Any other configuration different from the above but with at least one led off: the

card is not working properly. The causes of this can be:

− A card inside the equipment is faulty and trips the power supply voltage cutout.

In this case finding the fault requires in-depth knowledge of the CNC, therefore

we recommend replacing the part;

− the card power supply unit is faulty, replacing the card requires in-depth

knowledge of the CNC, therefore we recommend replacing the part;

− there is a fault in the equipment, please contact Esa/Gv Technical Assistance.

RUN/STOP LEDs LED 1 and LED 2 indicate the operational state of the machine, when it is powered

correctly. The following conditions may arise.

• LED 1 (RUN) is on and LED 2 (STOP) is off: the card is working properly.

• LED 1 (RUN) is on and LED 2 (STOP) is also on: impossible state, the card is not

working properly. In this case finding the fault requires in-depth knowledge of the

CNC, therefore we recommend replacing the part;

• LED 1 (RUN) is off and LED 2 (STOP) is on: the CNC is not working, the card is

not working properly. In this case finding the fault requires in-depth knowledge of

the CNC, therefore we recommend replacing the part.

3.2 00008.HW.0.GB Esa/Gv

HW Diagnostics

System Monitor The 7-segment display LED 7, indicates the state of the system. The following

display conditions may arise.

• The display is on and displays 8:

− If the operating system version is earlier than version 3.5 (firmware version

3.5) the display is not managed and therefore the card can work properly;

− If the operating system is version 3.5 or later, the display is managed and

below you will find the list and description of the messages.

• The display is off: the causes can be:

− the display is not working properly but the CNC is, in this case, if necessary

replace the CNC;

− there is a fault in the equipment, please contact Esa/Gv Technical Service.

System Monitor Below you will find the list of the LED 7 messages. There are other types of messages

display diagnostics that appear on the display called “exceptions”, these exceptions are described in the

software manual of the operating system.

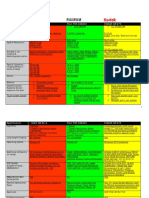

• 0 - OK.

− CNC working.

• 1 - Reserved.

• 2 - Reserved.

• 3 - Kvara install CNC.

− The ISO or the SLAVE or the PLC have not been installed. After executing the

application, if the display shows 3, this means that the PLC has not started or

has not been loaded or I/O are missing or are wrong. The I/O configuration

file, IOREDIR, on the disk H of the CNC may also be wrong, recover and

install the application correctly with autosetup.

• 4 - Kvara application.

− After executing STARTCN the display indicates 4 if the file KVARA.GZ is on

disk H of the CNC.

• 5 - Kvara loader.

− When the CNC is turned on, the display indicates 5 if both BIOSEXT and

LOADER are in the FLASH memory of the CNC, while waiting for the

execution of STARTCN.

• 6 - Kvara biosext.

− When the CNC is turned on the display indicates 6 if only BIOSEXT is in the

FLASH memory of the CNC; you will have to recover LOADER and run

autosetup.

Esa/Gv 00008.HW.0.GB 3.3

Diagnostics HW

• 7 - Power Fail.

− Drop in of the power supply voltage for a time below the system RESET; this

means that the power supply is unstable. In this case, turn the CNC off and

check the power supply before turning the equipment on again.

• 8 - Power ON.

− This appears when the CNC is turned on, but must disappear and leave 0 on

the screen when the CNC is running, 8 will be displayed when the CNC is not

operating.

• 9 - User interface DLL not present.

− The file GUIAPP.DLL in KVARA6 A and B is missing, recover the file.

• A - Diagnostic menu.

− After executing STARTCN the display indicates A if the file KVARA.GZ is

missing on disk H of the CNC or PERMISSION=LOADER is present in the

file KVARA.INI of the PC, run autosetup.

− Autosetup in progress.

− Recovery in progress.

− Loader, problems with decompressing KVARA.GZ or check the memory or

that the applications are loaded.

• B - CPU NC battery fail.

− CMOS SETUP backup battery flat, contact Esa/Gv Technical Assistance to

replace the NC card.

• C - Shut Down.

− You can turn the CNC off without loosing any machine data.

• D - Reserved.

− Debug.

• E - Reserved.

− Not used

• F - MFB reset.

− CNC in reset mode, CNC reset command has been sent, wait for the CNC to

reset.

− Loader has problems when opening File System disks.

System Monitor In operating systems that manage the System Monitor display, once the CNC is

display start-up supplied with power, the following messages will appear in sequence (after a few

sequence seconds).

• Power ON.

− Messages: 8 à 5 à 4 à 3 à 0.

3.4 00008.HW.0.GB Esa/Gv

HW Diagnostics

System Monitor

display orientation

Figure 3.1 - System Monitor display orientation

Esa/Gv 00008.HW.0.GB 3.5

S-ar putea să vă placă și

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.De la EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.Încă nu există evaluări

- Digital LED Thermometer with Microcontroller AVR ATtiny13De la EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Evaluare: 5 din 5 stele5/5 (1)

- Kvara 2005Document2 paginiKvara 2005belutziÎncă nu există evaluări

- KVARA 6 MAUAL 752tool0gbDocument48 paginiKVARA 6 MAUAL 752tool0gbhsynÎncă nu există evaluări

- Scrub & ReloadDocument5 paginiScrub & ReloadJUAN CARLOS MANRIQUEZ CARDONAÎncă nu există evaluări

- Pmc20-E 03Document65 paginiPmc20-E 03Juan FresnedaÎncă nu există evaluări

- Dimm PC 520 IDocument2 paginiDimm PC 520 IankitdhimancrÎncă nu există evaluări

- Connection Conditions Bosch CC220Document360 paginiConnection Conditions Bosch CC220Knezevic Bojan75% (4)

- Shark 320mxDocument30 paginiShark 320mxalbertdanicescu100% (1)

- BIESSE 325-336L Electrical Plant - BDocument89 paginiBIESSE 325-336L Electrical Plant - BTex Nz100% (1)

- Panasonic Minas A5 Manual PelnyDocument394 paginiPanasonic Minas A5 Manual PelnyMichał PotrzeszczÎncă nu există evaluări

- KVARA S630-S640-S650 Touch ENG Operational ManualDocument150 paginiKVARA S630-S640-S650 Touch ENG Operational ManualKaran Jaiswal100% (1)

- RV-30 2Document94 paginiRV-30 2Francois LandryÎncă nu există evaluări

- Delem: Installation ManualDocument36 paginiDelem: Installation ManualLademir FerreiraÎncă nu există evaluări

- Ratio TronicDocument31 paginiRatio TronicTinaManoussi100% (1)

- HFE M2 Operator S Manual X41176BDocument350 paginiHFE M2 Operator S Manual X41176BVladimir KuleshovÎncă nu există evaluări

- Conversor CC Gefran - TPD32 92 enDocument480 paginiConversor CC Gefran - TPD32 92 enBarbozma100% (1)

- Servodyn WM SM PDFDocument38 paginiServodyn WM SM PDFLeandro Gedolin100% (1)

- ModEvaRef2D enDocument102 paginiModEvaRef2D enboortekÎncă nu există evaluări

- "Air Control 2": 1. GeneralDocument32 pagini"Air Control 2": 1. GeneralmadiÎncă nu există evaluări

- Manual Fiac Airblock 20Document35 paginiManual Fiac Airblock 20Titus Dulacioiu100% (2)

- iTNC 530 Service ManualDocument539 paginiiTNC 530 Service ManualManuel Febrer80% (15)

- DM05 K Moduł Sterujący Delem Manual PDFDocument38 paginiDM05 K Moduł Sterujący Delem Manual PDFMićo DunićÎncă nu există evaluări

- Manual Universal3612 - CE - FTC - 1,0 - ENDocument240 paginiManual Universal3612 - CE - FTC - 1,0 - ENDan100% (2)

- 11505-HF MT (130-220 Ton) Operators Manual X40882e (Sep-03)Document220 pagini11505-HF MT (130-220 Ton) Operators Manual X40882e (Sep-03)Ion Plesa50% (2)

- Manual Instrucoes ALUP PDFDocument76 paginiManual Instrucoes ALUP PDFigor_sandulenko67% (3)

- 2361Document103 pagini2361Alen AnušićÎncă nu există evaluări

- Fanuc 0 C BACKUP PDFDocument2 paginiFanuc 0 C BACKUP PDFsunhuynhÎncă nu există evaluări

- 2946 7002 07 MB Mk5 Graphic Unit ControllersDocument48 pagini2946 7002 07 MB Mk5 Graphic Unit Controllersali100% (2)

- Bysprint Pro Handover Instructions: Apext - Instr - Bysprint - Bysprintpro - V008 - en - Docx © Bystronic Laser Ag 1/26Document26 paginiBysprint Pro Handover Instructions: Apext - Instr - Bysprint - Bysprintpro - V008 - en - Docx © Bystronic Laser Ag 1/26Kambiz ZahedÎncă nu există evaluări

- Promecam Parts ListDocument43 paginiPromecam Parts Listuump80% (5)

- Digital Weighing Indicator: Instruction ManualDocument71 paginiDigital Weighing Indicator: Instruction ManualFawzi Alzubairy100% (1)

- 1 - Ad-R Series - User ManualDocument79 pagini1 - Ad-R Series - User Manualنعيم سلمان100% (1)

- User Manual: Screw Air Compressor Controller MAM6080Document42 paginiUser Manual: Screw Air Compressor Controller MAM6080SupadmiÎncă nu există evaluări

- Heidenhain TNC 151 BQ PLC DescriptionDocument124 paginiHeidenhain TNC 151 BQ PLC DescriptionCostLowÎncă nu există evaluări

- MTADocument48 paginiMTAMalaquias Varavatché100% (2)

- Repairs ListDocument338 paginiRepairs ListEy Al Ko50% (4)

- 17 Ig5a General Io (20070507)Document2 pagini17 Ig5a General Io (20070507)cocodrilo360Încă nu există evaluări

- Armoire Moteur Wa300.Fr - enDocument44 paginiArmoire Moteur Wa300.Fr - enRaveen DulanjanaÎncă nu există evaluări

- IC - TC L 3030 - en - V0 - 93617-5-20Document32 paginiIC - TC L 3030 - en - V0 - 93617-5-20sjalife10% (1)

- Almig Air Control B Service ManualDocument41 paginiAlmig Air Control B Service ManualJunaid Ahmed50% (2)

- Technical Manual 426-430MDocument1.135 paginiTechnical Manual 426-430MStefanoTampieriÎncă nu există evaluări

- User Manual Modi5Document22 paginiUser Manual Modi5MJ AvalardÎncă nu există evaluări

- VIPROS-255 Ver. 2 Parts List PDFDocument468 paginiVIPROS-255 Ver. 2 Parts List PDFjcsantosr100% (1)

- 1 Preface: 1.1 Notes For The ReaderDocument14 pagini1 Preface: 1.1 Notes For The Readerahmed samierÎncă nu există evaluări

- Air Control 3: ManualDocument72 paginiAir Control 3: ManualNihat RustamliÎncă nu există evaluări

- DA56 EnglishDocument132 paginiDA56 EnglishDenis Villanueva PerezÎncă nu există evaluări

- e 1Document353 paginie 1Amit JholaparaÎncă nu există evaluări

- B561EN TruBendDocument216 paginiB561EN TruBendCremuss Tarapu67% (3)

- Progman MillPlus V410-V500 GB PDFDocument709 paginiProgman MillPlus V410-V500 GB PDFfiliposkiv100% (2)

- D Manuals官网英文手册20190528PIMM 9010433-SC A01 IS580+Servo+Drive+Advanced+User+Guide 161117Document199 paginiD Manuals官网英文手册20190528PIMM 9010433-SC A01 IS580+Servo+Drive+Advanced+User+Guide 161117Mr Mg Mg Myat ThuÎncă nu există evaluări

- Maillefer Doc. 550 0421X.1Document51 paginiMaillefer Doc. 550 0421X.1zinebÎncă nu există evaluări

- GYSMI 160 Inverter WelderDocument9 paginiGYSMI 160 Inverter Welderthorsharp100% (1)

- GA11-30C-EL-I Electrical DiagramsDocument2 paginiGA11-30C-EL-I Electrical DiagramsKrzysiek PodsiadłoÎncă nu există evaluări

- Industrial Screw Compressors: Installation & MaintenanceDocument26 paginiIndustrial Screw Compressors: Installation & Maintenanceershanquneri67% (6)

- S7-300 DiagnosticsDocument46 paginiS7-300 Diagnosticsmunawar munawarÎncă nu există evaluări

- Prestigio Geovision Pmp5597d Duo Service ManualDocument25 paginiPrestigio Geovision Pmp5597d Duo Service ManualhammerloÎncă nu există evaluări

- Learnings of PLC & ScadaDocument31 paginiLearnings of PLC & Scadakarthik prapannaÎncă nu există evaluări

- Dell EMC S4048-ON Switch Release Notes: Document Revision HistoryDocument12 paginiDell EMC S4048-ON Switch Release Notes: Document Revision Historylakis lalakis888Încă nu există evaluări

- S7-300 Diagnostics - NewDocument49 paginiS7-300 Diagnostics - NewDinh Sang100% (2)

- Convention On The Rights of Persons With Disabilities: United NationsDocument13 paginiConvention On The Rights of Persons With Disabilities: United NationssofiabloemÎncă nu există evaluări

- Innovations in Land AdministrationDocument66 paginiInnovations in Land AdministrationSanjawe KbÎncă nu există evaluări

- BYJU's July PayslipDocument2 paginiBYJU's July PayslipGopi ReddyÎncă nu există evaluări

- Ucm6510 Usermanual PDFDocument393 paginiUcm6510 Usermanual PDFCristhian ArecoÎncă nu există evaluări

- PLT Lecture NotesDocument5 paginiPLT Lecture NotesRamzi AbdochÎncă nu există evaluări

- Powerpoint Presentation: Calcium Sulphate in Cement ManufactureDocument7 paginiPowerpoint Presentation: Calcium Sulphate in Cement ManufactureDhruv PrajapatiÎncă nu există evaluări

- Cic Tips Part 1&2Document27 paginiCic Tips Part 1&2Yousef AlalawiÎncă nu există evaluări

- Guide To Growing MangoDocument8 paginiGuide To Growing MangoRhenn Las100% (2)

- Historical Development of AccountingDocument25 paginiHistorical Development of AccountingstrifehartÎncă nu există evaluări

- Hotel Reservation SystemDocument36 paginiHotel Reservation SystemSowmi DaaluÎncă nu există evaluări

- Agfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Document3 paginiAgfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Youness Ben TibariÎncă nu există evaluări

- Zelio Control RM35UA13MWDocument3 paginiZelio Control RM35UA13MWSerban NicolaeÎncă nu există evaluări

- Anaphylaxis Wallchart 2022Document1 paginăAnaphylaxis Wallchart 2022Aymane El KandoussiÎncă nu există evaluări

- How To Create A Powerful Brand Identity (A Step-by-Step Guide) PDFDocument35 paginiHow To Create A Powerful Brand Identity (A Step-by-Step Guide) PDFCaroline NobreÎncă nu există evaluări

- Basic Vibration Analysis Training-1Document193 paginiBasic Vibration Analysis Training-1Sanjeevi Kumar SpÎncă nu există evaluări

- Research Article: Finite Element Simulation of Medium-Range Blast Loading Using LS-DYNADocument10 paginiResearch Article: Finite Element Simulation of Medium-Range Blast Loading Using LS-DYNAAnonymous cgcKzFtXÎncă nu există evaluări

- DC Servo MotorDocument6 paginiDC Servo MotortaindiÎncă nu există evaluări

- Unit 2Document97 paginiUnit 2MOHAN RuttalaÎncă nu există evaluări

- Channel Tables1Document17 paginiChannel Tables1erajayagrawalÎncă nu există evaluări

- BluetoothDocument28 paginiBluetoothMilind GoratelaÎncă nu există evaluări

- As 60068.5.2-2003 Environmental Testing - Guide To Drafting of Test Methods - Terms and DefinitionsDocument8 paginiAs 60068.5.2-2003 Environmental Testing - Guide To Drafting of Test Methods - Terms and DefinitionsSAI Global - APACÎncă nu există evaluări

- PCDocument4 paginiPCHrithik AryaÎncă nu există evaluări

- Daraman vs. DENRDocument2 paginiDaraman vs. DENRJeng GacalÎncă nu există evaluări

- ADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementDocument33 paginiADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementNURATIKAH BINTI ZAINOL100% (1)

- Using Boss Tone Studio For Me-25Document4 paginiUsing Boss Tone Studio For Me-25Oskar WojciechowskiÎncă nu există evaluări

- An RambTel Monopole Presentation 280111Document29 paginiAn RambTel Monopole Presentation 280111Timmy SurarsoÎncă nu există evaluări

- Lea 4Document36 paginiLea 4Divina DugaoÎncă nu există evaluări

- Sample Annual BudgetDocument4 paginiSample Annual BudgetMary Ann B. GabucanÎncă nu există evaluări

- CLAT 2014 Previous Year Question Paper Answer KeyDocument41 paginiCLAT 2014 Previous Year Question Paper Answer Keyakhil SrinadhuÎncă nu există evaluări

- Jerome4 Sample Chap08Document58 paginiJerome4 Sample Chap08Basil Babym100% (7)