Documente Academic

Documente Profesional

Documente Cultură

Force Draft Tray Dryer Experimental Manual

Încărcat de

Shoaib PathanDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Force Draft Tray Dryer Experimental Manual

Încărcat de

Shoaib PathanDrepturi de autor:

Formate disponibile

1

INDEX

SR NO SUBJECT PAGE NO

1. INTRODUCTION 2–5

2. THEORY OF DRYING 6-7

3. DESCRIPTION OF APPARATUS 8

4. EXPERIMENTAL MANUAL 9 -14

5. SAMPLE CALCULATIONS 15 - 19

6. LINE DIAGRAM 20

7. WIRING DIAGRAM 21

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

2

INTRODUCTION:

Drying a solid means the removal of relatively small amounts of water or

other liquid from the solid material to reduce the content of residual liquid to an

acceptable low value. Drying is usually the final step in series of operations, and the

product from a dryer is often ready for final packaging.

Water or other liquids may be removed from solids mechanically by presses

or centrifuges or thermally by vaporization. This manual is restricted to drying by

thermal vaporization. It is generally cheaper to reduce the liquid content as much as

practicable before feeding the material to a heated dryer.

The liquid content of a dried substance varies from product to product;

occasionally the product contains no liquid and is called bone – dry. More

commonly, the product does contain some liquid. Dried table salt, for example,

contains about 0.5 % water, dried coal about 4 %, and dried casein about 8 %.

Drying is a relatively term and means merely that there is a reduction in liquid

content from an initial value to some acceptable final value.

The solid to be dried may be in many different forms – flakes, granules,

crystals, powders, slabs, or continuous sheet – and may have widely differing

properties. The liquid to be vaporized may be on the surface of the solid, as in drying

salt crystals; it may be entirely inside the solid, as in solvent removal from a sheet of

polymer; or it may be partly outside and partly inside. The feed to some dryers is a

liquid in which the solid is suspended as particles or is in solution. The dried product

may be able to stand rough handling and a very hot environment or it may require

gentle treatment at low or moderate temperatures. Consequently, a multitude of

types of dryers are on the market for commercial drying. They differ chiefly in the

way the solids are moved through the drying zone and in the way, heat is

transferred.

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

3

CLASSIFICATION OF DRYERS:

There is no simple way of classifying

drying equipments. Drying equipment

can be classified according to the

following design and operating features:

1. Batch or Continuous

2. Physical state of the feed: liquid,

slurry, and wet solid.

3. Method of conveyance of the

solid: belt, rotary, fluidized.

4. Heating system: conduction,

Figure – 1: Simple Batch Dryer

convection, radiation.

Except foe a few specialized applications, hot air is used as the heating and mass

transfer medium in industrial dryers. The air may be directly heated by the products

of combustion of the fuel used (oil, gas, or coal) or indirectly heated, usually by

banks of steam heated finned tubes. The heated air is usually propelled through the

dryer by electrically driven fans.

Batch dryers are normally used for small – scale production and where the drying

cycle is likely to be long. Continuous dryers requires less labor, less floor space; and

produce a more uniform quality product.

When the feed is solids, it is important to present the material to the dryer in a

form that will produce a bed of solids with an open, porous, structure.

For pastes and slurries, some form of pretreatment equipment will normally be

needed, such as extruction or granulation.

The main factors to be considered when selecting a dryer are:

1. Feed condition: solid, liquid, paste, powder, crystals

2. Feed concentration, the initial liquid content

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

4

3. Product specification: dryness required, physical form

4. Throughput required

5. Heat sensitivity of the product

6. Nature of the vapor: toxicity, flammability

7. Nature of the solid: flammability (dust explosion hazard), toxicity.

The basic types used in chemical process industries are: tray, band, rotary,

fluidized, pneumatic, drum and spray dryers.

When wet sample is placed in contact with air, water evaporates from its surface

and diffuses as vapor through the air film that covers the surface. The concentration

of moisture at the surface is decreased, a concentration difference is setup and

moisture then diffuses from the interior to the surface of the slab or it moves to the

surface as rapidly as it can vaporize from the surface, the rate of drying is

independent of the moisture content of the slab and is constant providing that the

air velocity, temperature and humidity do not change.

During this constant rate period the rate of drying is controlled by the rate of

vapor diffusion through the air film and is, therefore, dependent upon the humidity

difference across the film and the thickness of the film.

However, when the moisture content becomes less than a certain value known as

the critical moisture content, moisture can no longer move to the surface as rapidly

as it could be vaporized from the surface. The drying rate begins to fall and continues

to fall with decreasing moisture content until the equilibrium moisture content is

reached and no further drying is possible under the particular drying conditions.

TERMS USED IN DRYING - DEFINITIONS:

• MOISTURE CONTENT, WET BASIS:The moisture content of a solid or solution is

usually described in terms of weight percent moisture, and unless otherwise

qualified this is ordinarily understood to be expressed on the wet basis, i.e. as,

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

5

(kg moisture / kg wet solid) 100 = [(kg dry solid + kg moisture)] 100 = 100 X /

(1+X).

• MOISTURE CONTENT, DRY BASIS:

This is expressed as kg moisture / kg dry solid = X.

Percentage moisture, dry basis = 100 X.

• EQUILIBRIUM MOISTURE X*:

This is the moisture content of a substance when at equilibrium with a given

partial pressure of the vapor.

• BOUND MOISTURE:

This refers to the moisture contained by a substance, which exerts an equilibrium

vapor pressure less that of the pure liquid at the same temperature.

• UNBOUND MOISTURE:

This refers to the moisture contained by a substance, which exerts an equilibrium

vapor pressure equal to that of the pure liquid at the same temperature.

• FREE MOISTURE:

Free moisture is that moisture contained by a substance in excess of the

equilibrium moisture: X – X*. Only free moisture can be evaporated, and free –

moisture content of a solid depends upon the vapor concentration in the gas.

Equilibrium Moisture

Curve

1.0

Bound Unbound

Relative Humidity of Gas

Moisture Moisture

Equilibrium

Moisture Free Moisture

0 X* X

Moisture

FORCED DRAFT TRAY Content,

DRYER kg moisture / kgMANUAL

EXPERIMENTAL dry solid

Figure – 2: Types of Moisture

6

THEORY OF DRYING:

There are various modes of drying a material in various types of dryers. In the

present experiment, we study the cross – circulation drying in an adiabatic or direct

dryer. In this case, hot gas (air) is blown over a bed of wet solid (brick particles

wetted with water) under constant drying conditions by maintaining the

temperature, humidity and the velocity of the air across the drying surface constant.

A drying curve is then obtained by plotting drying rate against moisture content of

the solid. In drying, it is necessary to remove free moisture from the surface and also

moisture from the interior of the material. Thus, there is interplay of the surface

evaporation, inter - -particle and intra – diffusion processes during the drying of a

material. This gives rise to several distinct periods in the drying curve as the moisture

content of the solid is reduced from the high value to its final value, as given below:

Period – I0:

An initial period during which the drying rate may increase or decrease rapidly

drom an initial value and the drying conditions are adjusting themselves to the

steady state condition, which is the next period. This period is of relatively short

duration and in some experiments may be unobservable. Therefore, this period is

neglected in the mathematical analysis of the process.

Period – I:

An early stage of drying during which drying rate remains constant value, that

is, is independent of the moisture content. This period may be absent if the initial

moisture content of the solid is less than a certain minimum.

Period – II:

During this period, the drying rate decreases more or less linearly with

continued decreases of water content.

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

7

Period – III:

This stage immediately follows period – II but is not always clearly

distinguishable from it. The drying rate in this zone decreases further, but generally

in a non - -linear fashion with the moisture content.

The moisture content at which the drying rate falls for the first time is the first

critical moisture content, and the moisture content at which the drying rate falls, for

the second time is the second critical moisture content. In case of non – porous solid,

due to the absence of intra – particle moisture and hence intra - particle diffusion,

the constant - rate period is followed by only one falling rate – period. So that there

is only one critical moisture content.

Drying continues until equilibrium moisture content in the solid is attained.

Nature of the drying curve depends on the nature of the solid (porous / non –

porous), and the temperature, humidity and flowrate of the drying medium

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

8

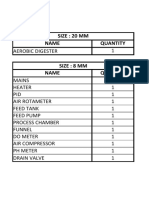

DESCRIPTION OF APPARATUS WITH TECHNICAL SPECIFICATIONS:

The equipment consists of a drying chamber, MS insulated with glass wool

and cladded with SS sheet in which tray rack (SS, Nonmagnetic, rustproof) & tray (1

Nos., SS (Nonmagnetic, Rustproof) is to be hanged. The drying chamber is provided

with toughened glass door and handle.

Hot air to the drying chamber is drawn with the help of a blower and before

entering it is heated by heaters of Nichrome wire (input to the heaters could be vary

with the help of controller).

Flow control valve is provided for varying the Flowrate of air through the

heating chamber.

Wet and Dry bulb thermocouples types are mounted at either ends of the

drying chamber to measure the humidity of the entering and leaving air. Wet bulb

thermocouple is provided with proper water storage facility in the back portion.

The loss of moisture shall from the material to be dried is continuously

monitored with the help of an electronic balance (1 kg cap. 1 gm accuracy, LED

display, 230 V AC power supply) and is to be mounted directly over the heating

chamber.

The control panel consists of Digital Temperature Controller, Temperature

Indicator, on/ off starter switch for blower and MCB for heater with Indictor lamps

(mains) & fuse. Space for manometer mounting.

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

9

EXPERIMENTAL MANUAL

AIM:

To find the rate of drying for given porous / nonporous material.

UTILITY:

230 v AC power supply, dryer assembly, water, brick particles (or sand or CaCO 3

powder), physical balance.

PROCEDURE:

• Switch on the power supply to the unit and press the ON/OFF key provided on

the digital weighing scale. The scale will indicate the weight of the trays and

tray cage. Press TARE switch.

• Open the drying chamber and take out the tray. Measure the surface area of

the trays.

• Prepare the sample whose drying characteristics are to be determined by

taking about 2-3 kg of material (usually fine sand) and adding about 10 % of

solvent (usually water).

• Fill the tray and spread the material evenly throughout the cross section of

the tray.

• Fill the bulb provided on the back of the tray dryer with water upto topmost

level to provide continuous water (wetting agent) to the wick of wet bulb

thermocouples provided at either ends of the drying chamber.

• Switch ON the blower and adjust the predetermined flow rate of air using the

flow control valve. When a steady state is reached, record the manometer

reading calculates the flowrate of air.

• Switch ON the heater. Adjust the temperature of air by using digital

temperature controller provided for heater on control panel.

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

10

• After achieving a fairly high & stable temperature note down the decrease in

weight displayed on the digital weighing scale after an interval of 5 minutes.

Also note down the wet & dry bulb temperatures of air entering and leaving

the drying chamber on digital temperature indicator.

• After certain time no loss of weight is observed for prolonged period of time,

switch OFF the heaters as well as weighing scale. Take out the trays after it is

cooled.

• Switch OFF the Blower. Remove the sample from the trays and clean them

with the help of cotton cloth first and then with water. Allow them to get sun

dried. Also clean the drying chamber with the cotton cloth, if there is any

spillage of material while operation.

• Repeat the experiment by either varying the flow rate for the same sample or

take different sample with the same conditions of air flow rate and compare

them with the initial results.

SETTING OF DRYING CHAMBER TEMPERATURE BY DIGITAL TEMPERATURE

CONTROLLER:

• Press SET key for 2 seconds.

• You are in SET MODE.

• Display 1 will show SEt.

• Display 2 will indicate current value of set point.

• You can change current value of set point by following PROCEDURE.

Increase the parameter by key.

Decrease the parameter by key.

Press ENT key to store it in memory or press SET key for next step.

If no key is pressed for 5 seconds previous value of parameter is retained and

controller goes in control mode.

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

11

PRECAUTION:

➢ Never run the equipment without blower ON for more than 1 minute,

immediately after switching on the MCB provided for the heaters, switch ON

the blower.

➢ While shutting down the tray dryer, we need to keep the blower on to cool

down the drying chamber and heaters so as to minimize the damage to the

heaters and drying chamber.

OBSERVATIONS:

• Cross sectional area of the trays = _____ m2

• Drying Chamber Temperature = _____ C

• Weight of the material (fine sand) taken Ls = _____ gm (1)

• Weight of the solvent (water) added W = _____ gm (2)

• Total initial weight of the sample = _____ gm (1) + (2)

• Velocity of Air = _____ m/sec

OBSERVATION TABLE:

Water Wt. Loss in

Inlet Air Temp. Outlet Air Temp.

Sr. Time weight, Indicated weight of

(C) (C)

No. (min) W on the LED Material

Dry Wet Dry Wet

(gram) (Gram) (Gram)

1.

2.

3.

4.

5.

6.

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

12

CALCULATION:

Moisture content (X t) is one of drying terms.

As time → ∞, X t → X*

Where X* is Equilibrium Moisture Content.

R = - (LS / A) (dX / dt) → (1)

Xt = W / LS → (2)

Where:

R: Rate of drying [kg water/m2 hr].

LS: Weight of dry solid [kg dry solid].

W: Weight of water [kg water].

A: Surface area [m2].

Xt: Moisture content at time t [kg water/kg dry solid].

• Air flow rate over the trays

= Air velocity over the trays * C/s area of the dryer

=

• Loss in weight with time

= (Wt. of the sample at first reading – Wt. of the sample at last time)

=

= ___________

• Plot the weight of the sample against time. Graphically differentiate this curve to

obtain the drying rate.

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

13

CALCULATION TABLE:

Moisture Rate of Drying,

Water Sample Content dX/dt R

wt., weight, Time (kg water/kg ((moisture (kg water/m2 hr) Free

X

W W (Minute) dry solid) content-5) / (sample wt / Water

(gram) (gram) (water wt / (0 -5)) Area of tray) *

sample wt) (dX/dt)

(1) (2) (3) (4) (5) (6) (7) (8)

• Free water content (gm / gm dry stock)

= (Wt. Sample - wt. of dry material) /wt. of dry material

=

= ___________

• Plot the drying rates (column (7)) against the free water content (column (8)).

• Plot the drying rates (column (7)) against time () (column (3)).

• Drying coefficient during the constant rate period:

Kg’ = dw/Adθ (1/Hw – Hg)

Where,

Dw/Adθ = Drying rate, gm water evaporated per hour per cm2

Kg’ = Drying coefficient, gm water evaporated per hr per cm2 per unit

humidity difference

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

14

Hw = Saturation humidity of air at the wet bulb temperature, gm water per gm dry air

Hg = Humidity of the drying air, gm water per gm dry air

The humidity diff. (Hw - Hg) is calculated from the

Equation = 0.26 (tg – tw) / λw

Where,

tg = Dry bulb temperature, oC (Average Value)

tw = Wet bulb temperature, oC (Average Value)

λw = Latent heat of evaporation of water at tw

CONCLUSION:

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

15

SAMPLE CALCULATIONS:

OBSERVATIONS:

• Cross sectional area of the trays = 0.119 m2

• Drying Chamber Temperature = 75 C

• Weight of the material (fine sand) taken Ls = 1095 gm (1)

• Weight of the solvent (water) added W = 75 gm (2)

• Total initial weight of the sample =1170 gm (1) + (2)

• Velocity of Air = 1.539 m/sec

TABLE 1: DATA OF WATER WEIGHT WITH TIME

Loss in

Water Wt. weight of

Inlet Air Temp. Outlet Air Temp.

Sr. Time weight, Indicated Material

(C) (C)

No. (min) W on the LED (Gram)

Dry Wet Dry Wet

(gram) (Gram) (Free

Water)

1. 0 75 1170 0 96 79 78 58

2. 5 72 1167 3 96 80 79 58

3. 10 67 1162 5 98 80 79 59

4. 15 62 1157 5 98 81 79 59

5. 20 56 1151 6 98 80 79 59

6. 25 48 1143 8 98 81 80 59

7. 30 39 1134 9 97 81 78 59

8. 35 29 1124 10 97 80 78 60

9. 40 19 1114 10 98 81 49 59

10. 45 10 1105 9 97 80 78 58

11. 50 5 1100 5 97 81 79 60

12. 55 0 1095 5 98 81 79 60

CALCULATIONS:

At t = 0 minute:

From equation (2):

Xt = W/Ls

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

16

= 75/1095

= 0.068493 kg water/kg dry solid

X* = Xt (t = ∞) = Xt (t = 60 min) = W (t = 60 min) / LS = 0 / 1095

= 0 kg water/kg dry solid.

X = Xt – X* = 0.068493 – 0 = 0.068493 kg water/kg dry solid.

dX/dt = [X (t = 0 min) – X (t = 5 min)] / [(t = 0 min) – (t = 5 min)]

= (0.068493 – 0.065753) / (0 – 5) = - 0.000548

From equation (1):

R = - (LS / A) * (dX / dt) = - (1095 / 0.119) * (-0.000548)

= 5.042521 kg water/m2 hr.

TABLE 2: THE REST OF CALCULATION

Moisture Rate of Drying,

Water Sample Content dX/dt R

Time

wt., weight, (kg water / ((moisture (kg water/m2 Free

(Minute X

W W kg dry solid) content-5) / hr) (sample wt Water

)

(gram) (gram) (water wt / (0 -5)) / Area of tray)

sample wt) * (dX/dt)

(1) (2 ) (3) (4) (5) (6) (7) (8)

75 1095 0 0.068493 0.068493 0.9863014 9075.63053 0

72 1095 5 0.065753 0.065753 0.9868494 9039.20879 3

67 1095 10 0.061187 0.061187 0.9877626 9089.07603 5

62 1095 15 0.056621 0.056621 0.9886758 9097.479 5

57 1095 20 0.052055 0.052055 0.989589 9105.88197 6

51 1095 25 0.046575 0.046575 0.990685 9115.96702 8

43 1095 30 0.039269 0.039269 0.9921462 9129.41251 9

34 1095 35 0.03105 0.03105 0.99379 9144.53824 10

24 1095 40 0.021918 0.021918 0.9956164 9161.34418 10

14 1095 45 0.012785 0.012785 0.997443 9178.15197 9

9 1095 50 0.008219 0.008219 0.9863014 9075.63053 5

5 1095 55 0.004566 0.004566 0.9868494 9039.20879 5

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

17

Air flow rate over the trays

= Air velocity over the trays * C/s area of the dryer

= 1.539 * 0.119

= 0.18314

Loss in weight with time

= (Wt. of the sample at first reading – Wt. of the sample at last time)

= 1170 - 1095

= 75 grams

• Plot the weight of the sample against time.

• Free water content (gm / gm dry stock)

= (Wt. Sample - wt. of dry material) /wt. of dry material

= (1170 – 1095) / 1095

= 0.06849 gm/gm dry stock

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

18

• Plot the drying rates (column (7)) against the free water content (column (8)).

Plot the drying rates (column n (7)) against time () (column

(3)).

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

19

• Drying coefficient during the constant rate period:

Kg’ = dw/Adθ (1/Hw – Hg)

= 75 (1 / 1.05884)

= 70.83

Where,

Dw/Adθ = Drying rate, gm water evaporated per hour per cm2

Kg’ = Drying coefficient, gm water evaporated per hr per cm2 per unit humidity difference

Hw = Saturation humidity of air at the wet bulb temperature, gm water per gm dry air

Hg = Humidity of the drying air, gm water per gm dry air

The humidity diff. (Hw - Hg) is calculated from the Equation = 0.26 (tg – tw)/λw

= 0.26 * (86.79 – 69.71) / 4.194 (from the Latent heat chart)

= 0.26 * (17.08/4.194)

= 0.26 * 4.07248

(Hw - Hg) = 1.05884

Where,

tg = Dry bulb temperature, oC (Average Value)

tw = Wet bulb temperature, oC (Average Value)

λw = Latent heat of evaporation of water at tw

CONCLUSION:

The moisture is decreasing with the time and by the time it becomes totally dry.

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

20

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

21

FORCED DRAFT TRAY DRYER EXPERIMENTAL MANUAL

S-ar putea să vă placă și

- ARRANGING For Marchong or Concert BandDocument13 paginiARRANGING For Marchong or Concert BandCheGus AtilanoÎncă nu există evaluări

- VI Sem Mass Transfer Lab ManualDocument53 paginiVI Sem Mass Transfer Lab Manualoctoviancletus80% (10)

- Hydrotest Test FormatDocument27 paginiHydrotest Test FormatRähûl Prätäp SïnghÎncă nu există evaluări

- Batch Distillation Laboratory ReportDocument17 paginiBatch Distillation Laboratory ReportNayantara Soni100% (1)

- A Quick Guide To Artificial IntelligenceDocument41 paginiA Quick Guide To Artificial IntelligenceFrancis Violet Raymond100% (2)

- Ball Mill Manual FDocument11 paginiBall Mill Manual FShoaib Pathan100% (3)

- Mass DrAnees LecturesDocument191 paginiMass DrAnees Lecturesنزار الدهامي100% (1)

- Plate and Frame Filter PressDocument11 paginiPlate and Frame Filter Presssampathkumar100% (2)

- Vibrating Screen Experimental ManualDocument16 paginiVibrating Screen Experimental ManualShoaib Pathan50% (2)

- Liquid Liquid ExtractionDocument16 paginiLiquid Liquid ExtractionShahrizatSmailKassimÎncă nu există evaluări

- Lab Report CSTR RTDDocument13 paginiLab Report CSTR RTDNurul IzzahÎncă nu există evaluări

- Spray Dryer ExperimentDocument17 paginiSpray Dryer Experimentthurgah100% (1)

- Cre Lab Manual 18bt01035Document55 paginiCre Lab Manual 18bt01035SARTHAK LATHIYAÎncă nu există evaluări

- Interacting and Non Interacting SystemDocument17 paginiInteracting and Non Interacting SystemGoutham Here100% (1)

- Exp 2 Bubble Cap DistillationDocument7 paginiExp 2 Bubble Cap DistillationFaris HamirÎncă nu există evaluări

- Tutorial-8-Examples-Downstream Processing-3-Solutions PDFDocument10 paginiTutorial-8-Examples-Downstream Processing-3-Solutions PDFAlaa SabriÎncă nu există evaluări

- Experiment 1.thermal Conductivity of Metal Rod-3Document6 paginiExperiment 1.thermal Conductivity of Metal Rod-3Prem ThakurÎncă nu există evaluări

- ERT 313 Liquid-Liquid Extraction (LLE) - 0 PDFDocument65 paginiERT 313 Liquid-Liquid Extraction (LLE) - 0 PDFngoctam9033Încă nu există evaluări

- Unit 5Document109 paginiUnit 5Mithila100% (2)

- Mass Transfer PartDocument54 paginiMass Transfer Partoctoviancletus100% (3)

- VRealize Operations Manager Installation and Configuration Guide For Linux and WindowsDocument98 paginiVRealize Operations Manager Installation and Configuration Guide For Linux and Windowsamdusias67Încă nu există evaluări

- Agitation and MixingDocument12 paginiAgitation and MixingSiri Nal100% (1)

- Sieve Plate Distillation ColumnDocument9 paginiSieve Plate Distillation ColumnAshish VermaÎncă nu există evaluări

- Introduction To Process Control: Chapter ContentsDocument14 paginiIntroduction To Process Control: Chapter ContentsBe VerchÎncă nu există evaluări

- Leaf Filter Experimental ManualDocument12 paginiLeaf Filter Experimental ManualShoaib Pathan67% (3)

- Solid-Liquid Separation: Batch Sedimentation: Experiment 2Document12 paginiSolid-Liquid Separation: Batch Sedimentation: Experiment 2Wan Muhammad FikriÎncă nu există evaluări

- Single Effect Evaporator 2Document22 paginiSingle Effect Evaporator 2Shailesh Lohare100% (1)

- Lab Manual (Cre)Document41 paginiLab Manual (Cre)akash100% (1)

- 3 DryingDocument29 pagini3 DryingRoza Savitri100% (1)

- The Future Mixed TensesDocument4 paginiThe Future Mixed TensesChernykh Vitaliy100% (1)

- Leaf Filter EXPT.NO:8: α = 2A² (1-mw) Δp / ρ µ w c (m²/Kg) R ρ α w v / A (1-mw) (m־¹)Document7 paginiLeaf Filter EXPT.NO:8: α = 2A² (1-mw) Δp / ρ µ w c (m²/Kg) R ρ α w v / A (1-mw) (m־¹)sampathkumar100% (2)

- BIR REliefDocument32 paginiBIR REliefJayRellvic Guy-ab67% (6)

- Cyclone Seperator Experimental ManualDocument12 paginiCyclone Seperator Experimental ManualShoaib PathanÎncă nu există evaluări

- Stirred Tank in Series ReportDocument20 paginiStirred Tank in Series ReportEmonbeifo EfosasereÎncă nu există evaluări

- Burj Khalifa: Engineer Abdul MananDocument29 paginiBurj Khalifa: Engineer Abdul MananabdulmananÎncă nu există evaluări

- GTU Question Bank-TPDocument5 paginiGTU Question Bank-TPlata sinsinwar100% (3)

- Cre Exp 9 Lab Report (CSTR & PFR IN SERIES)Document12 paginiCre Exp 9 Lab Report (CSTR & PFR IN SERIES)sukhmaniÎncă nu există evaluări

- Sieve Plate Distillation Column - Lab ReportDocument4 paginiSieve Plate Distillation Column - Lab ReportShrankhla NaryaÎncă nu există evaluări

- Exp - S1A - Solid in Air DiffusionDocument7 paginiExp - S1A - Solid in Air DiffusionAnuj SrivastavaÎncă nu există evaluări

- Leaching Notes PDFDocument14 paginiLeaching Notes PDFimmo50% (2)

- Mass Transfer Ecp 224: Unit 4: LeachingDocument53 paginiMass Transfer Ecp 224: Unit 4: LeachingTapiwa KapondaÎncă nu există evaluări

- CRE-II - Chapter-04 Fluid-Particle Systems - HKB 2.10.18Document42 paginiCRE-II - Chapter-04 Fluid-Particle Systems - HKB 2.10.18Ananya DaveÎncă nu există evaluări

- Exp-9 - Liquid Liquid Extraction in A Packed ColumnDocument5 paginiExp-9 - Liquid Liquid Extraction in A Packed ColumnSiddharth MohapatraÎncă nu există evaluări

- RESIDUE Curve MapsDocument9 paginiRESIDUE Curve MapsPratikLakkadÎncă nu există evaluări

- Batch Sedimentation ExperimentDocument23 paginiBatch Sedimentation ExperimentJohnÎncă nu există evaluări

- Separation Processes Lab ReportDocument15 paginiSeparation Processes Lab ReportArslanQureshi0% (1)

- Isothermal Batch ReactorDocument5 paginiIsothermal Batch ReactorSrikanthÎncă nu există evaluări

- Mass Transfer CoefficientDocument5 paginiMass Transfer CoefficientPinjala AnoopÎncă nu există evaluări

- Heat Transfer Lab Manual 2015-16Document99 paginiHeat Transfer Lab Manual 2015-16Harshit Sinha100% (1)

- Manual For Wetted Wall ColumnDocument8 paginiManual For Wetted Wall ColumnBalRam DhimanÎncă nu există evaluări

- Absorption in Packed Bed Lab ManualDocument5 paginiAbsorption in Packed Bed Lab ManualAshish Verma100% (1)

- Isothermal CSTR PDFDocument9 paginiIsothermal CSTR PDFprashant_cool_4_uÎncă nu există evaluări

- HT1 Horizontal and Vertical Condenser Nani 8 Nov 2016Document19 paginiHT1 Horizontal and Vertical Condenser Nani 8 Nov 2016Mihir Kumar Mech50% (2)

- Lab 10-Batch ReactorDocument22 paginiLab 10-Batch Reactorniraj_bairagiÎncă nu există evaluări

- Isothermal Semi-Batch Reactor PPT RJC SirDocument16 paginiIsothermal Semi-Batch Reactor PPT RJC Sirsdjdsf100% (1)

- 04.desbloqueadoDocument47 pagini04.desbloqueadoJhonatan Gerardo Soto Puelles67% (3)

- Experiment 2 - Study of Packed Column DistillationDocument7 paginiExperiment 2 - Study of Packed Column DistillationAdawiyah Az-zahra100% (1)

- Experiment 4 EmissivityDocument13 paginiExperiment 4 EmissivitySanjith Kaur100% (1)

- Lab Report 1 Tray DrierDocument7 paginiLab Report 1 Tray Drier_never_mind_100% (1)

- Schx4007 Mass Transfer LabDocument60 paginiSchx4007 Mass Transfer LabAhmed AliÎncă nu există evaluări

- Experiment: Screw Conveyor: Course Number and NameDocument10 paginiExperiment: Screw Conveyor: Course Number and NameMaheshree GohilÎncă nu există evaluări

- EXP-2 Verification of Rayleigh Equation For Batch DistillationDocument3 paginiEXP-2 Verification of Rayleigh Equation For Batch DistillationSiddharth Mohapatra100% (2)

- EXP 3 - RTD in Packed BedDocument21 paginiEXP 3 - RTD in Packed BedDanish Nu'man83% (6)

- Exp - P3 - RTD Studies in PBRDocument7 paginiExp - P3 - RTD Studies in PBRSiddesh PatilÎncă nu există evaluări

- Exp 15Document7 paginiExp 15Ishan GuptaÎncă nu există evaluări

- Batch Reactive DistillationDocument7 paginiBatch Reactive DistillationChalmer BelaroÎncă nu există evaluări

- 2-Forced Tray DryerDocument15 pagini2-Forced Tray DryerChintan ModiÎncă nu există evaluări

- S S.R R D C E: Apadiya OhammadaadilDocument20 paginiS S.R R D C E: Apadiya OhammadaadilChemical Engg.Încă nu există evaluări

- CH 4Document20 paginiCH 4ARBAZ KHOKHARÎncă nu există evaluări

- BP 304 T. Pharmaceutical Engineering (Theory) Unit Iii: B. Pharm. Third SemesterDocument33 paginiBP 304 T. Pharmaceutical Engineering (Theory) Unit Iii: B. Pharm. Third SemesterArghadeep BhattacharjeeÎncă nu există evaluări

- Drying 4Document48 paginiDrying 4『ABN』NARUTO أبن ناروتو (Gamer)Încă nu există evaluări

- Apparatus For Friction Losses in Pipe Fittings ManualDocument17 paginiApparatus For Friction Losses in Pipe Fittings ManualShoaib PathanÎncă nu există evaluări

- Aerobic Digester Experimental ManualDocument25 paginiAerobic Digester Experimental ManualShoaib PathanÎncă nu există evaluări

- Aerobic Digester Experimental ManualDocument25 paginiAerobic Digester Experimental ManualShoaib PathanÎncă nu există evaluări

- Cre Lab EquipmentDocument1 paginăCre Lab EquipmentShoaib PathanÎncă nu există evaluări

- Apparatus For Measurement of Thermal Conductivity of Good and Bad Conductors Manual FDocument13 paginiApparatus For Measurement of Thermal Conductivity of Good and Bad Conductors Manual FShoaib PathanÎncă nu există evaluări

- Aerobic Digester GraphsDocument4 paginiAerobic Digester GraphsShoaib PathanÎncă nu există evaluări

- Absorption and Stripping Equipment Manual FDocument19 paginiAbsorption and Stripping Equipment Manual FShoaib PathanÎncă nu există evaluări

- Basket CentrifugeDocument1 paginăBasket CentrifugeShoaib PathanÎncă nu există evaluări

- Gas Absorption Study ApparatusDocument1 paginăGas Absorption Study ApparatusShoaib PathanÎncă nu există evaluări

- Forced Draft Tray DryerDocument1 paginăForced Draft Tray DryerShoaib PathanÎncă nu există evaluări

- Sedimentation Equipment: Technical SpecificationDocument1 paginăSedimentation Equipment: Technical SpecificationShoaib PathanÎncă nu există evaluări

- Leaching Apparatus: Technical Specifications: The Equipment Consists Mainly of The Following: 1) Percolation LeacherDocument1 paginăLeaching Apparatus: Technical Specifications: The Equipment Consists Mainly of The Following: 1) Percolation LeacherShoaib PathanÎncă nu există evaluări

- Cyclone Separator and Water Scrubber: Technical SpecificationsDocument1 paginăCyclone Separator and Water Scrubber: Technical SpecificationsShoaib PathanÎncă nu există evaluări

- Wetted Wall Column Experimental ManualDocument17 paginiWetted Wall Column Experimental ManualShoaib PathanÎncă nu există evaluări

- Cocurrent and Counter Current Liquid-Liquid ExtractorDocument2 paginiCocurrent and Counter Current Liquid-Liquid ExtractorShoaib PathanÎncă nu există evaluări

- Wetted Wall Column: Technical SpecificationsDocument1 paginăWetted Wall Column: Technical SpecificationsShoaib PathanÎncă nu există evaluări

- Foam and PropertiesDocument40 paginiFoam and PropertiesShoaib PathanÎncă nu există evaluări

- Vibrating Screen: Technical SpecificationDocument1 paginăVibrating Screen: Technical SpecificationShoaib PathanÎncă nu există evaluări

- Sedimentation Unit Experimental ManualDocument17 paginiSedimentation Unit Experimental ManualShoaib PathanÎncă nu există evaluări

- Wetted Wall Column Experimental ManualDocument17 paginiWetted Wall Column Experimental ManualShoaib PathanÎncă nu există evaluări

- Construction, Working and Maintenance of Electric Vibrators and Vibrating ScreensDocument70 paginiConstruction, Working and Maintenance of Electric Vibrators and Vibrating ScreensmareesanÎncă nu există evaluări

- Sedimentation Unit Experimental ManualDocument17 paginiSedimentation Unit Experimental ManualShoaib PathanÎncă nu există evaluări

- Leaching Apparatus Experimental ManualDocument12 paginiLeaching Apparatus Experimental ManualShoaib PathanÎncă nu există evaluări

- Gas Absorption Study Apparatus Experimental ManualDocument11 paginiGas Absorption Study Apparatus Experimental ManualShoaib PathanÎncă nu există evaluări

- Wetted Wall Column Experimental ManualDocument17 paginiWetted Wall Column Experimental ManualShoaib PathanÎncă nu există evaluări

- The Eye WorksheetDocument3 paginiThe Eye WorksheetCally ChewÎncă nu există evaluări

- MATLAB For Data VisualizationDocument63 paginiMATLAB For Data Visualizationfahmi fawjiÎncă nu există evaluări

- ReflectionDocument3 paginiReflectionapi-174391216Încă nu există evaluări

- First Semester-NOTESDocument182 paginiFirst Semester-NOTESkalpanaÎncă nu există evaluări

- Abbott 2021 ApJL 915 L5Document24 paginiAbbott 2021 ApJL 915 L5Manju SanthakumariÎncă nu există evaluări

- Dosificación Gac007-008 Sem2Document2 paginiDosificación Gac007-008 Sem2Ohm EgaÎncă nu există evaluări

- Microcontrollers DSPs S10Document16 paginiMicrocontrollers DSPs S10Suom YnonaÎncă nu există evaluări

- Kaibigan, Kabarkada, Kaeskwela: Pinoy Friendships and School LifeDocument47 paginiKaibigan, Kabarkada, Kaeskwela: Pinoy Friendships and School LifeGerald M. LlanesÎncă nu există evaluări

- Chemistry For Changing Times 14th Edition Hill Mccreary Solution ManualDocument24 paginiChemistry For Changing Times 14th Edition Hill Mccreary Solution ManualElaineStewartieog100% (50)

- Splash25 Winner InstructionsDocument8 paginiSplash25 Winner InstructionsRamkrishna PaulÎncă nu există evaluări

- Solving Systems of Linear Equations in Three Variables: You Should LearnDocument8 paginiSolving Systems of Linear Equations in Three Variables: You Should LearnTheodore JoaquinnÎncă nu există evaluări

- How To Prepare Adjusting Entries - Step-By-Step (2023)Document10 paginiHow To Prepare Adjusting Entries - Step-By-Step (2023)Yaseen GhulamÎncă nu există evaluări

- Part TOEFLDocument7 paginiPart TOEFLFrisca Rahma DwinantiÎncă nu există evaluări

- EVS (Yuva)Document88 paginiEVS (Yuva)dasbaldev73Încă nu există evaluări

- Origins - and Dynamics of Culture, Society and Political IdentitiesDocument4 paginiOrigins - and Dynamics of Culture, Society and Political IdentitiesJep Jep Panghulan100% (1)

- Crop Science SyllabusDocument42 paginiCrop Science Syllabusbetty makushaÎncă nu există evaluări

- Viking 062293Document8 paginiViking 062293Lukman ZakariyahÎncă nu există evaluări

- The Origin, Nature, and Challenges of Area Studies in The United StatesDocument22 paginiThe Origin, Nature, and Challenges of Area Studies in The United StatesannsaralondeÎncă nu există evaluări

- An Enhanced RFID-Based Authentication Protocol Using PUF For Vehicular Cloud ComputingDocument18 paginiAn Enhanced RFID-Based Authentication Protocol Using PUF For Vehicular Cloud Computing0dayÎncă nu există evaluări

- Vialyn Group ResearchDocument17 paginiVialyn Group ResearchVial LynÎncă nu există evaluări

- Lifecycle of A Frog For Primary StudentsDocument10 paginiLifecycle of A Frog For Primary StudentsMónika KissÎncă nu există evaluări

- Good Manufacturing Practices in Postharvest and Minimal Processing of Fruits and VegetablesDocument40 paginiGood Manufacturing Practices in Postharvest and Minimal Processing of Fruits and Vegetablesmaya janiÎncă nu există evaluări

- A Database For Handwritten Text Recognition ResearchDocument5 paginiA Database For Handwritten Text Recognition Researchtweety492Încă nu există evaluări