Documente Academic

Documente Profesional

Documente Cultură

Hexion EPR-EPH 4908 Epoxy Resin

Încărcat de

SlobDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hexion EPR-EPH 4908 Epoxy Resin

Încărcat de

SlobDrepturi de autor:

Formate disponibile

Technical Information

Division Epoxy / Phenolic Resins

Epoxy Resins

BAKELITE® EPR 04908

BAKELITE® EPH 04908

new name: EPIKOTE™ Resin 04908

new name: EPIKURE™ Curing Agent 04908

Features

• Certified by German Lloyd

• Low viscosity

• Extended potlife

• Low exothermic heat

Application

Low viscous resin system designed for infusion applications with excellent wetting and adhesion

characteristics on fibreglass, carbon- or aramid-fibres, particularly in boats and yacht-building and

production of rotor blades. This system make it possible to manufacture construction elements of a

superior quality, with outstanding surface characteristics and good resistance to thermal deformation

and weathering.

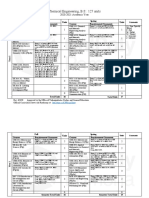

Product physical properties: (at time of manufacturing)

Property Unit EPR 04908 EPH 04908

Viscosity at 25°C mPa·s 500 ± 250 10 ± 5

Epoxy equivalent weight g/equiv. 165 ± 3

Amine equivalent weigth g/equiv. 50

3

Density at 20°C g/cm 1.15 ± 0.02 0.93 ± 0.02

Refractive index at 25°C 1.540 ± 0.003 1.468 ± 0.003

Mixing viscosity at 25°C mPa·s 130 ± 10

Pot life at 25°C minutes 300 ± 50

TG (TMA) °C 82

ATE-E1 Rev 02/07/06 Page 1 of 4

In the process of international testing system harmonization, the national standards previously used are being increasingly replaced by ISO (DIN EN ISO) Varziner Straße 49

standards. All information, recommendations and suggestions offered by Hexion Specialty Chemicals GmbH, whether orally, in written form or in 47135 Duisburg-Meiderich

database, are provided to the best of our knowledge and belief. However, they may not be construed as legally binding statements and do not represent the

basis of either a guarantee or specification. The same applies analogously o the data parameters stated for examples of cured binder systems; these Postfach 120552

represent analytical results and are only intended to simplify advance selection of the individual components of a binder. This information, these 47125 Duisburg

recommendations and suggestions describe our products and possible applications in general or exemplary terms, but do not refer to specific cases.

Changes in the data parameters, texts and illustrations can result from the constant process of technical development and improvement of our products; Germany

possible changes are not specially mentioned in the text. Our support does not free the customer from the obligation to conduct this own review of our

current information literature, in particular our product data sheets, safety data sheets and technical information leaflets. The customer must carry out Phone: +49 (0) 203 42 96 01

tests of our products on its own responsibility to determine their suitability for the intended processes and uses, as well as to establish whether their Fax: +49 (0) 203 42 54 222

processing characteristics are appropriate in a specific case, since the technical uses of our products are numerous and can vary widely in a specific www.hexionchem.com

instance. Therefore, such factors do not fail within our control, and are the exclusive responsibility of the customer. If a specific assurance of data

parameters should be required, an appropriate agreement must be reached to this effect. Any applicable patents, existing laws and regulations must be

observed by the customer or user of our products on its own responsibility. This publication does not represent a license, nor does it intend to infringe or

Technical Information

Division Epoxy / Phenolic Resins

Epoxy Resins

BAKELITE® EPR 04908

BAKELITE® EPH 04908

new name: EPIKOTE™ Resin 04908

new name: EPIKURE™ Curing Agent 04908

Processing Details

Mixing ratio

EPR 04908 100 parts by weight

EPH 04908 30 parts by weight

Mixing tolerance

The maximum allowable mixing tolerance is ±2pbw, but it is particularly important to observe the

recommend mixing ratio as exactly as possible. Adding more or less hardener will not effect a faster or

slower reaction - but an incomplete curing which cannot correct in any way.

Resin and hardener must be mixed very thoroughly. Mix until no clouding is visible in the mixing

container. Pay special attention to the walls and the bottom of the mixing container.

Processing temperature

A good processing temperature is in the range between 25°C and 35°C. Higher processing

temperatures are possible but will shorten the pot life. A rise in temperature of 10°C reduces the pot

life by approx. 50%. Different temperatures during processing have no significant effect on the

strength of the hardened product.

Do not mix large quantities at elevated processing temperatures. The mixture will heat up fast because

of the dissipating reaction heat (exothermic reaction). This can result in temperatures of more than

200°C in the mixing container.

Exemplify curing cycle:

4- 6h at 80°C

ATE-E1 Rev 02/07/06 Page 2 of 4

In the process of international testing system harmonization, the national standards previously used are being increasingly replaced by ISO (DIN EN ISO) Varziner Straße 49

standards. All information, recommendations and suggestions offered by Hexion Specialty Chemicals GmbH, whether orally, in written form or in 47135 Duisburg-Meiderich

database, are provided to the best of our knowledge and belief. However, they may not be construed as legally binding statements and do not represent the

basis of either a guarantee or specification. The same applies analogously o the data parameters stated for examples of cured binder systems; these Postfach 120552

represent analytical results and are only intended to simplify advance selection of the individual components of a binder. This information, these 47125 Duisburg

recommendations and suggestions describe our products and possible applications in general or exemplary terms, but do not refer to specific cases.

Changes in the data parameters, texts and illustrations can result from the constant process of technical development and improvement of our products; Germany

possible changes are not specially mentioned in the text. Our support does not free the customer from the obligation to conduct this own review of our

current information literature, in particular our product data sheets, safety data sheets and technical information leaflets. The customer must carry out Phone: +49 (0) 203 42 96 01

tests of our products on its own responsibility to determine their suitability for the intended processes and uses, as well as to establish whether their Fax: +49 (0) 203 42 54 222

processing characteristics are appropriate in a specific case, since the technical uses of our products are numerous and can vary widely in a specific www.hexionchem.com

instance. Therefore, such factors do not fail within our control, and are the exclusive responsibility of the customer. If a specific assurance of data

parameters should be required, an appropriate agreement must be reached to this effect. Any applicable patents, existing laws and regulations must be

observed by the customer or user of our products on its own responsibility. This publication does not represent a license, nor does it intend to infringe or

Technical Information

Division Epoxy / Phenolic Resins

Epoxy Resins

BAKELITE® EPR 04908

BAKELITE® EPH 04908

new name: EPIKOTE™ Resin 04908

new name: EPIKURE™ Curing Agent 04908

Properties of the cured, non-reinforced resin system: (curing: 4h at 70°C + 6h at 80°C)

Property Unit Value

3

Density g/cm 1.15

Tensile strength MPa 74

Tensile strain % 9.4

Modulus in tensile MPa 2900

Flexural strength MPa 112

Modulus in flexure MPa 3100

Water absorption after 24h 23°C pbw 0,180

Water absorption after 168h 23°C pbw 0,432

Properties of the cured, reinforced resin system (curing: 4h at 70°C + 6h at 80°C)

Property Unit Value

Tensile strength MPa 447

Flexural strength MPa 588

Modulus in flexure MPa 23400

ILSS MPa 40

TG (DMTA) °C 89

The values are measured on laminates made with glass fabric 181/Interglas 91745.

ATE-E1 Rev 02/07/06 Page 3 of 4

In the process of international testing system harmonization, the national standards previously used are being increasingly replaced by ISO (DIN EN ISO) Varziner Straße 49

standards. All information, recommendations and suggestions offered by Hexion Specialty Chemicals GmbH, whether orally, in written form or in 47135 Duisburg-Meiderich

database, are provided to the best of our knowledge and belief. However, they may not be construed as legally binding statements and do not represent the

basis of either a guarantee or specification. The same applies analogously o the data parameters stated for examples of cured binder systems; these Postfach 120552

represent analytical results and are only intended to simplify advance selection of the individual components of a binder. This information, these 47125 Duisburg

recommendations and suggestions describe our products and possible applications in general or exemplary terms, but do not refer to specific cases.

Changes in the data parameters, texts and illustrations can result from the constant process of technical development and improvement of our products; Germany

possible changes are not specially mentioned in the text. Our support does not free the customer from the obligation to conduct this own review of our

current information literature, in particular our product data sheets, safety data sheets and technical information leaflets. The customer must carry out Phone: +49 (0) 203 42 96 01

tests of our products on its own responsibility to determine their suitability for the intended processes and uses, as well as to establish whether their Fax: +49 (0) 203 42 54 222

processing characteristics are appropriate in a specific case, since the technical uses of our products are numerous and can vary widely in a specific www.hexionchem.com

instance. Therefore, such factors do not fail within our control, and are the exclusive responsibility of the customer. If a specific assurance of data

parameters should be required, an appropriate agreement must be reached to this effect. Any applicable patents, existing laws and regulations must be

observed by the customer or user of our products on its own responsibility. This publication does not represent a license, nor does it intend to infringe or

Technical Information

Division Epoxy / Phenolic Resins

Epoxy Resins

BAKELITE® EPR 04908

BAKELITE® EPH 04908

new name: EPIKOTE™ Resin 04908

new name: EPIKURE™ Curing Agent 04908

Shelf life

The resin and hardener can be stored at 20- 25°C for at least 12 months in their carefully sealed

original containers.

It is rarely possible that the resin or the hardener crystallize at temperatures below 15°C. The

crystallisation is visible as a clouding or solidification of the content of the container. Before

processing, the crystallisation must be removed by warming up. Slow warming up to 50- 60°C in a

water bath or oven and stirring or shaking will clarify the contents in the container without any loss of

quality. Use only completely clarify products. Before warming up, open containers slightly to permit

equalization of pressure. Caution during warm up! Do not warm up over open flame!

Precautions

When handling epoxy resins and hardeners, will you please observe the APME documentation

“Epoxy resins and curing agents”.

ATE-E1 Rev 02/07/06 Page 4 of 4

In the process of international testing system harmonization, the national standards previously used are being increasingly replaced by ISO (DIN EN ISO) Varziner Straße 49

standards. All information, recommendations and suggestions offered by Hexion Specialty Chemicals GmbH, whether orally, in written form or in 47135 Duisburg-Meiderich

database, are provided to the best of our knowledge and belief. However, they may not be construed as legally binding statements and do not represent the

basis of either a guarantee or specification. The same applies analogously o the data parameters stated for examples of cured binder systems; these Postfach 120552

represent analytical results and are only intended to simplify advance selection of the individual components of a binder. This information, these 47125 Duisburg

recommendations and suggestions describe our products and possible applications in general or exemplary terms, but do not refer to specific cases.

Changes in the data parameters, texts and illustrations can result from the constant process of technical development and improvement of our products; Germany

possible changes are not specially mentioned in the text. Our support does not free the customer from the obligation to conduct this own review of our

current information literature, in particular our product data sheets, safety data sheets and technical information leaflets. The customer must carry out Phone: +49 (0) 203 42 96 01

tests of our products on its own responsibility to determine their suitability for the intended processes and uses, as well as to establish whether their Fax: +49 (0) 203 42 54 222

processing characteristics are appropriate in a specific case, since the technical uses of our products are numerous and can vary widely in a specific www.hexionchem.com

instance. Therefore, such factors do not fail within our control, and are the exclusive responsibility of the customer. If a specific assurance of data

parameters should be required, an appropriate agreement must be reached to this effect. Any applicable patents, existing laws and regulations must be

observed by the customer or user of our products on its own responsibility. This publication does not represent a license, nor does it intend to infringe or

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Texas Essential Knowledge and Skills (TEKS) : Lesson Plan Type: Inquiry Based Learning, Discovery Learning and DiscussionDocument13 paginiTexas Essential Knowledge and Skills (TEKS) : Lesson Plan Type: Inquiry Based Learning, Discovery Learning and Discussionapi-322902620Încă nu există evaluări

- A Seminar On MetaphysicsDocument26 paginiA Seminar On MetaphysicsMark Anthony DacelaÎncă nu există evaluări

- Steve Mann - Chaos Theory and Strategic Thought PDFDocument16 paginiSteve Mann - Chaos Theory and Strategic Thought PDFErnesto Cazal100% (1)

- All India Aakash Test Series For JEE (Advanced) - 2022 TEST - 4A (Paper-2) - Code-FDocument8 paginiAll India Aakash Test Series For JEE (Advanced) - 2022 TEST - 4A (Paper-2) - Code-FNITIN NBNB100% (1)

- Fiberbond Fiberglass Piping Systems Series 110FW: DescriptionDocument2 paginiFiberbond Fiberglass Piping Systems Series 110FW: DescriptionIbhar Santos MumentheyÎncă nu există evaluări

- Spesifikasi Teknis PDFDocument3 paginiSpesifikasi Teknis PDFAco YamaÎncă nu există evaluări

- Nucl - Phys.B v.646Document538 paginiNucl - Phys.B v.646buddy72Încă nu există evaluări

- Limit SwitchDocument3 paginiLimit SwitchrofelsmÎncă nu există evaluări

- Stevin, Simon PDFDocument3 paginiStevin, Simon PDFcreeshaÎncă nu există evaluări

- Mitsubishi Hiden SystemsDocument3 paginiMitsubishi Hiden SystemsMedha Jog KatdareÎncă nu există evaluări

- Reaction MechanismDocument5 paginiReaction MechanismKatniss Tathagata100% (1)

- Gossen Metrawatt A2000 HandleidingDocument3 paginiGossen Metrawatt A2000 HandleidingDavidÎncă nu există evaluări

- Experiment 6'SDocument12 paginiExperiment 6'SShennyKoh67% (3)

- Gravitation - JEE Main 2024 January Question Bank - MathonGoDocument4 paginiGravitation - JEE Main 2024 January Question Bank - MathonGoAnil KhandekarÎncă nu există evaluări

- Categories: Subscribe To Trade AlertDocument6 paginiCategories: Subscribe To Trade AlertSaiful ArifÎncă nu există evaluări

- Cu 31924004658435Document606 paginiCu 31924004658435Quangvu HoangÎncă nu există evaluări

- Chemical EngineeringDocument5 paginiChemical Engineeringahmed elhamy mohamedÎncă nu există evaluări

- Parastesh (2019) - Shape Optimization of Cold-Formed Steel Beam-Columns With Practical and Manufacturing ConstraintsDocument11 paginiParastesh (2019) - Shape Optimization of Cold-Formed Steel Beam-Columns With Practical and Manufacturing ConstraintsGogyÎncă nu există evaluări

- RMT RFT Calculator & Calculated SheetsDocument3 paginiRMT RFT Calculator & Calculated SheetsAnimesh_Singh10% (1)

- Introduction To Weibull Analysis Ver4Document113 paginiIntroduction To Weibull Analysis Ver4arkcool100% (2)

- ATA 21. Air Conditioning As-05-02 (PLAN-09)Document81 paginiATA 21. Air Conditioning As-05-02 (PLAN-09)faisalÎncă nu există evaluări

- Juan Dela Cruz, RRT: Personal InformationDocument3 paginiJuan Dela Cruz, RRT: Personal InformationShiela Leomo-VillaramaÎncă nu există evaluări

- Catalog Copeland KCLDocument40 paginiCatalog Copeland KCLIsidro MendozaÎncă nu există evaluări

- Partial FractionDocument8 paginiPartial FractionKilon88100% (1)

- CRODocument4 paginiCROboopathy566Încă nu există evaluări

- TOP 3-2-807 1985 Nondestructive Testing of MaterialsDocument19 paginiTOP 3-2-807 1985 Nondestructive Testing of MaterialsDaoudÎncă nu există evaluări

- Plaxis ParameterDocument3 paginiPlaxis Parameterraju_420034520Încă nu există evaluări

- Astm c1439Document4 paginiAstm c1439Nik TarazÎncă nu există evaluări

- Rigging Plan and Lifting PlanDocument6 paginiRigging Plan and Lifting PlanAgung PermanaÎncă nu există evaluări