Documente Academic

Documente Profesional

Documente Cultură

W3S2-Engine Parts-Mdp

Încărcat de

NEMOTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

W3S2-Engine Parts-Mdp

Încărcat de

NEMODrepturi de autor:

Formate disponibile

Sustainable Mobility

Technical and environmental challenges for the automotive sector

Week 3 – Session 2 – Engine Parts

Maria Thirouard

© IFPEN / IFP School 2014

In the last section we saw the engine thermodynamic cycle and the different energy losses. You

now know that efficiency equals CO2 emissions and you have a better understanding of the

differences between diesel and gasoline engines.

In this lesson we’ll see the mechanical parts of an engine. To do so, we will follow the path of the

gases from the intake till the exhaust.

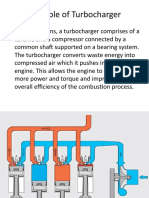

In naturally aspirated engines, fresh air is drawn into the cylinder directly from the surrounding

environment. Nowadays, most of the engines are equipped with a turbocharger since this means

the power of the engine can be considerably increased. The turbocharger increases the air pressure

so a higher mass of air can be inducted by the engine for each engine cycle. In this way a higher

quantity of fuel can be burned. There are two parts in the turbocharger: first the compressor that

increases the air pressure, and on the other side, the turbine that is used to drive the compressor

by using the residual energy from the exhaust gases. The compressor also increases the

temperature of the air so usually an intercooler is placed downstream of the compressor, before

the point where the air enters the engine. The purpose of this is to reduce the air temperature and

increase its density.

The air then goes into the intake manifold which distributes the air into each cylinder of the engine

through the cylinder head.

Here we need to separate diesel engines form gasoline engines:

In diesel engines, the intake manifold is equipped with swirl flaps which are used to regulate the

inflow of air in order to achieve optimal combustion. The swirl movement is also given by the shape

of the intake pipes inside the cylinder head. This is also called internal aerodynamics.

A modern common rail system sends up to 2000 bar of injection pressure to the fuel injectors

which distribute the fuel optimally in the combustion chamber. Due to the extremely quick reaction

time of the injector needles, up to 4 or 5 separate injection processes can be done per cycle. In

addition to the main injection process, pre- and post-injection processes are also possible. Pre-

injection moderates the acoustic hardness, what we called rattling of the combustion process. Post-

injections are used specifically to raise the temperature of the exhaust gas and therefore for

regeneration of the standard Diesel Particulate Filter. These factors combine to give exact and more

efficient combustion.

In gasoline engines, intake pipes are shaped to create an in-cylinder air motion which favors air

turbulence intensity and thus combustion speed. The injector is either placed in the intake manifold

or in the cylinder head, in what we call direct injection gasoline engines. Fuel injection is

electronically controlled for accurate injection quantity and phasing in order to obtain a correct

fuel/air mixture. When the piston approaches TDC, the spark plug supplies the amount of energy

necessary to initiate the combustion of the fuel/air mixture. The spark timing is accurately adjusted

to optimize engine performances.

All 4 stroke engines use poppet valves to control the gas exchange. Most of the time, there are four

valves per cylinder, two for the intake air and two for the exhaust gas. In a 4-cylinder engine this is

called a 16-valve cylinder head. The valves are generally actuated by means of cams and return

springs. The cams are placed in the camshaft. The camshaft is driven by the crankshaft via the

timing belt or chain.

Once combustion is completed, the exhaust gases go through the exhaust manifold. In diesel

engines, a part of these gases might be reintroduced into the cylinder and mixed with the fresh air.

This is called the exhaust gas recirculation or EGR system. EGR is commonly used in diesel engines

to reduce NOx emissions. The gases then go through the after-treatment devices. In gasoline

W3 – S2 – Engine Parts p. 1

© IFPEN / IFP School 2014

engines, a three-way catalyst is sufficient to control HC, CO and NOx emissions. In diesel engines

there are multiple after-treatment devices: a catalytic converter is used to reduce HC and CO

emissions. In some cases there is also a NOx trap or an SCR system to reduce NOx emissions. The

Particulate Filter traps the particle matter up to a certain load. When the particulate filter is

sufficiently loaded post-injections are activated to increase the exhaust gas temperature and

regenerate the particulate filter.

You can see here one of the reasons why diesel engines are more expensive compared to gasoline:

the after-treatment devices are multiple and more complex. Of course, we will look at each after-

treatment device in detail in a future lesson.

After all these explanations you might be wondering how the engine makes the car move. We’ve

seen that with the crankshaft a rotational movement is produced. If we use a very simple picture,

you can imagine that the crankshaft is solidly connected to the front wheels of the car. The wheels

then turn at the same speed as the engine and this makes the car move forward.

Well in reality, the wheel shaft or the drive shaft is connected to the crankshaft via the transmission

or the gear box. The gear box uses a clutch and a movable gear stick operated by the driver in the

case of manual transmissions. Each gear in the gear box is connected to the driveshaft of the

wheels. To make the car move, we need to connect the clutch from the engine to the driveshaft.

The clutch is connected when the driver steps on the clutch pedal. Each gear is different in size and

consequently, when selected and connected to the driveshaft, it rotates at a different speed, which

increases or decreases the speed of the output shaft that is connected to the wheels. This allows

the driver to select the correct gear to get more power or speed to reach the required performance

for any given driving condition.

We’ve seen now the main components of the engine and how the movement is converted to make

the car move.

W3 – S2 – Engine Parts p. 2

© IFPEN / IFP School 2014

S-ar putea să vă placă și

- Motori e Biofuel ENGDocument3 paginiMotori e Biofuel ENGIrene FranchinÎncă nu există evaluări

- 1.FSAE Turbocharger Design and ImplementationDocument27 pagini1.FSAE Turbocharger Design and ImplementationJoy NagÎncă nu există evaluări

- Criteria Diesel Engine Gasoline Engine: Week 3 - AssignmentDocument2 paginiCriteria Diesel Engine Gasoline Engine: Week 3 - AssignmentHarish KotharuÎncă nu există evaluări

- Experiment - No.2: To Study The Parts and Working of Four Stroke Petrol EngineDocument6 paginiExperiment - No.2: To Study The Parts and Working of Four Stroke Petrol EngineHafeez AliÎncă nu există evaluări

- Communication Lab 4-Stroke Petrol Engine: Hemanth Kumar R 07ME034Document6 paginiCommunication Lab 4-Stroke Petrol Engine: Hemanth Kumar R 07ME034Hemu723Încă nu există evaluări

- ICE (Internal Combustion Engine)Document22 paginiICE (Internal Combustion Engine)johnlloydsantossssÎncă nu există evaluări

- New Microsoft Word DocumentDocument3 paginiNew Microsoft Word DocumentSahil KalaÎncă nu există evaluări

- Comparison of Diesel and Petrol EnginesDe la EverandComparison of Diesel and Petrol EnginesEvaluare: 2.5 din 5 stele2.5/5 (3)

- Unit II Engine Auxiliary SystemsDocument28 paginiUnit II Engine Auxiliary SystemsRakeshkumarceg67% (3)

- Final Tdi Diesel 01Document28 paginiFinal Tdi Diesel 01rschhajedÎncă nu există evaluări

- EM II, 2 Engleza, PDFDocument36 paginiEM II, 2 Engleza, PDFAndrei Minca100% (2)

- Power TrainDocument11 paginiPower TrainKapil Dev SinghÎncă nu există evaluări

- By-Utkarsh Kushwah UpesDocument50 paginiBy-Utkarsh Kushwah UpesharmlesdragonÎncă nu există evaluări

- Air Brake System Using Exhaust Gas PowerPoint PresentationDocument16 paginiAir Brake System Using Exhaust Gas PowerPoint PresentationErole Technologies Pvt ltd Homemade Engineer100% (1)

- Cep IcDocument8 paginiCep IcMuhammad ArhamÎncă nu există evaluări

- Diesel Engine: Heavy VehiclesDocument33 paginiDiesel Engine: Heavy VehiclesAvinash GangadharanÎncă nu există evaluări

- Work Output and Efficiency Measurement of Diesel: Saka OluwadamilolaDocument32 paginiWork Output and Efficiency Measurement of Diesel: Saka OluwadamilolaeazydammyÎncă nu există evaluări

- Asi Unit 3Document21 paginiAsi Unit 3Raja RamÎncă nu există evaluări

- Work Output and Efficiency Measurement of Diesel Engines PDFDocument30 paginiWork Output and Efficiency Measurement of Diesel Engines PDFeazydammy100% (2)

- Diesel Automotive Engines: Energy and Power Technology TextbookDocument32 paginiDiesel Automotive Engines: Energy and Power Technology TextbookSrinivas EedaraÎncă nu există evaluări

- Diesel Automotive Engines Chapter 14Document32 paginiDiesel Automotive Engines Chapter 14Abdallah MansourÎncă nu există evaluări

- Applied Physics WORDDocument19 paginiApplied Physics WORDMojtaba AhmadiÎncă nu există evaluări

- Turbo ChargerDocument28 paginiTurbo ChargerCharles ChivengahÎncă nu există evaluări

- 45+ Automobile Engineering Interview QuestionsDocument15 pagini45+ Automobile Engineering Interview QuestionsVinayak GonelÎncă nu există evaluări

- Baba AutomobileDocument54 paginiBaba AutomobilerupeshÎncă nu există evaluări

- MD ProjectDocument35 paginiMD ProjectDar AkhtÎncă nu există evaluări

- 03 Principle of TurbochargerDocument19 pagini03 Principle of TurbochargerSky RÎncă nu există evaluări

- Component Parts of Internal Combustion EnginesDocument26 paginiComponent Parts of Internal Combustion EnginesPeter AshrafÎncă nu există evaluări

- 4 Stroke Diesel Engine ArslanDocument5 pagini4 Stroke Diesel Engine ArslanMuhammad Arslan AfzalÎncă nu există evaluări

- TurbochargerDocument17 paginiTurbochargerdinucv83% (6)

- ICE 4th ModuleDocument16 paginiICE 4th ModuleNithinÎncă nu există evaluări

- Basic Engine Edition (Common To All Work Ranks) : Structure of TextbookDocument111 paginiBasic Engine Edition (Common To All Work Ranks) : Structure of Textbookismail_69Încă nu există evaluări

- Fuel SystemDocument10 paginiFuel SystemnoahÎncă nu există evaluări

- Polytechnic University of ZacatecasDocument5 paginiPolytechnic University of ZacatecasANTONIO SANDATE CHAVEZÎncă nu există evaluări

- Fuel Supply System of Petrol EngineDocument8 paginiFuel Supply System of Petrol EngineSeena Sharma0% (1)

- Variable Valve Timing Lab ReportDocument14 paginiVariable Valve Timing Lab ReportSyed Imtinan AhmedÎncă nu există evaluări

- Practical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineDocument9 paginiPractical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineMuhammad Arslan AfzalÎncă nu există evaluări

- Internal Combustion EngineDocument136 paginiInternal Combustion Enginepreethu02Încă nu există evaluări

- Systems and Components of AutomobileDocument34 paginiSystems and Components of AutomobileSuperUserÎncă nu există evaluări

- Experiments - 06 & 07Document12 paginiExperiments - 06 & 07fakhar mahtabÎncă nu există evaluări

- General Overview of Automotive Systems: Entoto Polytechnic CollegeDocument9 paginiGeneral Overview of Automotive Systems: Entoto Polytechnic CollegeHenokÎncă nu există evaluări

- Below Is An Overview of Fuel System OperationDocument5 paginiBelow Is An Overview of Fuel System OperationAkram SiddigÎncă nu există evaluări

- Edexcel HNC/D Plant and Process Principles Outcome 4 - Power Supply Equipment Tutorial 1 - Diesel EnginesDocument9 paginiEdexcel HNC/D Plant and Process Principles Outcome 4 - Power Supply Equipment Tutorial 1 - Diesel EnginescataiceÎncă nu există evaluări

- Assignment On Mitsubishi LancerDocument10 paginiAssignment On Mitsubishi LancerMahrose GilaniÎncă nu există evaluări

- How A Car Engine WorksDocument2 paginiHow A Car Engine Worksanthony muthuiÎncă nu există evaluări

- Experiment No. 06: To Investigate The Operation 4 Stroke Diesel Engine For Power GenerationDocument4 paginiExperiment No. 06: To Investigate The Operation 4 Stroke Diesel Engine For Power GenerationAarizMalikÎncă nu există evaluări

- Petrol Engine (Nehru Garden, JalandharDocument7 paginiPetrol Engine (Nehru Garden, Jalandharapi-3731257Încă nu există evaluări

- Effect of Turbocharging On Exhaust Brake Performance in An AutomobileDocument6 paginiEffect of Turbocharging On Exhaust Brake Performance in An Automobileabhisaxena93Încă nu există evaluări

- Central RailwayDocument14 paginiCentral RailwayLazy ManÎncă nu există evaluări

- Internal Combustion EnginesDocument32 paginiInternal Combustion Enginespramodkb_cusatÎncă nu există evaluări

- Turbocharger and SuperchargerDocument16 paginiTurbocharger and SuperchargerPrajwal ZinjadeÎncă nu există evaluări

- Ic Engine: Assignment#02Document9 paginiIc Engine: Assignment#02Jawad ZafarÎncă nu există evaluări

- What Is The Difference Between A Two Stroke and Four Stroke EngineDocument7 paginiWhat Is The Difference Between A Two Stroke and Four Stroke EngineAllen NopreÎncă nu există evaluări

- Diesel Engine TechnologyDocument59 paginiDiesel Engine TechnologyAnonymous f2zDTm7kmÎncă nu există evaluări

- Supercharging and TurbochargingDocument8 paginiSupercharging and TurbochargingMudassir Hussain100% (1)

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyDe la EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyÎncă nu există evaluări

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsDe la EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsÎncă nu există evaluări

- Modeling & Simulation of Water Gas Shift ReactionDocument5 paginiModeling & Simulation of Water Gas Shift Reactionagarwalashwin32Încă nu există evaluări

- PS5000 1Document2 paginiPS5000 1swarupkumarnayakÎncă nu există evaluări

- Injection Blow Moulded Products Book PDFDocument13 paginiInjection Blow Moulded Products Book PDFShafeeq AhmedÎncă nu există evaluări

- Chemistry 3.part 1pptxDocument62 paginiChemistry 3.part 1pptxMaria Cyril DalusongÎncă nu există evaluări

- Low-Pressure Side Components: Figure 1. Examples of Low Pressure Fuel Systems For Heavy-Duty and LightDocument6 paginiLow-Pressure Side Components: Figure 1. Examples of Low Pressure Fuel Systems For Heavy-Duty and LightDanang Aji NugrohoÎncă nu există evaluări

- Tutorial 1Document2 paginiTutorial 1Syakirin Spears0% (2)

- WWW Slideshare Net Mobile UjjwalVarshney1 12th-Chemistry-project-rusting-Of-ironDocument6 paginiWWW Slideshare Net Mobile UjjwalVarshney1 12th-Chemistry-project-rusting-Of-ironharishÎncă nu există evaluări

- HRSG FundamentalsDocument11 paginiHRSG Fundamentalschatuusumitava100% (1)

- KEPCO's First 5000 MW of Flue Gas Desulfurization: Babcock & Wilcox Barberton, Ohio, U.S.ADocument6 paginiKEPCO's First 5000 MW of Flue Gas Desulfurization: Babcock & Wilcox Barberton, Ohio, U.S.AVishal RastogiÎncă nu există evaluări

- Flame Retardants: P.M. Visakh Yoshihiko Arao EditorsDocument321 paginiFlame Retardants: P.M. Visakh Yoshihiko Arao Editorssedat kumartaşlıÎncă nu există evaluări

- Deluge Valve - SD-DVA PDFDocument15 paginiDeluge Valve - SD-DVA PDFboxyfunÎncă nu există evaluări

- Case Studies For Fluid FlowDocument30 paginiCase Studies For Fluid FlowimranunarÎncă nu există evaluări

- THESIS - 2011106042 - Organic Inorganic Halide Perovskite Solar CellDocument49 paginiTHESIS - 2011106042 - Organic Inorganic Halide Perovskite Solar CellAbhinav PaikÎncă nu există evaluări

- Urine Preservatives - SLUDocument2 paginiUrine Preservatives - SLUShana Flame Haze0% (1)

- Phase Test Paper FiitjeeDocument34 paginiPhase Test Paper FiitjeeAshwani Pandey100% (2)

- AHU Instalation Manual YorkDocument36 paginiAHU Instalation Manual YorkBangto Yibsip50% (2)

- Flash Pont Test (Closed-Cup) Standard Operating Procedure: ScopeDocument2 paginiFlash Pont Test (Closed-Cup) Standard Operating Procedure: ScopeShunmuganathanÎncă nu există evaluări

- Lenzing Viscose-Modal Pretreatment Dyeing FinishinDocument16 paginiLenzing Viscose-Modal Pretreatment Dyeing FinishinPrabhu TexcomsÎncă nu există evaluări

- Nymax 1200 Processing GuideDocument4 paginiNymax 1200 Processing GuideJanaka MangalaÎncă nu există evaluări

- Oil Analysis Report: Test DetailsDocument1 paginăOil Analysis Report: Test DetailsAhmad HisyamÎncă nu există evaluări

- Gold Jewellery Manufacturing Process: Step-1 Step-2 Step-3Document2 paginiGold Jewellery Manufacturing Process: Step-1 Step-2 Step-3Siva KumarÎncă nu există evaluări

- Scientific Program TableDocument10 paginiScientific Program TableMd Iftekhar AhmadÎncă nu există evaluări

- Caterpillar 950F Maintenance Manual ExerptDocument47 paginiCaterpillar 950F Maintenance Manual Exerpttransteven9394% (16)

- Chem 31 Syllabus RobidilloDocument8 paginiChem 31 Syllabus RobidilloJolaine ValloÎncă nu există evaluări

- Pidicrete CF 160 M2Document1 paginăPidicrete CF 160 M2nickdash09Încă nu există evaluări

- L-Arginine HCL - Kyowa Shangai MSDSDocument3 paginiL-Arginine HCL - Kyowa Shangai MSDSМарина ПостернакÎncă nu există evaluări

- INDG254 CHEMICAL REACTION HAZARDS and The Risk of THERMAL Runaway PDFDocument9 paginiINDG254 CHEMICAL REACTION HAZARDS and The Risk of THERMAL Runaway PDFJayaprakasan Koyadan KorothÎncă nu există evaluări

- Mishra 2020Document79 paginiMishra 2020hanadi ahmedÎncă nu există evaluări

- Análisis de Diseño de Mexclas de Un Producto CosméticoDocument28 paginiAnálisis de Diseño de Mexclas de Un Producto CosméticoMaria Jose Moncayo PastasÎncă nu există evaluări

- 074 - Causeway Colourbox Ultra ShieldDocument1 pagină074 - Causeway Colourbox Ultra ShieldrushdiÎncă nu există evaluări