Documente Academic

Documente Profesional

Documente Cultură

Guides For Operation of Transformers Regulators and Reactors Aie 1945

Încărcat de

waqas_a_shaikh4348Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Guides For Operation of Transformers Regulators and Reactors Aie 1945

Încărcat de

waqas_a_shaikh4348Drepturi de autor:

Formate disponibile

former even under constant or closely

Guides for Operation of Transformers, controlled conditions, much less under

widely varying service conditions.

The change in rate of deterioration

Regulators, and Reactors with change in temperature has received

much study, but the actual values for

different operating temperatures are not

AIEE TRANSFORMER SUBCOMMITTEE completely agreed on. An average value

which has been used for a number of years

is that the rate of deterioration doubles

Guide for Loading Oil-Immersed the transformer subcommittee, and new with each eight degrees centigrade that

Distribution and Power findings may affect future revision of the the temperature of the insulation in-

Transformers guides. The word ' 'conservative'' is used creases. This value is not accurate for

in the sense that the expected loss of all temperatures nor for all points in the

SCOPE insulation life for a single recommended life of a transformer. It is given here to

T HIS guide covers general recom- overload will not be greater than the show the importance of controlling ambi-

mendations for loading all types of oil- amount stated. ent temperatures in indoor installations

immersed transformers with class--4 in- The rated kilovolt-ampere output of a by means of ventilation, thus controlling

sulation except water-cooled transformers transformer is that load which it can the insulation temperature and life.

built before 1929, self-cooled transformers deliver continuously at rated secondary Owing to the many variables men-

rated at 200 kva or less, and transformers voltage without exceeding a given tem- tioned and particularly to the many vary-

having a rated full-load current less than perature rise measured under prescribed ing conditions of load and ambient to

ten amperes. They include transformers test conditions. The temperature rise on which a transformer can be subjected in

immersed in synthetic or noninflammable which the rating is based takes into con- service, it is not possible to give definite

liquids. sideration the experience of the industry rules for the loading of transformers. It

The manufacturer should be ajßked for regarding is only possible to give suggested loadings

recommendations relating to water-cooled 1. Insulation life as affected by operating under specified conditions and look to the

transformers built before 1929 and for temperature. user to make the best use of this informa-

more specific recommendations for large tion for his particular problem.

2. The ambient temperatures assumed to

and important transformers if required. exist throughout the life of the transformer. AMBIENT TEMPERATURES AND LOADING

CAUTION The actual output which a transformer FOR NORMAL L I F E EXPECTANCY

can deliver at any time in service without The basic loading condition of a trans-

It must be recognized that loads above

undue deterioration of the insulation may former for normal life expectancy is con-

rating should not be applied without a

be more or less than the rated output, de- tinuous loading at rated kilovolt-amperes

thorough study of the various limitations

pending upon the ambient temperature and rated delivered voltage with the

involved. Among these limitations are

and other attendant operating conditions. temperature of the cooling air at no time

oil expansion, pressure in sealed-type

Practically all of the data in reference exceeding 40 degrees centigrade and with

units, bushings, leads, soldered connec-

to the aging of insulation at different the average temperature of the cooling air

tions, tap changers, and the thermal capa-

temperatures has been obtained in during any 24-hour period equal to 30

bility of associated equipment such as

laboratory tests in which the decrease in degrees centigrade. For water-cooled

■cables, reactors, circuit breakers, discon-

mechanical strength has been measured. transformers comparable temperatures

necting switches and current transform-

The relation between the life expectancy are 30 and 25 degrees centigrade, the five-

ers. These may constitute the practical

of insulation as indicated by laboratory degree-centigrade lower average tem-

limit in load-carrying ability.

tests and the actual life of a transformer perature of the cooling medium being to

Before loading apparatus above rating

is largely theoretical, so that loading allow for possible less efficient cooling due

to the full extent covered in these guides,

based on such information must be tem- to coils that are not clean. (It is as-

it is recommended that load capabilities

pered by sound judgment based on ex- sumed that operation under the foregoing

he checked with the manufacturer.

perience. conditions is equivalent to operation at a

-GENERAL As the evaluation of the cumulative continuous ambient temperature of 30

effects of temperature and time in causing degrees centigrade for cooling air and 25

Recommendations in this guide are

deterioration of transformer insulation is degrees centigrade for cooling water.)

based on life expectancy of transformer

insulation as affected by operating tem- not thoroughly established, it is not possi- The hottest-spot copper temperature

perature and time. Transformer life ex- ble to predict with any great degree of is the sum of the temperature of the cool-

pectancy at various operating tempera- accuracy the length of life of a trans- ing medium, the average temperature rise

tures is not accurately known, but the

r

information given regarding loss of life of

insulation is considered to be conservative

.and the best that can be produced from

present knowledge of the subject. The

-effects of temperature on insulation life

are being investigated continuously by

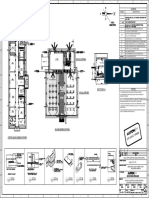

Figure 1 . Permissible loadins

for normal life expectancy

|J

based on top-oil temperature U

1 ft

Taper 45-130, recommended by the AIEE com-

mittee on electric machinery for publication in A—Water-cooled, self-cooled,

AIEE TRANSACTIONS. Manuscript submitted and forced-air-cooled trans-

February 26, 1945; made available f#r orinting ¿É.4

May 23, 1945. formers rated 133 per cent or 2

This paper is a complete revision of AMBRICAN less of self-cooled rating

RECOMMENDED PRACTICE—GUIDES FOR OPERATION 1.2

•OF TRANSFORMERS AND REGULATORS, American

B—Forced-oil-cooled trans-

Standard C57.3—1942. It will be presented to the formers or forced-air-cooled

American Standards Association sectional com- transformers rated over 133 per 1.0

mittee on transformers C57 for inclusion in proposed 5 l<3

1

kb 2O 25 30 35 A0 4 5 5O 55 6O 65 70 75> 8<

revision of transformer Standards. cent of self-cooled rating

NOVEMBER 1945, VOLUME 64 Transformers, Regulators, and Reactors TRANSACTIONS 797

of the copper and the hottest-spot allow-

ance. For oil-immersed transformers

operating continuously under the fore-

going conditions with normal life expec-

tancy this temperature has been assumed

to be 95 degrees centigrade.

Other usual service conditions, as given

in American Standard C57.1, section

2.000, must be complied with.

Years of experience have indicated that

a transformer rated in accordance with

the Standard and operated under the

foregoing conditions will have a reason-

ably long life.

AMBIENT TEMPERATURES

Ambient temperature is an important

factor in determining the load capability

of a transformer. Whenever the actual

ambient temperature can be determined

from readings taken at the time of the

load being considered, such temperatures

should be used. 100 120 140 160 ÉÈ0 200 100 120 140 160 180 200

It is often necessary to predict the load PER CENT RATED KVA PER CENT RATED KVA

that a transformer can carry safely at Figure 2. Short-time loading with moderate Figure 3. Short-time loading with moderate

some future time when the actual ambient sacrifice of life expectancy, self-cooled and sacrifice of life expectancy, self-cooled and

temperature is unknown. A method of water-cooled transformers water-cooled transformers

approximating the ambient temperature

for the month in which the expected load Following 50 per cent or less of rated kilovolt- Following 1 0 0 per cent of rated kilovolt-

is anticipated is as follows (Temperatures amperes or top-oil temperature rise of 25 amperes or top-oil temperature rise of 45

referred to are contained in reports pre- degrees centigrade degrees centigrade

pared by the Weather Bureau of the Ambient temperature 3 0 degrees centigrade Ambient temperature 3 0 degrees centigrade

United States Department of "Commerce for air, 25 degrees centigrade for water for air, 25 degrees centigrade for water

and are available for various section« of Subtract hottest-spot gradient from hottest- Subtract hottest-spot gradient from hottest-

the country): spot temperature to obtain top-oil temperature spot temperature to obtain top-oil temperature

A—Assumed temperature limitation for top o i l A—Assumed temperature limitation for top oil

1. For loads with normal\life expeotdiiey:

(protected) (protected)

Use the average temperature-over~a period

A'—Assumed temperature limitation for top A'—Assumed temperature limitation for top

of years for the month involved. Some be-

lieve that this temperature should be in- oil (unprotected) oil (unprotected)

creased by as much as five degrees centi- B—Assumed temperature limitation for hot- B—Assumed temperature limitation for hot-

grade because test-spot copper test-spot copper

(a). The average temperature for a given month

may be above the average temperature of the same Times Rated Kilovolt-Amperes Times Rated Kilovolt-Amperes

month for a period of years. to Use not More Than Following Life to Use not More Than Following Life

(b). Increased aging at higher than average tem- Time, (Per Cent) Time, (Per Cent)

perature is not offset by decreased aging at lower Hours 0.1 0.25 0.50 1.0 Hours 0.1 0.25 0.50 1.0

than average.

2. For short-time loads with moderate Vi... ...2.00. 2.00 2.00 2.00 V i . . . ...1.75 1.92 2.00 2.00

1.... ...1.76. 1.91 2.00 2.00 1 . . . ....1.54 1.69 1.81 1.92

sacrifice of life expectancy: 2 ...1.50. .....1.62 1.72 1.82 2 ...1.35 1.48 1.58 1.68

Use the average of the daily maximum tem- 4 ...1.27. 1.38 1.46 1.53 4 . . . . ...1.20 1.32 1.40 1.48

peratures for the month involved averaged 8.... ...1.13. 1.21 1.30 1.37 8 . . . . ...1.11 1.20 1.28 1.35

24.... ...1.05. 1.10 1.15 1.23 2 4 . . . . ...1.05 1.09 1.15 1.23

with similar values for the same month over

a period of years. For explanation of degree of accuracy, see Appendix II. For explanation of degree of accuracy, see Appendix I

During any one day there is an even chance

that the maximum temperature will exceed

this value. Some feel that five degrees On account of large variations in the accurate guide, by using the hottest-spot

centigrade should be added to the average of difference between the hottest-spot cop- copper gradient of any particular trans-

the daily maximum temperatures. If this per and the top-oil temperatures of vari- former for the load it is carrying at the

is done, the assumed temperature will not be ous designs under full load, oil tempera- time. If the hottest-spot copper gradient

exceeded on more than a few days of the ture alone should not be used as a guide in at full load is known, the gradient at

month, and, where it is exceeded, the loss of loading transformers. other loads may be determined easily by

life will not be more than twice that for the using Figure 10 in Appendix II. The

temperature assumed. However, by taking the temperature

rise of the hottest-spot copper over top limiting oil temperature for normal life

LOADING UNDER SPECIFIED CONDITIONS oil (hottest-spot copper gradient) into expectancy for any load, regardless of the

W I T H NORMAL L I F E EXPECTANCY account, oil temperatures may be used as time carried, can be determined by sub-

an approximate guide in loading. When tracting the hottest-spot copper gradient

Loading Determined by Measured Tem-

so operated for any period of time, the for that load from 95 degrees centi-

perature. Transformers may be loaded

measured top-oil temperature should not grade.

above rating for any period of time pro-

vided the hottest-spot temperature is not exceed the values given in Figure 1 for Loading on Basis of Test Temperature

greater than 95 degrees centigrade. Hot- the load being carried. These loads can Rise. For each degree centigrade in excess

test-spot temperature indicators are avail- be applied to any transformer covered by of two degrees that the test temperature

able by which this temperature may be these guides as they are conservative. rise is below the standard temperature rise

measured. Oil temperatures may be used as a more specified in the Standard, the transformer

798 TRANSACTIONS Transformers, Regulators, and Reactors ELECTRICAL ENGINEERING

load may be increased above rated kilo- approximately the same as if it had been 3. Either loading on basis of load factor or

volt-amperes by the percentages shown operated at rated kilovolt-amperes during loading on basis of short-time overloads.

in second column of Table I. Making that period. Do not use both.

use of this factor gives the kilovolt-

amperes that the transformer can deliver Effect of Various Factors Existing at SHORT-TIME LOADING W I T H MODERATE

with 55 degrees centigrade temperature One Time. When two or more of the SACRIFICE ÖF L I F E EXPECTANCY

rise. The leeway of two degrees is to following factors affecting loading for

normal life expectancy exist at one time, To be able to give an idea of the rela-

provide for a negative tolerance in the tive loss of life due to loads above rating

measurement of temperature rise. the effects are cumulative and the increase

in loads due to each may be added to se- under various conditions, we have as-

Some transformers are designed to have sumed a conservative aging rate of insula-

cure the maximum suggested load (each

the difference between hottest-spot and increase must be based on rated kilovolt- tion based on tests and operating experi-

average copper temperatures greater than amperes) : ence. The information is not intended

the nominal allowance of ten degrees to furnish a basis for calculating the nor-

centigrade. This will result in a tem- 1. Loading on basis of test temperature mal life expectancy of transformer insula-

perature rise for average copper of less rise. tion.

than 55 degrees centigrade, but the hot- 2. Loading on basis of ambient tempera- Transformers may be loaded above

test-spot copper temperature rise may be ture. rated kilovolt-amperes following various

at the limiting value of 65 degrees centi-

grade.

Such transformers should not be loaded

above rating as outlined under this head-

ing. The manufacturer should be con-

sulted to give information as to design

hottest-spot allowances.

Loading on Basis of Ambient Tempera-

ture. For each degree centigrade that

the average temperature of the cooling

medium is above or below 30 degrees

centigrade for air or 25 degrees centigrade

for water, a transformer may be loaded

for any period of time below or above its

kilovolt-ampere rating as specified in

Table I. Average temperature should be

for periods of time not exceeding 24 hours

with maximum temperatures not more

than ten degrees centigrade greater than

average temperatures for air and five de-

grees centigrade for water. On the basis

used in this guide for calculating loss of

life, life expectancy will be approximately

the same as if it had been operated at

rated kilovolt-amperes and standard ambi- 100 120 140 160 180 200 100 120 140 160 180 200

ent temperatures over that period. PER C E N T RATED KVA. PER C E N T RATED KVA

The use of transformers in cooling air Figure 4. Short-time loading with moderate Figure 5. Short-time loading with moderate

above 50 degrees centigrade, or below 0 sacrifice of life expectancy, forced-air-cooled sacrifice of life expectancy, forced-air-cooled

degrees centigrade, or with cooling water transformers rated 133 per cent or less of self- transformers rated 133 per cent or less of self-

above 35 degrees centigrade is not covered cooled rating cooled rating

by Table I and should be taken up with

the manufacturer. Following 50 per cent or less of rated kilo- Following 1 0 0 per cent of rated kilovolt-

volt-amperes or t o p - o i l temperature rise of 25 amperes or top-oil temperature rise of 45

Loading on Basis of Load Factor. degrees centigrade degrees centigrade

When the load factor for a period of time Ambient temperature 3 0 degrees centigrade Ambient temperature 3 0 degrees centigrade

not exceeding 24 hours is below 100 per for air for air

cent, the maximum loading of a trans- Subtract hottest-spot gradient from hottest-spot Subtract hottest-spot gradient from hottest-

former during that period may be in- temperature to obtain t o p - o i l temperature spot temperature to obtain top-oil temperature

creased above rated kilovolt-amperes by

A—Assumed temperature limitation for top o i l A—Assumed temperature limitation for top

the percentages shown in Table II for

(protected) oil (protected)

each per cent that the load factor is be-

low 100 per cent. On the basis used in A'—Assumed temperature limitation for top A'—Assumed temperature limitation for top

this guide for calculating loss of life, life o i l (unprotected) o i l (unprotected)

expectancy will be approximately the B—Assumed temperature limitation for hot- B—Assumed temperature limitation for hot-

same as if it had been operated at rated test-spot copper test-spot copper

kilovolt-amperes during that period.

Times Rated Kilovolt-Amperes Times Rated Kilovolt-Amperes

Loading on Basis of Short-Time Loads to Use not More Than Following Life to Use not More Than Following Life

Above Rating. When short-time loads Time, (Per Cent) Time, (Per Cent)

Hours 0.1 0.25 0.50 1.0 Hours 0.1 0.25 0.50 1.0

above rating occur not more than once in

any 24-hour period, the maximum loading 1 .97... ..2.00.. ...2.00 .2.00 .1.67.. .1.82. .1.94. .2.00

of a transformer during that period may 1 . 1 .66... .1.79.. . . . 1 . 9 0 . . .... . . 2 . 0 0 1 .. .1.47.. .1.60. 1.71 1.81

be increased -conservatively above rated 2 . 1.39... ..1.51.. .. .1.59 . . . . 1 . 6 8 2 .. .1.29.. .1.41. ....1.50 1.58

4 . 1 . 2 1 . . . . 1.31..

. ...1.38 ...1.45 4 .. .1.18.. .1.28. 1.35 1.43

kilovolt-amperes, as given in Table III. 8 . 1.11... .1.19.. ...1.26. ...1.33 8 .. .1.10.. .1.18. . . . . 1 . 2 6 1.33

On the basis used in this guide for calcu- 24. 1 .05.... .1.09.. ...1.15. ...1.22 24.. .1.05.. .1.09. . . . . 1 . 1 5 1.21

lating loss of life, life expectancy will be For explanation of degree of accuracy, see Appendix I For explanation of degree of accuracy, see Appendix I I .

NOVEMBER 1945, VOLUME 64 Transformers, Regulators, and Reactors TRANSACTIONS 799

life of the transformer and the approx-

imate percentage of life which he is willing

to sacrifice.

Appendix I gives a method by which

the user can produce similar data for

transformers having other characteristics, j

and the loads for a given hottest-spot !

temperature may be somewhat greater

than those given hereafter.

In the curves and tables that follow, :

the following limitations.have been used: !

Maximum oil temperature (unprotected)*

90 degrees centigradet

Maximum oil temperature (protected)*

100 degrees centigradet

Maximum hottest-spot copper temperature

150 degrees centigrade

Maximum short-time loading (one-half hour

or more). . 200 per cent**

Short-Time Loads Above Rating for

Transformer With Specified Characteristics

iOO 120 140 160 ÉâÏ 200 I20 I40

PER C E N T RATED KVA

PER C E N T RATED KVA- Assumed Transformer Characteristics.

(See Table IV.) By the use of the data in

Figure 6. Short-time loading with moderate Figure 7. Short-time loading with moderate

the Table V the user may determine hot-

sacrifice of life expectancy, forced-oil-cooled sacrifice of life expectancy, forced-oil-cooled

test-spot copper temperature for various

transformers or forced-air-cooled transformers transformers or forced-air-cooled transformers

loads and times following 50-per-cent load

rated over 133 per cent of self-cooled rating rated over 133 per cent of self-cooled rating

or less and 100-per-cent load and from

Following 50 per cent or less of rated kilovolt- Followins 100 per cent of rated kilovolt- this determine the approximate loss of

amperes or top-oil temperature rise of 22 amperes or top-oil temperature rise of 40 life for such loading. Or he may deter-

degrees centigrade degrees centisrade mine loading for any selected loss of life.

Ambient temperature 30 degrees centigrade Ambient temperature 30 degrees centigrade The user can select loadings and losses of

for air for air life most suitable to his conditions. An

Subtract hottest-spot gradient from hottest- Subtract hottest-spot gradient from hottest- average loss of life of one per cent per year

spot temperature to obtain top-oil temperature spot temperature to obtain top-oil temperature incurred during emergency operations is

considered reasonable.

A—Assumed temperature limitation for top oil A—Assumed temperature limitation for top oil Top-oil temperature, when known, is a

(protected) (protected) better criterion of conditions at the start

A'—Assumed temperature limitation for top A'—Assumed temperature limitation for top of a given load than the previous condi-

oil (unprotected) oil (unprotected) tions of load, because the oil may not

B—Assumed temperature limitation for hot- B—Assumed temperature limitation for hottest-

have reached its ultimate temperature for

test-spot copper spot copper

the previous load.

On each of the afore-mentioned figures

Times Rated Kilovolt-Amperes Times Rated Kilovolt-Amperes

to Use not More Than Following Life to Use not More Than Followins Life ultimate top-oil temperature rise for the

Time, (Per Cent) Time, (Per Cent) preceding load is given. This value may

Hours 0.1 0.25 0.50 1.0 Hours 0.1 0.25 0.50 1.0 be used to determine the curve to use and

as a guide in interpolation.

v«..

1 ..

....1

....1

.78... . . .1 .92

. . . 1 64

. 2 . 0 0 . . . . .2.00

.1 .73 .1 82

Vl 1.56... . . . 1 . 7 0 . . . ...1.80.. ...1.90

Hottest-spot copper temperatures ver-

53... 1 1.39... . . . 1 . 5 0 . . . ...1.59.. ...1.69

2 .. . . . . 1 32... . . . 1 .42 .1 .49 . . 1 57 2 1.26... . . . 1 . 3 6 . . . . ..1.43.. ...1.51 sus loss of life assumed in making up

4 .. ....1 18... . . . 1 26 .1 .33 .1 .40 4 1.16... . . . 1 . 2 5 . . . ...1.32.. ...1.39

8 .. ....1 10... . . . 1 .17 .1 . 2 4 . . . . .1 .31 8 1.10... . . . 1 . 1 8 . . . ...1.24.. ...1.31 figures are given in Figure 11.

24.. ....1 05... . . .1 .08 .1 . 1 4 . . . . .1 .20 24 1.05... . . . 1 . 0 9 . . . ...1.14.. ...1.20

Additional Short-Time Loading Avail-

For exp anatior of desree of accuracy, see Appendix II. For explanation of desree of accuracy, see Appendix II. able. In addition to the short-time

loads outlined, the transformer may be

loaded above or below kilovolt-ampere

loads by various amounts for various Therefore, such values are given for a rating in accordance with directions given

times, and the approximate relative loss transformer having specified character- under "Loading for Normal Life Expec-

of life may be estimated. istics, and these characteristics have been tancy." (Each increase must be based

The load capability of transformers selected so that allowable loads for practi- on rated kilovolt-amperes.)

varies widely and is affected by the cally all other combinations of character-

following characteristics: istics will be at least as great as those 1. Loading on basis of test temperature

given. rise.

º . Top-oil rise lover ambient temperature. As the operating conditions under

2. Hottest-spoi rise over top-oil tempera- which transformers may be loaded are so *See Appendix II for explanation.

ture (hottest-sp*t copper gradient). extremely variable, particularly with re- fOil is considered to be protected, or unprotected,

3. Ratio of loari losses to no-load loss. gard to frequency of load, data are given depending on whether the transformer is or is not

so that the approximate relative loss of equipped with conservator or inert gas above the

4. Time constant.* oil.

insulation life for various loads for various

5. Ambient temperature. times may be determined. The user can JAt high oil temperatures precautionary measures,

such as draining oil, may be necessary to prevent

It is not possible to give a single set of then determine the allowable load for his overflow or excessive pressures.

loads which will apply to all transformers conditions by taking into account the **Current-carrying parts, other than windings, may

for a given set of operating conditions. probable number of such loads during the impose a lower limit.

800 TRANSACTIONS Transformers, Regulators, and Reactors ELECTRICAL ENGINEERING

2. Loading on basis of ambient temDera- No general guides can be given for such ULTIMATE OIL RISE IN DEGREES C

ture. supplemental cooling, and each trans- 0 20 4 0 60 80 100 120 140 160

former should be considered individually.

THERMAL RELAYS

Thermal relays designed for application

to individual transformers are available.

Guide for Loading Pole-Type

They make use of hottest-spot tempera- Constant-Current Transformers

ture in their operation and automatically

take into account ambient temperature INCREASED PERIODS OF OPERATION

and previous conditions of loading, since OF POLE-TYPE CONSTANT-CURRENT

the actuating element is influenced by the TRANSFORMERS FOR AMBIENT

hottest oil and the load current. Higher TEMPERATURES LOWER THAN NORMAL

loads are permitted for short times than Since pole-type constant-current trans-

are permitted for long times. These re- formers operate outdoors at night when

lays can be designed, at the option of the the ambient temperature is compara-

user, to permit loads which will produce tively low, it is often desirable to take ad-

practically no sacrifice of life expectancy vantage of the longer period of opera-

or some predetermined moderate sacrifice tion within the limiting temperature rise

of such expectancy. Contacts may be which is made possible by an ambient

wired to cause sounding an alarm, starting temperature lower than normal. The

of fans, or disconnecting of the trans- time of operation of a pole-type constant-

former. Application of such relays current transformer may be increased as 0 40 80 120 160 200240

should be discussed with the manufac- the average ambient temperature de-

PER CENT RATED KVA.

turer. creases, as shown in Table VI.

Figure 8. Ultimate top-oil temperature rise

SUPPLEMENTAL COOLING OF EXISTING

SELF-COOLED TRANSFORMERS Guide for Loading Step-Voltage and

Induction-Voltage Regulators capable of operating or holding against

The load that can be carried on existing the torque produced by load. In the case

self-cooled transformers can be increased of a step-voltage regulator, the burning of

by as much as 66 per cent by adding A voltage regulator has a short-time

load capability greater than the name- contacts is the limiting feature.

auxiliary cooling equipment such as fans, A working group of the AIEE trans-

external forced-oil coolers, or water-spray plate rating, the magnitude depending on

the initial load and ambient temperature, former subcommittee is now reviewing

equipment. The amount of additional the loading of regulators to determine if

loading varies widely, depending on: as in the case of a transformer. How-

ever, there are some additional factors the loads given here can be increased

(a). Design characteristics of the trans- that must be considered in this type of safely.

former. equipment. The fact that the induction

(b). Type of cooling equipment. machine has a winding in slots on a rotat- SHORT-TIME LOADS ABOVE RATING

ing member mounted in bearings necessi-

(c). Permissible increase in voltage regula- FOR OIL-IMMERSED SELF-COOLED

tion. tates a limit to the load to prevent exces-

REGULATORS

sive hottest-spot temperatures and undue

(d). Limitations of associated equipment. vibration. Also, a regulator must be Short-time loads above rated kilovolt-

amperes may be applied to oil-immersed

Table I. Loading on Basis of Ambient self-cooled regulators with daily average

Temperature Table II. Loading on Basis of Load Factor cooling air at 30 degrees centigrade in

accordance with the limits given in Table

Per Cent of Rated Kva Increase in Maximum VII.

Per Cent of Per Cent Loads with normal life expectancy may

Decrease Increase Type of Cooling Rated Kva Increase*

Load for Load for be carried once every 24 hours, whereas

Type of Cooling Higher Temp Lower Temp

those with moderate sacrifice of life ex-

Self-cooled 0.5 25

Water-cooled 0.5 25 pectancy should be carried infrequently.

Self-cooled 1.5 1 0

Water-cooled 1.5 10 Forced-air-cooled.... 0.4 20 With cooling-air temperatures other

Forced-oil-cooled 0.4 20

Forced-air-cooled.... 1.0 0.75 than 30 degrees centigrade the short-time

Forced-oil-cooled in 0 75

* Corresponds t o 50 per cent load factor. loads may be increased by one per cent of

Table III. Loading on Basis of Short-Time Loads Above Rating

Times Rated Kilovolt-Amperes

Forced-Air-Cooled

Forced-Air-Cooled Transformers Rated More than

Transformers Rated 133 Per 133 Per Cent of Self-Cooled

Time, Cent or Less of Self-Cooled Rating and All Forced-Oil-

Hours Self-Cooled and Water-Cooled Transformers Rating Cooled

♦initial Load (per cent). 90 . . 70 50 90 70 50 . . . . . . 90 . . . . 70 . . . . 50

V* 1.59. . 1.77 1.89 ....1.45.... 1.58 1.68 1.36 1.47 1.50

1 1.40.. 1.54 ....1.60.... ....1.31.... 1.38 1.50 ...1.24.... ....1.31 1.34

2 1.24.. 1.33.... ....1.37 ....1.19.... 1.23 1.26 ...1.14 ....1.18.... ....1.21

4 1.12.. 1.17 1.19 ....1.11 ....1.13 1.15 ...1.09 1.10 ....1.10

8 1.06.. 1.08 1.08 1.06 ....1.07 1.07 ...1.¼5 1.06 1.06

♦Percentages fix the load which is assumed to exist before the short-time load is applied. Use either average load for two hours previous to load above rating or

average load for 24 hours (less overload period), whichever is greater.

Ambient temperature assumed for this table is 30 degrees centigrade for air and 25 degrees centigrade for water.

As the loads may be applied once every 24 hours, and as there is some evidence that the rate of insulation deterioration a t about 100 degrees centigrade doubles

with less than 8 degrees centigrade increase in insulation temperature the values have been based on 4 degrees centigrade rather than on 8 degrees centigrade.

NOVEMBER 1945, VOLUME 64 Transformers, Regulators, and Reactors TRANSACTIONS 801

rated kilovolt-amperes for each degree per cent of the continuous self-cooled not exceed the values for the respective

centigrade that the average temperature rating below the recommended load for altitudes given in Table VIII. Standard

is below 30 degrees centigrade, except each degree centigrade that the daily temperature limits will not be exceeded.

that no further increases are recom- average temperature of the cooling air Obviously when advantage is taken of

mended beyond the 25-per-cent limit cited exceeds 30 degrees centigrade. lower ambient temperatures at the higher

in the table. Average temperature altitudes to offset the increased tempera-

should be for periods of time not exceeding Guide for Loading Current-Limiting ture rise caused by decreased air density,

24 hours with maximum temperatures Reactors the output cannot be increased to the full

not more than ten degrees centigrade extent covered under "Loading on Basis

greater than average temperatures. See Interim Report on Overloading of Ambient Temperature." For such

Short-time loads should be reduced two Current-Limiting Reactors, by trans- loading the temperature base should be in

former subcommittee of the AIEE com- accordance with Table VIII.

mittee on electric machinery. 1 OPERATION AT STANDARD AMBIENT

Table I V . Assumed Transformer Characteristics TEMPERATURES

Application at Altitudes Greater

It is recognized as good practice to use

Than 3,300 Feet (1,000 Meters)

Self- Forced- apparatus of standard temperature rise at

Cooled Forced- Air-Cooledf

Water- Air- or Forced- OPERATION AT LESS THAN STANDARD altitudes greater than 3,300 feet (1,000

Cooled Cooled* Oil-Cooled

AMBIENT TEMPERATURES meters), provided the load to be carried is

reduced below rating by the percentages

Hottest-spot rise

It is recognized as good practice to use given, in Table IX for each 330 feet (100

(degrees centi- apparatus of standard temperature rise at meters) that the altitude is above 3,300

grade) 65 .65 65 rated kilovolt-amperes at altitudes greater

Top-oil rise (de- feet (1,000 meters). Standard tempera-

grees centi- than 3,300 feet (1,000 meters), provided ture rise will not be exceeded.

grade) 45 . . 45 40 the temperature of the cooling air does

Time constant INSULATION

at full load

(hours) 3.0 ..2.0 1.5 The dielectric strength of equipment

Ratio of copper Table VI. Loading Pole-Type Constant-

to iron losses... 2.5 to 1. . 3.5 to 1 5 to 1 which depends upon air for its insulation

Ambient tem- Current Transformers decreases as the altitude increases. The

perature (de-

grees centi- dielectric strength at 3,300 feet or less for

grade) 30 30 30 Average Ambient Period of a given insulation class should be multi-

Temperature, Operation,

*Forced-air-cooled rating is 133 per cent or less of Degrees Centigrade Hours plied by the proper altitude correction

self-cooled rating. factor to obtain the dielectric strength at

fForced-air-cooled rating is over 133 per cent of 30 8 the required altitude (see Table X).

self-cooled rating. 25 10

20 12

15 14

10 16 Appendix I. Calculations of

Table V . Reference to Figures Temperature and Loss of Life for

Short-Time Loading of Transformers

Self- Forced Table V I I . Loading Regulators

Cooled Forced- Air-Cooledt

Water- Air- or Forced-

Moderate

Short-time loads above rating that use up

Cooled Cooled* Oil-Cooled different amounts of life expectancy for

Starting at an Oil Normal Sacrifice of

Temperature Life Life Expec- transformers having definite characteristics

Following 50- Corresponding Expectancy, tancy, Per have been given in Figures 2 through 7.

per-cent load to Continuous Per Cent Cent Generally, transformers included in these

or less Figure 2. . Figure 4. . . . Figure 6 Operation at 1 Hr 2 Hr 1 Hr 2 Hr

Following 100- guides which have other characteristics

per-cent load. . Figure 3. . Figure 5. . . . Figure 7 will have greater load capabilities. This

Full load 0 0 35 . . . . 3 0 appendix gives information by which similar

Values between 50 and 100-per-cent load may be VUoad 20 14 50* 45 curves may be derived for such transformers.

interpolated with sufficient accuracy. V 2 load 25* 17 50* 50*

In explaining the use of Figures 8 and 9

*Forced-air-cooled rating is 133 per cent or less of through 11, a self-cooled transformer having

self-cooled rating. *This load is the maximum that can be allowed, ow-

ing to hottest-spot temperature, vibration, torque, the same characteristics as those selected in

tForced-air-cooled rating is over 133 per cent of or contact-burning considerations on this class of the main portion of the guides, and having a

self-cooled rating. equipment.

load of 160 per cent for two hours following

50 per-cent load, is used as an example.

The figures also apply to forced-air-cooled

Table V I I I . Application at Altitudes Greater Than 3,300 Feet ( 1 , 0 0 0 Meters) and forced-oil-cooled transformers.

Maximum Allowable Average Temperature of Cooling Air for

Carrying Rated Kilovolt-Amperes, Degrees Centigrade Characteristics at Rated Kilovolt-

Amperes Required to Be Known Example

3,300 Ft 6,600 Ft 9,900 Ft 13,200 Ft

Method of Cooling Apparatus (1,000 M) (2,000 M) (3,000 M) (4,000 M)

1. Hottest-spot rise 65 C

2. Top-oil rise 45 C

Oil-immersed self-cooled 30*. .28. .25. .23 3. Time constant at full load 3.0 hr

Oil-immersed forced-air-cooled 30*. .26. .23. .20 4. Ratio of copper to iron losses 2.5 to 1

Oil-immersed forced-oil-cooled with oil 5. Ambient temperature 30 C

to air cooler 30*. .26. .23.

Dry-type self-cooled

Class- A insulation .30 .27. .24. .21 Top-Oil Rise

Class- B insulation .30 .26. .22. .18 1. Determine ultimate top-oil rise for

Dry-type forced-air-cooled initial load (50 per cent). On Figure 8 start

Class-A insulation .30 .24. .19. .14

Class- B insulation .30 .22. .14. . 6

at per cent 'or initial load (50) and go up to

curve for ratio of losses (R =2.5). Go to

*See section 2.000 of American Standard C57.1 for explanation of average ambient temperature. left to line for full-load oil rise (45 degrees

802 TRANSACTIONS Transformers, Regulators, and Reactors ELECTRICAL ENGINEERING

centigrade). Go vertically and read ulti- Table IX. A p p l i c a t i o n at A l t i t u d e s Greater Table X . A p p l i c a t i o n at A l t i t u d e s Greater

mate oil rise (25 degrees centigrade). Than 3,300 Feet ( 1 , 0 0 0 Meters) Than 3,300 Feet ( 1 , 0 0 0 Meters)

2. Determine ultimate top-oil rise for

short-time load in question. Repeat pro- Correction Altitude Correction

cedure in paragraph 1, starting at per-cent Factor, Factor A for Insula-

Types of Cooling Per Cent Altitude tion Class

load in question (160) and read ultimate oil

rise (82 degrees centigrade).

Oil-immersed self-cooled apparatus 0.4 3,300 feet (1,000 meters) 1.00

3. On Figure 9 set a straightedge at the Oil-immersed water-cooled apparatus 0.0 4,000 feet (1,200 meters) 0.98

initial oil temperature rise on the left scale Oil-immersed forced-air-cooled appa- 5,000 feet (1,500 meters) 0.95

(25 degrees centigrade) and a t the ultimate ratus 0.5 6,000 feet (1,800 meters) 0.92

Oil-immersed forced-oil-cooled appa- 7,000 feet (2,100 meters) 0.89

oil temperature rise on the right scale (82 ratus with oil to air cooler 0.5 8,000 feet (2,400 meters) 0.86

degrees centigrade). At the intersection of Oil-immersed forced-oil-cooled appa- 9,000 feet (2,700 meters) 0.83

the line so determined and the vertical line ratus with oil to water cooler 0.0 10,000 feet (3,000 meters) 0.80

Dry-type self-cooled apparatus 0.3 12,000 feet (3,600 meters) 0.75

through the intersection of lines for the de- Dry-type forced-air-cooled apparatus 0.5 14,000 feet (4,200 meters) 0.70

sired time (two hours) and time constant 15,000 feet (4,500 meters) 0.67

(three hours), determine the oil temperature

rise (52 degrees centigrade) at the end of the Altitude of 15,000 feet is considered a maximum for

P = ratio of load to full load standard apparatus.

assumed time (two hours).

Pi — ratio of equivalent initial load to full

load (load which results in an ulti-

Hottest-Spot Copper Rise Over Top-

Oil Temperature (Copper Gradient) mate rise of è%)

R = ratio of load loss to no-load loss

On Figure 10 start at per-cent load (160) e = 2.71828 C=0.06 (weight of core and coils)+0.04

on horizontal scale and go up to the curve / = time load is applied in hours (weight of t a n k ) + 1 . 3 3 (gallons of oil)

for full-load hottest-spot rise (20 degrees

B = thermal time constant of transformer for

centigrade). Go to left and read copper Theoretical Corrections for Preceding

gradient (42 degrees centigrade^ for the per- any load or any ratio of initial to ulti-

mate oil temperature (hours) Formulas

cent load in question (160 .

i5 r = time constant for full load beginning Theoretically, several corrections should

Hottest-Spot Copper Temperature with initial temperature rise of 0 be made in the foregoing formulas when one

degrees (hours) is calculating transient oil rises, such as

Obtain hottest-spot copper temperature corrections for change in:

Wji = total loss at full load (watts)

by adding ambient temperature (30 degrees

centigrade), top-oil rise (52 degrees centi- C—thermal capacity of transformer (watt- 1. Time constant for loads above rating.

grade), and hottest-spot rise (42 degrees hours per pound per degree centi- 2. Ultimate copper loss at end of load period.

grade) 3. Oil viscosity.

centigrade), giving 124 degrees centigrade.

Practical Application of Formulas for

Per Cent Loss of Life Hottest-Spot Temperature Calculation of Oil Rises

From Figure 11 obtain the loss of life The hottest-spot temperature In making general calculations based on

(0.2 per cent) for the hottest-spot copper a sumptions of transformer characteristics

temperature (125 degrees centigrade) and (i) and maximum hot-spot temperatures which

the duration of the load (two hours). In Transient heating and cooling equation generally have a large factor of safety, re-

calculating these curves it has been assumed sults close enough for all practical purposes

for top-oil rise over ambient temperature

that hottest-spot temperature is constant at are obtained if all of these corrections are

its final value during the overload period. omitted and the simpler formulas are used

When this assumption is made, the elevated è0=(âç-èÌ1-â ")+0, (2) The overload values given in Figures 2 t o

temperature during the cooling period need 7 were calculated by the formulas without

not be considered. Ultimate top-oil rise for load P corrections.

Table X I is suggested as a convenient 1. Time Constant. The time constant

method of tabulating values obtained by the eu = efl[(P*R + l)/(R + l)}»'* (3)

is the length of time which would be required

foregoing procedure and covers values for

Hottest-spot rise over top oil for the temperature of the oil to change from

the example assumed.

the initial value to the ultimate value if t h e

(4) initial rate of change were continued until

the ultimate temperature was reached.

average copper rise over top oil * +

Appendix II. Formulas for 10 degrees centigrade

*At rated kilo volt-amperes from

test.

manufacturer's

Calculating Transient Heating of 0

™ Time constant at rated kilovolt- (5) The time constant is usually the length of

amperes time required for a specified percentage of

Oil-Immersed Transformers

List of Symbols Figure 9 . Top-oil 200 200

# a -ambient temperature (degrees centi- temperature" rise at

grade) end of specified load

00=hottest-spot rise over top-oil tempera- period

, ture (degrees centigrade)

eg(fi)= hottest-spot rise over top-oil tem-

perature at full load

6hs=hottest-spot temperature (degrees

centigrade)

h~top-oil rise over ambient temperature

(degrees centigrade)

ââ-full-load top-oil rise (degrees centi-

grade)

0i = initial oil rise for / = 0 (degrees centi-

grade)

9U- ultimate oil rise for load P (degrees

centigrade) .1 2 .3 .4 .5 .6 .7 .8 .9 I 1.25

VALUES OF ilN(l-£-fc)

1.5 2 2.5.

{ 7h

4 oo

NOVEMBER 1945, VOLUME 64 Transformers, Regulators, and Reactors TRANSACTIONS 803

rise. If the initial temperature is approx-

imately equal to the final temperature,

whether just above or just below it, the per-

centage is approximately 63. If the initial

temperature is greater than the ultimate

temperature, the percentage is less than 63.

Since evaluation of the exact percentage

for cases where n is not unity and the initial

temperature rise is not zero becomes very

laborious, it is frequently advisable to use

the value of 63 per cent as an approximation.

In the more frequently encountered cases

where n is approximately 0.8, the error

resulting from this procedure is not large

compared to the expected error in transient

thermal calculations.

If w = 1.0, equation 6 is correct for any

load and any starting temperature. If n is

less than 1.0, equation 6 holds only for full- 9 0 9 5 K)0 105 110 115 120 125 130 05140 145 150

HOTTEST-SPOT TEMP. IN DEGREES C.

rating starting cold. If w = 0.8, the time

constant for any load and for any starting Figure 1.1. Hottest-spot copper temperature

temperature for either a heating cycle or versus loss of Hie

cooling cycle is given by equations 7 and 8.

0 2 0 4 0 60 80 100 120 140 160180 220

Temperatures in Desrees Centisrade

PER CENT RATED KVA. to Use not More Than Following Life

B=Br (7)

.feT-Gn

Figure 10. Hottest-spot copper rise over top- Time, (Per Cent)

Hours 0.1 0.25 0.50 1.0

oil temperature

Vt ....132.... ...142.. 150

If starting cold (0<=O) equation 7 reduces 1 ....124.... ...134.. 142 150

2 ....117.... ...126.. 134 142

the change in temperature from initial value to . . . . 1 1 1 . . . . ...119.. 126 134

-<tr

4

to ultimate value to take place. 8 105 ...112.. 119 126

24 .... 99.... ...104.. 109 115

If w* equals unity, 63 per cent of the tem- B (8)

perature change occurs in a length of time For explanation of degree of accuracy, see Appendix II.

equal to the time constant, regardless of the

relationship of initial temperature and ulti- 2. Copper Loss. As the resistance of

the copper for ultimate conditions is greater cosity of the oil. For hot-spot rise over oil

mate temperature. If n is not unity, the the viscosity correction tends to offset the

percentage varies and is a function of both when the temperature is greater for loads

above rating than for rated load conditions, effect of increased resistance.

initial temperature rise and ultimate

temperature rise. In particular, if n equals a resistance correction factor should be

added to equations 3 and 4. Explanation of Degree of Accuracy of

0.8, the percentage is 67 if the initial tem- Figures 2 to 7 and Figure 11

perature rise is zero. 3. Viscosity of Oil. The ultimate

temperature rise of oil for a constant loss de- The percentage loss-of-life values which

If the initial temperature rise is greater

creases slightly as the temperature of the oil will not be exceeded, shown on these figures,

than zero, the percentage is lower than 67

increases, owing to a decrease in the vis- of necessity have been made quite conserva-

and decreases as the initial temperature rise

increases for a eiyen ultimata temperature ♦Exponential power of temperature rise versus loss. tive, as they depend on the rate of insulation

Table XI. Summary of Values Used in Plotting Figure 2

Per Cent Ultimate Hours Duration

Rated Kva Oil Rise 0.5 1.0 1.5 2.0 3.0 4.0 6.0 8.0 12.0 16.0 24.0

Top Oil Rise—Degrees Centigrade (do), From Figure 9

105 48 . . . . 2 8 . . . .. 3 1 . . . .. 34.. .. 36.. .. 39... .. 42 . 45.. .. 47.. .. 47.. .. 48.. .. 48

110 51 28... .. 32... .. 35... .. 37.. .. 4 1 . . . .. 44 . 47.. .. 49.. .. 50..

120 56 2 9 . . . .. 3 3 . . . .. 37... .. 40... .. 44... 52... .. 54.. .. 55..

140 68 3 1 . . . .. 36... .. 42... .. 46... .. 52... .. 57 62... .. 65... .. 68... .. 69... .. 69

160.... 82 3 4 . . . .. 4 1 . . . .. 47... .. 5 2 . . . .. 6 1 . . . .. 67 74... .. 78... .. 8 1 . . . .. 82... .. 82

180 97 36... .. 4 5 . . . .. 5 3 . . . .. 60... .. 71... . 78.... 87... .. 92... .. 9 6 . . . .. 97... .. 97

200 113 3 7 . . . .. 4 8 . . . .. 59... .. 66... .. 80... . 89 101 , , . 107

Hottest-Spot Copper Temperature—Degrees Centigrade

0 g (From Figure 10) 0g+0» 0he = 0o~|-0g"f"0a

105 22 52 80... .. 8 3 . . . .. 86... .. 88... .. 9 1 . . . . . 94 97... .. 99... .. 99...

110.: 24 54 . . . . 82... .. 86... .. 8 9 . . . .. 9 1 . . . .. 9 5 . . . . . 98 101... .. 103... .. 1 0 4 . . . . . 1 0 5 . . . . . 105

120 27 57 . 86... .. 90... .. 9 4 . . . .. 97... .. 1 0 1 . . . . 105 109... .. 111... .. 1 1 2 . . . . . 1 1 3 . . . . . 113

140 34 64 95... .. 100... .. 106... .. 110... .. 1 1 6 . . . . 121 126... .. 129... .. 1 3 2 . . . . . 1 3 3 . . . . . 133

160 42 72 106... .. 113... .. 119... .. 124... .. 1 3 3 . . . . 139 146... .. 150... .. 153...

180 : 51 81 . . . . 117... .. 126... .. 134... .. 141... .. 1 5 2 . . . . 159

200 61 91...... 128... .. 139... .. 150... .. 157

Loss of Life—Not More Than—Per Cent, From Figure 11

105 ..0.05.. ..0.11

110 ..0.06.. ..0.13.. ..0.18.. ..0.27

120 .0.12.. 0.21.. ..0.38.. ..0.53.. ..0.80

..1.43.. ..2.49.. ..3.60.. ..5.40

160 ..0.10.. ..0.22.. ..0.74... ..1.65 4.70.. ..8.40

180 ..0.13.. ..0.96.. ..9.50

200.. . . . . 0 . 0 7 . . . ..0.40.. ..1.46... ..3.90

The above values contain numbers to the second de cimal place to give figures used in plotting curves. N o such high degree of accuracy in actual life loss is implied.

See Appendix II for explanation of symbols.

804 TRANSACTIONS Transformers, Regulators, and Reactors ELECTRICAL ENGINEERING

S-ar putea să vă placă și

- 380kV CT-VT Calculation - C4 - Rev - D 17.12.09Document137 pagini380kV CT-VT Calculation - C4 - Rev - D 17.12.09siva2001eee80% (5)

- On-Site Testing of 220kV XLPE Cable SystemsDocument7 paginiOn-Site Testing of 220kV XLPE Cable SystemsAnonymous F71F47EnKÎncă nu există evaluări

- Additional Materials Supply for 900MW CCPP ProjectDocument2 paginiAdditional Materials Supply for 900MW CCPP Projectwaqas_a_shaikh4348Încă nu există evaluări

- Calculating Cable Fault RatingsDocument8 paginiCalculating Cable Fault Ratingswaqas_a_shaikh4348Încă nu există evaluări

- Cable Cleaning Solvents Their Use and EvaluationDocument4 paginiCable Cleaning Solvents Their Use and Evaluationwaqas_a_shaikh4348Încă nu există evaluări

- A Comparison of Generator Excitation Systems - EE PublishersDocument10 paginiA Comparison of Generator Excitation Systems - EE Publisherswaqas_a_shaikh4348Încă nu există evaluări

- Power System Dynamics & Stability: Symmetrical Components Transient Stability IntroDocument39 paginiPower System Dynamics & Stability: Symmetrical Components Transient Stability IntroWilian GuamánÎncă nu există evaluări

- 01437476Document5 pagini01437476sanjayaÎncă nu există evaluări

- Turbine - Generator Topics For Power Plant Engineers - Motoring of A Synchronous GeneratorDocument46 paginiTurbine - Generator Topics For Power Plant Engineers - Motoring of A Synchronous Generatorakm-ntpcÎncă nu există evaluări

- High Level Flexibility Assessment and Benchmarking ToolDocument150 paginiHigh Level Flexibility Assessment and Benchmarking Toolwaqas_a_shaikh4348Încă nu există evaluări

- Fiber Optic Cable Types - Single Mode Vs Multimode Fiber Cable - FS Community - HTMLDocument9 paginiFiber Optic Cable Types - Single Mode Vs Multimode Fiber Cable - FS Community - HTMLwaqas_a_shaikh4348Încă nu există evaluări

- Calculating Cable Fault RatingsDocument1 paginăCalculating Cable Fault Ratingswaqas_a_shaikh4348Încă nu există evaluări

- Load Flow Management in The Interconnected Power Systems Using UDocument5 paginiLoad Flow Management in The Interconnected Power Systems Using Uwaqas_a_shaikh4348Încă nu există evaluări

- PK1024-MKF-MDB060-365097 01Document9 paginiPK1024-MKF-MDB060-365097 01waqas_a_shaikh4348Încă nu există evaluări

- Consequences and Standards From Using CP Systems To Prevent CorrosionDocument7 paginiConsequences and Standards From Using CP Systems To Prevent CorrosionAdnan RanaÎncă nu există evaluări

- BS EN IEC 62305 Standard Series PDFDocument16 paginiBS EN IEC 62305 Standard Series PDFDarshana Herath LankathilakÎncă nu există evaluări

- Broken Conductor ProtectionDocument3 paginiBroken Conductor Protectionwaqas_a_shaikh4348Încă nu există evaluări

- Energies 12 03075 PDFDocument14 paginiEnergies 12 03075 PDFBat-ErdeneeeeeÎncă nu există evaluări

- Chapter 939276Document47 paginiChapter 939276waqas_a_shaikh4348Încă nu există evaluări

- Electrical Test After Site Installation 62067 IEC-2011Document5 paginiElectrical Test After Site Installation 62067 IEC-2011waqas_a_shaikh4348Încă nu există evaluări

- XD China JWG-252 IEC 62271-102 3 Motor ChargedDocument2 paginiXD China JWG-252 IEC 62271-102 3 Motor Chargedwaqas_a_shaikh4348Încă nu există evaluări

- Tuloo-e-Ashk by Mohsin NaqviDocument103 paginiTuloo-e-Ashk by Mohsin Naqviheera100% (3)

- Application IEC 60287Document117 paginiApplication IEC 60287roxi50100% (1)

- CIRED2011 0499 FinalDocument4 paginiCIRED2011 0499 Finalwaqas_a_shaikh4348Încă nu există evaluări

- Gis Testing RequirementsDocument7 paginiGis Testing Requirementswaqas_a_shaikh4348Încă nu există evaluări

- IEC Standard Clause For Auxiliary and Control Circuit Test PDFDocument3 paginiIEC Standard Clause For Auxiliary and Control Circuit Test PDFwaqas_a_shaikh4348Încă nu există evaluări

- Dhabeji S/S Trafo 1 Future Boc S/S Metering Bus Coupler: T2 P2 P1 P1 P2 T1 P2 P1 T1 P2 P1 T1 P2 P1 T1 P2 P1Document1 paginăDhabeji S/S Trafo 1 Future Boc S/S Metering Bus Coupler: T2 P2 P1 P1 P2 T1 P2 P1 T1 P2 P1 T1 P2 P1 T1 P2 P1waqas_a_shaikh4348Încă nu există evaluări

- GIS, AIS, CHB - Earthing Detail PDFDocument1 paginăGIS, AIS, CHB - Earthing Detail PDFwaqas_a_shaikh4348Încă nu există evaluări

- Aeria Fiber Optices PDFDocument9 paginiAeria Fiber Optices PDFwaqas_a_shaikh4348Încă nu există evaluări

- F0126405 PB OLTCsDocument24 paginiF0126405 PB OLTCsDEADMANÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- VPRS-4300D Catalogue PDFDocument4 paginiVPRS-4300D Catalogue PDFHoàngTrầnÎncă nu există evaluări

- Lecture 2 - Kinematics Fundamentals - Part ADocument30 paginiLecture 2 - Kinematics Fundamentals - Part ASuaid Tariq BalghariÎncă nu există evaluări

- ROBERT_BECKER.BOM Wrapped Ref Des (Current Date, Sort by Item SeqDocument5 paginiROBERT_BECKER.BOM Wrapped Ref Des (Current Date, Sort by Item SeqNAUBERTO F. DOS SANTOSÎncă nu există evaluări

- Engineering Circuit Analysis 7th Edition: Chapter 17 SolutionDocument50 paginiEngineering Circuit Analysis 7th Edition: Chapter 17 SolutionTaif ArifÎncă nu există evaluări

- XCKN2145G11: Limit Switch XCKN - TH - Plastic Roller Lever Var - Length - 1NO+1NC - Snap - Pg11Document2 paginiXCKN2145G11: Limit Switch XCKN - TH - Plastic Roller Lever Var - Length - 1NO+1NC - Snap - Pg11Boby SaputraÎncă nu există evaluări

- Lab 8 - LP Modeling and Simplex MethodDocument8 paginiLab 8 - LP Modeling and Simplex MethodHemil ShahÎncă nu există evaluări

- Priority Academic Student Skills Mathematics Grades 1-5Document44 paginiPriority Academic Student Skills Mathematics Grades 1-5faithinhim7515Încă nu există evaluări

- 2 Fourier and Wavelet Transforms: 2.1. Time and Frequency Representation of SignalsDocument25 pagini2 Fourier and Wavelet Transforms: 2.1. Time and Frequency Representation of SignalszvjpÎncă nu există evaluări

- Homework ClassDocument11 paginiHomework ClassHossain100% (1)

- 7-3 IP Board Part (SMPS Part) : 7 Block DiagramsDocument8 pagini7-3 IP Board Part (SMPS Part) : 7 Block DiagramsSonu KumarÎncă nu există evaluări

- Pipe Flow Expert BrochureDocument2 paginiPipe Flow Expert BrochurecristinelbÎncă nu există evaluări

- 2 Power System and Stability (Read-Only)Document17 pagini2 Power System and Stability (Read-Only)Avik PoudelÎncă nu există evaluări

- Chemistry Investigatory File Handmade NewDocument17 paginiChemistry Investigatory File Handmade NewMadhusudan PeriwalÎncă nu există evaluări

- 4-1 E Handbook 2013-14Document53 pagini4-1 E Handbook 2013-14Siva Reddy KunduruÎncă nu există evaluări

- PDF Ecs h81h3 Ad DDDocument37 paginiPDF Ecs h81h3 Ad DDsanak tiuhÎncă nu există evaluări

- Topic 4 - Chemical Kinetics 4b - Half LifeDocument20 paginiTopic 4 - Chemical Kinetics 4b - Half LifeJoshua LaBordeÎncă nu există evaluări

- SERIES-90 180cc SERVICE BLN-2-41695 1997-05Document52 paginiSERIES-90 180cc SERVICE BLN-2-41695 1997-05thailanÎncă nu există evaluări

- Standard Test Methods For Time of Setting of Hydraulic Cement by Vicat NeedleDocument4 paginiStandard Test Methods For Time of Setting of Hydraulic Cement by Vicat NeedleCeddie PamintuanÎncă nu există evaluări

- Breathing AND Exchange of Gases MCQs PDFDocument78 paginiBreathing AND Exchange of Gases MCQs PDFJatin SinglaÎncă nu există evaluări

- Engineering Graphics (046) Marking Scheme: Sample Question Paper (2017-18)Document8 paginiEngineering Graphics (046) Marking Scheme: Sample Question Paper (2017-18)RaghuSrinivasanÎncă nu există evaluări

- Math 2nd Year CompleteDocument369 paginiMath 2nd Year CompleteJabir Ali Siddique100% (1)

- Drum RudimentsDocument4 paginiDrum Rudimentsmaame nyarkoaÎncă nu există evaluări

- Subsurface Remote Sensing of Kelp ForestsDocument20 paginiSubsurface Remote Sensing of Kelp Forestsjpeterson1Încă nu există evaluări

- The Gist of NCERT General Science PDFDocument148 paginiThe Gist of NCERT General Science PDFSatyajitSahooÎncă nu există evaluări

- Foundation DetailsDocument29 paginiFoundation DetailsSUSOVAN BISWASÎncă nu există evaluări

- Brahma 152 192sm CM MMDocument6 paginiBrahma 152 192sm CM MMThiago FernandesÎncă nu există evaluări

- Bahir Dar University Introduction to Logic Final ExamDocument6 paginiBahir Dar University Introduction to Logic Final ExamEskinder TeferiÎncă nu există evaluări

- tc107 Research PaperDocument6 paginitc107 Research PaperAtharva BhideÎncă nu există evaluări

- An Overview On Reliability, Availability, Maintainability and Supportability (RAMS) EngineeringDocument15 paginiAn Overview On Reliability, Availability, Maintainability and Supportability (RAMS) EngineeringKrinta AlisaÎncă nu există evaluări