Documente Academic

Documente Profesional

Documente Cultură

Pumb Room

Încărcat de

Mohamed HamzaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pumb Room

Încărcat de

Mohamed HamzaDrepturi de autor:

Formate disponibile

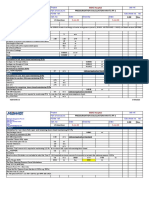

GENERATOR ROOM VENTILATION CALCULATION

Fire pump Capacity= 1000 GPM

H

Ventilating air (cu.m/min.) =

D x SH x Dt

Where :-

H = Total Heat Radiation in (KW) For (Diesel Pump +Electrical Pump +Jockey Pump)

Diesel Pump= ((Break HORSE POWER *2545)/EFFICIENCY) =

H = 125.5 KW (Ref. To specs. Sheet)

V = Ventilating air (cu.m/min.)

D = Density of air (kg/m3)

= 1.07 At 54 deg. C

SH = Specific heat of air ( kw.min/Kg.C)

= 0.017

dT= Temp. Rise inside engine room ( deg.C)

= 10 deg.C

ECA = Engine Combustion Air (Exhaust gas flow )

= 120 cu.m/min (Ref. To specs. Sheet)

7,182 cu.m/hr.

THEN :-

125.5

Ventilating air (V) = + 120

1.07 x 0.017 x 10

V = 810 cu.m/min

V = 28,575 cu.ft/min.

INTAKE LOUVER SIZE

- Consider Air Velocity = 1000 ft/min.

Total Air Quantity = 28,575 cu.ft/min.

Louver Area = 29 Sq.ft

2.7 Sq.m

Important Notes :-

1- clean , cool , dry air circulates around the switchgear , flows through the rear of the generator , across the engine , a

through the radiator

2- Cool air shoul always be available for the engine air cleaner (air filter ).

3- For best ventilation results , air should flow first across the generator then to both sides of the engine .

4- Inlets located at the end of the room will provide adequate ventilation only to the engine nearast the inlet.

5- Air flow restriction should be 0.5 inch W.G

generator , across the engine , and discharges

des of the engine .

ine nearast the inlet.

S-ar putea să vă placă și

- Engine Room Ventilation - Necesar AerDocument1 paginăEngine Room Ventilation - Necesar AerBirshopulosÎncă nu există evaluări

- Fan Laws and Fan HP Rev1Document3 paginiFan Laws and Fan HP Rev1agung gunandarÎncă nu există evaluări

- Psychrometry. Heat Recovery Air Handling Unit (Ahu) - by Ömer Faruk DDocument13 paginiPsychrometry. Heat Recovery Air Handling Unit (Ahu) - by Ömer Faruk DKarl WeierstrassÎncă nu există evaluări

- Static Pressure Calculations V1.1Document1 paginăStatic Pressure Calculations V1.1sachinsaklani23Încă nu există evaluări

- Ventilation Summary For Carpark & VRV System: (M /S) (M /S)Document4 paginiVentilation Summary For Carpark & VRV System: (M /S) (M /S)sachinsaklani23Încă nu există evaluări

- External Static Pressure Calculation (Revision 1) 20/4/2016 SEF-B1-01 (Smoke Exhaust Fan For Compartment D Carpark SES System)Document14 paginiExternal Static Pressure Calculation (Revision 1) 20/4/2016 SEF-B1-01 (Smoke Exhaust Fan For Compartment D Carpark SES System)kkkkÎncă nu există evaluări

- S&W CalculationDocument10 paginiS&W CalculationSameera LakmalÎncă nu există evaluări

- Stair Case Pressurization - DARDocument4 paginiStair Case Pressurization - DARKoushikÎncă nu există evaluări

- Delivery Pipe: System CurvesDocument3 paginiDelivery Pipe: System CurvestankimsinÎncă nu există evaluări

- Smoke Extraction - TECDocument1 paginăSmoke Extraction - TECdasmechÎncă nu există evaluări

- StairCase Press-Eclipse - (Printed 29.01.2020) PDFDocument3 paginiStairCase Press-Eclipse - (Printed 29.01.2020) PDFmhmdjdgmailcomÎncă nu există evaluări

- Staircase Pressurization Tower ADocument6 paginiStaircase Pressurization Tower AShanku ChakrabartyÎncă nu există evaluări

- Lift Well Pressurization Calculation Pasanger Liftwell No. 1-6 Tower-7 (3rd Basment To 14th Floor)Document1 paginăLift Well Pressurization Calculation Pasanger Liftwell No. 1-6 Tower-7 (3rd Basment To 14th Floor)Akash SaxenaÎncă nu există evaluări

- Central Water Heating Design: A, This Heat Pump Engineering Project Design Hot Water System IncludeDocument3 paginiCentral Water Heating Design: A, This Heat Pump Engineering Project Design Hot Water System Includehifon1Încă nu există evaluări

- Project: FT Catcher Fpso Feed: Hvac - Heater Load CalculationDocument7 paginiProject: FT Catcher Fpso Feed: Hvac - Heater Load CalculationinstrengÎncă nu există evaluări

- GDL Louvre CalculatorDocument1 paginăGDL Louvre Calculatorsainath_84Încă nu există evaluări

- 3) Sme & Makeup Air CalculationDocument33 pagini3) Sme & Makeup Air CalculationAshiq NishmaÎncă nu există evaluări

- GDL Louvre CalculatorDocument1 paginăGDL Louvre CalculatorAbraham JyothimonÎncă nu există evaluări

- ClimateMaster Pool SizingDocument5 paginiClimateMaster Pool SizingNghiaÎncă nu există evaluări

- Air Changes Per Hour (ACH) and Time in Minutes Required For RemovalDocument1 paginăAir Changes Per Hour (ACH) and Time in Minutes Required For RemovalalbrgmailÎncă nu există evaluări

- Fahu 2 (Te)Document15 paginiFahu 2 (Te)Abdo RagabÎncă nu există evaluări

- Chilled Water and Condensor Water Pump Head CalculaitonDocument3 paginiChilled Water and Condensor Water Pump Head CalculaitonYusuf RampÎncă nu există evaluări

- HVAC Thermal Load EstimatingDocument28 paginiHVAC Thermal Load EstimatingIntisar Ali SajjadÎncă nu există evaluări

- CAL-03 - Staircase Pressurization CalculationDocument4 paginiCAL-03 - Staircase Pressurization CalculationAbdul Sami100% (1)

- 08-Electric Water HeaterDocument3 pagini08-Electric Water Heatermohamed IbrahemÎncă nu există evaluări

- FireSmoke Control Stair PressurizationDocument10 paginiFireSmoke Control Stair PressurizationAshokÎncă nu există evaluări

- Documents Room DY Auto Heat Load RaphaDocument18 paginiDocuments Room DY Auto Heat Load RaphaShaikh TauseefÎncă nu există evaluări

- HVAC Useful Conversions ChartDocument2 paginiHVAC Useful Conversions ChartdheerajdorlikarÎncă nu există evaluări

- Stair PressurizationDocument11 paginiStair Pressurization185412Încă nu există evaluări

- 925 - Fahu Cal - 1 & 2Document2 pagini925 - Fahu Cal - 1 & 2Designer ForeverÎncă nu există evaluări

- Air Change RateDocument18 paginiAir Change Ratemumbaimale20009776Încă nu există evaluări

- Shubharambh Banquets HL - All Halls 26-5-2017Document5 paginiShubharambh Banquets HL - All Halls 26-5-2017calvin.bloodaxe4478Încă nu există evaluări

- Heat Load For Guest Room (N&E)Document1 paginăHeat Load For Guest Room (N&E)words4devÎncă nu există evaluări

- Staircase Pressurization SPV BuildingDocument2 paginiStaircase Pressurization SPV BuildingNandan RajeÎncă nu există evaluări

- L&T MLCP East Block HVAC Heat Load SUMMARYDocument3 paginiL&T MLCP East Block HVAC Heat Load SUMMARYSatheesh Kumar NatarajanÎncă nu există evaluări

- Heat Load Estimation MS1525 DesignDocument10 paginiHeat Load Estimation MS1525 Designhans weemaesÎncă nu există evaluări

- FAHUDocument4 paginiFAHUSundar DAACÎncă nu există evaluări

- Staircase Pressurization Calculation SheetDocument4 paginiStaircase Pressurization Calculation SheetTariq AsgharÎncă nu există evaluări

- Duck Work Calculation (Inch)Document2 paginiDuck Work Calculation (Inch)pratheeshÎncă nu există evaluări

- Cooling Load Calculation: ME 511 Aircondition and Ventilation SystemsDocument13 paginiCooling Load Calculation: ME 511 Aircondition and Ventilation SystemsErvenjee BascoÎncă nu există evaluări

- DAR Stair Case PressurizationDocument16 paginiDAR Stair Case PressurizationfebousÎncă nu există evaluări

- Smoke Management For Retails Calculation PDFDocument1 paginăSmoke Management For Retails Calculation PDFSudhir KulkarniÎncă nu există evaluări

- Cooling Tower CalculationeditedDocument3 paginiCooling Tower CalculationeditedMark LouieÎncă nu există evaluări

- Stair Case-01 Pressurisation Calculation: 3.3 7.255 2.56 64.78 2.2 1.1 - 6.6 Walls (Tight) Door Frame (Single Leaf)Document7 paginiStair Case-01 Pressurisation Calculation: 3.3 7.255 2.56 64.78 2.2 1.1 - 6.6 Walls (Tight) Door Frame (Single Leaf)Shabeer HamzaÎncă nu există evaluări

- Heat Load EstimationDocument5 paginiHeat Load EstimationSultan FirassuddinÎncă nu există evaluări

- PIPE LOSS (Incl Eq) : Pump Head Calculation S-1 3Document4 paginiPIPE LOSS (Incl Eq) : Pump Head Calculation S-1 3Fadi YasinÎncă nu există evaluări

- 300 Lit Water Tanks Stem Heating CalculationDocument8 pagini300 Lit Water Tanks Stem Heating CalculationEngFaisal AlraiÎncă nu există evaluări

- Project Name: Doc No: Air System Name: Rev: Equipment Type: Date: Space Used For: Sheet No: Floor: Reference: ClientDocument10 paginiProject Name: Doc No: Air System Name: Rev: Equipment Type: Date: Space Used For: Sheet No: Floor: Reference: ClientMukti WibowoÎncă nu există evaluări

- Acmv Technical ReportDocument10 paginiAcmv Technical Reportarun kurlanÎncă nu există evaluări

- Design Calculation Sheet: System Class Class A Class B Class C Class D Class E Class FDocument3 paginiDesign Calculation Sheet: System Class Class A Class B Class C Class D Class E Class FMohd Najeeb Ali FathaanÎncă nu există evaluări

- PLANT ROOM EFFICENCY-karleDocument13 paginiPLANT ROOM EFFICENCY-karleAzher IrfanÎncă nu există evaluări

- E20 Heat Load Estimation Form: DT Is Too High, Determine Supply CFM For Desired Difference by SupplyDocument1 paginăE20 Heat Load Estimation Form: DT Is Too High, Determine Supply CFM For Desired Difference by Supplypsn_kylmÎncă nu există evaluări

- Hvac Project: An-Najah National UniversityDocument29 paginiHvac Project: An-Najah National Universityمحمود عسكرÎncă nu există evaluări

- Exp Tank SizingDocument5 paginiExp Tank Sizinghasanadel88Încă nu există evaluări

- Kitchen & Bakery Hvac BoqDocument5 paginiKitchen & Bakery Hvac BoqRajeshÎncă nu există evaluări

- DBR of Ventilation System 162Document10 paginiDBR of Ventilation System 162pukhrajsoniÎncă nu există evaluări

- VS Lab & Office - Hvac Boq 29032016Document16 paginiVS Lab & Office - Hvac Boq 29032016Ganesh RamÎncă nu există evaluări

- Design Calculation Sheet: Mechanical & Industrial DepartmentDocument40 paginiDesign Calculation Sheet: Mechanical & Industrial Departmentwado11Încă nu există evaluări

- Generator RoomDocument3 paginiGenerator Roomparthiv100% (1)

- Generator Calculation 01Document1 paginăGenerator Calculation 01Mahmoud FakhereddinÎncă nu există evaluări

- Coastal Blue Carbon - Methods For Assessing Carbon Stocks and Emissions Factors in Mangroves Tidal Salt Marshes and Seagrass MeadowsDocument182 paginiCoastal Blue Carbon - Methods For Assessing Carbon Stocks and Emissions Factors in Mangroves Tidal Salt Marshes and Seagrass Meadowsapi-245803001Încă nu există evaluări

- Module 2 - Part III - UpdatedDocument38 paginiModule 2 - Part III - UpdatedDhriti NayyarÎncă nu există evaluări

- DbmsDocument5 paginiDbmsRohit KushwahaÎncă nu există evaluări

- Management Accounting/Series-4-2011 (Code3024)Document18 paginiManagement Accounting/Series-4-2011 (Code3024)Hein Linn Kyaw100% (2)

- Packing List For GermanyDocument2 paginiPacking List For GermanyarjungangadharÎncă nu există evaluări

- The Names of Allah and Their ReflectionsDocument98 paginiThe Names of Allah and Their ReflectionsSuleyman HldÎncă nu există evaluări

- Valuing Construction Variation by Using PWA, FIDIC, ICWMF and CEDA Fluctuation Formula MechanismDocument5 paginiValuing Construction Variation by Using PWA, FIDIC, ICWMF and CEDA Fluctuation Formula MechanismAzman YahayaÎncă nu există evaluări

- Device InfoDocument3 paginiDevice InfoGrig TeoÎncă nu există evaluări

- Grade 7 Math Lesson 22: Addition and Subtraction of Polynomials Learning GuideDocument4 paginiGrade 7 Math Lesson 22: Addition and Subtraction of Polynomials Learning GuideKez MaxÎncă nu există evaluări

- T HR El 20003 ST PDFDocument20 paginiT HR El 20003 ST PDFAngling Dharma100% (1)

- To Tell The TruthDocument5 paginiTo Tell The TruthNabeel Ahmed KhanÎncă nu există evaluări

- EUROJAM Diary3Document4 paginiEUROJAM Diary3Susan BakerÎncă nu există evaluări

- Firststep To AlaskaDocument28 paginiFirststep To AlaskaBarbara NelsonÎncă nu există evaluări

- Lecture Planner - Chemistry - MANZIL For JEE 2024Document1 paginăLecture Planner - Chemistry - MANZIL For JEE 2024Rishi NairÎncă nu există evaluări

- Language Loss in Waray: Ni Voltaire Q. UyzonDocument23 paginiLanguage Loss in Waray: Ni Voltaire Q. UyzonMary Rose OmbrogÎncă nu există evaluări

- Discover India, January 2018Document51 paginiDiscover India, January 2018calebfriesenÎncă nu există evaluări

- Atlantis Implant Compatibility Chart 79214-US-1107Document2 paginiAtlantis Implant Compatibility Chart 79214-US-1107Jean-Christophe PopeÎncă nu există evaluări

- Lay Planning TypesDocument1 paginăLay Planning TypesGaurav Shakya100% (1)

- The Roti Canai StoryDocument5 paginiThe Roti Canai StoryDr Bugs TanÎncă nu există evaluări

- FRQ Vocabulary ReviewDocument1 paginăFRQ Vocabulary ReviewDrew AbbottÎncă nu există evaluări

- Introduction of Woman Role in SocietyDocument12 paginiIntroduction of Woman Role in SocietyApple DogÎncă nu există evaluări

- IRAQ Reproductive Maternal, Newborn, Child and Adolescent HealthDocument32 paginiIRAQ Reproductive Maternal, Newborn, Child and Adolescent HealthbejarhasanÎncă nu există evaluări

- 14 Days of Prayer and FastingDocument40 pagini14 Days of Prayer and FastingntsakoramphagoÎncă nu există evaluări

- Self-Actualization in Robert Luketic'S: Legally Blonde: A HumanisticDocument10 paginiSelf-Actualization in Robert Luketic'S: Legally Blonde: A HumanisticAyeshia FréyÎncă nu există evaluări

- Bhagavatam English Chapter 10bDocument22 paginiBhagavatam English Chapter 10bsrimatsimhasaneshwarÎncă nu există evaluări

- თინათინ ზურაბიშვილი, თვისებრივი მეთოდებიDocument111 paginiთინათინ ზურაბიშვილი, თვისებრივი მეთოდებიNino LomaiaÎncă nu există evaluări

- Zoology LAB Scheme of Work 2023 Hsslive HSSDocument7 paginiZoology LAB Scheme of Work 2023 Hsslive HSSspookyvibee666Încă nu există evaluări

- 2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Document28 pagini2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Manuel ValenteÎncă nu există evaluări

- Unit 4 ADocument10 paginiUnit 4 AChetan p ShirahattiÎncă nu există evaluări

- Bach Polonaise G Min BWV 119 A4Document1 paginăBach Polonaise G Min BWV 119 A4vincenzovaiaÎncă nu există evaluări