Documente Academic

Documente Profesional

Documente Cultură

AT 5 Research Assignment Student On Complex System Fault PDF

Încărcat de

Arshad IssopTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

AT 5 Research Assignment Student On Complex System Fault PDF

Încărcat de

Arshad IssopDrepturi de autor:

Formate disponibile

Assessment 5

AURTTA021 Diagnose complex system faults

Assessment 5 - Research Assignment AURTTA021

First submission Re-submission

Due date: ____/____/________ Due date: ____/____/________

Assessor and student instructions for research assignment:

As the student you are required to:

Students must successfully research and answer all 7 questions below.

Student is to complete the questions either handwritten (must be legible) or completed on a word

processor and submitted in hard copy form to your lecturer by the due date.

Students are to talk to their lecturer if they have any questions related to completing the tasks.

Students are to ensure the Student declaration is signed prior to submission stating all submitted work is

their own.

The student is advised that their performance on assessment 4 and assessment 5 will be compared to

authenticate the students work in assessment 5. The student must demonstrate that the 10 similar

knowledge questions are answered successfully on both assessment 4 (5 questions in part A and 5

questions in part B) and assessment 5 to determine authenticity of assessment 5. If authenticity is unable

to be determined through successful completion of assessment 4, the student may also be deemed not

yet satisfactory for assessment 5.

Adjustments to assessments may be made for you, providing the adjustments comply with set principles

of assessment and rules of evidence If you require support for literacy and numeracy issues; support for

hearing, sight or mobility issues; change to assessment times/venues; use of special or adaptive

technology; considerations relating to age, gender & cultural beliefs; format of assessment materials; or

presence of a scribe you need to inform your lecturer. Necessary adjustments can be discussed with the

trainer prior to the commencement of the course. Refer to college intranet for Policy and Legislation:

http://intranet.smtafe.wa.edu.au/org/cs/services/Pages/policy.aspx

Assessor Instructions: Students are to adequately answer all of the following questions. If any questions are

NOT answered correctly or completely, the student must be provided with feedback and will be required to

reattempt the question again and re-submit by a due date to be negotiated with them.

The assessor is required to authenticate the students work in assessment 5 by comparing their responses to

similar knowledge questions as those in assessment 4, 10 questions (5 questions in part A and 5 questions in part

B, refer to mapping document for specific details). The student must demonstrate satisfactory understanding of

the required knowledge assessed in assessment 4, before a satisfactory result can be given for assessment 5.

If a student requires reasonable adjustment please discuss with your Academic Leader, refer to the DAP and to

the Policy and Legislation on the Intranet: http://intranet.smtafe.wa.edu.au/org/cs/services/Pages/policy.aspx

7 March 2019 Version 1.3 Page 1 of 9 AT 5 Research Assignment Student on

Complex system fault

Assessment 5

AURTTA021 Diagnose complex system faults

Student ID:

Student Name

I declare that the evidence submitted is my own work:

Student

Declaration

…………………………………………..

Assessor

Feedback:

Student

Feedback:

Attempt Date Student performance

Student signature

(I confirm this is my own work)

Assessor Name Assessor signature

(Theory to be kept with

Summary)

1. Briefly describe the work health and safety (WHS) and occupational health and

safety (OHS) requirements relating to diagnosing complex system faults

including procedures for:

a) Selecting and using the correct PPE

RISK ASSESSMENTS:

o Proper movements such as bending, stretching, lifting or moving equipment and

materials, and working in awkward positions, such as under car bonnets.

o Proper clothing should be worn

o All jewelleries should be removed

o Appropriate PPE: Safety glasses, safety boots, gloves

o Noise is a big concern when working with engines, machinery and power tools. Use

ear muffs.

o Always perform automotive testing in a safe environment

o Put transmission in PARK (for automatic transmission) or NEUTRAL (for manual

transmission) and make sure the parking brake is engaged

7 March 2019 Version 1.3 Page 2 of 9 AT 5 Research Assignment Student on

Complex system fault

Assessment 5

AURTTA021 Diagnose complex system faults

HAZARDS PRESENT HARMS PRESENT THINGS TO DO TO CONTROL

THE RISKS

Engine exhausts Fumes can cause eye irritations Use exhaust extractor

and breathing problems

Battery Charging Can cause burns from acids Do a safety check

Battery can explode from over Use PPE such a safety glasses

charging and gloves

Hoist Failure of Hoist, car can get off Do an inspection every 6

the hoist months

Check Safe Working Loads, SWL

Vehicle Airbags Airbags can explode if not fitted Do proper training for removing

correctly and cause injury and re fitting Airbags

Petrol and LPG Can cause fire, severe injuries Install Fire Alarms

and breathing difficulties

Fire extinghuishers – Inspected

Special Exits

Store Containers in a safe place

b) Using tools and equipment

Use Warrning/ Safety signs for co-workers' safety

Put Tags on Faulty Equipments.

Mechanical Equipments : Can cause serious injury from moving parts, sharp edges, hot parts

• Check equipments before use

• Put a Tag if necessary

• Get proper training

• Turn off equipment when not using

Electrical Equipments : Can cause burns/ Can get electric shocks. Faults can cause a fire

• Do a safety checks

• Ensure equipments are safe to use

7 March 2019 Version 1.3 Page 3 of 9 AT 5 Research Assignment Student on

Complex system fault

Assessment 5

AURTTA021 Diagnose complex system faults

2. In the table below describe in detail the types, application, function and links of the

given complex systems.

Name Types Application Function Links

a) ABS ABS ABS ESP uses the

ABS and Four Channel ABS system: Vehicles with ABS stop at While braking, if a wheel- ABS system’s

ESP has a different valve for a shorter distance than locking situation is

(systems wheel-speed

that each wheel and also a other vehicles, more detected or anticipated, sensors, as

integrates separate speed sensor stable and safe,it ensures the ECU alerts the HCU by

well as

two or more for each of the four full control of the steering sending a current and

steering-angle

automotive wheels wheel by preventing the commands it to release the

systems) vehicle from locking the brake pressure, allowing and yaw-angle

The controller monitors wheels in sudden braking the wheel velocity to sensors, to

each wheel individually situations in all road increase and the wheel slip detect a loss of

to make sure it is conditions and at all to decrease stability. The

getting the required speeds car’s computer

braking force. ESP is then able to

It is controlled by an This system is developed to apply brake

Three Channel ABS electronic control unit

system: help the driver avoid the pressure to

which is called Brake danger of losing the control individual

has a speed sensor on

Control Module (BCM) of the vehicle stability due

all four wheels and a wheels, while

separate valve for each to under-steering or

ESP also

of the front wheels, but oversteering during

recognizes critical driving moderating

only one valve for both cornering

conditions, such as panic engine power,

of the rear wheels ESP ECU controls it by

reactions in dangerous to bring the

controlling the vehicle

situations, and stabilizes car back into

stability using the input

the vehicle by wheel-

values from the sensors line

individual braking and

and applying the brakes

engine control

independently to the

involvement

corresponding wheels

7 March 2019 Version 1.3 Page 4 of 9 AT 5 Research Assignment Student on

Complex system fault

Assessment 5

AURTTA021 Diagnose complex system faults

b) Mechanical Usually pumps draws off As the camshaft rotates

EFI (a Fuel Pump fuel from the gas tank. It during engine operation, a

system that Usually mounted on the then pushes it to the shaft or rocker arm in the

incorporates

three or side of the engine block carburetor when the pump moves up and down

more or engine is cranking or or back and forward,

mechanical, cylinder head and running depending on the fuel

hydraulic, operated by a part on pump’s position. This

pneumatic, the engine's camshaft A check valve is used in causes the diaphragm to

electrical or the pump to prevent fuel move back and foward,

electronic from being pumped back

sub- drawing fuel from the fuel

into the tank. tank and sending it to the

systems)

carburetor or injectors

Hydraulic Controlled by a small Responsible for the

Fuel Pressure Regulator vacuum hose that goes to distribution of fuel to the

the intake engine

A device which controls

the pressure of fuel

supplied to the fuel

injectors on an engine

Pneumatic The ECU detects the A throttle position sensor

Throttle Body accelerator’s position and communicates the position

gives a message to the of the valve to the ECU.

Part of the air intake throttle body to open the The airflow meter

system that controls the valve recognizes the increased

amount of air flowing volume of air and gives a

into the engine message to the injection

system to inject more fuel

Electronic Allows fuel to spray out Fuel delivered is controlled

Injector of the nozzle and into the by cycling the injector

engine voltage on and off very

Responsible form rapidly

injection the fuel into

the engine, it is

controlled by ECU

7 March 2019 Version 1.3 Page 5 of 9 AT 5 Research Assignment Student on

Complex system fault

Assessment 5

AURTTA021 Diagnose complex system faults

3. Describe in detail the diagnostic procedures and stages used for diagnosing faults in

complex systems.

- Gather information from the customer - Ask questions such as “when did you first notice the

problem? What conditions was the vehicle operating under at the time? In traffic? Cruising

on the freeway? How long since the engine was started? What repairs or service have been

done recently?”

- Confirm the Fault – Make sure what the customer said was true. Do a road test with the

customer to confirm the symptom

- Consider the information gathered – Use own knowledge

- Locate the fault and its cause

- Repair the fault - Decide on the most suitable repair to eliminate the fault, whether to repair

it or replace with new parts.

- Always confirm with the customer first before carrying out repairs, tell him about the cost,

time etc.

- Repair the fault - check all related systems, as well as the faulty one, to confirm that and also

no other faults has been introduced

4. Briefly describe 4 methods of gathering information on complex system faults,

including the use of questions when talking to customers.

- Own Knowledge

- Workshop Manual & Manufacturer’s Websites

- Other Technicians in the workshop

- Internet – Google Search & Forums

5. Briefly describe TWO different types of diagnostic flow charts and when you would

use them.

a) Type 1 – OEM Manufacturer’s Flowchart

When it is used – when diagnosing the causes of

various trouble codes

has a “feedback loop” which

prompts you to re-test or do further

tests if you don’t find the fault on

the first attempt

has actual Specs of vehicle

b) Type 2- Generic Fault Diagnostic Flowchart

When it is used – This could be used as a general

procedure to follow on other

diagnosis tasks.

Often you can make a few small

adjustments to suit the particular

job

Does not have actual Specs of Vehicle

7 March 2019 Version 1.3 Page 6 of 9 AT 5 Research Assignment Student on

Complex system fault

Assessment 5

AURTTA021 Diagnose complex system faults

6. Given the following diagnostic tools in the table below briefly describe situations

where they are usually used, how they are used and any limitations they may have

Tool Where are they How are they used Limitations

used

(Operation)

(Application)

a) multimeters Testing for electrical Has connector such a Voltage limits

problems in a vehicle back probes, alligator Eg: Hybrid vehicles

clips (positive and require a more

negative) advanced type of

Used for Voltage test, multimeter

Resistance Test

Continuity Test

Cranking Battery

Load Test

Current Draw

b) scan tools access the vehicle’s - always refer to it cannot tell you if

including: ECU workshop manual the sensor is bad or

diagnosis trouble first the wiring is broken

codes (DTC) and display the DTCs on - has a 16 pin

the conditions the screen connector about 600 Software out of date

that caused the mm of the driver’s

code to be set, clear codes from the seat - near the Non-OEM

live data and

ECU’s memory steering column, or in Specifications

snap shots

the centre console

Live Data allows you - allow the mechanic

to view vehicle to run a diagnostic

sensor, switch and check when any

relay inputs in real service lights comes

time, while the engine on the dash in a

is running vehicle — check

engine, service light,

etc

- eliminates repairs -

Fault codes and other

scan tool data give

information about

area of malfunction

or the specific

component

7 March 2019 Version 1.3 Page 7 of 9 AT 5 Research Assignment Student on

Complex system fault

Assessment 5

AURTTA021 Diagnose complex system faults

c) oscilloscopes a kind of electronic - always refer to Can be costly

test instrument workshop manual

designed to first Limited frequency/

graphically display - has Scope mode and voltages

different types of different adaptor

signal voltages over probes No storage memory

time using waveforms to store data

to interpret the values - has 3 different

Eg: Ignition (Primary & systems:

Secondary) vertical system –

• Injectors & Fuel control voltage range

Pumps

• Starter & Charging horizontal system –

Circuits to set the

• ABS sensors, Crank appropriate time

& Cam Sensors needed

• Lambda, Airflow,

Knock & MAP Sensors trigger system – to

stabalize a repeating

signal

d) mechanical test Torque wrench Wear PPE Size limitations

equipment

tighten fasteners Get specific torque

(nuts, bolts, studs and from workshop

screws) to a specific manual Sensitive when over

tightness used

Once the fastener

becomes tight, apply

steady, even pressure

until the torque

wrench clicks. You

will both hear, and

feel this click through

the torque wrench.

e) hydraulic test Hydraulic Spring Refer to workshop Very expensive

equipment compressor manual first

To remove and Wear PPE

replace springs from Requires periodic

your struts Has a foot pedal to maintenance

compress the strut

Slide strut into the

compressor correctly Need necessary

to secure it training before use to

avoid serious injuries

Position lower and

upper bracket then

compress the spring

until it can be

removed safely

7 March 2019 Version 1.3 Page 8 of 9 AT 5 Research Assignment Student on

Complex system fault

Assessment 5

AURTTA021 Diagnose complex system faults

f) Pneumatic test Tyre pressure gauge Use workshop Dead battery (if

equipment such manual or the digital)

as tyre pressure Keeping the correct driver's door sticker

gauges, tyre pressures for best to get actual tyre

Compression driving condition pressure specs

Gauges. Petrol or

Diesel engines Connect pressure

gauge to read tyre

pressure

Compare values

7. a) Briefly describe how a fault symptom differs from a fault cause?

A symptom is a clue that something is wrong.

It is a noticeable change - we might see, hear, smell or feel something different

Finding the cause of the faults will allow the technician to choose the right repair to

correct the fault

Eg:

Symptom Fault Cause

Engine stopped suddenly, Broken cam belt, bent Belt overdue for replacement.

won’t re-start valves Leaking camshaft oil seal.

b) Briefly describe 2 methods that are used to differentiate between fault symptoms

and fault causes.

A symptom might indicate a fault in a customer’s vehicle, and a faulty (worn, broken)

component might be found

Something must have caused that change.

Finding the cause of the faults will allow the technician to choose the right repair to correct

the fault

Symptom Cause

In fifth gear, engine revs hard Clutch plate worn out

but car won’t accelerate

7 March 2019 Version 1.3 Page 9 of 9 AT 5 Research Assignment Student on

Complex system fault

S-ar putea să vă placă și

- TEMSA TS-35 Workshop ManualDocument78 paginiTEMSA TS-35 Workshop ManualJörgen Mannberg50% (2)

- Welder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamDe la EverandWelder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamÎncă nu există evaluări

- AURETR131 - Assessment 1 - Written Knowledge Questions - V3Document27 paginiAURETR131 - Assessment 1 - Written Knowledge Questions - V3MUHAMMAD UMARÎncă nu există evaluări

- Studyguide csm2 Ed2 PDFDocument73 paginiStudyguide csm2 Ed2 PDFfooÎncă nu există evaluări

- Control Volume Analysis Using EnergyDocument40 paginiControl Volume Analysis Using EnergyOmar FarukÎncă nu există evaluări

- AssessmentTask 1.3 - WHS Hazard ChecklistDocument12 paginiAssessmentTask 1.3 - WHS Hazard ChecklistAnonymous mAo95q0% (2)

- Lab Report 2 RheologyDocument17 paginiLab Report 2 Rheologyluis nunezÎncă nu există evaluări

- Calibration PDFDocument27 paginiCalibration PDFDonig FermanianÎncă nu există evaluări

- Crane and Hoist Safety ProgramDocument22 paginiCrane and Hoist Safety Programshahrilmr6934Încă nu există evaluări

- 2018 How To Score Goals in Floorball KIHUDocument36 pagini2018 How To Score Goals in Floorball KIHUrizki maulanaÎncă nu există evaluări

- Eme Lab Manual PDFDocument45 paginiEme Lab Manual PDFpatidar montuÎncă nu există evaluări

- Uncertainty AnalysisDocument29 paginiUncertainty AnalysisAmna RashidÎncă nu există evaluări

- Price List Hino Update 22 Mei 2018Document943 paginiPrice List Hino Update 22 Mei 2018Jojo Sosorodotan75% (4)

- Vishwakarma Institute of TechnologyDocument36 paginiVishwakarma Institute of TechnologyGaurav AthavaleÎncă nu există evaluări

- CPB 40002 Engineering Technologist in Society UniKL MICET Assignment 1 (Individual) : Codes of Engineering EthicsDocument10 paginiCPB 40002 Engineering Technologist in Society UniKL MICET Assignment 1 (Individual) : Codes of Engineering EthicsSiti Hajar MohamedÎncă nu există evaluări

- Sample CHP Feasability ReportDocument5 paginiSample CHP Feasability Reporteoghan mulliganÎncă nu există evaluări

- 4 Quality in Facilities and ServicesDocument6 pagini4 Quality in Facilities and ServicesyradwohcÎncă nu există evaluări

- Fluid Mech Orifice 3Document9 paginiFluid Mech Orifice 3TatendaÎncă nu există evaluări

- Venturi MeterDocument2 paginiVenturi MeterVijay KumarÎncă nu există evaluări

- Flow Over Weir With Hydraulic BenchDocument19 paginiFlow Over Weir With Hydraulic BenchAzim RahmanÎncă nu există evaluări

- Particle Technology Lab Safety RulesDocument1 paginăParticle Technology Lab Safety RulesUsamaÎncă nu există evaluări

- Hydraulics Topic 6 Hydraulic Machinery PDFDocument48 paginiHydraulics Topic 6 Hydraulic Machinery PDFVictoria JungÎncă nu există evaluări

- Metrology & Measurement: Anand K Bewoor & Vinay A KulkarniDocument9 paginiMetrology & Measurement: Anand K Bewoor & Vinay A KulkarniKuwer ThakurÎncă nu există evaluări

- Young Worker Readiness Module3Document53 paginiYoung Worker Readiness Module3Sisay CheruÎncă nu există evaluări

- Quality Consciousness: College of Information TechnologyDocument47 paginiQuality Consciousness: College of Information TechnologyJames Lao TapiaÎncă nu există evaluări

- Technicalguidebook 1 10 en ReveDocument446 paginiTechnicalguidebook 1 10 en RevetheerawsÎncă nu există evaluări

- BSBWHS401 Risk Management Policy PDFDocument2 paginiBSBWHS401 Risk Management Policy PDFdavidÎncă nu există evaluări

- Final Project Question COEB422 Project Sem 1 2016 - 17Document5 paginiFinal Project Question COEB422 Project Sem 1 2016 - 17Elyas Mohammed100% (1)

- On-Site Building Construction Management Level IV: MODULE TITLE: Managing Subordinates andDocument58 paginiOn-Site Building Construction Management Level IV: MODULE TITLE: Managing Subordinates andKinfe Dufera GonfaÎncă nu există evaluări

- Generic Terms of Reference For ESIADocument11 paginiGeneric Terms of Reference For ESIADragoljub DjordjevicÎncă nu există evaluări

- Experiment 1Document10 paginiExperiment 1Mary Tilt100% (2)

- Heat Transfer Lab 1 PDFDocument10 paginiHeat Transfer Lab 1 PDFPeter LauÎncă nu există evaluări

- Experiment 3 Hydraulics LabDocument12 paginiExperiment 3 Hydraulics LabMatt NashrudinÎncă nu există evaluări

- Condition Monitoring of Pump (Vibration)Document5 paginiCondition Monitoring of Pump (Vibration)Zaki Rizqi FadhlurrahmanÎncă nu există evaluări

- Balancing of Rotating MassesDocument4 paginiBalancing of Rotating MassesAhmad FaidhiÎncă nu există evaluări

- Thermo Fluid Lab Manual PDFDocument92 paginiThermo Fluid Lab Manual PDFaben777Încă nu există evaluări

- AnocalprDocument27 paginiAnocalprDiego Fernado AvendañoÎncă nu există evaluări

- 03 Koutnik - Hydro Power PlantsDocument33 pagini03 Koutnik - Hydro Power PlantsmindphaserÎncă nu există evaluări

- Terotechnology Teaching TMDocument77 paginiTerotechnology Teaching TMCharles Ondieki100% (1)

- LID ICT Assessment - BSBSMB407 Manage A Small Team Sem1 - 2020Document7 paginiLID ICT Assessment - BSBSMB407 Manage A Small Team Sem1 - 2020aliÎncă nu există evaluări

- Phase 1 Disk Space Rental System ReportDocument29 paginiPhase 1 Disk Space Rental System Reporthotsync.solutionsÎncă nu există evaluări

- Mechanical Operations Lab Report On Comparing The Efficiency of Cyclone Separator On Different Types of MaterialsDocument13 paginiMechanical Operations Lab Report On Comparing The Efficiency of Cyclone Separator On Different Types of Materialsnkar037Încă nu există evaluări

- Preview of Road and Off Road Vehicle System Dynamics HandbookDocument2 paginiPreview of Road and Off Road Vehicle System Dynamics HandbookFiorenzo TassottiÎncă nu există evaluări

- 2.steps and Procedure of Tensile TestDocument2 pagini2.steps and Procedure of Tensile TestMuhammad Faiz bin Ahmad ShafiÎncă nu există evaluări

- ME Environmental EngineeringDocument61 paginiME Environmental EngineeringBhency monikaÎncă nu există evaluări

- This Assessment Measures The Student's Ability For The Following OutcomesDocument10 paginiThis Assessment Measures The Student's Ability For The Following OutcomesMuhd Farhan Bin IbrahimÎncă nu există evaluări

- Tut+6 Sol ReleaseDocument5 paginiTut+6 Sol ReleaseThu Vu100% (1)

- Discussion - JunctionDocument2 paginiDiscussion - JunctionNur Syaf FiqahÎncă nu există evaluări

- Project Sky TaxiDocument23 paginiProject Sky TaxiSahilÎncă nu există evaluări

- Dimensionless Characteristics of Centrifugal PumpDocument4 paginiDimensionless Characteristics of Centrifugal PumpEn CsakÎncă nu există evaluări

- Automation Studio E7 Automotive en HighDocument8 paginiAutomation Studio E7 Automotive en HighquoctuanÎncă nu există evaluări

- Specification, Boat Ambulance PDFDocument1 paginăSpecification, Boat Ambulance PDFErick Galarza100% (1)

- Static and Dynamic BalancingDocument13 paginiStatic and Dynamic BalancingTuanbk NguyenÎncă nu există evaluări

- Introduction of Smart Power Module: For Low-Power Motor Drives ApplicationsDocument27 paginiIntroduction of Smart Power Module: For Low-Power Motor Drives ApplicationsChristian AztecaÎncă nu există evaluări

- Soalan Praktikal-Wsmb 2023 Pra-KelayakanDocument3 paginiSoalan Praktikal-Wsmb 2023 Pra-Kelayakanazhar ngahÎncă nu există evaluări

- ES195 Lab Tensile Testing PDFDocument12 paginiES195 Lab Tensile Testing PDFtopbanana09Încă nu există evaluări

- Lab 3 VibDocument3 paginiLab 3 VibAvenger4Încă nu există evaluări

- Synopsis of Design and Development of Corn SeperatorDocument9 paginiSynopsis of Design and Development of Corn SeperatorTejas KadamÎncă nu există evaluări

- Industrial Electrical Machines and Drives Servicing Level II Learning Guide-38Document34 paginiIndustrial Electrical Machines and Drives Servicing Level II Learning Guide-38kedirÎncă nu există evaluări

- Assessment 2 Assessor Direct Observation Practical Demonstration of Tasks Job Card 1 AURETK002 V2Document22 paginiAssessment 2 Assessor Direct Observation Practical Demonstration of Tasks Job Card 1 AURETK002 V2Tam TranÎncă nu există evaluări

- Week 2Document8 paginiWeek 2Be NjÎncă nu există evaluări

- Assessment 2 Assessor Direct Observation Practical Demonstration of Tasks Job Card 2 AURETK002 V2Document22 paginiAssessment 2 Assessor Direct Observation Practical Demonstration of Tasks Job Card 2 AURETK002 V2Tam TranÎncă nu există evaluări

- FL-60-EX Parts ManualDocument116 paginiFL-60-EX Parts ManualpiotrwezÎncă nu există evaluări

- La MD Premiums Week GreasesDocument20 paginiLa MD Premiums Week GreasesRaden ArdyÎncă nu există evaluări

- Infineon Hybrid Electric and Electric Cars 2019 ApplicationBrochureDocument32 paginiInfineon Hybrid Electric and Electric Cars 2019 ApplicationBrochureAdailton SantosÎncă nu există evaluări

- Megane Rs Brochure March2019 PDFDocument44 paginiMegane Rs Brochure March2019 PDFTõnis TranzeÎncă nu există evaluări

- Wacker Neuson G100 Operator ManualDocument78 paginiWacker Neuson G100 Operator ManualCesar Palacios ToctoÎncă nu există evaluări

- StackPack 300 TechsheetDocument2 paginiStackPack 300 TechsheetmanishÎncă nu există evaluări

- Chapter 402-00 Power Window Switch: CatalogueDocument6 paginiChapter 402-00 Power Window Switch: CataloguejuliaÎncă nu există evaluări

- Exhaust System: SectionDocument6 paginiExhaust System: SectionRifki AwaludinÎncă nu există evaluări

- Your DBX707Document16 paginiYour DBX707Sifiso DubeÎncă nu există evaluări

- Vehicle History Report: 2008 Honda Accord Ex-LDocument10 paginiVehicle History Report: 2008 Honda Accord Ex-LCole WalshÎncă nu există evaluări

- فرایویلDocument18 paginiفرایویلali chivaeiÎncă nu există evaluări

- Sample ValveDocument20 paginiSample ValveLuis Eduardo Aguilar Dueñas100% (1)

- 05 inDocument1 pagină05 inossoskiÎncă nu există evaluări

- XRT1500 ManualDocument60 paginiXRT1500 Manualold.smogÎncă nu există evaluări

- Nidec Motor Corporation: Assembled View V01 ADocument1 paginăNidec Motor Corporation: Assembled View V01 AEDUARDOMTZÎncă nu există evaluări

- Stainless Series S115-2 or S6115-2 (Globe), S1115-2 or S61115-2 (Angle) Installation InstructionsDocument1 paginăStainless Series S115-2 or S6115-2 (Globe), S1115-2 or S61115-2 (Angle) Installation InstructionsWattsÎncă nu există evaluări

- 4 Types of Spark Plugs (Copper Vs Iridium Vs Platinum Vs Double Platinum) PDFDocument10 pagini4 Types of Spark Plugs (Copper Vs Iridium Vs Platinum Vs Double Platinum) PDFNazmul HassanÎncă nu există evaluări

- Water Tanker 1Document1 paginăWater Tanker 1Arjun SatheesanÎncă nu există evaluări

- RT-127 Crank Angle Sensor ReplacementDocument12 paginiRT-127 Crank Angle Sensor ReplacementGeorgios MariolisÎncă nu există evaluări

- Cylinder Block 3126 EspecificacionesDocument3 paginiCylinder Block 3126 EspecificacionesGerardoÎncă nu există evaluări

- Spek Dental Panoramic Rotograph EVODocument2 paginiSpek Dental Panoramic Rotograph EVOtekmed koesnadiÎncă nu există evaluări

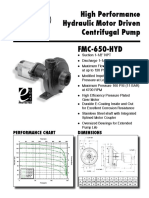

- Fmc-650-Hyd Rev 01-08Document2 paginiFmc-650-Hyd Rev 01-08Ruben SaccoÎncă nu există evaluări

- PZ MODS 2022 v3Document41 paginiPZ MODS 2022 v3Av ZÎncă nu există evaluări

- Engine Oil Pressure Sensor - Remove and Install - Intake Valve Actuator (RENR9705) C13Document2 paginiEngine Oil Pressure Sensor - Remove and Install - Intake Valve Actuator (RENR9705) C13Allan LariosaÎncă nu există evaluări

- Bent Axis Fixed Displacement Heavy Duty Motors and Pumps: Motor/PumpDocument28 paginiBent Axis Fixed Displacement Heavy Duty Motors and Pumps: Motor/PumpDecio SchuckÎncă nu există evaluări

- BMW Motorrad F 650 / F 650 ST Maintenance ScheduleDocument1 paginăBMW Motorrad F 650 / F 650 ST Maintenance ScheduleGaltÎncă nu există evaluări

- Pipe Cold Cutting MachineDocument4 paginiPipe Cold Cutting Machinecement drÎncă nu există evaluări

- Zack Casha - Bachelor of Engineering (Honours) in Mechanical Engineering (Plant)Document25 paginiZack Casha - Bachelor of Engineering (Honours) in Mechanical Engineering (Plant)Zack CashaÎncă nu există evaluări