Documente Academic

Documente Profesional

Documente Cultură

Approval of Welding Consumables For High Strength For Welded Structures

Încărcat de

Jose VargasTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Approval of Welding Consumables For High Strength For Welded Structures

Încărcat de

Jose VargasDrepturi de autor:

Formate disponibile

W23

W23

W23 Approval of Welding Consumables for High

(1995)

(cont)

(Rev.1

Strength Steels for Welded Structures

1997)

(Rev.2 1. General

Apr 2018)

(Corr.1 1.1 Scope

June 2019)

1.1.1 These requirements supplement the UR W17 and give the conditions of approval and

inspection of welding consumables used for high strength steels for welded structures

according to UR W16 with yield strength levels from 420 N/mm2 up to 960 N/mm2, and impact

grades A, D, E and F, except that impact grade F is not applicable for 890 N/mm2 and 960

N/mm2 yield strength levels.

Where no special requirements are given, those of UR W17 apply in analogous manner.

1.1.2 The welding consumables preferably to be used for the steels concerned are divided

into several categories as follows:

- covered electrodes for manual welding,

- wire-flux combinations for multi-run* submerged arc welding,

- solid wire-gas combinations for arc welding (including rods for gas tungsten arc

welding),

- flux cored wire with or without gas for arc welding.

1.2 Grading, Designation

1.2.1 Based on the yield strength of the weld metal, the welding consumables concerned are

divided into eight (yield) strength groups:

- Y42 - for welding steels with minimum yield strength 420 N/mm2

- Y46 - for welding steels with minimum yield strength 460 N/mm2

- Y50 - for welding steels with minimum yield strength 500 N/mm2

- Y55 - for welding steels with minimum yield strength 550 N/mm2

- Y62 - for welding steels with minimum yield strength 620 N/mm2

* Wire-flux combinations for single or two-run technique are subject to special consideration of the

Classification Society.

_______________________________________________________________________________________________________________

Note:

1. Rev.2 of this UR is to be uniformly implemented by IACS Societies when an application

for approval is dated on or after 1 July 2019.

Page 1 of 6 IACS Req. 1995/Corr.1 2019

W23

- Y69 - for welding steels with minimum yield strength 690 N/mm2

W23

(cont) - Y89 - for welding steels with minimum yield strength 890 N/mm2

- Y96 - for welding steels with minimum yield strength 960 N/mm2

1.2.2 Each of the eight (yield) strength groups is further divided into three main grades in

respect of Charpy V-notch impact test requirements (test temperatures):

- Grade 3, test temperature -20oC

- Grade 4, test temperature -40oC

- Grade 5, test temperature -60oC

1.2.3 Analogously to the designation scheme used in UR W17 the welding consumables for

high strength steels are subject to classification designation and approval as follows:

- According to 1.2.2 with the quality grades 3, 4 or 5

- With the added symbol, Y and an appended code number designating the minimum

yield strength of the weld metal corresponding 1.2.1: Y42, Y46, Y50, Y55, Y62, Y69,

Y89 and Y96.

- With the added symbol H10 or H5 for controlled hydrogen content of the weld metal,

- With the added symbol, S (= semi-automatic) for semi-mechanised welding,

- With the added symbol, M designating multi-run technique* (and is applicable only to

welding consumables for fully mechanised welding).

1.2.4 Each higher quality grade includes the one (or those) below Grade A... and D... steels

acc. to UR W16 are to be welded using welding consumables of at least quality grade 3,

grade E... steels using at least quality grade 4 and grade F... steels using at least quality

grade 5., see the following table:

Consumable Grade Steel Grades covered

3Y.. D.. and A..

4Y.. E.., D.. and A..

5Y.. F.., E.., D.. and A..

Welding consumables approved with grades ..Y42, ..Y46 and ..Y50 are also considered

suitable for welding steels in the two strength levels below that for which they have been

approved. Welding consumables approved with grades ..Y55, ..Y62 and ..Y69 are also

considered suitable for welding steels in the one strength level below that for which they have

been approved.

* Wire-flux combinations for single or two-run technique are subject to special consideration of the

Classification Society.

Page 2 of 6 IACS Req. 1995/Corr.1 2019

W23

Welding consumables with grade Y89 are considered suitable for welding steels in the same

W23 strength level only. Welding consumables with grade Y96 are also considered suitable for

(cont) welding steels in the one strength level below that for which they have been approved.

For grades Y89 and Y96, where the design requirements permit undermatching weld joint,

then welding consumables within the scope of this UR can be considered subject to Society

discretion and Manufacturer’s recommendations.

The Society may, in individual cases, restrict the range of application in (up to) such a way,

that approval for any one strength level does not justify approval for any other strength level.

1.3 Manufacture, testing and approval procedure

1.3.1 Manufacturer’s plant, production methods and quality control measures shall be such

as to ensure reasonable uniformity in manufacture, see also UR W17.

1.3.2 Testing and approval procedure shall be in accordance with UR W17, sections 2 and 3

and as required in UR W17 for the individual categories (types) of welding consumables

mentioned in 1.1.2 above.

2. Testing of the weld metal

2.1 For testing the deposited weld metal, test pieces analogous to those called for in UR

W17, sections 4.2, 5.2, 6.2 or 6.3 respectively shall be prepared, depending on the type of

the welding consumables (and according to the welding process). The base metal used shall

be a fine-grained structural steel compatible with the properties of the weld metal, or the side

walls of the weld shall be buttered with a weld metal of the same composition.

2.2 The chemical composition of the deposited weld metal shall be determined and certified

in a manner analogous to that prescribed in UR W17, section 4.2.2. The results of the

analysis shall not exceed the limit values specified in the standards or by the manufacturer,

the narrower tolerances being applicable in each case.

2.3 Depending on the type of the welding consumables (and according to the welding

process), the test specimens prescribed in UR W17, sections 3.1 and 4.2, 5.2, 6.2 or 6.3

respectively shall be taken from the weld metal test pieces in a similar manner.

2.4 The mechanical properties must meet the requirements stated in Tables 1 and 2. The

provisions of UR W17 apply in analogous manner to the performance of the tests, including in

particular the maintenance of the test temperature in the notched bar impact test and the

carrying out of results.

Page 3 of 6 IACS Req. 1995/Corr.1 2019

W23

Table 1 Required toughness properties of the weld metal

W23

(cont) Quality grade Test temperature Minimum notch impact

[oC] energy [J]1)

3 -20 Y42: ≥ 47

Y46: ≥ 47

4 -40

Y50: ≥ 50

Y55: ≥ 55

Y62: ≥ 62

5 -60 Y69: ≥ 69

Y89: ≥ 692)

Y96: ≥ 692)

1) Charpy V-notch impact test specimen, mean value of three specimens; for requirements regarding minimum

individual values and retests, see UR W17, section 3.3.2.

2)

Quality grade 5 is not applicable for Y89 and Y96 grade consumables.

Table 2 Required strength properties of the weld metal

Symbols added to Minimum yield Tensile Strength Minimum

quality grade strength or 0.2% elongation

proof stress

[N/mm2] [N/mm2] [%]

Y42 420 520-680 20

Y46 460 540-720 20

Y50 500 590-770 18

Y55 550 640-820 18

Y62 620 700-890 18

Y69 690 770-940 17

Y89 890 940-1100 14

Y96 960 980-1150 13

3. Testing on welded joints

3.1 Depending on the type of the welding consumables (and according to the welding

process), the testing on the welded joints shall be performed on butt-weld test pieces in

analogous manner to UR W17, sections 4.3, 5.2, 6.2, 6.3, or 6.4 respectively.

3.2 Depending on the type of the welding consumables (and according to the welding

process), the butt-weld test pieces called for in para. 3.1 shall be welded in a manner

analogous to that prescribed in UR W17. The base metal used shall be a high-strength fine-

grained structural steel with a minimum yield strength and tensile strength matching the

consumable grade being approved and compatible with the added symbol for which

application is made.

3.3 Depending on the type of the welding consumables (and according to the welding

process), the test specimens described in UR W17 shall be taken from the butt-weld test

pieces.

3.4 The mechanical properties must meet the requirements stated in Table 3. The

provisions of UR W17 apply in analogous manner to the performance of the tests, including in

particular the maintenance of the test temperatures in the notched bar impact test and the

requirements regarding the retest specimens.

Page 4 of 6 IACS Req. 1995/Corr.1 2019

W23

W23 Table 3 Required properties of welded joints

(cont)

Quality Added Minimum Minimum Minimum Bend

grade symbol tensile notch impact bending ratio

strength energy, test angle1)

[N/mm2] temperature D/t2)

3 to 5 Y42 520 Depending on 4

accordance Y46 540 the quality 120° 4

with Table 1 Y50 590 grade & yield 4

Y55 640 strength in 5

Y62 700 accordance 5

Y69 770 Table 1 5

Y89 940 6

Y96 980 7

1)

Bending angle attained before the first incipient crack, minor pore exposures up

to a maximum length of 3mm allowed.

2) D = Mandrel diameter, t = specimen thickness

3.5 Where the bending angle required in Table 3 is not achieved, the specimen may be

considered as fulfilling the requirements, if the bending elongation on a gauge length Lo

fulfills the minimum elongation requirements stated in Table 2. The gauge length Lo = Ls + t

(Ls = width of weld, t = specimen thickness), see sketch below.

4. Hydrogen test

4.1 The welding consumables, other than solid wire-gas combinations, shall be subjected to

a hydrogen test in accordance with the mercury method to ISO 3690, or any other method

such as the gas chromatographic method which correlates with that method, in respect of

cooling rate and delay times during preparation of the weld samples, and the hydrogen

volume determinations.

Page 5 of 6 IACS Req. 1995/Corr.1 2019

W23

4.2 The diffusible hydrogen content of the weld metal determined in accordance with the

W23 provisions of UR W17, section 4.5 shall not exceed the limits given in table 4.

(cont)

Table 4 Allowable diffusible hydrogen content

Yield strength group Hydrogen symbol Maximum hydrogen content

[cm3/100 g deposited weld metal]

Y42

Y46 H 10 10

Y50

Y55

Y62 H5 5

Y69

Y89

Y96 H5 5

5. Annual repeat test

The annual repeat tests specified in UR W17 shall entail the preparation and testing of weld

metal test pieces as prescribed under 2. For grades Y69 to Y96 annual hydrogen test is

required. In special cases, the Society may require more extensive repeat tests.

End of

Document

Page 6 of 6 IACS Req. 1995/Corr.1 2019

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Design of Rectangular FootingDocument19 paginiDesign of Rectangular FootingAbdul Rasheed75% (4)

- High Strength ConcreteDocument6 paginiHigh Strength ConcreteOnline AdoroÎncă nu există evaluări

- 5 Bridge N Tunnel - Lecture 71 PDFDocument103 pagini5 Bridge N Tunnel - Lecture 71 PDFGajendra Joshi100% (1)

- On Site Water Tightness Testing For Curtain WallingDocument4 paginiOn Site Water Tightness Testing For Curtain WallingManojkumar kondaveetiÎncă nu există evaluări

- GEOWEB Load Support Contruction PackageDocument31 paginiGEOWEB Load Support Contruction PackageJohnEMERYÎncă nu există evaluări

- Irrigation Manual W-22Document38 paginiIrrigation Manual W-22zoheb ahmedÎncă nu există evaluări

- Drawings Hanson Park H19!25!0010 Part4Document40 paginiDrawings Hanson Park H19!25!0010 Part4DhanyaÎncă nu există evaluări

- Propulsion I: Unit Ii InletsDocument64 paginiPropulsion I: Unit Ii InletsnaveenreddyÎncă nu există evaluări

- 970 Taken by Surprise 0tDocument10 pagini970 Taken by Surprise 0ttwinkle00033% (6)

- Piping Construction PhaseDocument3 paginiPiping Construction PhasefarhanyazdaniÎncă nu există evaluări

- Method Statement For STG Foundation Basemat WorksDocument7 paginiMethod Statement For STG Foundation Basemat WorksBijaya RaulaÎncă nu există evaluări

- Ferrocement Construction Technology and Its Applications PDFDocument20 paginiFerrocement Construction Technology and Its Applications PDFPranavaDart0% (1)

- 5 Over 2 Podium Design WoodWorks Part 2Document4 pagini5 Over 2 Podium Design WoodWorks Part 2albertoxinaÎncă nu există evaluări

- Shaft Failure Journal PDFDocument7 paginiShaft Failure Journal PDFBahim BahimanÎncă nu există evaluări

- Khaleeq PaperDocument125 paginiKhaleeq Papervikas chawlaÎncă nu există evaluări

- Part 5 Soil Report ADocument15 paginiPart 5 Soil Report Ashashirajhans2140Încă nu există evaluări

- Environmental System DesignDocument25 paginiEnvironmental System DesignTeweldeÎncă nu există evaluări

- Bio Inspired Passive Drag Reduction Techniques: A ReviewDocument20 paginiBio Inspired Passive Drag Reduction Techniques: A ReviewHasn FXÎncă nu există evaluări

- Flowtite GRP Pipe and Fittings: InstallationDocument8 paginiFlowtite GRP Pipe and Fittings: InstallationMohammed khaleelÎncă nu există evaluări

- B31.3 Process Piping Course - 04 - PressureDesignofMetalsDocument28 paginiB31.3 Process Piping Course - 04 - PressureDesignofMetalslyesÎncă nu există evaluări

- Pipelines 2015 - Recent Advances in Underground Pipeline Engineering and Construction - Proceedings of The Pipelines 2015 Conference, August 23-26, 2015, Baltimore, MarylandDocument1.935 paginiPipelines 2015 - Recent Advances in Underground Pipeline Engineering and Construction - Proceedings of The Pipelines 2015 Conference, August 23-26, 2015, Baltimore, MarylandmabroukÎncă nu există evaluări

- Study Plan Muhammad Hamzah FansuriDocument9 paginiStudy Plan Muhammad Hamzah FansuriMas Hamzah FansuriÎncă nu există evaluări

- Guidelines For Pipe Bursting: U.S. Army Corps of Engineers Engineering Research and Development Center (ERDC)Document55 paginiGuidelines For Pipe Bursting: U.S. Army Corps of Engineers Engineering Research and Development Center (ERDC)Pilar MartínezÎncă nu există evaluări

- Jiroga Weir SchemeDocument10 paginiJiroga Weir SchemeShashi PrakashÎncă nu există evaluări

- RS 114-1-2011 Structural Design - Part 1 ActionsDocument43 paginiRS 114-1-2011 Structural Design - Part 1 Actionsbaher4everÎncă nu există evaluări

- What Is CLSVOFDocument15 paginiWhat Is CLSVOFjimgogreatÎncă nu există evaluări

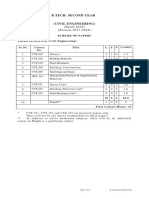

- B.Tech (Civil Engineering) Part-II (Sem III & IV) Batch 2016 PDFDocument27 paginiB.Tech (Civil Engineering) Part-II (Sem III & IV) Batch 2016 PDFHoe BhajiÎncă nu există evaluări

- Difference Between Hot Rolled and Cold Rolled BarsDocument4 paginiDifference Between Hot Rolled and Cold Rolled BarsAlvaroÎncă nu există evaluări

- Series NG 900 Road Pavements - Bituminous Bound Materials: Clause Title Clause TitleDocument52 paginiSeries NG 900 Road Pavements - Bituminous Bound Materials: Clause Title Clause Titlealejandraoy9Încă nu există evaluări