Documente Academic

Documente Profesional

Documente Cultură

Float Test of Bitumen

Încărcat de

anbertjonathanDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Float Test of Bitumen

Încărcat de

anbertjonathanDrepturi de autor:

Formate disponibile

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

10.8 Float Test of Bitumen

10.8.1 Scope

This test is used to determine the floating time of bituminous materials.

10.8.2 Apparatus

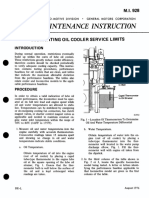

a) Float - The float (Figure 10.8.1 is made of aluminium or aluminium alloy in

accordance with the following requirements :

Min. Normal Max.

Weight of float, g ................................. 37.70 37.90 38.10

Total height of float, mm ..................... 34.00 35.0 36.0

Height of rim above lower side of

shoulder mm ........................................ 26.5 27.0 27.5

Thickness of shoulder, mm ................. 1.3 1.4 1.5

Diameter of opening, mm ..................... 11.0 11.1 11.2

b) Collar - The collar (Figure 10.8.1) is made of brass in accordance with the

following requirements :

Min. Normal Max.

Weight of collar, g ................................ 9.60 9.80 10.00

Over all height of collar, mm ................ 22.3 22.5 22.7

Inside diameter at bottom, mm ............. 12.72 12.82 12.92

Inside diameter at top, mm ............. 9.65 9.70 9.75

The top of the collar shall screw up tightly against the lower side of the shoulder.

c) Calibration of Assembly - The assembled float and collar, with the collar filled flush

with the bottom and weighted to a total weight of 53.2 g, shall float upon water with

the rim 8.5 ± 1.5 mm above the surface of the water. This adjustment of the total

weight of the assembly is for the purpose only of calibrating the depth of

immersion in the testing bath. Dimension of the apparatus additional to those

required above are given in Figure 10.8.1.

d) Thermometer - Having a rang of - 2 to + 80 0C or + 30 to + 180 0F.

e) Water Bath - 185 or more millimetres in its smallest lateral dimension and

containing water 185 or more millimetres in depth. The height of the container

above the water shall be 100 or more millimetres. The bath may be heated by

either a gas or electric heater. A stand or other suitable support shall be

available to hold the thermometer in the proper position in the bath during the

test.

f) Water bath at 5 0C - A water bath of suitable dimensions maintained at 5.0 ± 1.0

0

C, which may be accomplished by means of melting ice.

g) Heater - An oven or hot plate, heated by electricity or gas, for melting samples for

testing.

h) Trimmer - A spatula or steel knife of convenient size.

i) Plate - The plate shall be made of non-absorbent material of convenient size and

of sufficient thickness to prevent deformation. The plate shall be flat so that the

bottom surface of the collar touches it throughout.

j) Timer - A stop watch or other timer graduated in divisions of 1 s or less.

MAY 2001 Page 10.58

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

Methods of sampling and testing

d. m

Ra .6 m

53

92.0± 2.0 mm

27.0±0.5 mm

Thermometer

Hot Float Tapered

11.1± 0.1 mm

35.0±1.0

Bath Tester to make

mm

Weight

m 1.4± 0.1 mm

m

95 ad.

R 12.0±0.5 mm

Float

(Aluminum)

9.70

1.40±0.10 mm ± 0.05

mm

22.5± 0.2 mm

Tapered

3 mm

to make

Weight

Tripod Standard

Support 1.40 ±0.10 12.12

Bunsen mm ±0.10

Burner mm

Collar

(Brass)

Weight of Float, 37.90±0.20 g

Weight of Collar, 9.80±0.20 g

Assembly

Figure 10.8.1 Float Test Apparatus

10.8.3 Procedure

a) The brass collar is placed with the smaller end down on the plate which has been

previously coated with a suitable release agent (Note 1).

Note 1. Mixtures of glycerine and dextrine or talc (3 grams glycerine to about 5

grams dextrine or talc has been used satisfactorily), Dow-Corning

Silicone Stop-Cock Grease, or castor oil-Versamid 900 [100:1 mixture

by weight heated to 204 to 232 0C (400 to 450 0F) and stirred until

homogeneous] have proven suitable. Other release agents may be

used provided results obtained are comparable to those obtained when

using one of the above .

b) The sample shall be completely melted at the lowest possible temperature that

will bring it to a sufficiently fluid condition for easy pouring, excepting creosote-oil

MAY 2001 Page 10.59

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

residues, which shall be mixed and poured at a temperature of 100 to 125 0C. Stir

the sample thoroughly until it is homogeneous and free from air bubbles then

pour it into the collar in any convenient manner until slightly more than level with

the top.

c) Asphalt and Asphalt Products - Asphalt and asphalt products are cooled to room

temperature for 15 to 60 min. then place them for 5 min in the water bath at 5 0C,

after which trim the surplus material flush with the top of the collar by means of a

spatula or steel knife that has been slightly heated. Then the collar and plate are

placed in the water bath at 5 0C and leave them in this bath for not less than 15

nor more than 30 min.

d) The water is heated in the testing bath to the temperature at which the test is to

be made. This temperature shall be accurately maintained without stirring, and

shall at no time throughout the test be allowed to very more than 0.5 0C from the

temperature specified. The temperature shall be determined by immersing the

thermometer with the bottom of the bulb at a depth of 40 ± 2 mm below the water

surface.

e) After the material to be tested has been kept in the water bath at 5 0C for not

less than 15 nor more than 30 min remove the collar with its contents from the

plate and screw into the aluminum float. The assembly is completely immersed for

1 min in the water bath at 5 0C. Then the water is removed inside of the float and

immediately float the assembly on the testing bath. Lateral drift of the assembly

shall be permitted, but no spinning motion shall be intentionally imparted thereto.

As the plug of material becomes warm and fluid, it is forced upward and out of the

collar until the water gains entrance into the saucer and causes it to sink.

f) The time, in seconds, between placing the apparatus in the water and the water

breaking through the material shall be determined by means of a stop watch or

other timer, and shall be taken as a measure of the consistency of the material

under examination.

10.8.4 Precautions

Special precautions should be taken to insure that the collar fits tightly into the float

and to see that there is no seepage of water between the collar and float during the

test.

MAY 2001 Page 10.60

S-ar putea să vă placă și

- NAD Factory Default and Software CheckDocument13 paginiNAD Factory Default and Software CheckNorma FloresÎncă nu există evaluări

- D20S-7 Sb1159e01 PDFDocument678 paginiD20S-7 Sb1159e01 PDFGORDÎncă nu există evaluări

- Casa GrandeDocument6 paginiCasa GrandeXendra AqeylaaÎncă nu există evaluări

- ASTM C 1437 - Flow of MortarsDocument2 paginiASTM C 1437 - Flow of MortarsWan T Trianto80% (5)

- Atlas Bradford (Ver03-Apr05)Document8 paginiAtlas Bradford (Ver03-Apr05)Gabriel IbarraÎncă nu există evaluări

- CIVL354 Notes 1 Soil CompactionDocument20 paginiCIVL354 Notes 1 Soil Compactionmusiomi2005Încă nu există evaluări

- Pavement DistressesDocument45 paginiPavement DistresseswedjefdbenmcveÎncă nu există evaluări

- Bulk Specific GravityDocument9 paginiBulk Specific Gravityelnaqa176Încă nu există evaluări

- Factors Affecting Workability of ConcreteDocument7 paginiFactors Affecting Workability of ConcreteNeseth Eleuterio Badato100% (1)

- Construction and Quality Control of Flexible PavementsDocument83 paginiConstruction and Quality Control of Flexible PavementsSayan GharÎncă nu există evaluări

- Civil Engineering MCQ'S: Ans. (D)Document1 paginăCivil Engineering MCQ'S: Ans. (D)Nishikanta MondalÎncă nu există evaluări

- National Institute of Technology, Patna: Submitted To:-Submitted ByDocument57 paginiNational Institute of Technology, Patna: Submitted To:-Submitted ByVipul MishraÎncă nu există evaluări

- Asphalt ExtractionDocument4 paginiAsphalt ExtractionOsikur RahamanÎncă nu există evaluări

- Mix Design by Marshall MethodDocument27 paginiMix Design by Marshall MethodS K SinghÎncă nu există evaluări

- M.E QuestionsDocument7 paginiM.E QuestionsStephen John ClementeÎncă nu există evaluări

- T122 TorsionalDocument6 paginiT122 Torsionalprabin kumar ashishÎncă nu există evaluări

- CPC-18 Measurement of Hardened Concrete Carbonation Depth: Rilem Recommendations Recommandations de La RilemDocument3 paginiCPC-18 Measurement of Hardened Concrete Carbonation Depth: Rilem Recommendations Recommandations de La RilemmanuelisantosÎncă nu există evaluări

- D 139 AstmDocument3 paginiD 139 AstmNuMbÎncă nu există evaluări

- Unconfined Compression Test - Procedure and Data SheetDocument4 paginiUnconfined Compression Test - Procedure and Data SheetphaeiÎncă nu există evaluări

- Viscosity TestDocument1 paginăViscosity TestDeven PatleÎncă nu există evaluări

- Bitumen ExtractionDocument7 paginiBitumen ExtractionArjun Raj100% (1)

- Dense Bituminous MacadamDocument22 paginiDense Bituminous MacadamahmadsulÎncă nu există evaluări

- CBR Test Procedure Determination of California Bearing Ratio For Road Design PDFDocument5 paginiCBR Test Procedure Determination of California Bearing Ratio For Road Design PDFMohamed AdelÎncă nu există evaluări

- EM 1110-2-1909 - Calibration of Laboratory Soils Testing EquipmentDocument45 paginiEM 1110-2-1909 - Calibration of Laboratory Soils Testing EquipmentPDHLibraryÎncă nu există evaluări

- Water Cement Ratio (Gate60 Short Notes)Document4 paginiWater Cement Ratio (Gate60 Short Notes)akash rathodÎncă nu există evaluări

- RoadCem Manual 2008Document192 paginiRoadCem Manual 2008Esteban FinoÎncă nu există evaluări

- 36) Settlement & Storage of EmulsionDocument3 pagini36) Settlement & Storage of EmulsionPn EkanayakaÎncă nu există evaluări

- Series 4000 - Bituminous Layers and SealsDocument52 paginiSeries 4000 - Bituminous Layers and SealsBatenda Felix0% (1)

- Spec For Sand CementDocument5 paginiSpec For Sand CementHüseyin EkiciÎncă nu există evaluări

- BS 5835-1-1980 PDFDocument21 paginiBS 5835-1-1980 PDFMohammad Twaha JaumbocusÎncă nu există evaluări

- Astm d1856Document3 paginiAstm d1856Jose AruquipaÎncă nu există evaluări

- BS EN 933-2 - Nominal Size of Apetures PDFDocument8 paginiBS EN 933-2 - Nominal Size of Apetures PDFCraig LongÎncă nu există evaluări

- Effect of Varying Mixing & Compaction Temperature On Marshall Properties of Bituminous Concrete MixDocument44 paginiEffect of Varying Mixing & Compaction Temperature On Marshall Properties of Bituminous Concrete Mixshiva5059100% (1)

- Compaction Factor Test&Slump Test ReportDocument1 paginăCompaction Factor Test&Slump Test ReportMUN SIM SOHÎncă nu există evaluări

- Percolation TestDocument3 paginiPercolation TestKothiyal MukeshÎncă nu există evaluări

- Concrete Mix Design C 25 For KamoaDocument9 paginiConcrete Mix Design C 25 For KamoaMitendra Kumar ChauhanÎncă nu există evaluări

- M 20-70 (2004) Penetration-Graded Asphalt CementDocument2 paginiM 20-70 (2004) Penetration-Graded Asphalt CementWalticoZegarraHerreraÎncă nu există evaluări

- Flexural Strength of ConcreteDocument4 paginiFlexural Strength of ConcreteAicet Guru0% (1)

- Flexural Modulus of Elasticity of Dimension Stone: Standard Test Method ForDocument3 paginiFlexural Modulus of Elasticity of Dimension Stone: Standard Test Method ForRufo CascoÎncă nu există evaluări

- Fly Ash As Binder in ConcreteDocument10 paginiFly Ash As Binder in ConcreteZuhair NadeemÎncă nu există evaluări

- Specific Gravity and Absorption of Fine Aggregate: Standard Method of Test ForDocument10 paginiSpecific Gravity and Absorption of Fine Aggregate: Standard Method of Test ForDannyChaconÎncă nu există evaluări

- Astm Ac20Document3 paginiAstm Ac20Juan QuiñonesÎncă nu există evaluări

- R0028 Manual of Cement Testing PDFDocument18 paginiR0028 Manual of Cement Testing PDFKennedy Kenzo Ken ObochelengÎncă nu există evaluări

- TE Lab Manual - 2017 New - 2.1 LatestDocument94 paginiTE Lab Manual - 2017 New - 2.1 LatestArundhathi PushpagaranÎncă nu există evaluări

- Exp 3 - Ten Percent Fines ValueDocument6 paginiExp 3 - Ten Percent Fines ValueMd Tanvir Haider 191-47-915Încă nu există evaluări

- Astm C143 C143MDocument4 paginiAstm C143 C143MhavalÎncă nu există evaluări

- Cube TestDocument10 paginiCube Testridhuanzainal100% (1)

- Mixing and Compaction Temp of Modified BindersDocument9 paginiMixing and Compaction Temp of Modified BindersreashmapsÎncă nu există evaluări

- Mechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Document10 paginiMechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Kamukwema johnÎncă nu există evaluări

- 2015 Calibration ScheduleDocument11 pagini2015 Calibration SchedulechinhonÎncă nu există evaluări

- Tutorial 1Document9 paginiTutorial 1Alfred PatrickÎncă nu există evaluări

- Development of in Situ Mass Stabilization Technique in FinlandDocument6 paginiDevelopment of in Situ Mass Stabilization Technique in Finlandvickneshj9406Încă nu există evaluări

- Is Concrete Mix DesignDocument21 paginiIs Concrete Mix DesignahmedanyÎncă nu există evaluări

- Question 1-Open EndedDocument4 paginiQuestion 1-Open EndedAshadi HamdanÎncă nu există evaluări

- Micro Surfacing Process Design Overview - 0Document3 paginiMicro Surfacing Process Design Overview - 0RenugopalÎncă nu există evaluări

- Creep NCHRPDocument106 paginiCreep NCHRPFranklinÎncă nu există evaluări

- Aggregate Mix DesignDocument5 paginiAggregate Mix DesignFatma MerxhaniÎncă nu există evaluări

- BitumenDocument76 paginiBitumenvasudeva yasasÎncă nu există evaluări

- Valid Design: Design of Two Way Slab (S-1)Document1 paginăValid Design: Design of Two Way Slab (S-1)Pipoy ReglosÎncă nu există evaluări

- Project Name Engineer Ref Dwg. No. Approver: ABC Building XX-XX-XX Project ManagerDocument9 paginiProject Name Engineer Ref Dwg. No. Approver: ABC Building XX-XX-XX Project ManagerFritz NatividadÎncă nu există evaluări

- Diseño Muro H 4MDocument4 paginiDiseño Muro H 4MPedro FloresÎncă nu există evaluări

- 324 Prespan Weidmann 7Document2 pagini324 Prespan Weidmann 7hiren_mistry55Încă nu există evaluări

- Certificate of Analysis Conveyor Belt PT. Mutiara Tanjung Lestari Order Tahun 2022Document29 paginiCertificate of Analysis Conveyor Belt PT. Mutiara Tanjung Lestari Order Tahun 2022RestuÎncă nu există evaluări

- Waqtc tm11Document3 paginiWaqtc tm11Perkresht PawarÎncă nu există evaluări

- Section 916 Bituminous Materials 916-1 GeneralDocument4 paginiSection 916 Bituminous Materials 916-1 GeneralanbertjonathanÎncă nu există evaluări

- Report About Fish PDFDocument18 paginiReport About Fish PDFanbertjonathanÎncă nu există evaluări

- Pipe Precast 4 9 2019 PDFDocument9 paginiPipe Precast 4 9 2019 PDFanbertjonathanÎncă nu există evaluări

- Fishery v4n1p54 Fa PDFDocument40 paginiFishery v4n1p54 Fa PDFanbertjonathanÎncă nu există evaluări

- Aashto T 255 and 265 2014Document8 paginiAashto T 255 and 265 2014anbertjonathanÎncă nu există evaluări

- Curing, Capping and Determining The Compressive Strength of Cylindrical Concrete SpecimensDocument13 paginiCuring, Capping and Determining The Compressive Strength of Cylindrical Concrete SpecimensanbertjonathanÎncă nu există evaluări

- Material Sampling and Testing of Existing Hot-Mix Asphalt PavementsDocument3 paginiMaterial Sampling and Testing of Existing Hot-Mix Asphalt PavementsanbertjonathanÎncă nu există evaluări

- MREI 11-01 VTrans Subsurface Investigation Process Engineering PDFDocument11 paginiMREI 11-01 VTrans Subsurface Investigation Process Engineering PDFanbertjonathanÎncă nu există evaluări

- MREI 11-01 VTrans Subsurface Investigation Process Engineering PDFDocument11 paginiMREI 11-01 VTrans Subsurface Investigation Process Engineering PDFanbertjonathanÎncă nu există evaluări

- Density (Unit Weight), Yield, and Air Content (Gravimetric) of ConcreteDocument4 paginiDensity (Unit Weight), Yield, and Air Content (Gravimetric) of ConcreteYanny FfsÎncă nu există evaluări

- Sampling Hot Mix Asphalt (Hma) After Compaction (Obtaining Cores) Waqtc TM 11 ScopeDocument4 paginiSampling Hot Mix Asphalt (Hma) After Compaction (Obtaining Cores) Waqtc TM 11 ScopejojomarbunÎncă nu există evaluări

- Note 1: Tests Run On Extracted or Belt Run Mixture Samples Are Considered To Be TheDocument6 paginiNote 1: Tests Run On Extracted or Belt Run Mixture Samples Are Considered To Be TheanbertjonathanÎncă nu există evaluări

- HMA PlantTech FieldManual PDFDocument249 paginiHMA PlantTech FieldManual PDFanbertjonathanÎncă nu există evaluări

- Normal Consistency of Hydraulic Cement T129Document4 paginiNormal Consistency of Hydraulic Cement T129Willard ApengÎncă nu există evaluări

- CADD Work Plan PDFDocument8 paginiCADD Work Plan PDFanbertjonathanÎncă nu există evaluări

- EBA00011 0116 Testing Lab Handout - v2Document1 paginăEBA00011 0116 Testing Lab Handout - v2anbertjonathanÎncă nu există evaluări

- Aashto T 166Document10 paginiAashto T 166Chainun Taidamrong100% (1)

- CADD Work PlanDocument8 paginiCADD Work PlananbertjonathanÎncă nu există evaluări

- Slump of Hydraulic Cement Concrete Fop For Aashto T 119Document2 paginiSlump of Hydraulic Cement Concrete Fop For Aashto T 119anbertjonathanÎncă nu există evaluări

- Procedure Checklist ASTM C430/AASHTO T192 Fineness of Hydraulic Cement by 325 SieveDocument1 paginăProcedure Checklist ASTM C430/AASHTO T192 Fineness of Hydraulic Cement by 325 SieveanbertjonathanÎncă nu există evaluări

- Lesson03 IsDocument106 paginiLesson03 IsmuhanadÎncă nu există evaluări

- 248Document8 pagini248Dileepa DissanayakeÎncă nu există evaluări

- Maintaining Gravel Roads SpecsDocument7 paginiMaintaining Gravel Roads SpecsanbertjonathanÎncă nu există evaluări

- 3 TopologyDocument8 pagini3 TopologyHusam A. Al-HaidriÎncă nu există evaluări

- Time Impact Analysis by BrewerConsultingDocument3 paginiTime Impact Analysis by BrewerConsultingAAKÎncă nu există evaluări

- TM - A5ck, CC, CM - y PDFDocument102 paginiTM - A5ck, CC, CM - y PDFslipargolokÎncă nu există evaluări

- Wavin QuickStream Specification Oct 14Document6 paginiWavin QuickStream Specification Oct 14Syahrisal SaputraÎncă nu există evaluări

- Chapter 1 AnswersDocument3 paginiChapter 1 Answersdeerhntr22Încă nu există evaluări

- ANTENASDocument10 paginiANTENASGreo HernandezÎncă nu există evaluări

- Managerial Communication - (MC) - SEM I-GTUDocument93 paginiManagerial Communication - (MC) - SEM I-GTUkeyurÎncă nu există evaluări

- Ebara Pump Brochure DML-DMLFDocument15 paginiEbara Pump Brochure DML-DMLFkutecoolÎncă nu există evaluări

- Opamp 5Document42 paginiOpamp 5Ann RazonÎncă nu există evaluări

- Detailed Lesson Log in MathematicsDocument7 paginiDetailed Lesson Log in MathematicsChan Chan100% (1)

- SAS Hot Fix Analysis Download and Deployment ToolDocument11 paginiSAS Hot Fix Analysis Download and Deployment ToolAdrian GallegosÎncă nu există evaluări

- Cabezas de Rotulas-RotulasDocument64 paginiCabezas de Rotulas-RotulasFRANCISCO100% (1)

- Emd-Mi928 Sistema de LubricacionDocument6 paginiEmd-Mi928 Sistema de LubricacionVictor Raul Tobosque Muñoz100% (1)

- Based On CIRIA Report 108:1985: Formwork Load Calculator - ResultsDocument4 paginiBased On CIRIA Report 108:1985: Formwork Load Calculator - Resultsyassir dafallaÎncă nu există evaluări

- Calculating The Pathlength of Liquid Cells by FTIR PIKEDocument1 paginăCalculating The Pathlength of Liquid Cells by FTIR PIKEMoises RomeroÎncă nu există evaluări

- Characterization and Application of Cerium Fluoride Film in InfraredDocument4 paginiCharacterization and Application of Cerium Fluoride Film in InfrarednguyenthanhhopÎncă nu există evaluări

- RedBull MediaHouseDocument15 paginiRedBull MediaHousedr989981Încă nu există evaluări

- Software Project Engineer in Richland Kennewick Pasco WA Resume Robert VeklotzDocument2 paginiSoftware Project Engineer in Richland Kennewick Pasco WA Resume Robert VeklotzRobertVeklotzÎncă nu există evaluări

- Trane VAV Equipment SpecificationsDocument52 paginiTrane VAV Equipment Specificationsyu4212Încă nu există evaluări

- Ta Elastomer Cure DatesDocument3 paginiTa Elastomer Cure DatesRay FaiersÎncă nu există evaluări

- Fenelon - Dialogues With The DeadDocument279 paginiFenelon - Dialogues With The DeadjuanojedamenaÎncă nu există evaluări

- Texture Formats Used by CFS3Document2 paginiTexture Formats Used by CFS3Hillmen HussinÎncă nu există evaluări

- Aicte 2010 EVENDocument105 paginiAicte 2010 EVENbalusharma1212Încă nu există evaluări

- English For Information Technology TEST 1 (Time: 90 Minutes)Document30 paginiEnglish For Information Technology TEST 1 (Time: 90 Minutes)Lộc Ngô XuânÎncă nu există evaluări

- Renderoc RsxtraDocument4 paginiRenderoc RsxtraBalasubramanian AnanthÎncă nu există evaluări

- M.Tech. 2nd (Non CBCS) May 2018 - 9 - 5 - 18Document2 paginiM.Tech. 2nd (Non CBCS) May 2018 - 9 - 5 - 18doob marroÎncă nu există evaluări

- Bituthene Mastic - Data SheetDocument2 paginiBituthene Mastic - Data SheettamilnishaÎncă nu există evaluări

- Maintenance and Repair Instructions TM 124/11: Spring-Applied Sliding Caliper Brake FSG110 With Hub CenteringDocument11 paginiMaintenance and Repair Instructions TM 124/11: Spring-Applied Sliding Caliper Brake FSG110 With Hub CenteringNik100% (1)