Documente Academic

Documente Profesional

Documente Cultură

Japan AE HV VCB

Încărcat de

Anonymous j5apk2Aum0 evaluări0% au considerat acest document util (0 voturi)

44 vizualizări2 paginiDrepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

44 vizualizări2 paginiJapan AE HV VCB

Încărcat de

Anonymous j5apk2AumDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

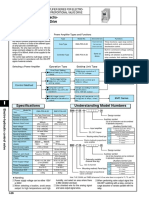

N E W S F R O M J A P A N

From these viewpoints, Japan AE Another idea is to optimize the elec-

Power Systems Corporation, which was tric field distribution by considering the

formed in July 2001, unifying the power conditioning effect, which is a well-known

transmission and distribution systems fact that repetition of discharges removes

business of Hitachi, Ltd., Fuji Electric flaws in the vacuum insulation, such as

Co., Ltd., and Meidensha Corporation has micro protrusions or contaminants on the

developed some leading-edge, high-volt- electrode surface and considerably in-

age VCBs. Their first venture in the 21st creases the breakdown voltage. Although

century is the development of a 145 kV/ this effect is complicated and sensitive,

40 kA VCB, shown in Figure 1, with a its full utilization is necessary for a high-

single-break system and its vacuum inter- voltage vacuum interrupter. Therefore,

by rupter shown in Figure 2. Prof. Hitoshi Okubo and his research as-

Y. Ohki To achieve a very high withstand volt- sociates in Nagoya University conducted

age, various measures were tried. A a joint study with Japan AE Power Sys-

simple idea is making it large in scale. tems to gain a thorough understanding of

According to the clump theory of vacuum the conditioning phenomena for nonuni-

Japan AE Power Systems breakdown, the breakdown voltage is pro- form long gaps. They found that the break-

Develops High-Voltage, portional to the square root of the gap down electric field strength became al-

Vacuum Circuit Breakers length. This means a similarly extended most constant for a well-conditioned gap

vacuum interrupter leads to an inefficient with a distance longer than 10 mm as

In Japan, high-voltage, vacuum circuit product in terms of cost and voltage with- shown in Figure 3. This result indicates

breakers (VCBs) underwent intensive de- stand performance. that the breakdown strength of a fully con-

velopment during the 1970s. The maxi-

mum rated voltage of a commercial VCB

before the 1990s was 84 kV for the dead-

tank type with a single-break interrupter,

and 168 kV for the live-tank type with

double-break unit. However, SF6-gas cir-

cuit breakers (GCBs) also have been de-

veloped actively since the 1960s. For

voltages over 72 kV, GCBs have great

advantages over VCBs in terms of

downsizing and cost reduction due to the

high-current interruption and voltage-

withstanding performance of SF 6 gas.

However, as SF6 gas has the potential to

be a major contributor to global warm-

ing, its consumption and release into the

atmosphere must be reduced. Thus, a

wider use of VCBs is an ideal solution

from an environmental perspective, be-

cause VCBs do not use SF6 gas for cur-

rent interruption, and they have many

other outstanding features such as com-

pactness, lightness in weight, ease of

maintenance and inspection, no environ-

mental damage, long operation life, su-

perior total life cycle cost, and so on. If

the rated voltage of VCBs could be in-

Figure 1. A prototype 145kV/40kA vacuum circuit breaker with a single-break

creased, their use could provide a new

interrupter per pole.

avenue for circuit breakers.

48 IEEE Electrical Insulation Magazine

to overhauling and scrapping. However,

the air-insulated VCBs can release the in-

sulation gas into the atmosphere without

any problems.

The company regards its developed

VCBs a key technology to an environmen-

tally friendly society. It developed the

world’s first 72/84 kV completely SF6-free

dead-tank type VCBs in 2004, and over

30 units have been installed in electric

power systems in Japan. Its vacuum in-

Figure 2. A vacuum interrupter used for the 145 kV/40 kA single-break, vacuum terrupter is compact and is able to with-

circuit breaker. stand high-pressure dry air with its spe-

cial bellows and ceramic envelope.

ditioned vacuum interrupter could be con- interruptions also contributes The company has announced that a

trolled by the electric field distribution, to minimization of the overall size of a more compact 72.5 kV dry air-insulated

even in the long-gap system. Practically, vacuum interrupter. Its structure has been dead-tank VCB shown in Figure 4 will be

the conditioning process for products is a improved with an even smaller size thanks commercialized soon. It uses a new seal-

combination of several high-voltage and to computer-aided analyses and measure- ing system that can reduce the pressure

large-current discharge processes. The ment techniques since it first appeared in on the bellows, which allows using a con-

know-how needed for this was built up the 1980s. ventional vacuum interrupter with normal

through the long history of manufactur- It is also important to note that this 145 bellows.

ing. kV VCB is a circuit breaker using dry air This article was completed with coop-

The electrode material is also impor- for internal insulation and is completely eration of Dr. Hitoshi Saito of Japan AE

tant. In the 1980s, Cu-Cr-based materi- free fromSF6. Most conventional gas-in- Power Systems.

als with superior current interruption per- sulated VCBs use SF6 for internal insula-

formance and withstand voltages came tion, and this necessitates a gas recovery

into use. In order to achieve a higher with- operation at each stage, from inspection

stand voltage, the company increased its

Cr content. Adequate design of an axial

magnetic field electrode that can

well control vacuum arcs upon current

Figure 3. Relationship between the breakdown field

strength and gap distance in high vacuum with a rod- Figure 4 A new 72.5 kV/31.5 kA dry, air-insulated, dead-tank

plane electrode system. The letter R represents the type vacuum circuit breaker.

radius of the rod electrode.

January/February 2007 — Vol. 23, No. 1 49

S-ar putea să vă placă și

- 21-26 EngDocument6 pagini21-26 EngVaibhav SanÎncă nu există evaluări

- Wet Aging of MV XLPE CablesDocument7 paginiWet Aging of MV XLPE CablesiiscbangaloreÎncă nu există evaluări

- Cigre Insulated Cable Energy TransmissionDocument15 paginiCigre Insulated Cable Energy TransmissionllovarÎncă nu există evaluări

- 2nd PPT For VCBDocument15 pagini2nd PPT For VCBShaikh Tauqeer AhmedÎncă nu există evaluări

- 2017-An Assessment of Material Selection For High Voltage DCDocument5 pagini2017-An Assessment of Material Selection For High Voltage DCmajidÎncă nu există evaluări

- INT Switchgear Developments For IMEDocument7 paginiINT Switchgear Developments For IMEcarlos vidalÎncă nu există evaluări

- A Wide Band Gap Devices Based Switched Capacitor Circuits For Photovoltaic ApplicationsDocument10 paginiA Wide Band Gap Devices Based Switched Capacitor Circuits For Photovoltaic ApplicationsMIKS DARKÎncă nu există evaluări

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingDe la EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingÎncă nu există evaluări

- Testing High-Voltage: Electrical Insulation Rotating Machinery DirectDocument16 paginiTesting High-Voltage: Electrical Insulation Rotating Machinery DirectJairo Corimanya SeminarioÎncă nu există evaluări

- Modern HVDC: State of The Art and Development Trends: Víctor F. LescaleDocument5 paginiModern HVDC: State of The Art and Development Trends: Víctor F. Lescalenithin krishnaÎncă nu există evaluări

- 5.a High Voltage Gain DC-DC Converter Based On Three WindingDocument9 pagini5.a High Voltage Gain DC-DC Converter Based On Three Windingreza mohajeryÎncă nu există evaluări

- Vacuum Switchgear Past Present and FutureDocument6 paginiVacuum Switchgear Past Present and FutureyvetteÎncă nu există evaluări

- Ultra High-Voltage Gas-Insulated Switchgear - A Technology MilestoneDocument24 paginiUltra High-Voltage Gas-Insulated Switchgear - A Technology MilestoneSa'dun ArifÎncă nu există evaluări

- Zhao F., Hu B., Yang H. & Wang Y., (2017), Development of An Indoor 40.5 KV Vacuum Circuit Breaker For Back-To-Back Capacitor Bank Switching Duty PDFDocument4 paginiZhao F., Hu B., Yang H. & Wang Y., (2017), Development of An Indoor 40.5 KV Vacuum Circuit Breaker For Back-To-Back Capacitor Bank Switching Duty PDFRicardo Rivas ZuñigaÎncă nu există evaluări

- Modelling of Dry Lightning Impulse Test On 145 KV Oil Impregnated Paper Bushing For High Voltage TransformerDocument6 paginiModelling of Dry Lightning Impulse Test On 145 KV Oil Impregnated Paper Bushing For High Voltage TransformerFaridah HassanÎncă nu există evaluări

- A Study of Power Formers and Their Impact On Power System Reliability and EnvironmentDocument9 paginiA Study of Power Formers and Their Impact On Power System Reliability and EnvironmentdhcpÎncă nu există evaluări

- SACE Low Voltage Air Circuit-Breakers: Sometimes Evolution Takes A LeapDocument16 paginiSACE Low Voltage Air Circuit-Breakers: Sometimes Evolution Takes A Leaphonafa- R.O.N.OÎncă nu există evaluări

- Cci Ehv CableDocument27 paginiCci Ehv Cableswagata12345Încă nu există evaluări

- A New Type of Oil-Free Power Transformer With Low Environmental ImpactDocument6 paginiA New Type of Oil-Free Power Transformer With Low Environmental ImpactOSAMAÎncă nu există evaluări

- 04073335Document9 pagini04073335Bodhayan PrasadÎncă nu există evaluări

- Base PaperDocument11 paginiBase PaperDhanush NÎncă nu există evaluări

- 3286-Article Text-13228-1-10-20190808Document6 pagini3286-Article Text-13228-1-10-20190808David RodríguezÎncă nu există evaluări

- Development and Characteristics of A 1000000-Volt Cascade Transformer at CaliforDocument6 paginiDevelopment and Characteristics of A 1000000-Volt Cascade Transformer at CaliforTiago GonçalvesÎncă nu există evaluări

- An Actively Cooled Coaxial Winding Transformer For Fast Charging Electric VehiclesDocument8 paginiAn Actively Cooled Coaxial Winding Transformer For Fast Charging Electric VehiclesJaroslav KnopÎncă nu există evaluări

- Met Is 123209Document9 paginiMet Is 123209shahinÎncă nu există evaluări

- An Integrated Step-Up Inverter Without Transformer and Leakage Current For Grid-Connected Photovoltaic SystemDocument14 paginiAn Integrated Step-Up Inverter Without Transformer and Leakage Current For Grid-Connected Photovoltaic SystemroyÎncă nu există evaluări

- Super-Capacitor Based UpsDocument15 paginiSuper-Capacitor Based Upsakashlogic100% (1)

- Generation of The Large DC Gain Step-UpDocument18 paginiGeneration of The Large DC Gain Step-Upahmedallehyani5aÎncă nu există evaluări

- Ian Poole Reports On A New Device That Provides Both Current and Voltage ControlDocument2 paginiIan Poole Reports On A New Device That Provides Both Current and Voltage Controlsuperser123465Încă nu există evaluări

- Presenting A New Method To Estimate The Remaining Life of Aerial Bundled Cable NetworkDocument5 paginiPresenting A New Method To Estimate The Remaining Life of Aerial Bundled Cable NetworknoumanraoÎncă nu există evaluări

- 2000 Development of A RFB SystemDocument7 pagini2000 Development of A RFB SystemEGLÎncă nu există evaluări

- HV BushingsDocument5 paginiHV BushingssabrahimaÎncă nu există evaluări

- IET Power Electronics - 2020 - Lopez Santos - Quadratic Boost Converter With Low Output Voltage RippleDocument9 paginiIET Power Electronics - 2020 - Lopez Santos - Quadratic Boost Converter With Low Output Voltage RippleRenato GiugniÎncă nu există evaluări

- Top Cable Catálogo Solar Cables For PV InstallationsDocument25 paginiTop Cable Catálogo Solar Cables For PV InstallationsVEMATELÎncă nu există evaluări

- CIGRE 2012: 21, Rue D'artois, F-75008 PARISDocument6 paginiCIGRE 2012: 21, Rue D'artois, F-75008 PARISfgdfgdfÎncă nu există evaluări

- JJicable 11Document5 paginiJJicable 11WardencasianAlanisÎncă nu există evaluări

- Disconnectors Reliability On The French Grid and Means To Reduce The Consequences of Their FailuresDocument7 paginiDisconnectors Reliability On The French Grid and Means To Reduce The Consequences of Their Failureskushwah9kpriyaÎncă nu există evaluări

- Breathe Easy (Electrostatic Precipitator)Document6 paginiBreathe Easy (Electrostatic Precipitator)wessamÎncă nu există evaluări

- Pushing Gis Limits To New Horizons Think Grid Gis Limits Tg11pdfthe AlstomDocument4 paginiPushing Gis Limits To New Horizons Think Grid Gis Limits Tg11pdfthe Alstomabdalla AljzÎncă nu există evaluări

- 50 Years in Icing Performance of Outdoor InsulatorsDocument12 pagini50 Years in Icing Performance of Outdoor Insulatorssridhar_gandra1253Încă nu există evaluări

- Reviewof Supercapacitor TechnologyDocument7 paginiReviewof Supercapacitor Technologypaganag333Încă nu există evaluări

- CAble Injection - A Green Method For Cable Diagnostics Coupled - 2010Document4 paginiCAble Injection - A Green Method For Cable Diagnostics Coupled - 2010Ali NaderianÎncă nu există evaluări

- Insulation Co-ordination in High-voltage Electric Power SystemsDe la EverandInsulation Co-ordination in High-voltage Electric Power SystemsEvaluare: 4.5 din 5 stele4.5/5 (5)

- GPV Fuse: Special Characteristics For Photo Voltaic Cells ProtectionDocument9 paginiGPV Fuse: Special Characteristics For Photo Voltaic Cells ProtectionnmulyonoÎncă nu există evaluări

- 2016 - Evaluation of An Integrated Roof Wind Energy System For Urban EnvironmentsDocument12 pagini2016 - Evaluation of An Integrated Roof Wind Energy System For Urban EnvironmentsKhoirul BeÎncă nu există evaluări

- Novel Concept in High Voltage Generation: Powerformertm: A New Generator, Powerformertm, Which IsDocument4 paginiNovel Concept in High Voltage Generation: Powerformertm: A New Generator, Powerformertm, Which IsnandhakumarmeÎncă nu există evaluări

- JEE SampleDocument9 paginiJEE Samplejebarani.s.eeeÎncă nu există evaluări

- Novel Silicon Carbide Integrated Power Module For EV ApplicationDocument5 paginiNovel Silicon Carbide Integrated Power Module For EV ApplicationBhawna GuptaÎncă nu există evaluări

- Environmentally - Friendly - Compact - Air - Insulated Substation AlternativesDocument14 paginiEnvironmentally - Friendly - Compact - Air - Insulated Substation AlternativesLindo PatoÎncă nu există evaluări

- Webarticle Blue Switch enDocument5 paginiWebarticle Blue Switch envijayÎncă nu există evaluări

- A High-Input Power Rectifier Circuit For 2.45Ghz Microwave Wireless Power TransmissionDocument8 paginiA High-Input Power Rectifier Circuit For 2.45Ghz Microwave Wireless Power Transmissionsaeed gholamiÎncă nu există evaluări

- Automation, Protection, Switching Applications: Gas-Free, Oil-Free, Maintenance-Free Easy Handling, Easy InstallationDocument28 paginiAutomation, Protection, Switching Applications: Gas-Free, Oil-Free, Maintenance-Free Easy Handling, Easy InstallationItalo MartinangeliÎncă nu există evaluări

- Cables (HT<) : Energy Estimation & Audit (15ee430)Document73 paginiCables (HT<) : Energy Estimation & Audit (15ee430)rohith mukkamalaÎncă nu există evaluări

- Power FormerDocument6 paginiPower FormerVijay RichardÎncă nu există evaluări

- Electric and Magnetic Fields in 400kv Compact SubstationDocument6 paginiElectric and Magnetic Fields in 400kv Compact Substationlcm3766lÎncă nu există evaluări

- Submarine Solutions 2015 B3 6 Extension of Qualification Applied On A MV Extruded Submarine Cable in France PDFDocument4 paginiSubmarine Solutions 2015 B3 6 Extension of Qualification Applied On A MV Extruded Submarine Cable in France PDFcskkrakenÎncă nu există evaluări

- Ups GraphsDocument7 paginiUps GraphsHouse of WisdomÎncă nu există evaluări

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDe la Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsEvaluare: 4 din 5 stele4/5 (1)

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringDe la EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringÎncă nu există evaluări

- (1 - 02) Capacitors Type EX-7L Single-Phase UnitsDocument4 pagini(1 - 02) Capacitors Type EX-7L Single-Phase UnitsDaniela Emilia Insuaste CorreaÎncă nu există evaluări

- MiCOM P44xDocument8 paginiMiCOM P44xnotsag001Încă nu există evaluări

- Power CapacitorDocument2 paginiPower Capacitorkunsridhar8901Încă nu există evaluări

- ANSI MV TechTopics28 EN PDFDocument3 paginiANSI MV TechTopics28 EN PDFAnonymous j5apk2AumÎncă nu există evaluări

- SotfDocument2 paginiSotfDanielÎncă nu există evaluări

- Cu0144 - Efficiency and Loss Evaluation of Large Power Transformers - v1 PDFDocument23 paginiCu0144 - Efficiency and Loss Evaluation of Large Power Transformers - v1 PDFAnonymous j5apk2AumÎncă nu există evaluări

- Merriam-Webster's A Dictionary of Prefixes, Suffixes, and Combining FormsDocument62 paginiMerriam-Webster's A Dictionary of Prefixes, Suffixes, and Combining FormsEchoing Memories95% (55)

- Line Post - Catalog NGKDocument23 paginiLine Post - Catalog NGKRantaroÎncă nu există evaluări

- MobileDocument43 paginiMobileAnonymous j5apk2AumÎncă nu există evaluări

- MobileDocument43 paginiMobileAnonymous j5apk2AumÎncă nu există evaluări

- MobileDocument40 paginiMobileAnonymous j5apk2AumÎncă nu există evaluări

- Catalogue TD InsulatorsDocument24 paginiCatalogue TD InsulatorsmartinpellsÎncă nu există evaluări

- Evaluation of Different Switchgear Technologies Ais Mtsgis PDFDocument96 paginiEvaluation of Different Switchgear Technologies Ais Mtsgis PDFAbdallah SalemÎncă nu există evaluări

- whr08 enDocument357 paginiwhr08 enzaheeruddin_mohdÎncă nu există evaluări

- Multi-Step Back-To-Back Capacitor Bank Switching On 115 KV SubstationDocument5 paginiMulti-Step Back-To-Back Capacitor Bank Switching On 115 KV SubstationAnonymous j5apk2AumÎncă nu există evaluări

- Water FaqDocument17 paginiWater FaqgimanbenÎncă nu există evaluări

- Tamco GV3NDocument15 paginiTamco GV3NAnonymous j5apk2AumÎncă nu există evaluări

- 6288 ControlledSwitching DT-JP-DG 20080206 WebDocument17 pagini6288 ControlledSwitching DT-JP-DG 20080206 Webbramhanand vermaÎncă nu există evaluări

- Tamco GV3NDocument15 paginiTamco GV3NAnonymous j5apk2AumÎncă nu există evaluări

- Cold Weather Operating Problems With SF Circuit Breakers: IEEE StandardsDocument13 paginiCold Weather Operating Problems With SF Circuit Breakers: IEEE StandardsAnonymous j5apk2AumÎncă nu există evaluări

- Kerchnar K.214 PDFDocument12 paginiKerchnar K.214 PDFAnonymous j5apk2AumÎncă nu există evaluări

- Dlink Dir-615 DsDocument2 paginiDlink Dir-615 DsAnonymous j5apk2AumÎncă nu există evaluări

- FedreDocument283 paginiFedreAnonymous j5apk2AumÎncă nu există evaluări

- Dcs 930l b1 Manual v2 10 WWDocument62 paginiDcs 930l b1 Manual v2 10 WWElias ACHI HALLÎncă nu există evaluări

- JVC Car Stereo KD-S595 Schematic DiagramDocument10 paginiJVC Car Stereo KD-S595 Schematic DiagramAnonymous j5apk2AumÎncă nu există evaluări

- Panasonic Air Con CWXC103VUDocument16 paginiPanasonic Air Con CWXC103VUAnonymous j5apk2AumÎncă nu există evaluări

- JVC Car Stereo KD-S595 Parts ListDocument13 paginiJVC Car Stereo KD-S595 Parts ListAnonymous j5apk2AumÎncă nu există evaluări

- JVC Car Stereo KD-S595 Schematic DiagramDocument10 paginiJVC Car Stereo KD-S595 Schematic DiagramAnonymous j5apk2AumÎncă nu există evaluări

- JVC Car Stereo KD-S595 Service ManualDocument42 paginiJVC Car Stereo KD-S595 Service ManualAnonymous j5apk2AumÎncă nu există evaluări

- 45TTBFDocument28 pagini45TTBFRobÎncă nu există evaluări

- Brushless Excitation For Hydro GeneratorsDocument24 paginiBrushless Excitation For Hydro GeneratorsEliyanto E BudiartoÎncă nu există evaluări

- Operation Manual - Erection and MaintenanceDocument697 paginiOperation Manual - Erection and MaintenanceJuan Peña BáezÎncă nu există evaluări

- Series BootsDocument2 paginiSeries Bootsvictor laraÎncă nu există evaluări

- DTC 144 EkaDocument3 paginiDTC 144 EkaHicham DiabeÎncă nu există evaluări

- Hysense Pr100 / Pr110 Mobile Pressure SensorDocument2 paginiHysense Pr100 / Pr110 Mobile Pressure SensorANDRES DEGADOÎncă nu există evaluări

- Bom SWBD2Document2 paginiBom SWBD2Prasanna SinthajeÎncă nu există evaluări

- Lucas Wire Colour Codes For Land RoverDocument5 paginiLucas Wire Colour Codes For Land RoverRobert KrugerÎncă nu există evaluări

- Siemens VL250Document4 paginiSiemens VL250Mạnh LêÎncă nu există evaluări

- Smart Roads - 3rd EvaluationDocument23 paginiSmart Roads - 3rd EvaluationUmeshÎncă nu există evaluări

- Single-Phase Bridge RectifierDocument4 paginiSingle-Phase Bridge RectifiercarlosÎncă nu există evaluări

- Low Voltage-380vacDocument1 paginăLow Voltage-380vacTantely RazafimahatratraÎncă nu există evaluări

- 160 69-rp1Document12 pagini160 69-rp1Nha Trang100% (1)

- SubstationControl InterlockingDocument14 paginiSubstationControl Interlockingdundi_kumarÎncă nu există evaluări

- H1000e I Ema-Emc PDFDocument4 paginiH1000e I Ema-Emc PDFNguyen Van ChungÎncă nu există evaluări

- Ip-Xdr Verter-08 - 080610Document4 paginiIp-Xdr Verter-08 - 080610flavioovalle100% (1)

- Zig Zag TransformersDocument8 paginiZig Zag Transformersblprasad50% (4)

- Mac 156Document4 paginiMac 156digitonicsÎncă nu există evaluări

- Paulinesh Experiment 2 Bs Ece PDFDocument20 paginiPaulinesh Experiment 2 Bs Ece PDFBrian Jay G. DinoyÎncă nu există evaluări

- Handout 6.11.bDocument2 paginiHandout 6.11.bManeehaÎncă nu există evaluări

- FVR Micro S2 IM INR-SI47-1921b-E - 20160914Document98 paginiFVR Micro S2 IM INR-SI47-1921b-E - 20160914kayak10Încă nu există evaluări

- Voltage RegularotDocument39 paginiVoltage RegularotchaninpmsÎncă nu există evaluări

- Abb Power Supply CP - 24/20.0Document8 paginiAbb Power Supply CP - 24/20.0Ricardo AbreuÎncă nu există evaluări

- APRIL 2018: Thankyou!! Mr. Ritesh Singh Chauhan For Sharing This PaperDocument2 paginiAPRIL 2018: Thankyou!! Mr. Ritesh Singh Chauhan For Sharing This PaperSatyam KumarÎncă nu există evaluări

- Boq 15-3Document8 paginiBoq 15-3Al-Dessoqi SamakÎncă nu există evaluări

- Astron 40 W-Wiring Diagram W SignatureDocument1 paginăAstron 40 W-Wiring Diagram W SignatureTinkerÎncă nu există evaluări

- EEG284 Electronics II Chapter - 6 - Differential AmplifiersDocument48 paginiEEG284 Electronics II Chapter - 6 - Differential AmplifiersMohamed JamaalÎncă nu există evaluări

- DC Molded Case BreakersDocument6 paginiDC Molded Case BreakersMrÎncă nu există evaluări

- PPT-Electric WiringDocument12 paginiPPT-Electric WiringVineeth TGT100% (1)

- NewnameDocument7 paginiNewnameDANIEL ANDRES ARROYO ESPITIAÎncă nu există evaluări